Patents

Literature

50 results about "Beta-FeOOH" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

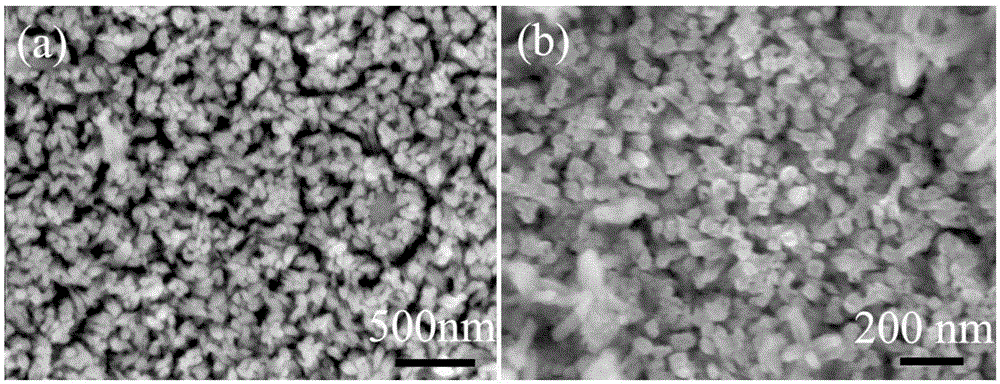

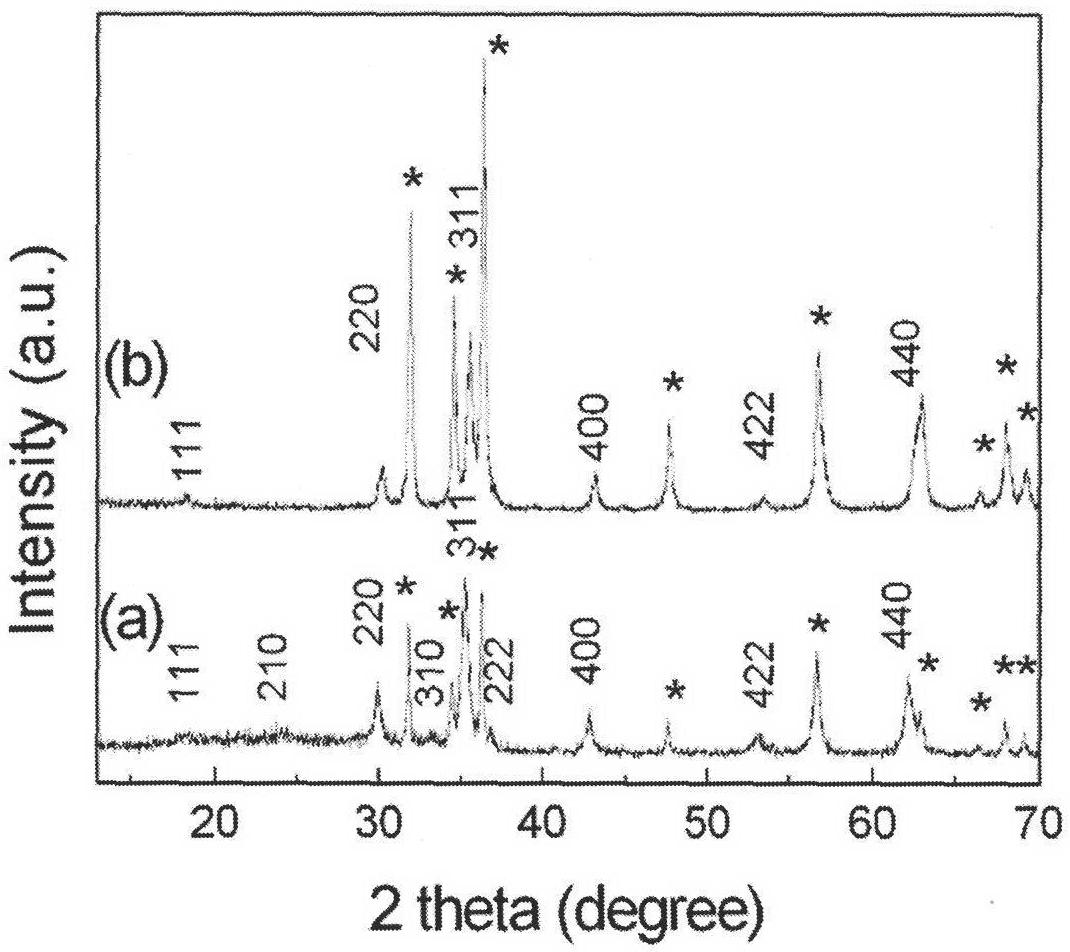

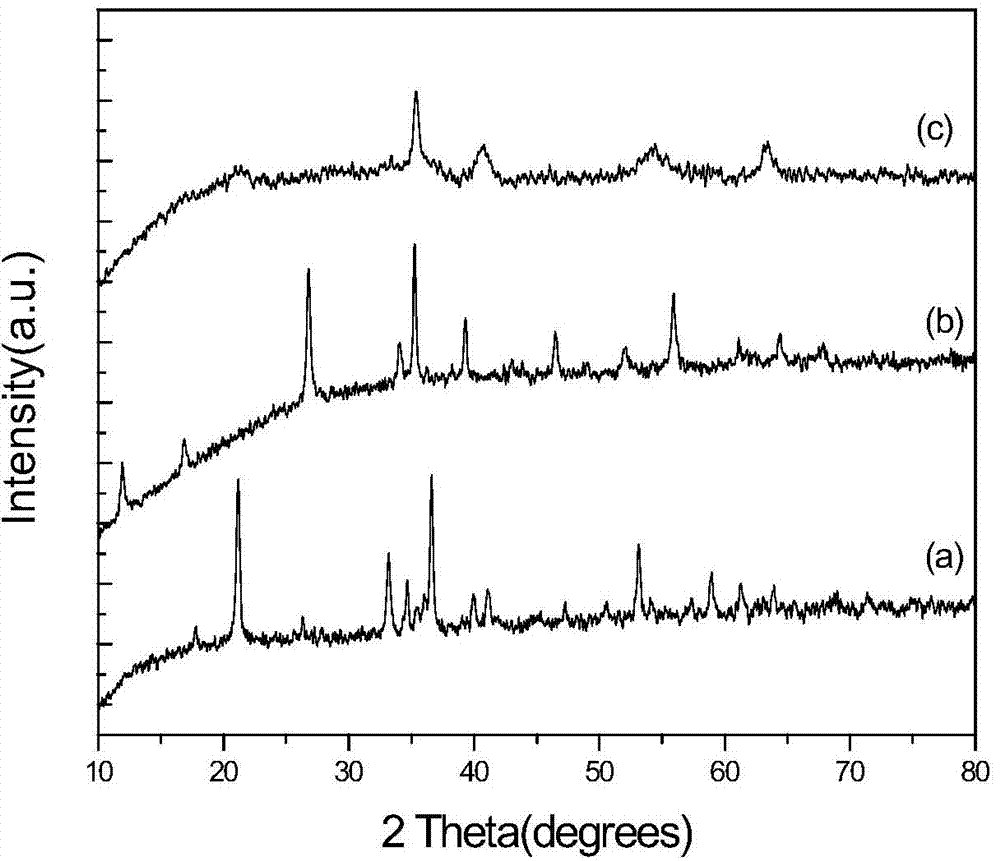

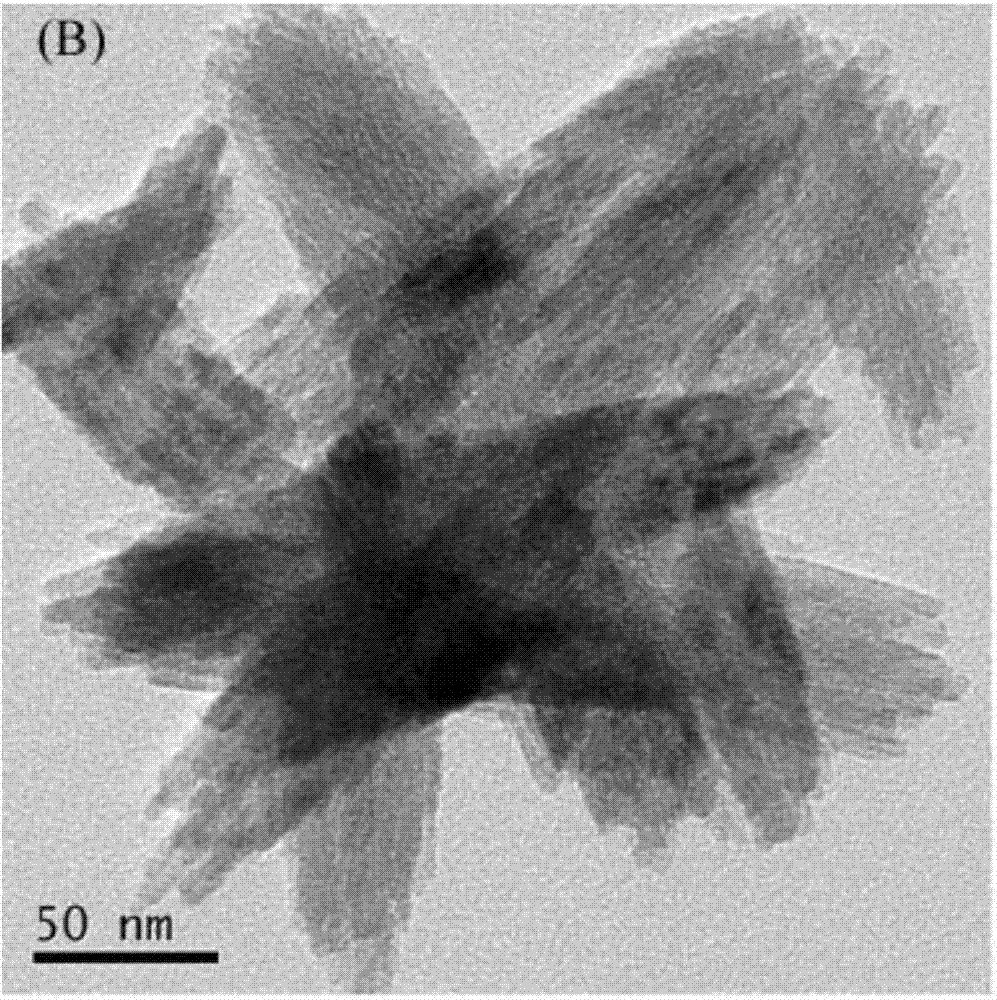

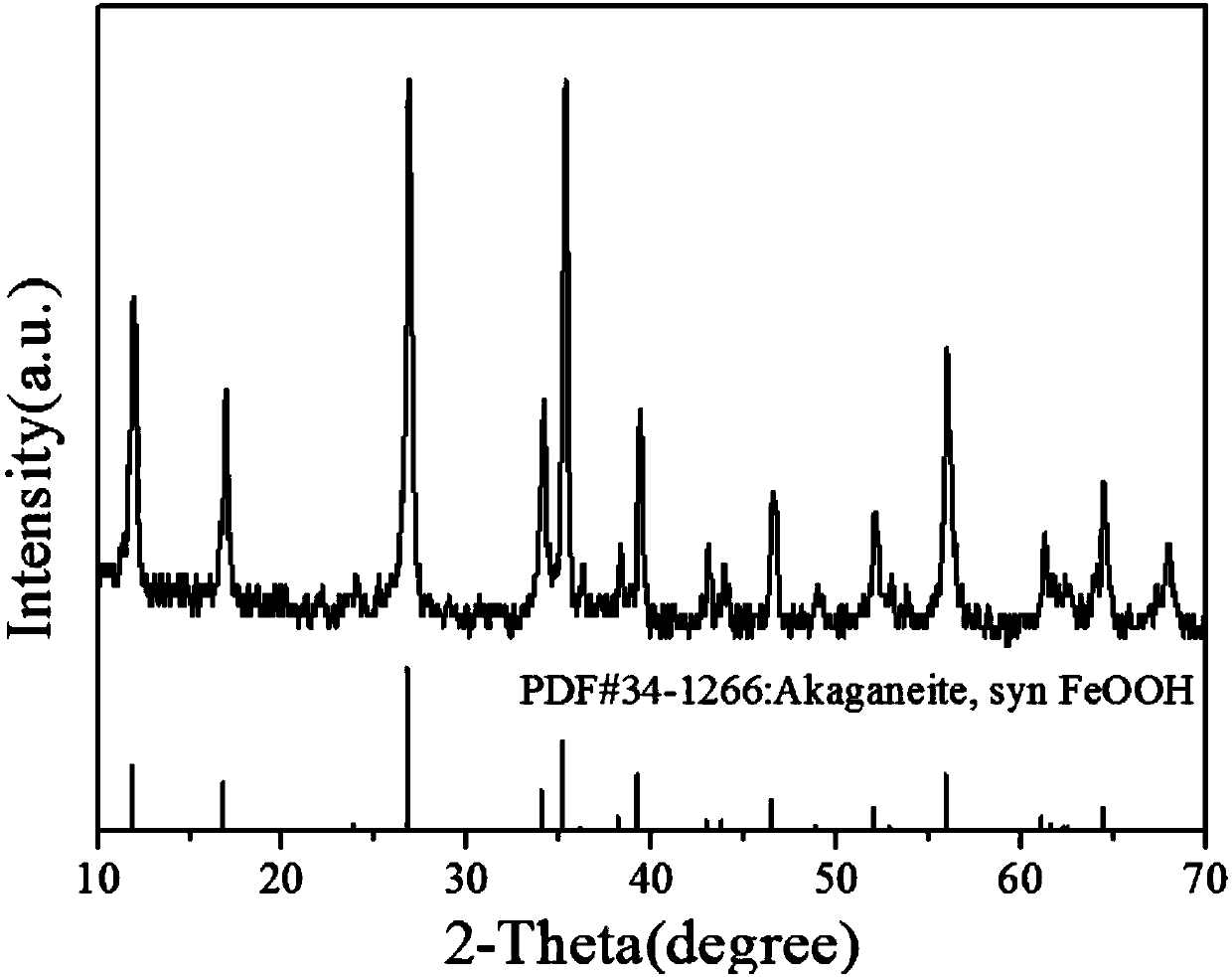

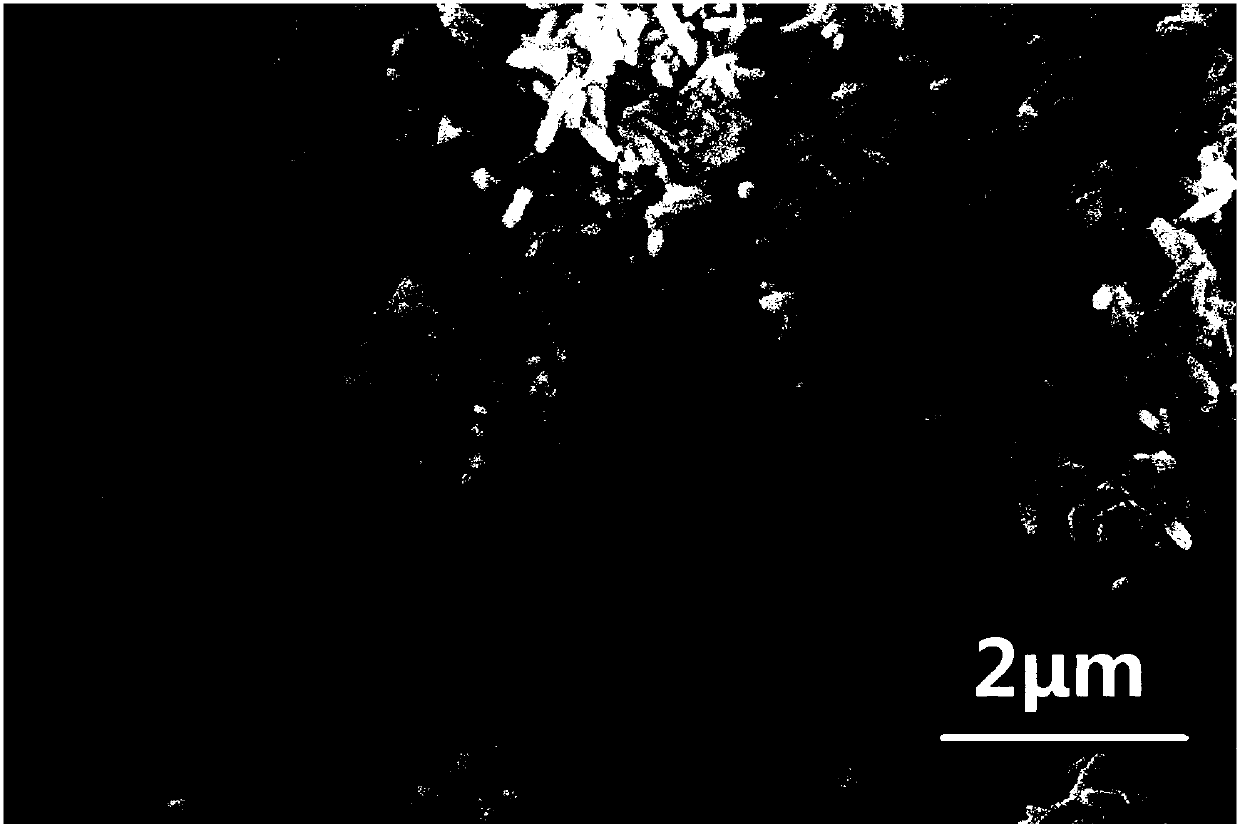

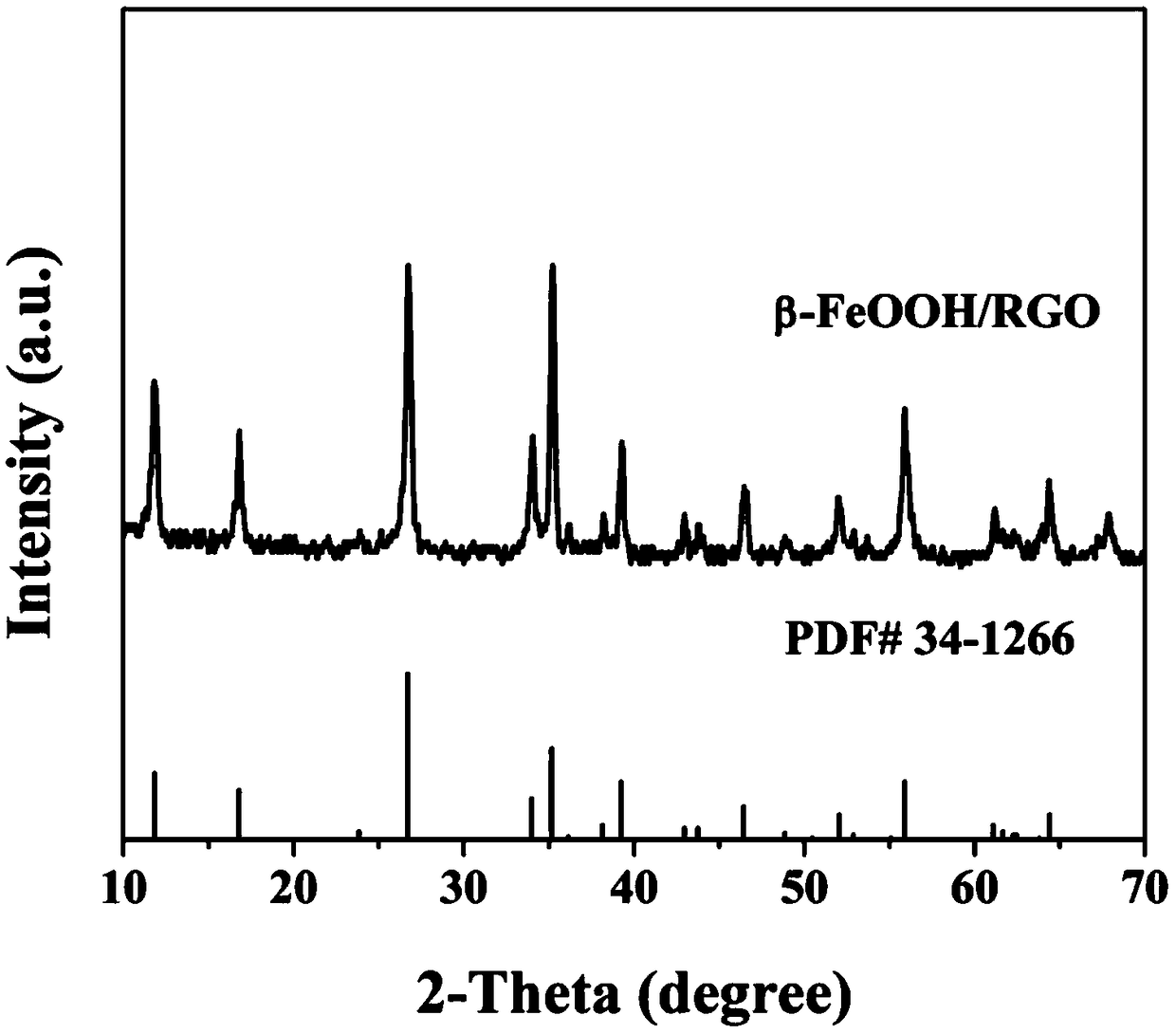

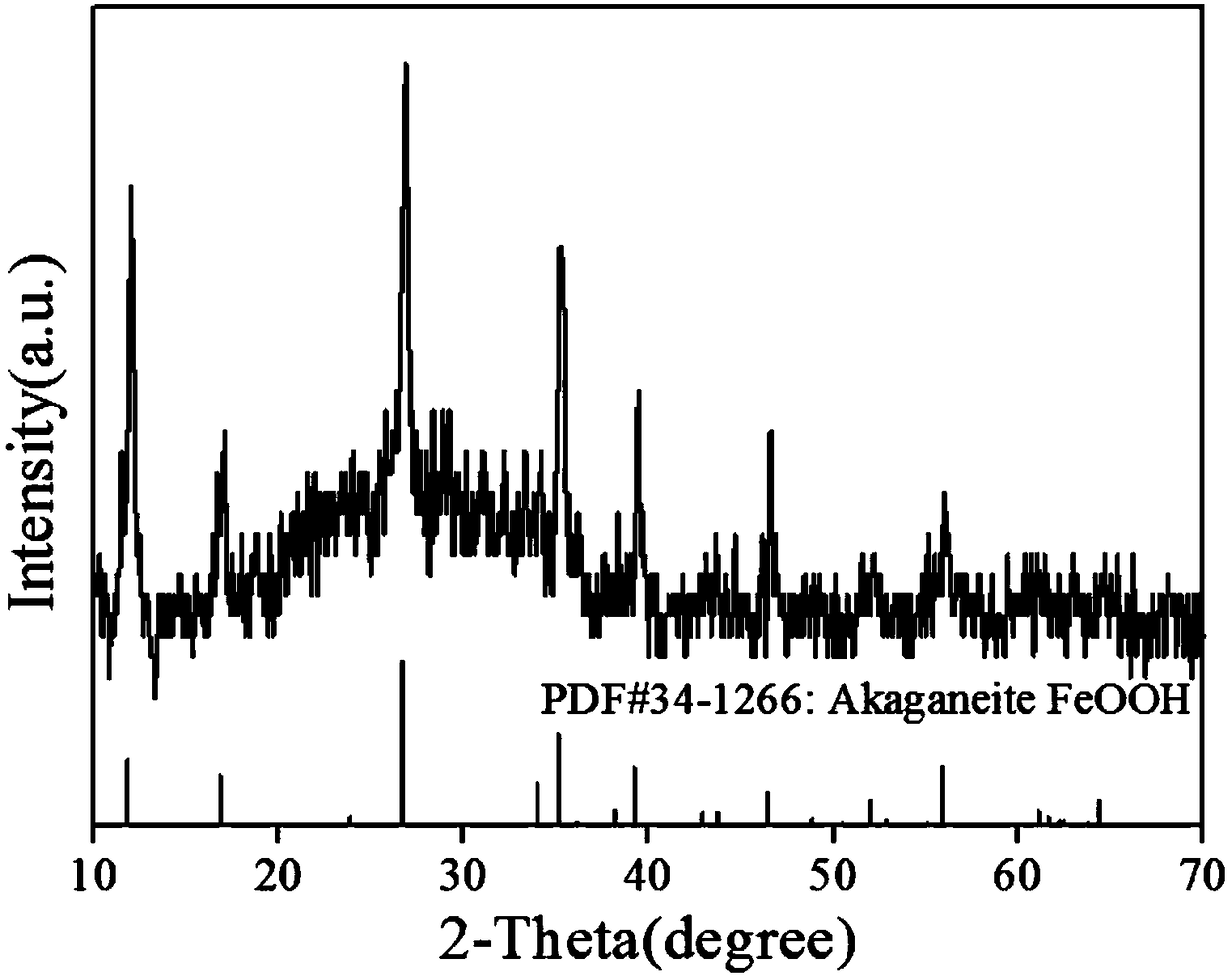

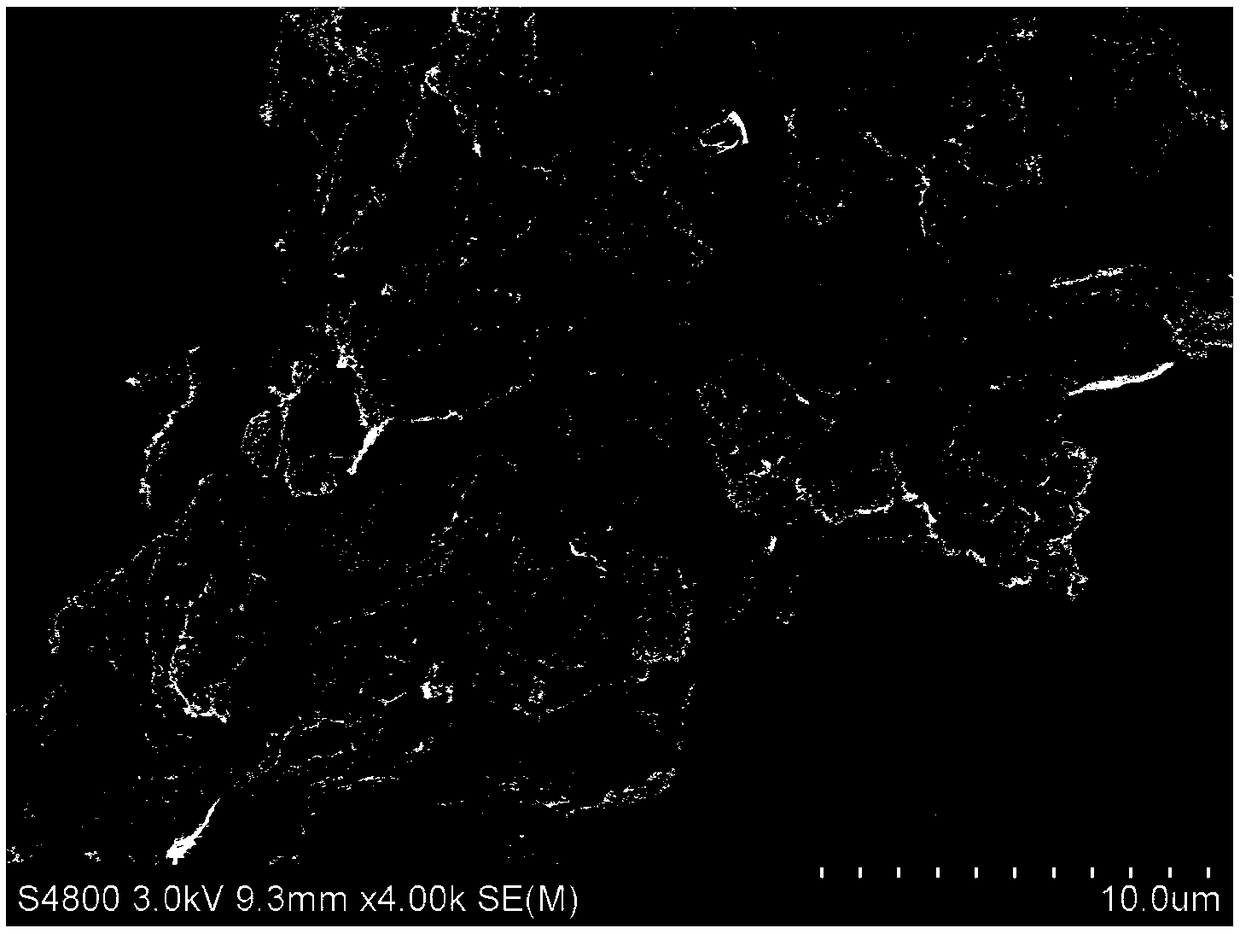

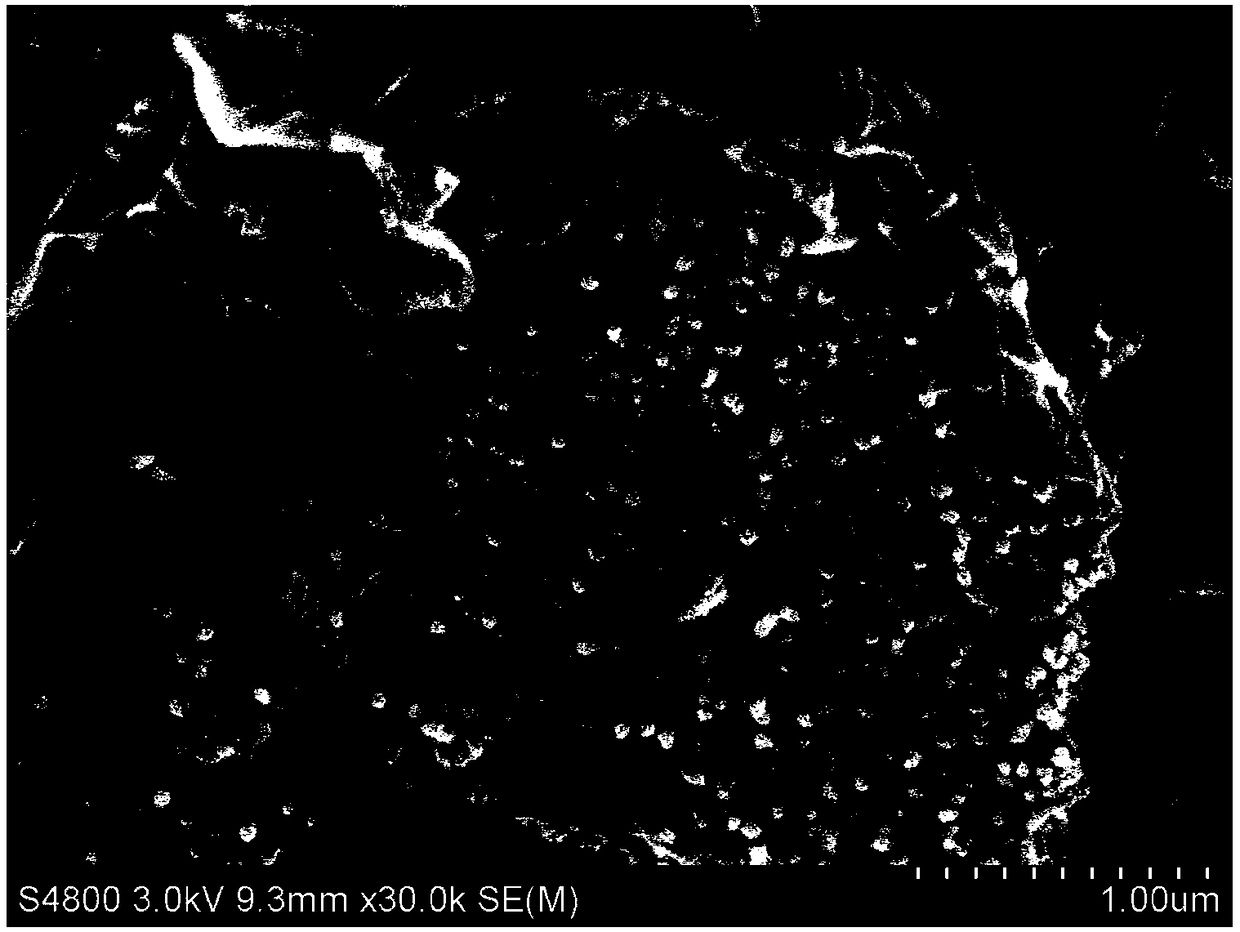

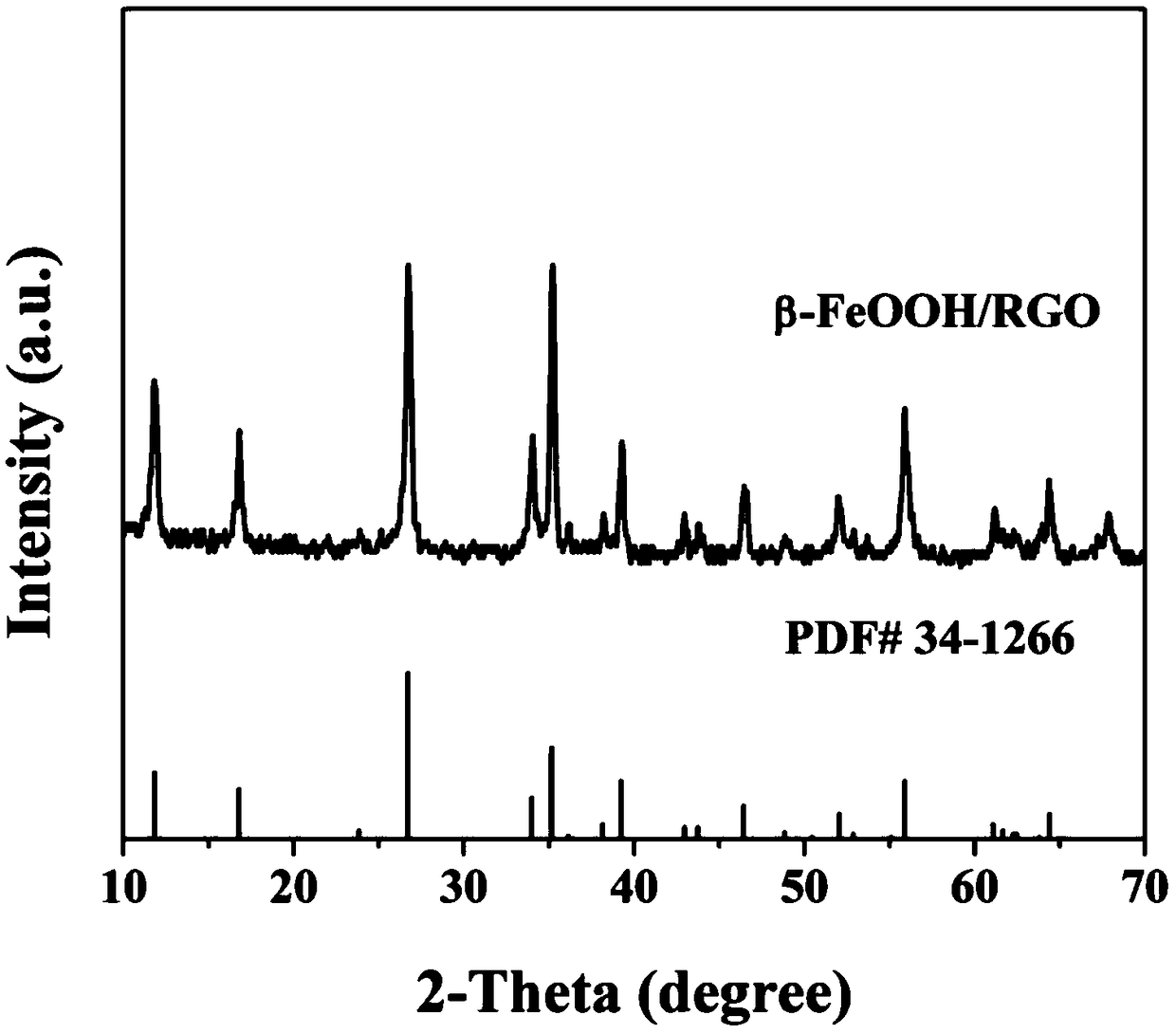

