Novel high efficient aqueous printing ink cleaning agent and preparation method thereof

A technology of water-based ink and cleaning agent, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of insignificant cleaning effect, poor placement stability, unfavorable health and other problems, achieving low toxicity, safe use, and difficult to use. flash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

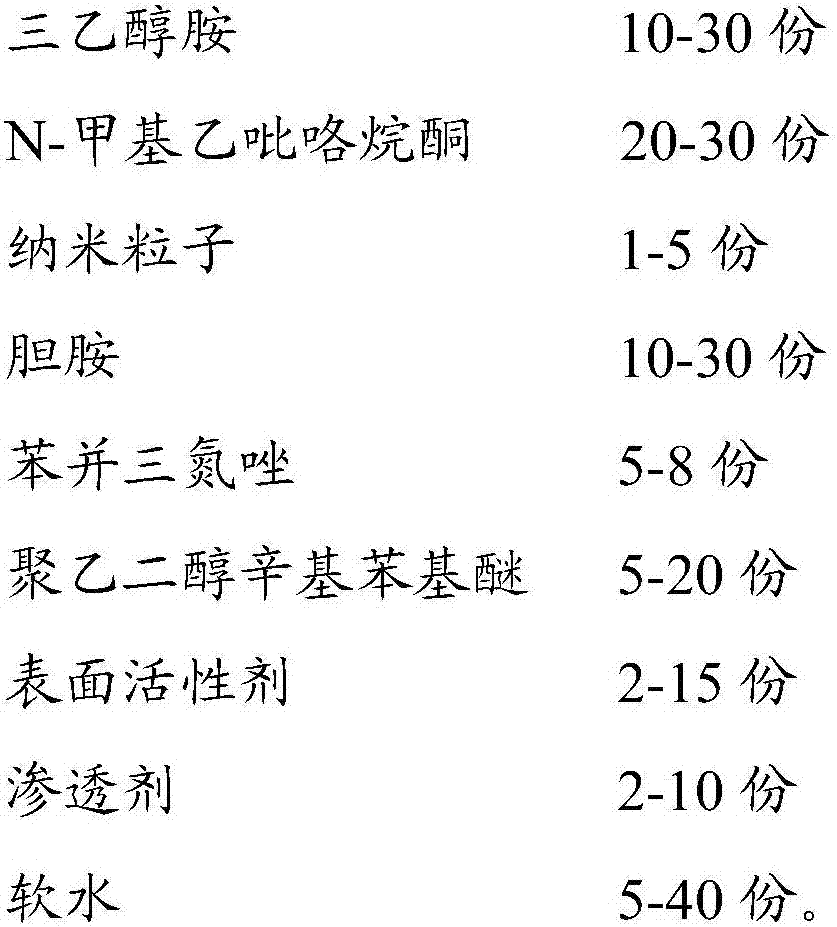

Method used

Image

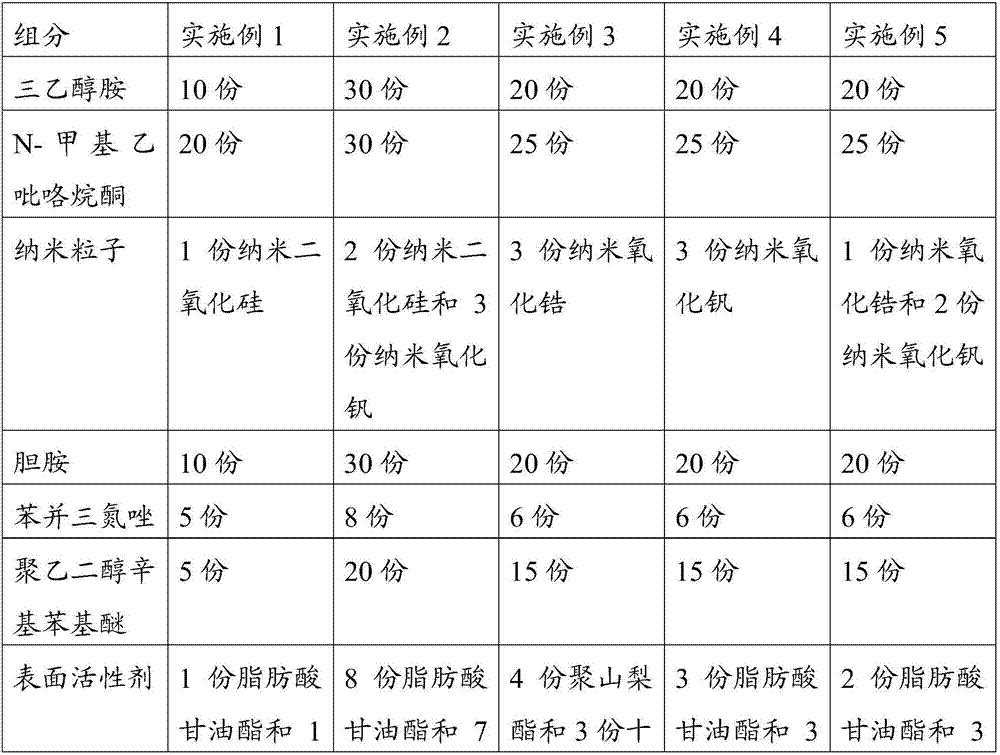

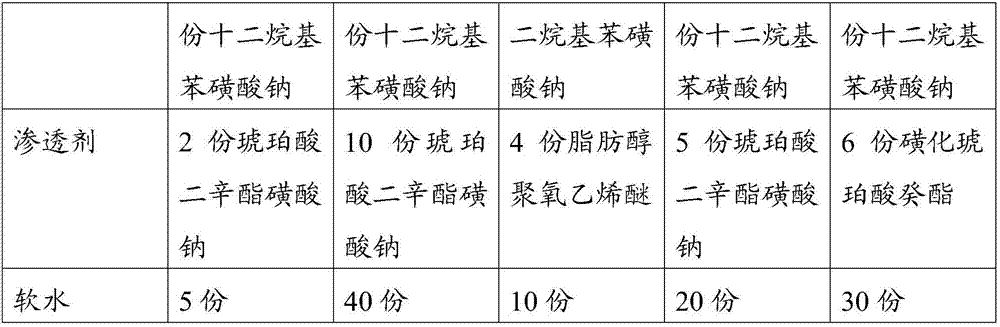

Examples

Embodiment 1

[0026] A new type of high-efficiency water-based ink cleaning agent. The raw materials are weighed according to the parts by weight of each component specified in Table 1, and the surfactant and penetrating agent are added to soft water, stirred for 3 minutes to mix evenly, and then added with a particle size of 10- 20nm nanoparticles, after stirring at 500r / min for 5min, ultrasonically disperse at 20°C and 500W for 10min, then add triethanolamine, N-methylethylpyrrolidone, cholamine, and benzotriazole in sequence , polyethylene glycol octylphenyl ether, and stir and mix evenly at a speed of 800r / min to obtain an ink cleaning agent.

Embodiment 2

[0028] A new type of high-efficiency water-based ink cleaning agent, the raw materials are weighed according to the parts by weight of the components specified in Table 1, the surfactant and penetrant are added to soft water, stirred for 5 minutes to mix evenly, and then added with a particle size of 40- For 50nm nanoparticles, stir at 1000r / min for 10min, then ultrasonically disperse at 40°C and 1000W for 30min, then add triethanolamine, N-methylethylpyrrolidone, cholamine, and benzotriazole in sequence , polyethylene glycol octyl phenyl ether, and stir and mix evenly at a rotating speed of 1200r / min to obtain an ink cleaning agent.

Embodiment 3

[0030] A new type of high-efficiency water-based ink cleaning agent, the raw materials are weighed according to the parts by weight of each component specified in Table 1, surfactants and penetrants are added to soft water, stirred for 5 minutes to mix evenly, and then added with a particle size of 20- For 30nm nanoparticles, stir at 800r / min for 8min, then ultrasonically disperse at 30°C and 800W for 20min, then add triethanolamine, N-methylethylpyrrolidone, cholamine, and benzotriazole in sequence , polyethylene glycol octyl phenyl ether, and stir and mix evenly at a rotating speed of 1000r / min to obtain an ink cleaning agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com