Beta-FeOOH/polyacrylonitrile composite nanofiber membrane, preparation method thereof and application of membrane

A technology of composite nanofibers and nanofiber membranes, applied in the field of materials, can solve the problems of anti-pollution ability, poor self-cleaning ability, poor anti-pollution ability of organic substances, poor stability performance, etc., so as to improve hydrophilicity, facilitate adsorption, improve Wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

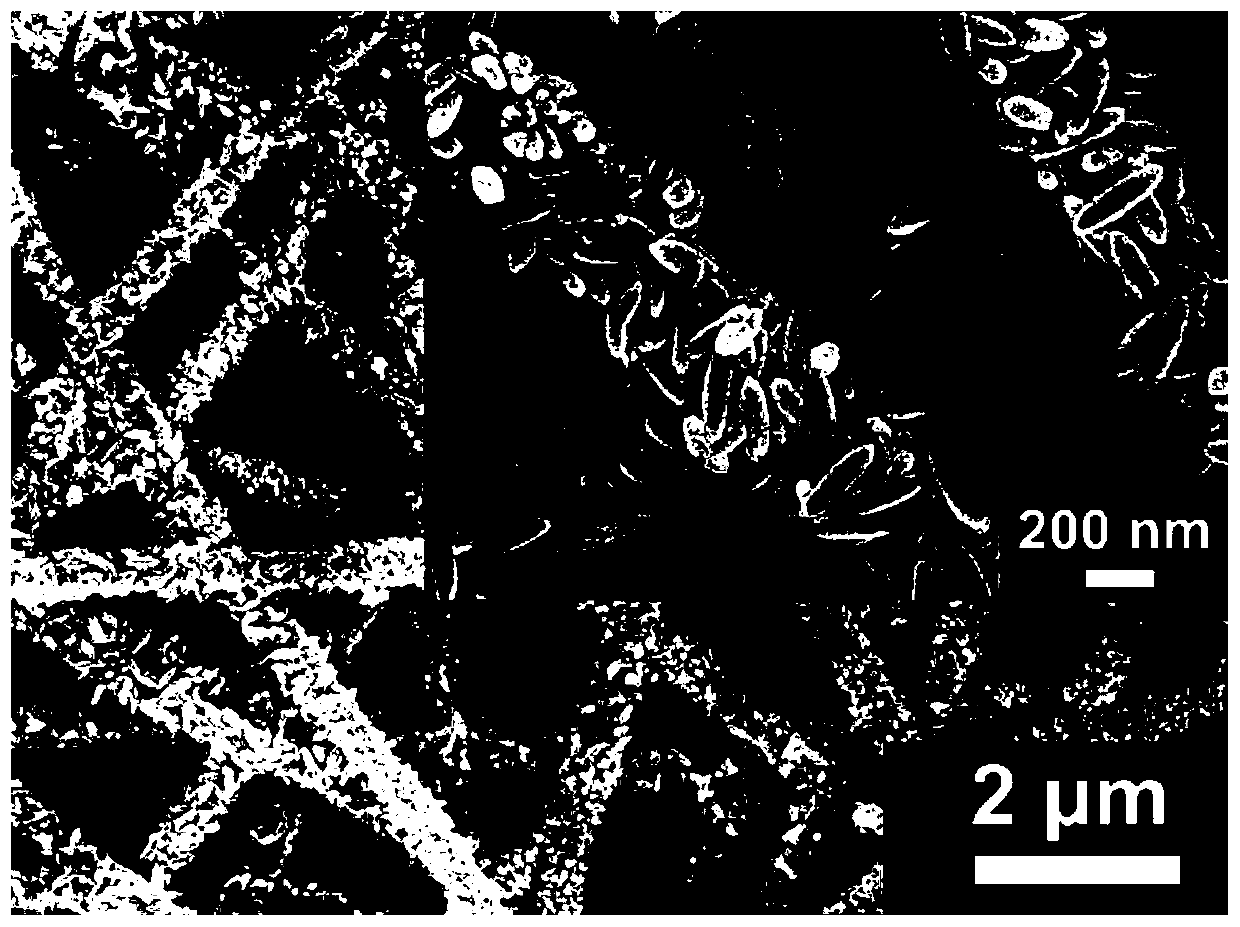

[0038] The preparation method of a composite nanofiber membrane of β-FeOOH / polyacrylonitrile provided by the embodiment of the present invention comprises the following steps:

[0039] Preparation of polyacrylonitrile nanofiber membrane: mix polyacrylonitrile powder and N,N-dimethylformamide solution evenly to make spinning solution, and then spin polyacrylonitrile nanofiber membrane through electrospinning device, polypropylene The ratio of nitrile powder to N,N-dimethylformamide solution is 1-1.4g:10mL.

