3D printing PVD mold and method thereof

A 3D printing and mold technology, applied in 3D printing related fields, can solve the problems of low mold precision, limited mold waterway design, and difficult demoulding, etc., and achieve the effect of improving product quality, excellent tensile strength, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A processing method for 3D printing PVD moulds, comprising the following steps:

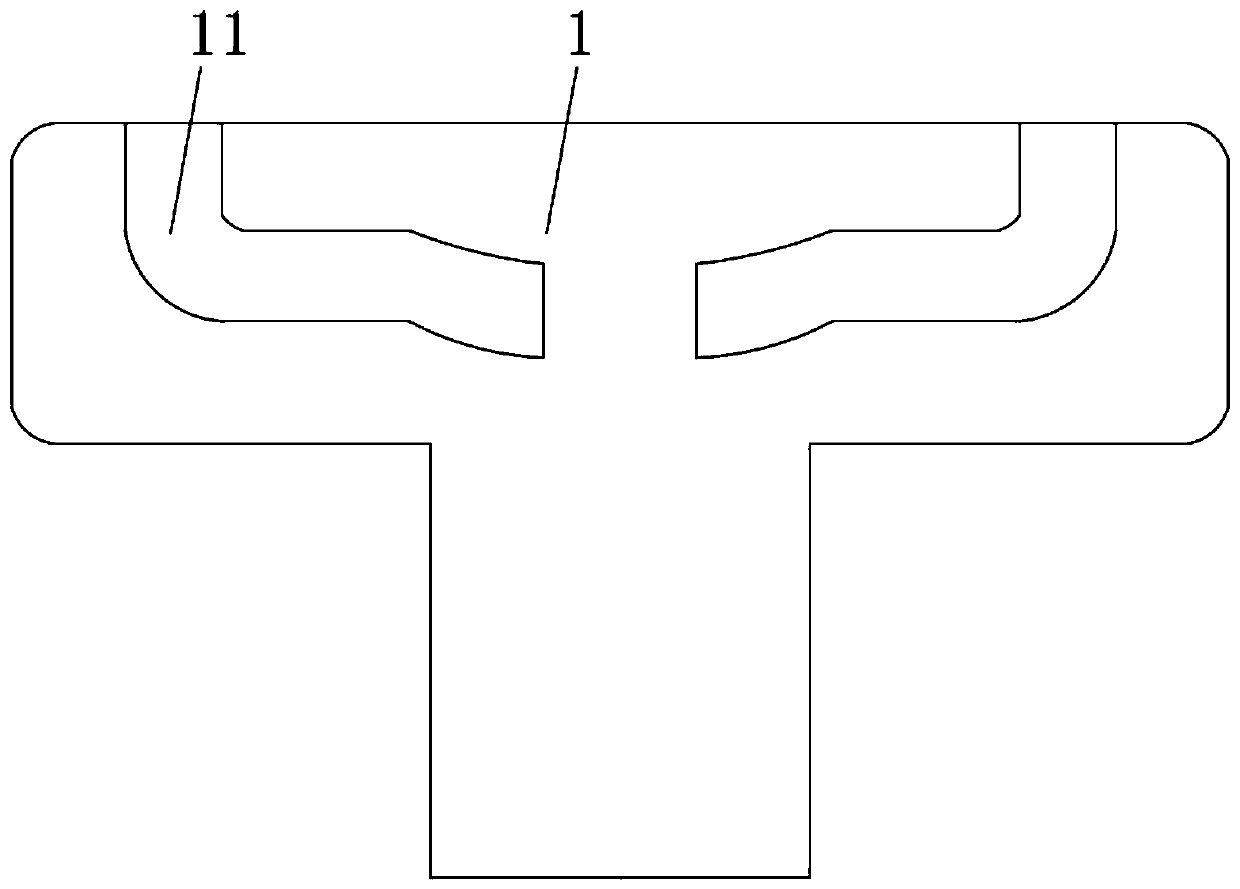

[0043] A: Modeling; scan the mold prototype and the conformal waterway 11 through a 3D scanning device to obtain the 3D dimensions, import the 3D dimensions to the computer client and process them to obtain a 3D digital model, and import the 3D digital model file into the 3D printing molding device Terminal, set printing parameters;

[0044] B: Add material: Lay the alloy powder on the working platform of the 3D printing molding equipment to obtain the powder working layer, and then choose to execute the printing function. The 3D printer performs laser scanning on the powder working layer, so that the alloy powder in the scanned area is melted and solidified. Laser sintering processing technology is used to process the material layer by layer, and the conformal waterway 11 changes with the shape of the part model. The working room of the laser scanning is an inert atmosphere, and the laser...

