Dust collection disc of cleaning trolley

A vacuum cleaner and cleaning vehicle technology, which is applied to road cleaning, cleaning methods, construction, etc., can solve the problems of complex structure of vacuum cleaner, high maintenance cost, unsatisfactory cleaning effect, etc., to improve the working ability and service life, Reduced maintenance costs and good floor cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

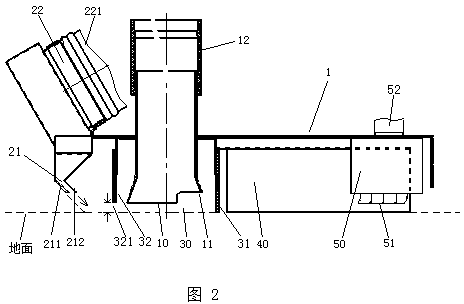

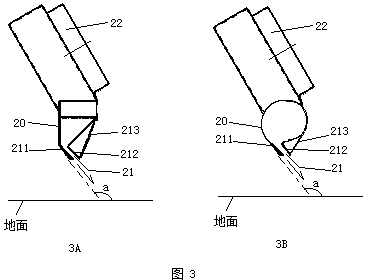

[0024] Attached below figure 1 , attached figure 2 , attached image 3 And attached Figure 4 The structure of the dust suction pan of the present invention will be described in detail.

[0025] figure 1 Shown is a schematic plan view of an embodiment of the dust suction pan 1 of the present invention, figure 2 It is a schematic cross-sectional view along the LL' direction of the suction cup 1. Such as figure 1 , figure 2 As shown in , the dust suction plate 1 includes a dust suction port 10 and a strip-shaped air channel 20 arranged on the plate body. The tuyere 22 is connected to the fan return duct 221 , and a slit-type air duct outlet 21 is arranged on the lower side of the strip-shaped air duct 20 along the air duct. The direction of the air outlet 21 corresponds to the dust suction port 10. When the fan is working, the high-speed air flow enters the strip air passage 20 from the fan return pipe 221 through the air inlet 22, and then sprays from the air outlet ...

Embodiment 2

[0031] In this embodiment, the structural design of the suction cup 1 is the same as the content of the first embodiment, and will not be repeated here. figure 1 , attached figure 2 The specific content of this embodiment will be described in detail.

[0032] in the attached figure 1 , attached figure 2 The structure of a specific embodiment of the dust suction pan is shown in , and the structure of the dust suction pan 1 of this embodiment is described in detail with reference to the L direction, ie, the driving direction, as the front direction. A front deflector rubber plate 31 is provided in front of the dust suction port 10, a rear deflector rubber plate 32 is provided behind the dust suction port 10, and the front deflector rubber plate 31 is connected with the rear deflector. The rubber plate 32 encloses the area around the dust suction port 10 to form a negative pressure area 30 of the dust suction port, which is equivalent to forming a large dust suction port; a ...

Embodiment 3

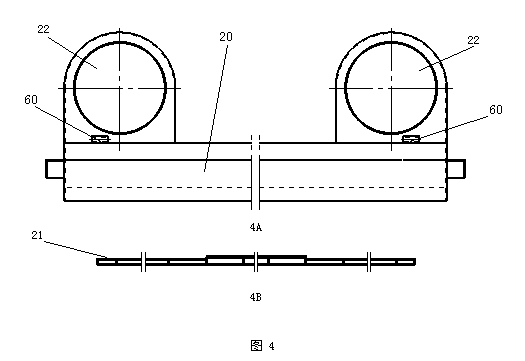

[0035] In this embodiment, the same parts about the structure design of the dust-absorbing pan as those of the previous embodiments will not be repeated here, and only the different parts will be combined with the attached parts below. figure 1 , attached figure 2 , attached Figure 4 The specific content of this embodiment will be described in detail.

[0036] In this embodiment, the structure of the dust suction pan 1 of this embodiment is described in detail with the L direction as the driving direction as the forward direction. The dust suction pan 1 is provided with two suction ports 10, which are symmetrically located on both sides under the main beam of the vehicle body chassis (not shown in the figure); the front deflector rubber plate 31 and the rear deflector rubber plate 32 correspond to the two The dust suction port 10 is bent so that it is bent to form two independent vacuum port negative pressure areas 30; the scraper 40 is arranged in an inverted V shape in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com