Process for producing negative electrode material coke by taking supercritical extraction oil slurry as raw material and application of process

A negative electrode material and supercritical technology, applied in the petroleum industry, coke ovens, battery electrodes, etc., can solve problems such as low cycle life, limited performance improvement space, complex process, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

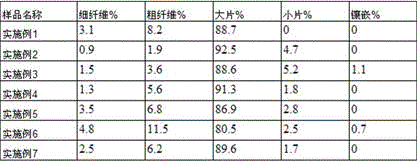

Embodiment 1

[0030] ①Raw material preheating: put the aromatic-rich raw material into the convection section of the coking heating furnace through the aromatic-rich oil tank, and heat it to 300-340°C; ②After heating, the aromatic-rich oil enters the bottom of the coking fractionation tower in two ways The mass ratio of the aromatic-rich oil in the coking fractionation tower is 7:3; ③ fractionation: the temperature at the top of the coking fractionation tower 3 is controlled at 110-130°C to fractionate light components, and the temperature at the bottom of the coking fractionation tower is 330- 360°C to obtain heavy aromatics-rich oil components and tail oil; ④ Heating and coking: The heavy aromatics-rich oil components at the bottom of the coking fractionation tower enter the radiant section of the coking heating furnace through the heating furnace feed pump and are heated to 450-500°C and enter the coke tower for further processing. Coking; Among them, the coking temperature in the coke to...

Embodiment 2

[0032] ①Raw material preheating: The aromatic-rich raw material is pumped into the convection section of the coking heating furnace through the raw material pump, and heated to 300-340°C; The mass ratio of aromatic oil in the tower is 7:3; ③ Fractionation: the temperature at the top of the coking fractionation tower is controlled at 110-130°C to fractionate light components, and the temperature at the bottom of the coking fractionation tower is 330-360°C. Obtain heavy aromatics-rich oil components and tail oil; ④ Heating and coking: The heavy aromatics-rich oil components at the bottom of the coking fractionation tower enter the radiant section of the coking heating furnace through the heating furnace feed pump and are heated to 450-500°C and enter the coke tower for coking; , the coking temperature in the coke tower is 430-500°C; the coking pressure is 0.5-0.8MPa; the cycle weight ratio is 0.5-1.0; the coking cycle is 24-48h; The aromatic-rich oil in the coking fractionation ...

Embodiment 3

[0034]①Raw material preheating: The aromatic-rich raw material is pumped into the convection section of the coking heating furnace through the raw material pump, and heated to 300-340°C; The mass ratio of aromatic oil in the tower is 7:3; ③ Fractionation: the temperature at the top of the coking fractionation tower is controlled at 110-130°C to fractionate light components, and the temperature at the bottom of the coking fractionation tower is 330-360°C. Obtain heavy aromatics-rich oil components and tail oil; ④ Heating and coking: The heavy aromatics-rich oil components at the bottom of the coking fractionation tower enter the radiant section of the coking heating furnace through the heating furnace feed pump and are heated to 450-500°C and enter the coke tower for coking; , the coking temperature in the coke tower is 500-520°C; the coking pressure is 0.5-0.8MPa; the cycle weight ratio is 0.5-1.0; the coking cycle is 24-48h; The aromatic-rich oil in the coking fractionation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com