High-specific-gravity tungsten-nickel-iron alloy for balancing weight of golf club and preparation method thereof

A tungsten-nickel-iron alloy and golf club technology, applied in the field of alloys, can solve the problems that the coating cannot be completely dissolved, the cost is high, and the scrap rate of the ball head is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

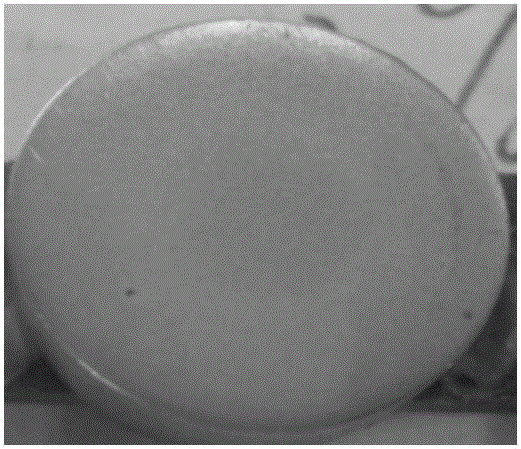

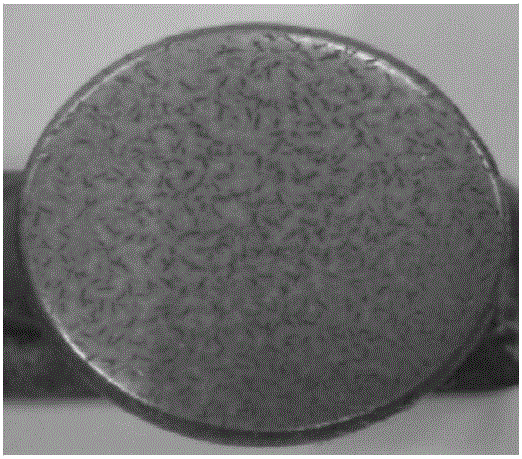

Image

Examples

Embodiment 1

[0035] A high-specific-gravity tungsten-nickel-iron alloy for a golf club counterweight, the preparation process of which is as follows:

[0036] (1) Material preparation: The metal powders used are reduced tungsten powder, hydroxynickel powder and hydroxyiron powder. The physical properties of each powder are: the W content of the tungsten powder is >99.95%, and the particle size is 2-5 μm; the Ni content of the nickel powder is >99.8%, and the particle size is 3-5 μm; the Fe content of the iron powder is >99.5%, and the particle size is 3-5 μm.

[0037] (2) Powder blending: weigh W powder, Fe powder, and Ni powder according to the proportion, mix them in a V-shaped mixer for 24 hours, and the speed is 50r / min;

[0038] (a) Firstly weigh the tungsten powder, iron powder and nickel powder screened by corresponding weight according to the required weight ratio in a clean working environment. The weight ratio of tungsten-nickel-iron is W: 72%, Ni: 12%, Fe: 16 %;

[0039] (b) P...

Embodiment 2

[0044] A high-specific-gravity tungsten-nickel-iron alloy for a golf club counterweight, the preparation process of which is as follows:

[0045] (1) Material preparation: The metal powders used are reduced tungsten powder, hydroxynickel powder and hydroxyiron powder. The physical properties of each powder are: the W content of the tungsten powder is >99.95%, and the particle size is 2-5 μm; the Ni content of the nickel powder is >99.8%, and the particle size is 3-5 μm; the Fe content of the iron powder is >99.5%, and the particle size is 3-5 μm.

[0046] (2) Powder blending: weigh W powder, Fe powder, and Ni powder according to the proportion, mix them in a V-shaped mixer for 24 hours, and the speed is 50r / min;

[0047] (a) Firstly weigh the tungsten powder, iron powder and nickel powder screened by corresponding weight according to the required weight ratio in a clean working environment. The weight ratio of tungsten-nickel-iron is W: 73%, Ni: 7%, Fe: 20 %;

[0048] (b) Pr...

Embodiment 3

[0053] A high-specific-gravity tungsten-nickel-iron alloy for a golf club counterweight, the preparation process of which is as follows:

[0054] (1) Material preparation: The metal powders used are reduced tungsten powder, hydroxynickel powder and hydroxyiron powder. The physical properties of each powder are: the W content of the tungsten powder is >99.95%, and the particle size is 2-5 μm; the Ni content of the nickel powder is >99.8%, and the particle size is 3-5 μm; the Fe content of the iron powder is >99.5%, and the particle size is 3-5 μm.

[0055] (2) Powder blending: weigh W powder, Fe powder, and Ni powder according to the proportion, mix them in a V-shaped mixer for 24 hours, and the speed is 50r / min;

[0056] (a) Firstly weigh the tungsten powder, iron powder and nickel powder screened by corresponding weight according to the required weight ratio in a clean working environment. The weight ratio of tungsten-nickel-iron is W: 72%, Ni: 15%, Fe: 13 %;

[0057] (b) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com