Synthesis of akageneite (beta-FeOOH)/reduced graphene oxide nanocomposites for oxidative decomposition of 2-chlorophenol by Fenton-like reaction Author links open overlay panel Feng Xiao a Wentao Li a Liping Fang b Dongsheng Wang a

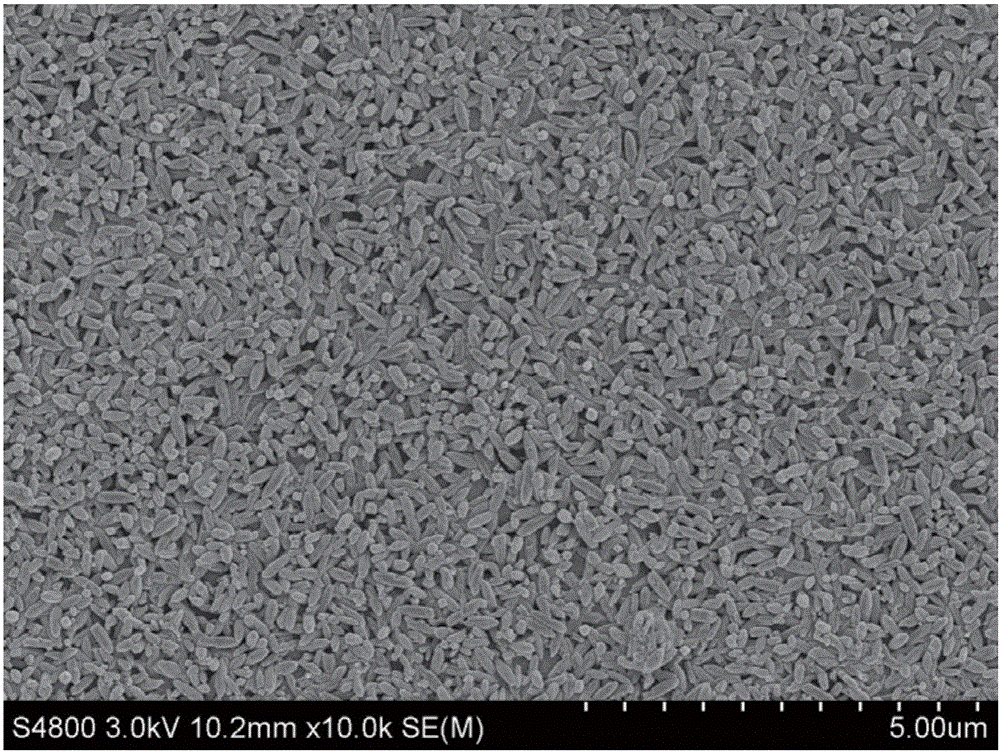

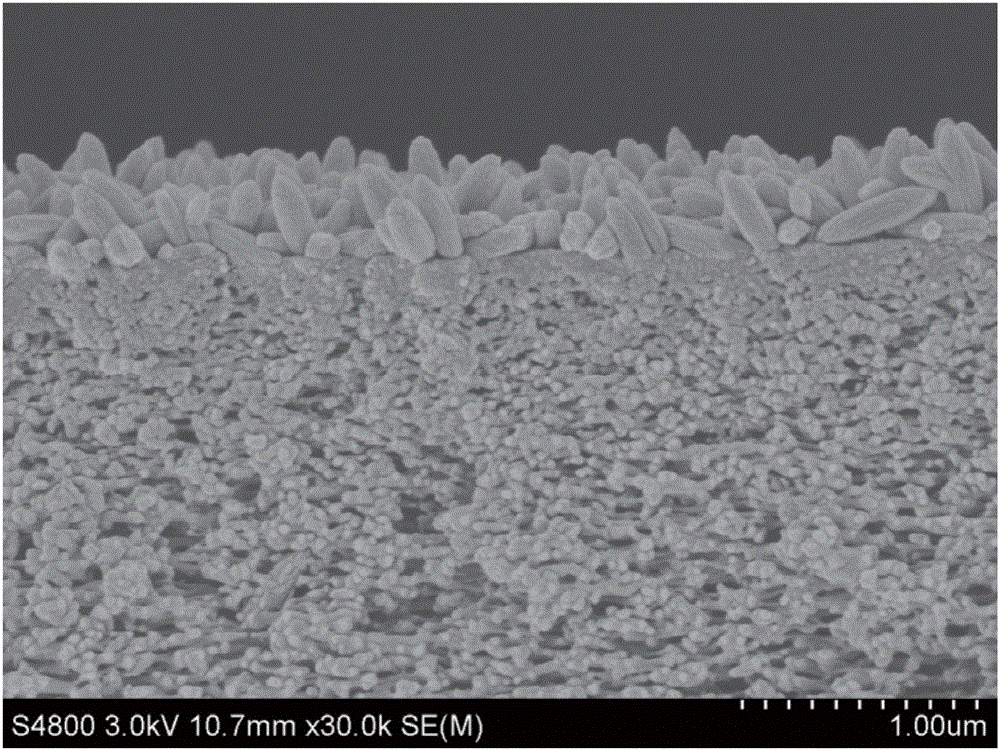

Beta-FeOOH nanocrystal-loaded photocatalytic composite nanofiltration membrane and preparation method thereof

ActiveCN106039998AImprove separation efficiencyExtended service lifeMembranesWater/sewage treatment by irradiationSurface layerWastewater

The invention discloses a beta-FeOOH nanocrystal-loaded photocatalytic composite nanofiltration membrane and a preparation method thereof. The photocatalytic composite nanofiltration membrane is prepared by performing codeposition on dopamine and polyethyleneimine on a porous supporting membrane to form a crosslinking nanofiltration membrane with a separating surface layer first and then loading beta-FeOOH nanocrystals on the separating surface layer. The loaded beta-FeOOH nanocrystals can promote photocatalytic oxidation reaction in the presence of hydrogen peroxide to degrade organic pollutants in wastewater or attached to the surface of the composite membrane, so that not only is achievement of the completely-innocent treatment of pollutant-containing wastewater facilitated, but also the pollution of the membrane surface can be reduced to achieve self cleaning of the membrane surface, and thus the separating efficiency of the composite nanofiltration membrane is improved and the service life of the composite nanofiltration membrane is prolonged.