[0040] Among them, when the temperature is low, it is easy to cause the solution to be reduced by fluidity, resulting in the blockage of the spinneret. When the temperature is high, it is easy to cause the excessive volatilization of N,N-dimethylformamide in the solution, affecting The formation of polyacrylonitrile nanofiber membrane; when the voltage is low, the electric field force is too small, the electrostatic field force cannot overcome the surface tension of the sol...

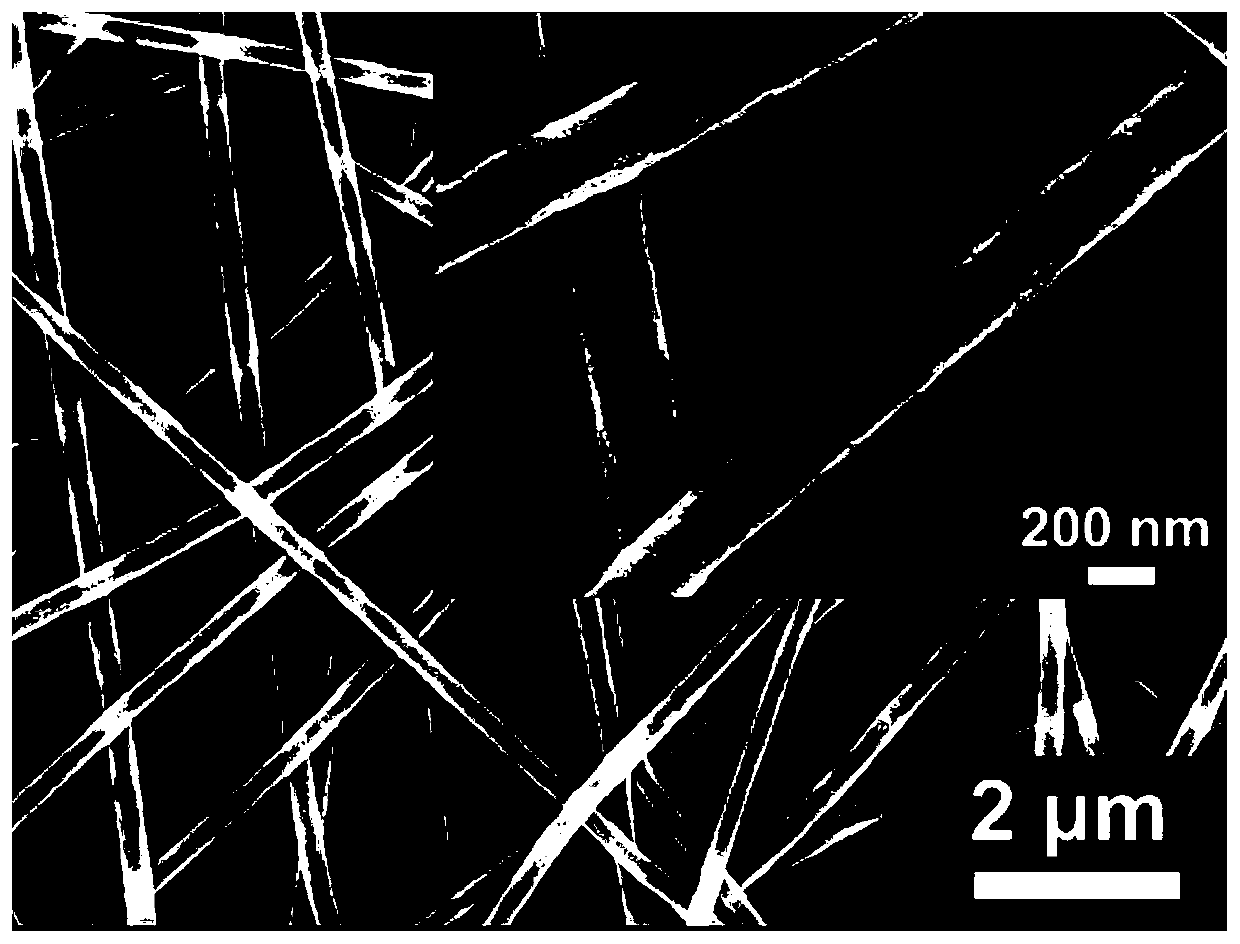

Embodiment 1

[0059] A preparation method of a composite nanofibrous membrane of β-FeOOH / polyacrylonitrile, comprising the following steps:

[0060] Preparation of polyacrylonitrile nanofiber membrane: Mix 1.2% polyacrylonitrile powder with 10mL N,N-dimethylformamide solution to make a spinning solution, and then spin it into polyacrylonitrile nanofiber membrane through an electrospinning device. Then dry under vacuum conditions, wherein the spinning conditions are: the spinning temperature is 35°C, the spinning voltage is 25kv, the receiving distance is 20cm, the ambient humidity is 50%, and the flow rate is 1mL / h. For: drying temperature 60 ℃, drying time 12h.

[0061] Stabilization treatment: The polyacrylonitrile nanofiber membrane was subjected to gradient temperature rise treatment, kept at 238°C for 0.5h, at 248°C for 0.5h, and at 260°C for 0.5h, then took it out and cooled it to Stabilized polyacrylonitrile nanofibers were prepared at room temperature;

[0062] Biomineralization t...

