Two-piece type self-cleaning ball valve adopting floating seal

A floating seal, two-piece technology, applied in the field of two-piece self-cleaning ball valves, can solve the problems of easily retained impurities, labor, time, etc., high cost, corroded balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

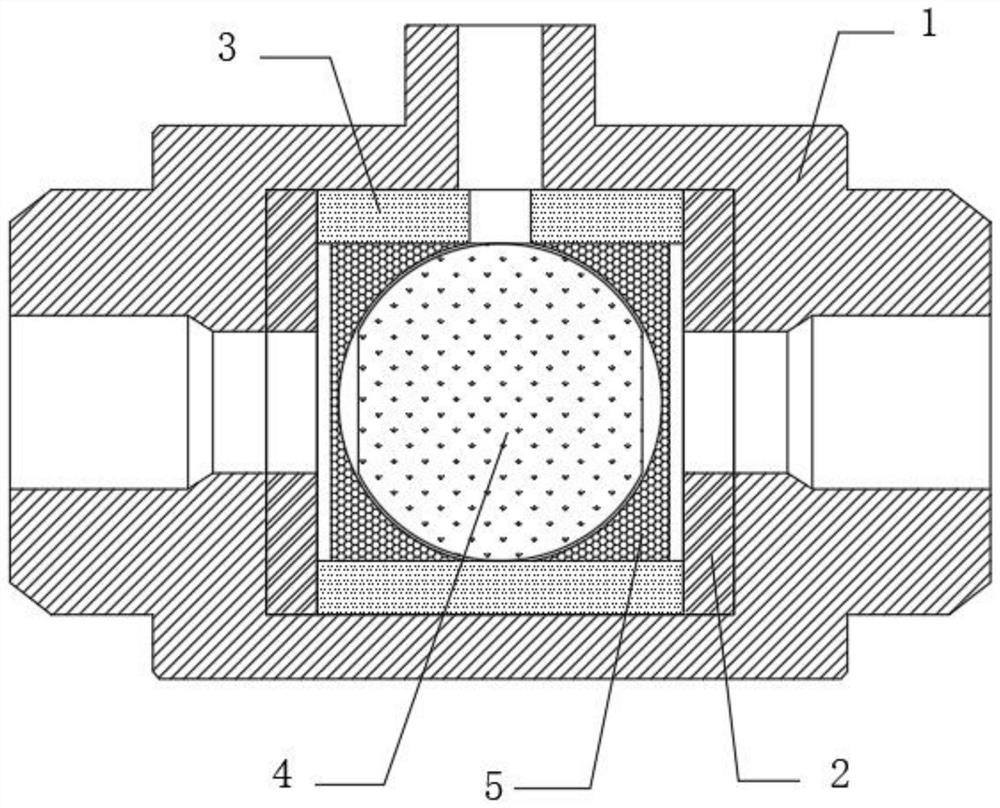

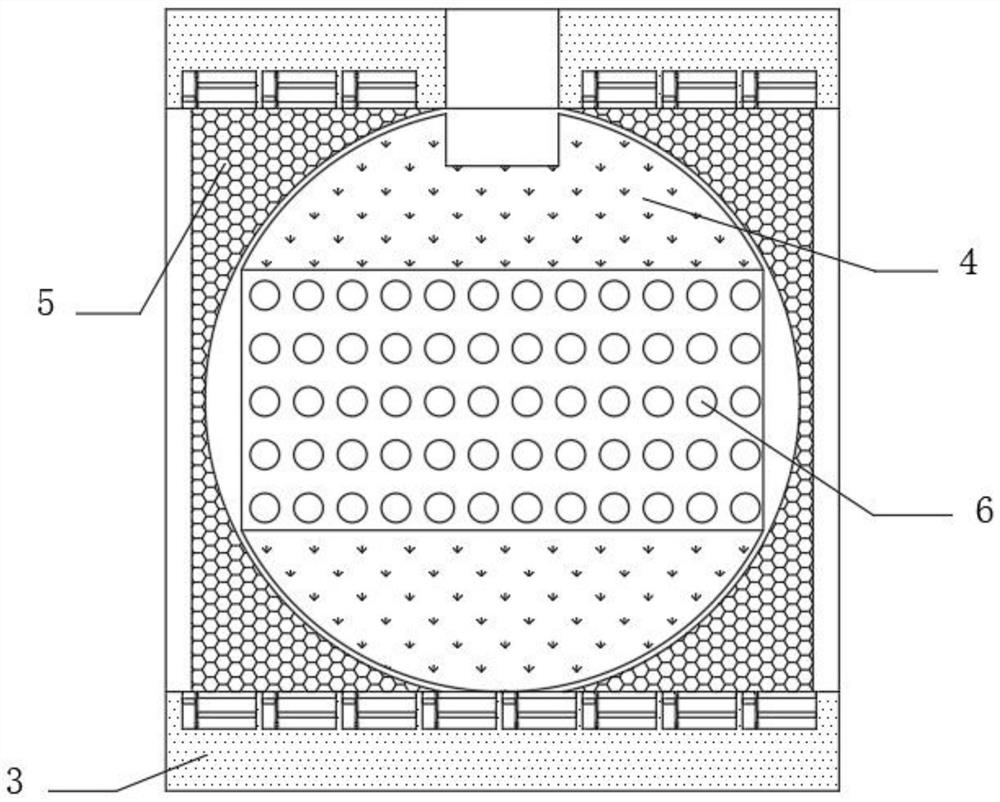

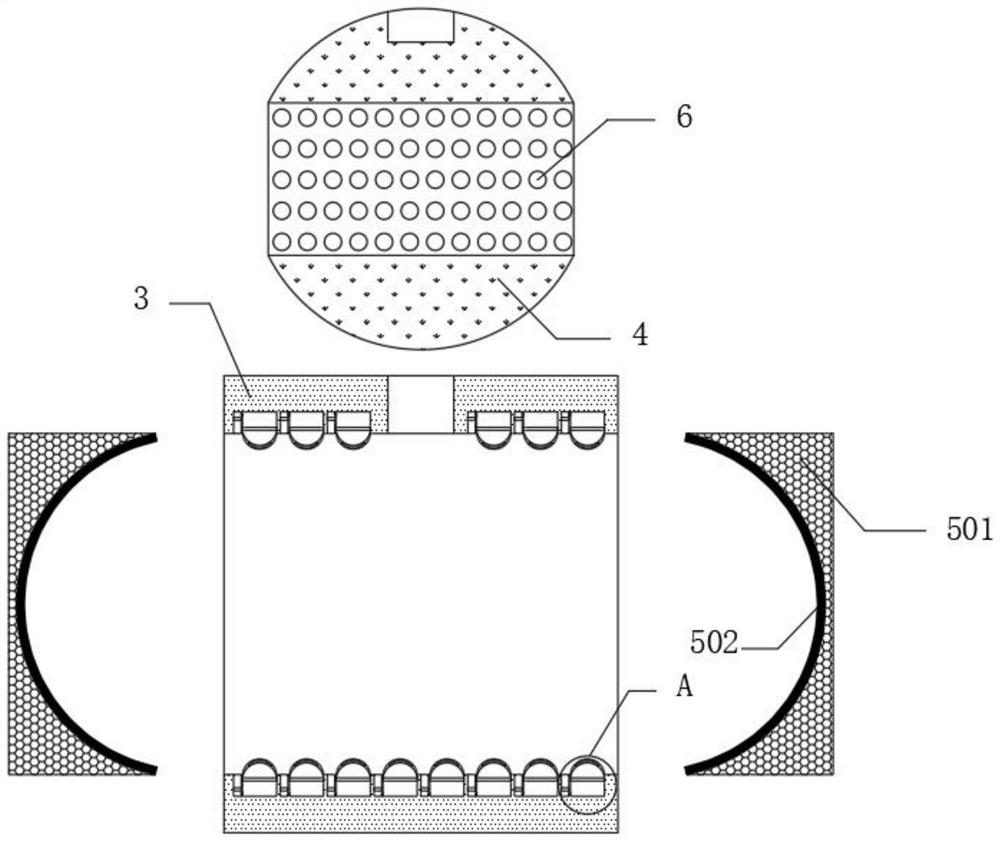

[0043] see Figure 1-8 , a floating seal two-piece self-cleaning ball valve, including the seat body 1, see figure 1 and Figure 8 The inside of the valve seat body 1 is provided with two seal rings 2, and the ball seat 3 is clamped between the two seal rings 2, the ball seat 3 is rotatably connected with a ball 4, and the inner wall of the ball seat 3 is fixedly connected with two The cleaning scrapers 5, and the ball 4 is located between the two cleaning scrapers 5;

[0044] see Figure 2-4 The cleaning scraper 5 includes a support body 501, one side wall of the support body 501 is arc-shaped, and the support body 501 is attached to the outer wall of the sphere 4, and the arc-shaped side wall of the support body 501 is fixedly connected with a scraper 502 , and the scraper 502 is made of silica gel material. During the rotation of the sphere 4, the scraper 502 scrapes off the impurities stuck on the outer surface of the sphere 4, avoiding a large amount of accumulation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com