Owner:ZHEJIANG UNIV

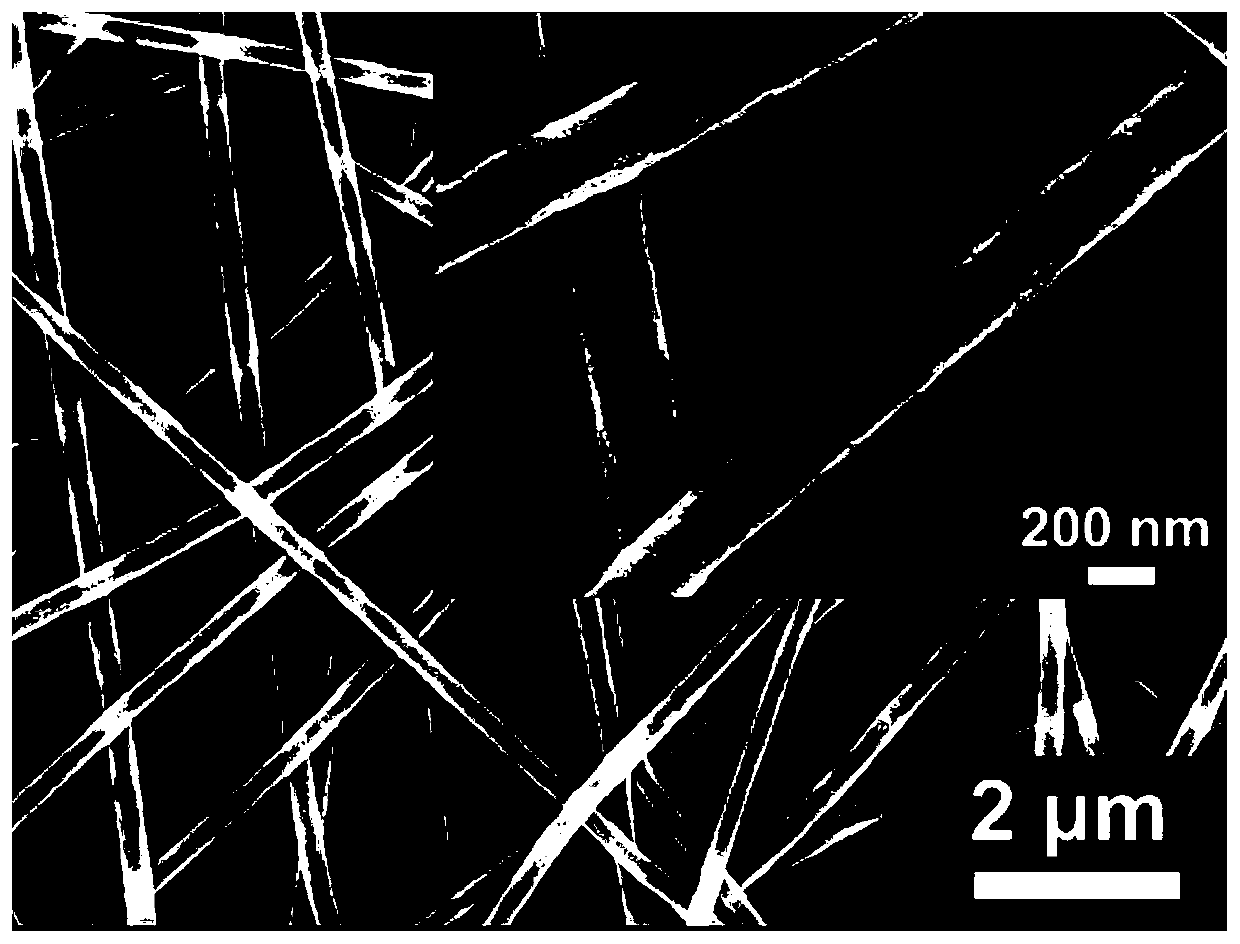

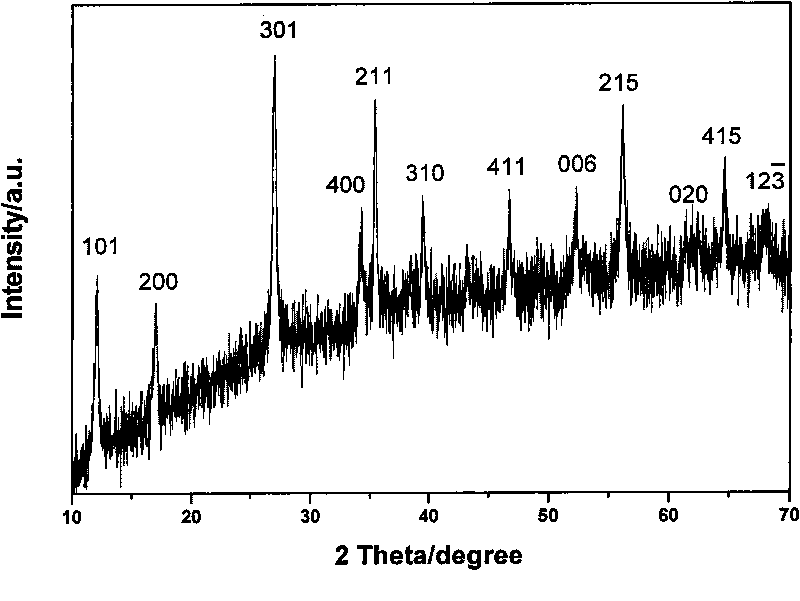

Porous Fe3O4/Fe/SiO2 core-shell nanorod absorbing high-frequency electromagnetic waves and a preparation method

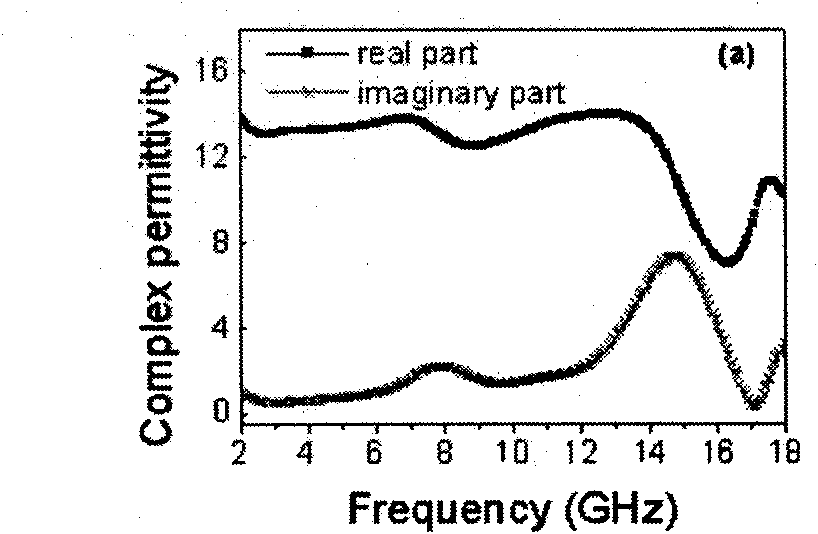

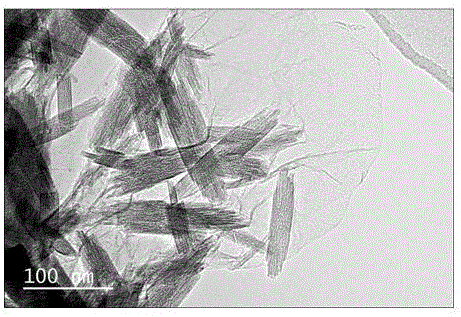

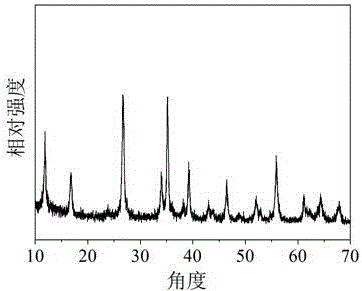

InactiveCN101514282AWide frequency rangeHas strong absorbing propertiesOther chemical processesRoom temperatureCore shell