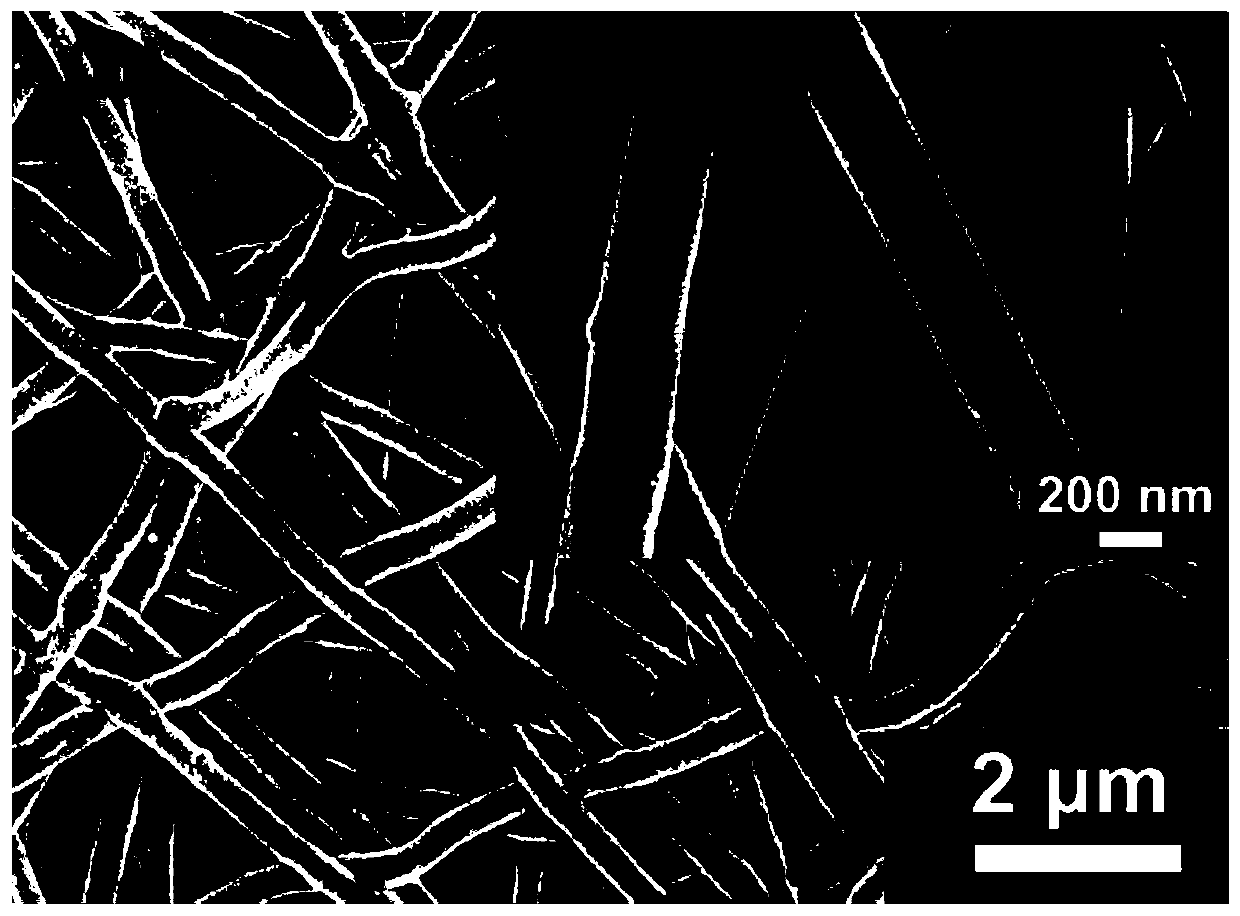

Embodiment 2

[0064] A preparation method of a composite nanofibrous membrane of β-FeOOH / polyacrylonitrile, comprising the following steps:

[0065] Preparation of polyacrylonitrile nanofiber membrane: Mix 1g polyacrylonitrile powder with 10mL N,N-dimethylformamide solution to make a spinning solution, and then spin it into a polyacrylonitrile nanofiber membrane through an electrospinning device. Then dry under vacuum conditions, wherein the spinning conditions are: spinning temperature is 30°C, spinning voltage is 20kv, receiving distance is 18cm, ambient humidity is 45%, and flow rate is 0.6mL / h. The conditions are: the drying temperature is 55°C, and the drying time is 10 hours.

[0066] Stabilization treatment: The polyacrylonitrile nanofiber membrane is subjected to gradient temperature rise treatment, kept at 235°C for 2h, kept at 245°C for 2h, kept at 258°C for 2h, and then taken out and cooled to room temperature. Stabilized polyacrylonitrile nanofibers;

[0067]Biomineralization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com