Embodiment 2

[0049] A processing method for 3D printing PVD moulds, comprising the following steps:

[0050] A: Modeling; scan the mold prototype and the conformal waterway 11 through a 3D scanning device to obtain the 3D dimensions, import the 3D dimensions to the computer client and process them to obtain a 3D digital model, and import the 3D digital model file into the 3D printing molding device Terminal, set printing parameters;

[0051] B: Add material: Lay the alloy powder on the working platform of the 3D printing molding equipment to obtain the powder working layer, and then choose to execute the printing function. The 3D printer performs laser scanning on the powder working layer, so that the alloy powder in the scanned area is melted and solidified. Laser sintering processing technology is used to process the material layer by layer, and the conformal waterway 11 changes with the shape of the part model. The working room of the laser scanning is an inert atmosphere, and the laser...

Embodiment 3

[0056] A processing method for 3D printing PVD moulds, comprising the following steps:

[0057] A: Modeling; scan the mold prototype and the conformal waterway 11 through a 3D scanning device to obtain the 3D dimensions, import the 3D dimensions to the computer client and process them to obtain a 3D digital model, and import the 3D digital model file into the 3D printing molding device Terminal, set printing parameters;

[0058] B: Add material: Lay the alloy powder on the working platform of the 3D printing molding equipment to obtain the powder working layer, and then choose to execute the printing function. The 3D printer performs laser scanning on the powder working layer, so that the alloy powder in the scanned area is melted and solidified. Laser sintering processing technology is used to process the material layer by layer, and the conformal waterway 11 changes with the shape of the part model. The laser scanning working room is an inert atmosphere, and the laser energy...

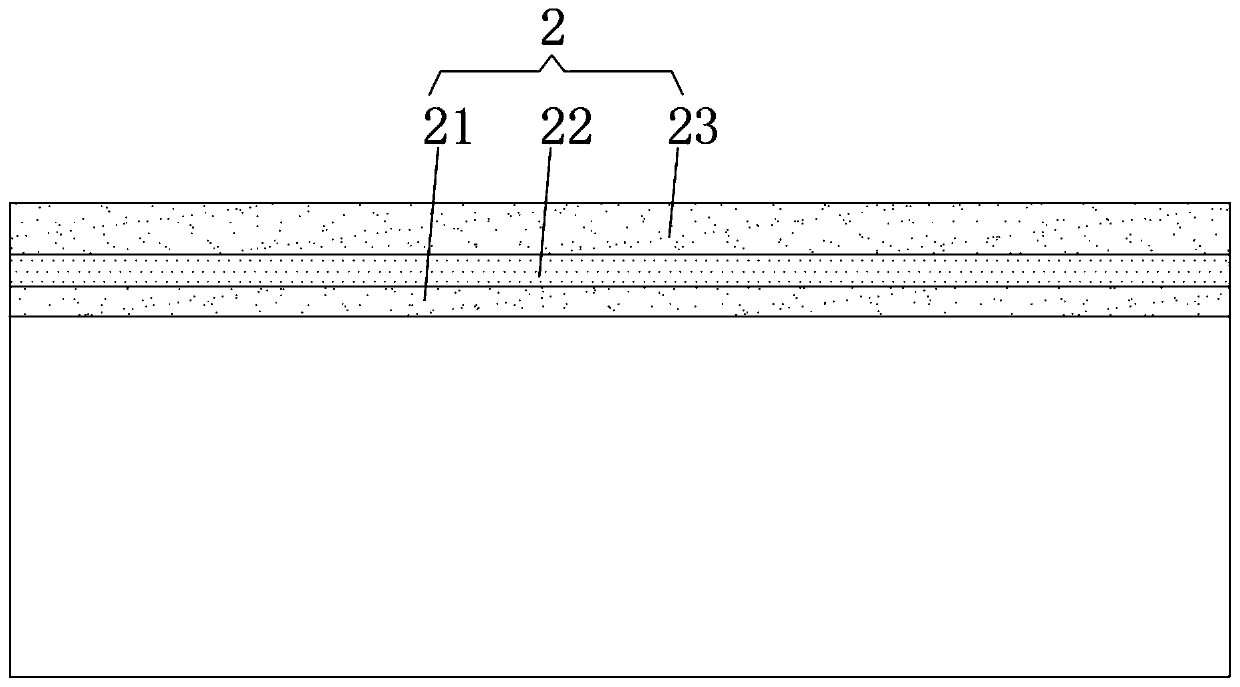

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com