Non-metal yarn inlaid ratproof optical cable and manufacturing method thereof

A production method and mosaic technology, applied in the direction of fiber mechanical structure, etc., can solve problems such as difficulty in ensuring the protective effect and life cycle of optical cables, inconvenient manufacturing and construction, loss of anti-rat effect, etc., to increase protective performance and tensile performance, Easy construction and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

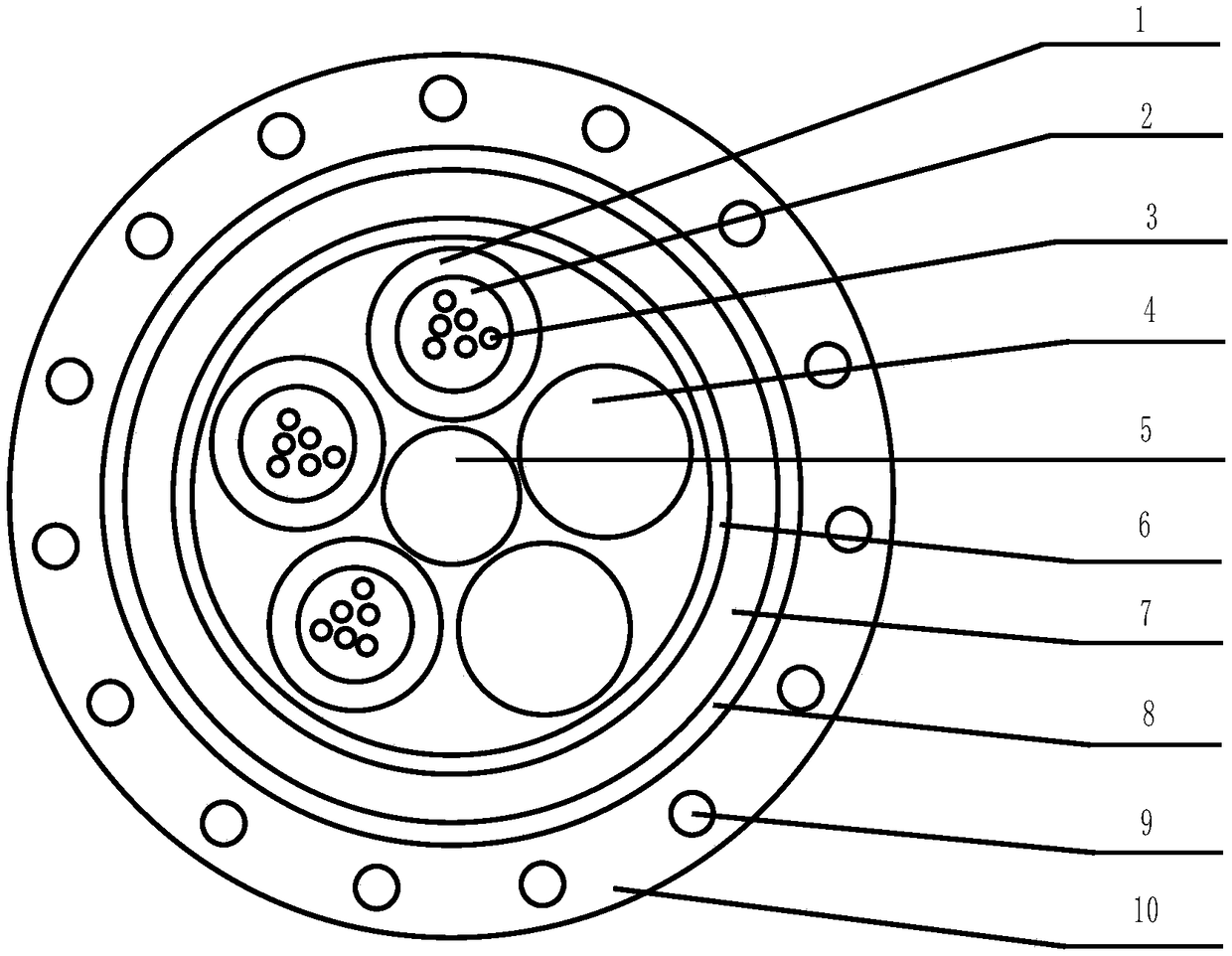

[0047] figure 1It is a cross-sectional view of the optical cable of the present invention. The non-metallic yarn inlaid anti-rodent optical cable of the present invention adopts a new structure to replace the traditional anti-rat optical cable structure, including an outer sheath 10 and an inner sheath 7. The inner sheath 7 is provided with a stainless steel tape armor Layer 6 and inner sheath layer 7 are made of stainless steel tape armored layer 6 armored polyethylene sheath structure. A glass fiber yarn 9 is inlaid along the axial direction of the outer sheath 10, and the outer sheath 10 and the inner sheath 7 are separated by a water-blocking layer 8, and the stainless steel belt armor layer 6 is provided with a central strength member 5 and an optical fiber filler....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pay-off tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com