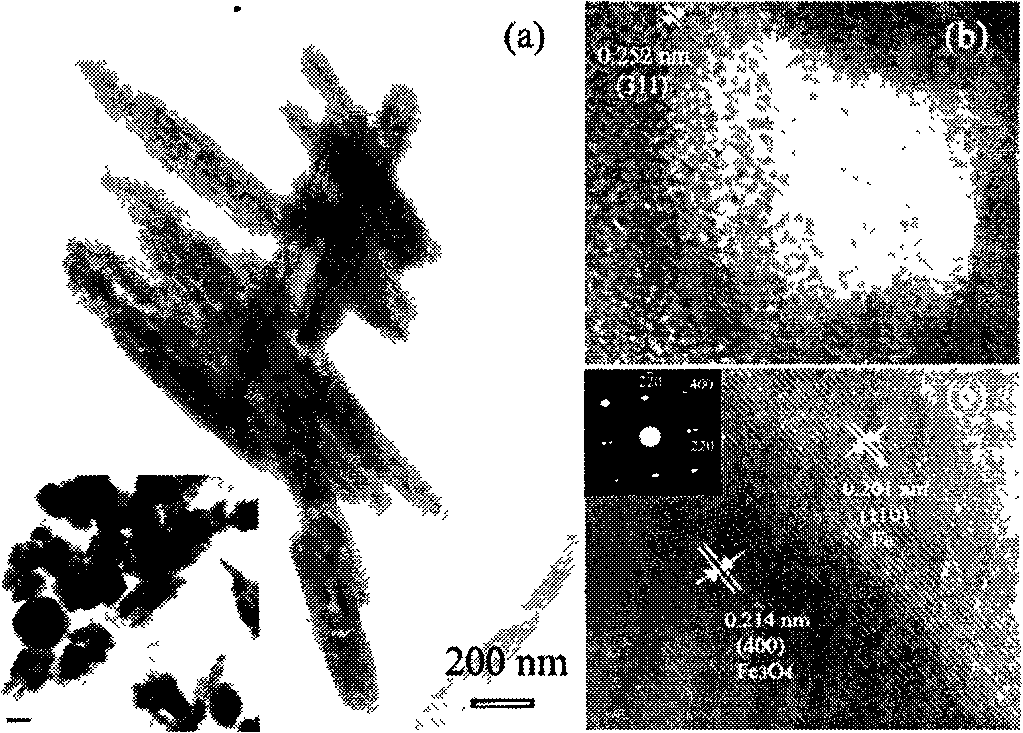

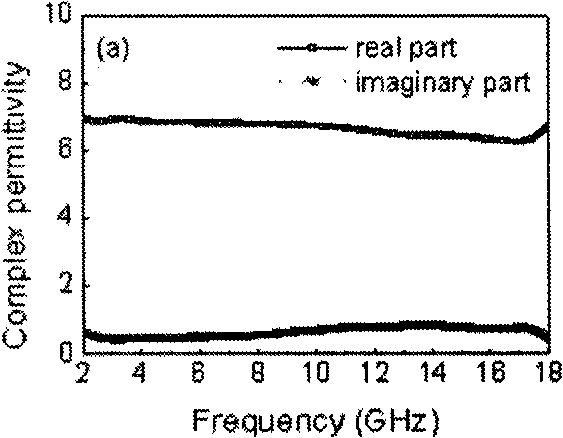

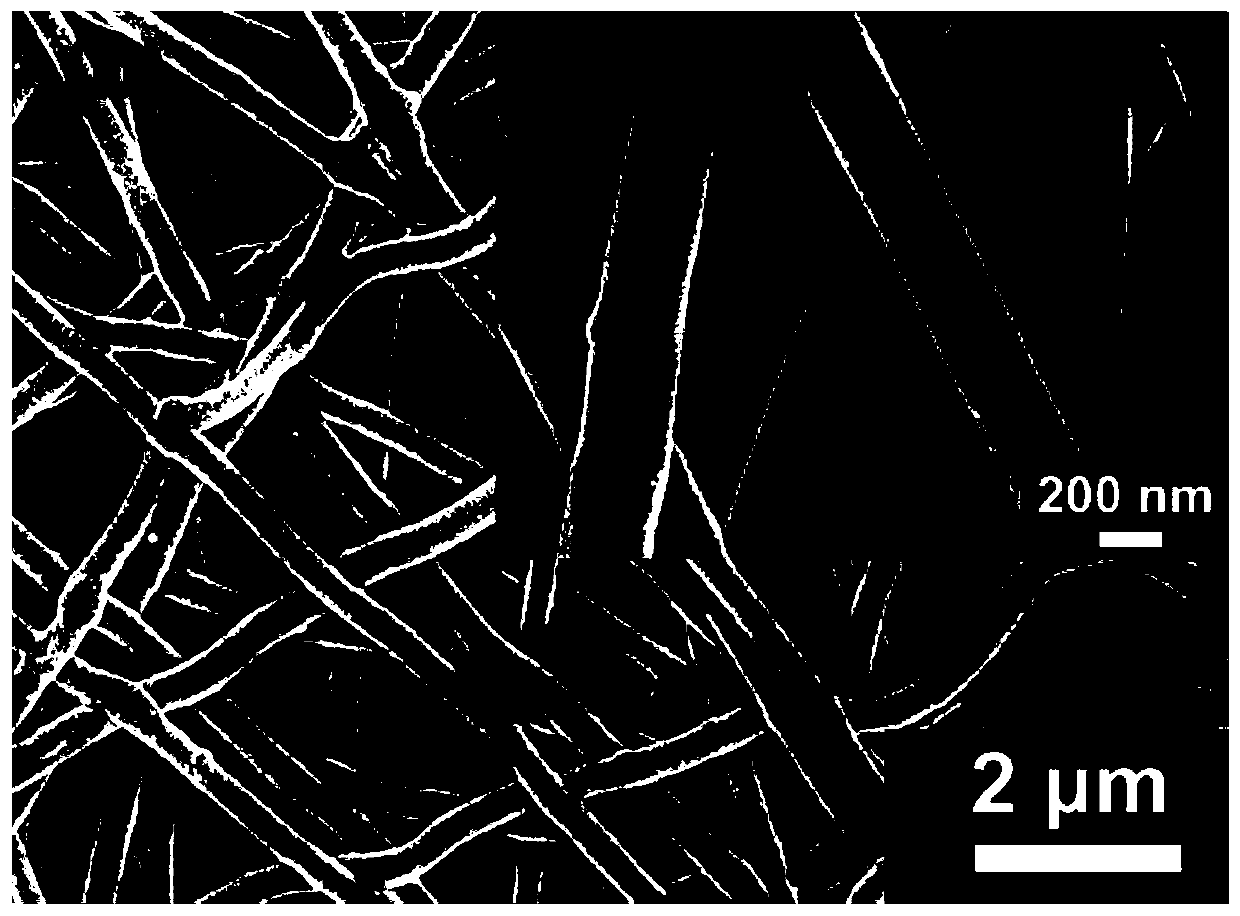

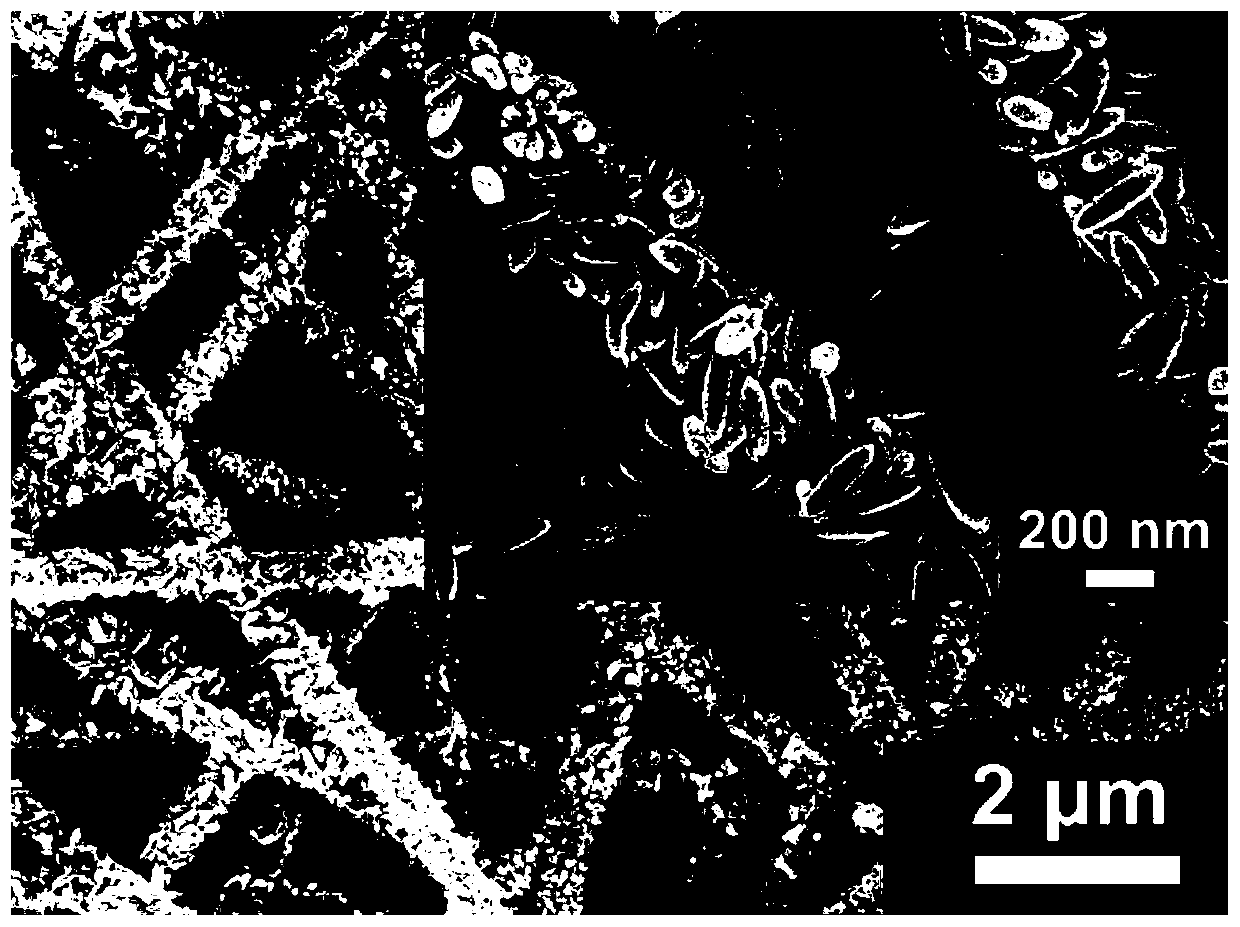

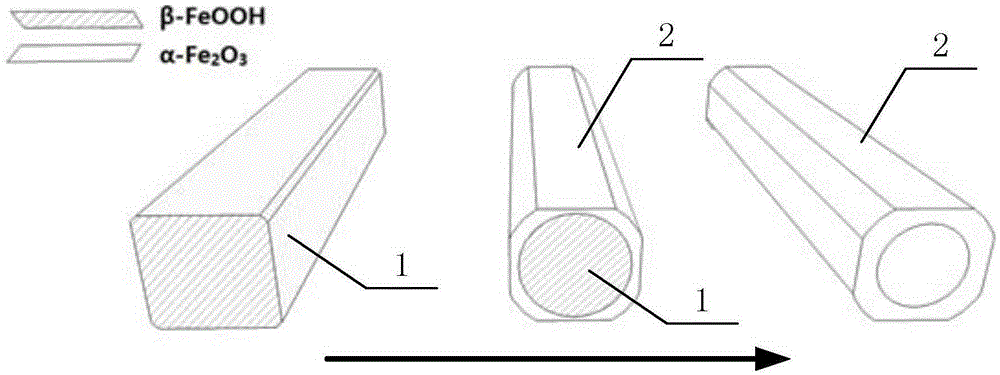

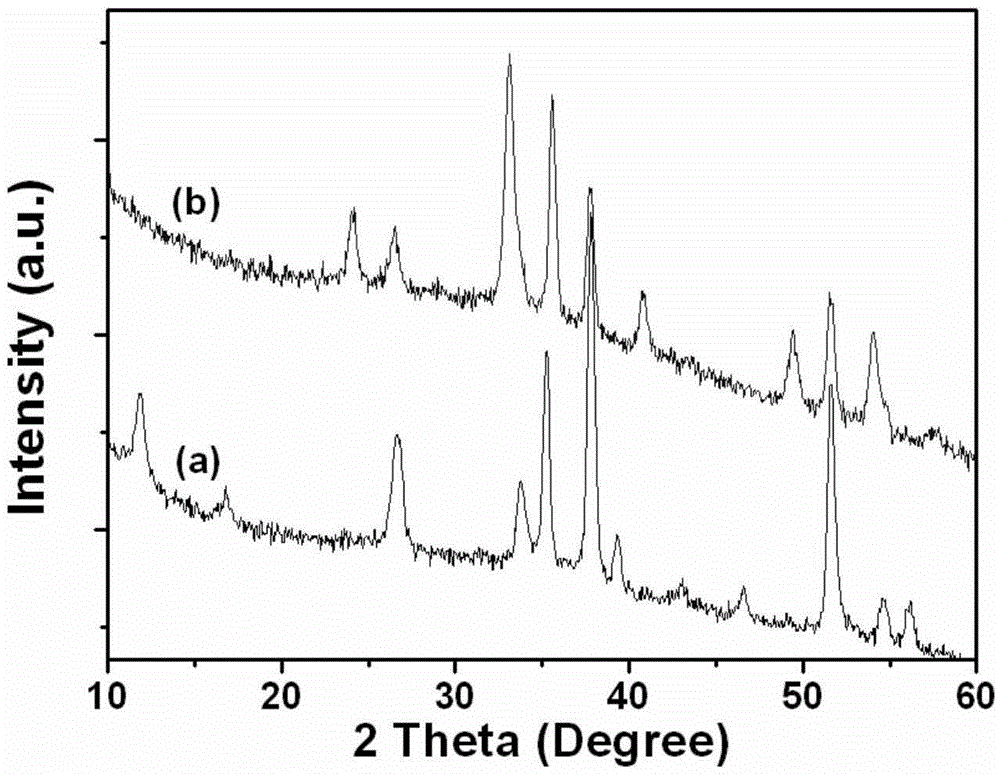

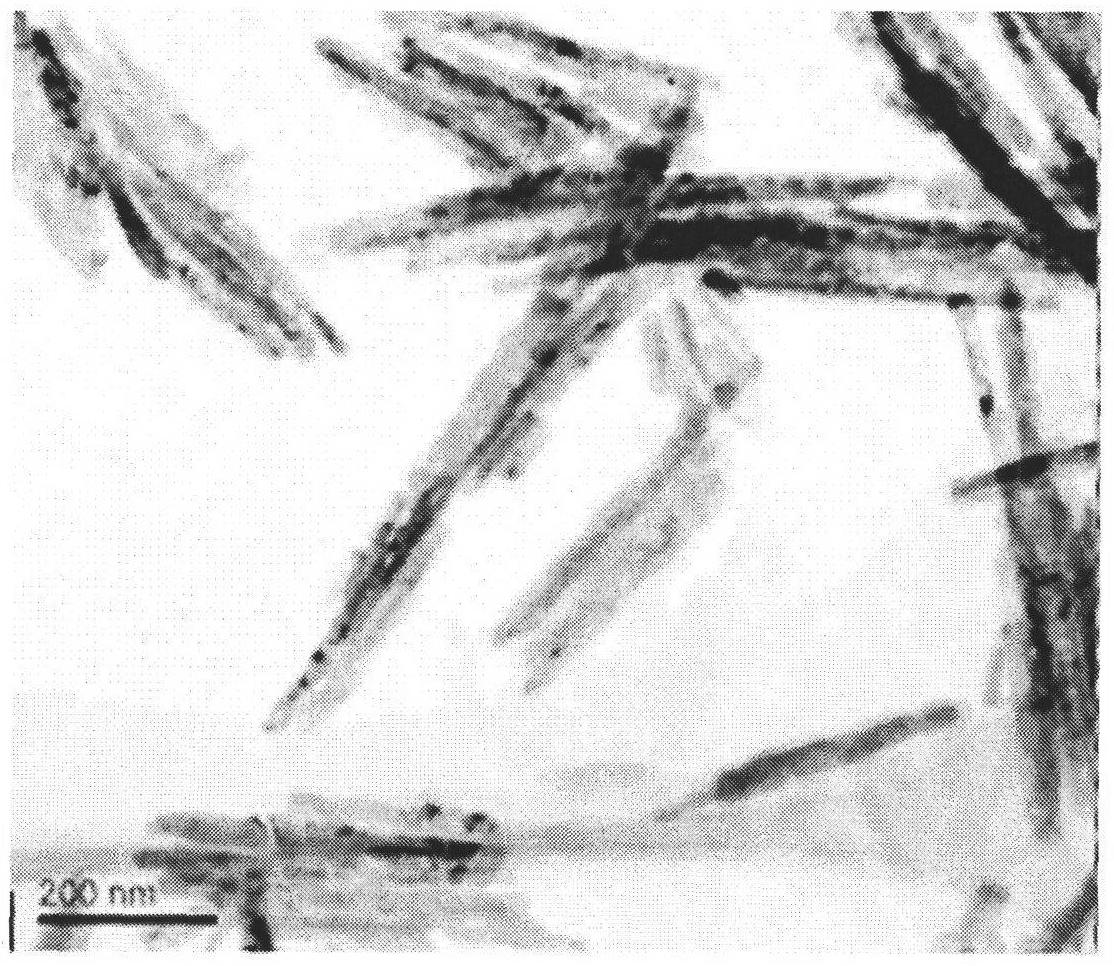

The invention provides a porous Fe3O4 / Fe / SiO2 core-shell nanorod absorbing high-frequency electromagnetic waves and a preparation method. FeCl3 liquid of 0.25 to 1.0 mol is poured into a stainless steel sealed autoclave, and is maintained for 12 hours in an oven under 100 and 120 DEG C; after the autoclave is naturally cooled to the room temperature, the precipitation in the autoclave is washed by water and ethanol, and dried under 80 DEG C to obtain a beta-FeOOH nanorod; the beta-FeOOH nanorod is hydrolyzed in ethyl orthosilicate / isopropanol solution to obtain a beta-FeOOH / SiO2 core-shell nanorod; the beta-FeOOH / SiO2 core-shell nanorod is annealed for 2.5 hours in the air under 500 DEG C to obtain an alpha-Fe2O3 / SiO2 core-shell nanorod; then the alpha-Fe2O3 / SiO2 core-shell nanorod is annealed for 7 hours under 400 DEG C in the N2 / H2 atmosphere, of which the volume of H2 accounts for 8 percent to finally obtain the porous Fe3O4 / Fe / SiO2 core-shell nanorod. The method of the invention has the advantages of simple operation, and suitability for industrial production; moreover, the obtained product has strong absorption characteristic to the high-frequency electromagnetic waves.

Owner:HARBIN ENG UNIV

Ferriferous oxide/tin oxide core-shell nanometer rod absorbing high-frequency electromagnetic wave and preparing method thereof

InactiveCN101586019AExhibits dual frequency absorption characteristicsStrong absorption propertiesOther chemical processesPotassiumHigh pressure

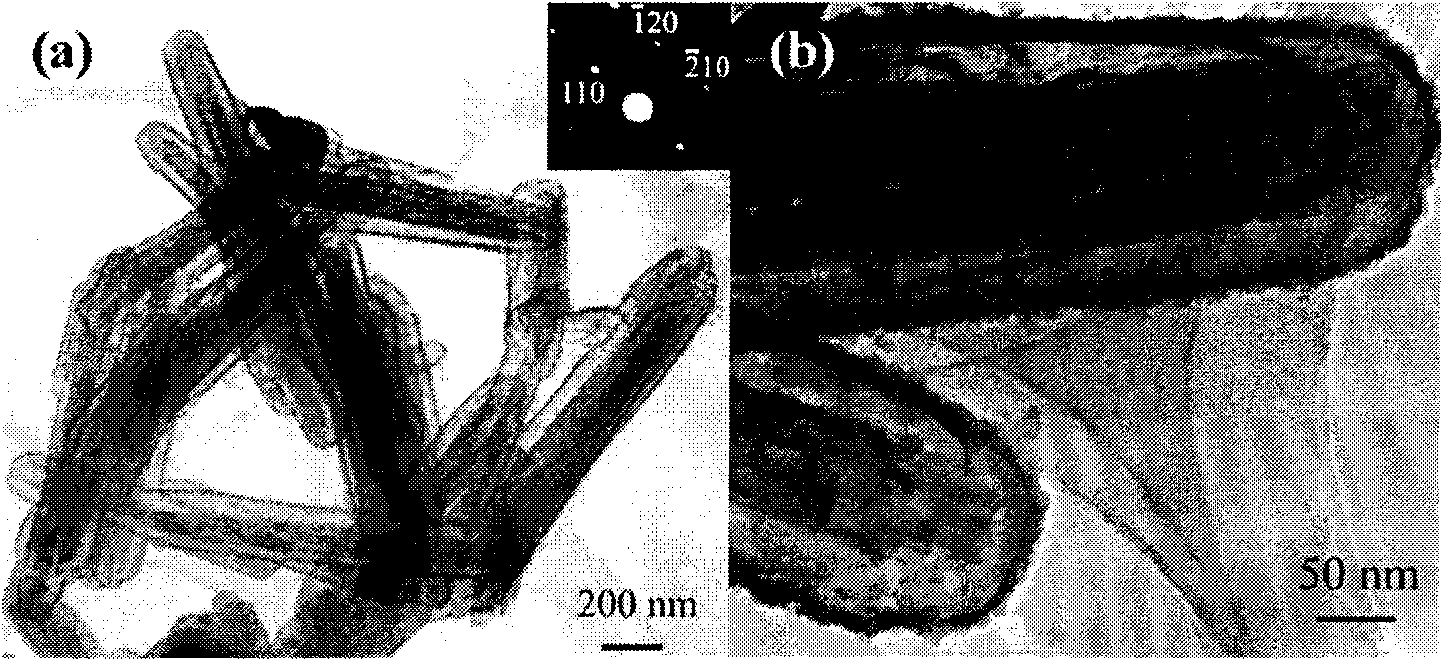

The present invention provides a ferriferous oxide / tin oxide core-shell nanometer rod absorbing high-frequency electromagnetic wave and a preparing method thereof. The FeCl3 solution with the concentration of 0.25-1.0mol / L is placed in a hermetical high-pressure autoclave made of stainless steel and is kept for 12 hours in a baking oven in the temperature of 100-120 DEG C. After the high-pressure autoclave is naturally cooled to the room temperature, cleaning the deposit in the autoclave with water and ethanol. After dried in the temperature of 80 DEG C, the beta-FeOOH nanometer rod is obtained. Then the beta-FeOOH nanometer rod is annealed for 2.5 hours in the temperature of 500 DEG C, and the alpha-Fe2O3 nanometer rod is obtained. The 0.08g of alpha-Fe2O3 nanometer rod is ultrasonically dispersed into 32ml of water-ethanol solution. Then 0.75g of urea and 0.115g of potassium stannate are added. After mixing, the obtained solution is placed in the hermetical high-pressure autoclave made of stainless steel and is kept for 36 hours in the baking oven in the temperature of 170 DEG C. After the high-pressure autoclave is naturally cooled to the room temperature, the deposit in the autoclave is cleaned with water and ethanol. After drying in the temperature of 80 DEG C, the alpha-Fe2O3 / SnO2 core-shell nanometer rod is obtained. The alpha-Fe2O3 / SnO2 core-shell nanometer rod is annealed for 7 hours in the atmosphere of N2 / H2 in which the volume of the H2 accounts for 8% for obtaining the porous ferriferous oxide / tin oxide nanometer rod. The method of the invention has the advantages of simple operation and suitability for the industrial production.

Owner:HARBIN ENG UNIV

Preparation method and application of beta-FeOOH-loaded graphene oxide catalyst

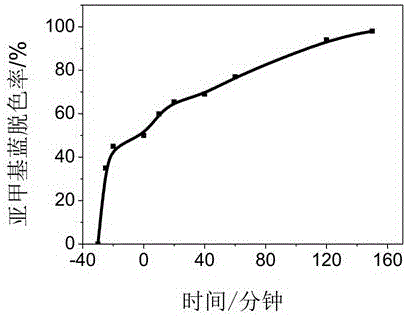

InactiveCN105921151AEasy to operateGood removal effectWater/sewage treatment by irradiationWater contaminantsWater bathsWater quality

The invention discloses a preparation method and application of a beta-FeOOH-loaded graphene oxide catalyst. The preparation method comprises the following steps: dispersing graphene oxide in water, carrying out ultrasonic treatment so as to obtain uniform dispersion liquid of graphene oxide, then adding ferric trichloride into the dispersion liquid of graphene oxide, carrying out heating in a constant-temperature water-bath so as to load beta-FeOOH onto the surface of graphene oxide and subjecting the obtained product to centrifugation, washing and drying so as to obtain the nanometer beta-FeOOH-loaded graphene oxide catalyst. The catalyst and hydrogen peroxide are added into a dye water body with a certain concentration; and under illumination of visible light, dye chroma is removed, biotoxicity is reduce, and the water body is purified. The catalyst is free of secondary pollution, and an intermediate produced in the reaction has obvious reduced biotoxicity; reaction conditions are mild, and the reaction can be carried out under the condition of visible light; process flow is simple in operation; raw materials used for preparation of the catalyst are easily available; the reacted solid phase catalyst is easy to separate; so the catalyst has good application prospects in the field of water pollution treatment.

Owner:EAST CHINA NORMAL UNIV

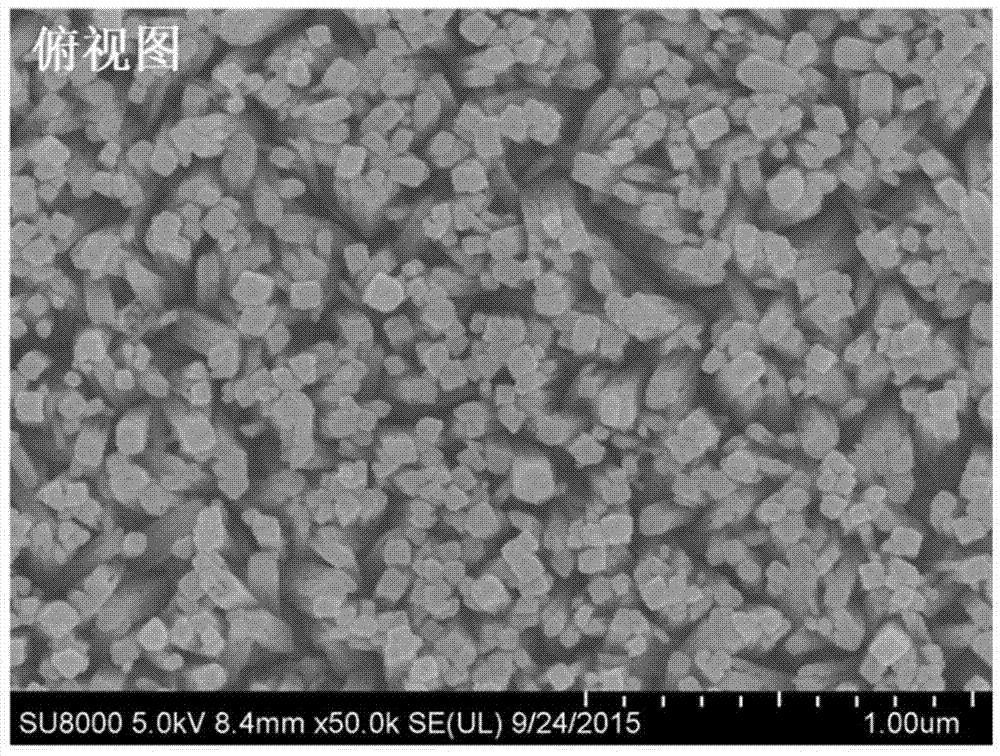

Method for preparing beta-FeOOH nano granule suspension solution

InactiveCN101423256AEvenly dispersedImprove stabilityIron oxides/hydroxidesNanoparticleEnhanced heat transfer

The invention discloses a Beta-FeOOH nanoparticle suspension preparation method, relating to a preparation method of an enhanced heat transfer medium, in particular to a stable Beta-FeOOH nanoparticle suspension. The method comprises the steps as follows: firstly, the aqueous solution of ferric trichloride and urea is prepared, wherein, the mass ratio of the ferric trichloride and the urea is 6:1; and then the aqueous solution is added into an airtight PTFE reactor, reacted at the temperature of 80 plus or minus 2 DEG C till the end, and naturally cooled to room temperature, so that the Beta-FeOOH nanoparticle suspension is obtained. The method adds no stabilizing agent, and the produced Beta-FeOOH is small in size and good in uniformity and stability. The method has the advantages of small number of production equipment, simple operating steps, low cost, and requires no additives except raw materials, thus being suitable for industrial production.

Owner:YANGZHOU UNIV

Beta-FeOOH/polyacrylonitrile composite nanofiber membrane, preparation method thereof and application of membrane

ActiveCN110205748ALarge specific surface areaImprove adsorption capacityNon-woven fabricsComposite nanofibersNanofiber

The invention provides a beta-FeOOH / polyacrylonitrile composite nanofiber membrane, a preparation method thereof and an application of the membrane, and belongs to the technical field of materials. The preparation method of the beta-FeOOH / polyacrylonitrile composite nanofiber membrane includes the steps: polyacrylonitrile nanofiber membrane preparation: preparing a polyacrylonitrile nanofiber membrane by electrostatic spinning; stabilizing treatment: performing gradient heating treatment on the polyacrylonitrile nanofiber membrane; biological mineralization treatment: preparing ferric chloridesolution and hydrochloric acid according to the volume ratio of 2:1, placing the stabilized polyacrylonitrile nanofiber membrane into mixed solution and stirring the mixed solution for 1-3 minutes, performing reaction under the condition of 55-65 DEG C for 10-14 hours, and then cleaning and drying the polyacrylonitrile nanofiber membrane to prepare the beta-FeOOH / polyacrylonitrile composite nanofiber membrane. The beta-FeOOH / polyacrylonitrile composite nanofiber membrane has good stability, mechanical performance, super-hydrophilic-underwater super-oleophobic properties and high adsorption efficiency and can be recycled.

Owner:成都石大力盾科技有限公司

Hydrothermal method-based method for preparing alpha-Fe2O3 nanotube array

InactiveCN105251490AHigh density oxygen vacanciesIncrease the carrier concentrationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNitrogen gasPollution

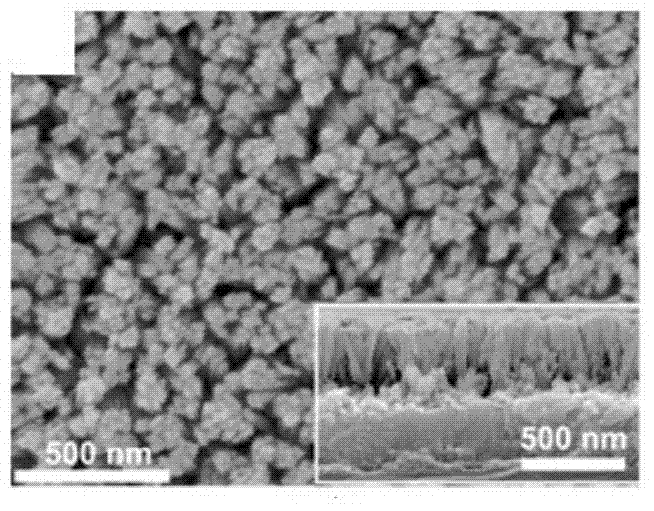

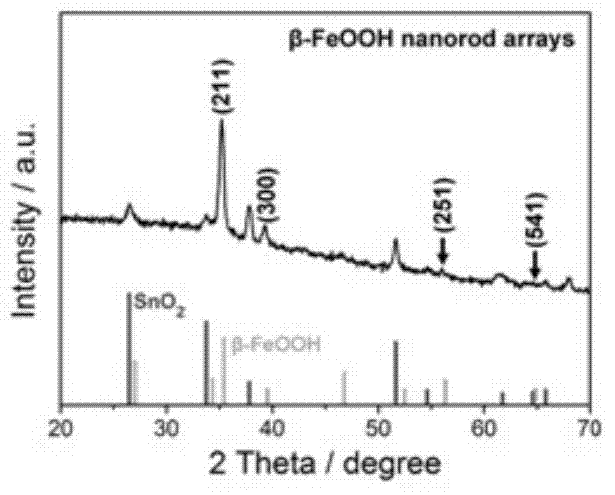

The invention discloses a hydrothermal method-based method for preparing a alpha-Fe2O3 nanotube array. The method comprises the following steps: preparing a beta-FeOOH nanorod array, namely obliquely placing a glass substrate coated with fluorine-doped stannic oxide (FTO) in a mixed liquid of FeCl3 and NaNO3, and performing hydrothermal reaction at 100 DEG C for 12h so as to obtain a beta-FeOOH nanorod array which grows on the glass substrate; and preparing the alpha-Fe2O3 nanotube array, namely annealing the beta-FeOOH nanorod array in nitrogen gas for 6h so as to obtain the alpha-Fe2O3 nanotube array. The method is high in preparation efficiency, short in production period, low in production cost, low in device requirments, and easy to operate, has effects of environment friendliness and no pollution and is suitable for mass production.

Owner:STATE GRID CORP OF CHINA +2

Ferroferric oxide and zinc oxide nuclear shell nano-rod for absorbing high-frequency electromagnetic waves and manufacturing method thereof

InactiveCN101767767AStrong absorption propertiesReduce thicknessIndividual molecule manipulationUltrasonic dispersionZinc oxide nanorod

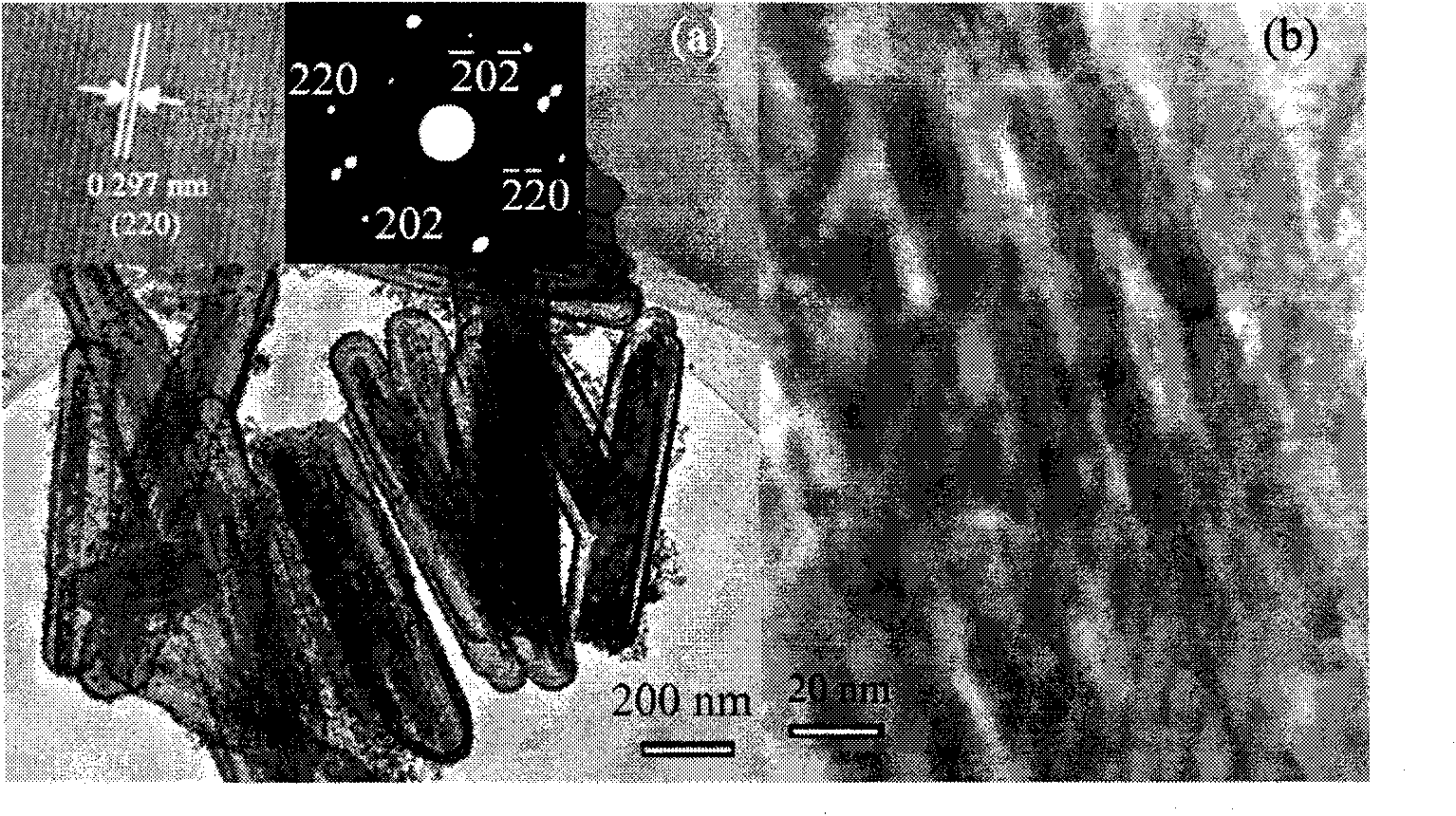

The invention provides a ferroferric oxide and zinc oxide nuclear shell nano-rod for absorbing high-frequency electromagnetic waves and a manufacturing method thereof. The manufacturing method comprises the following steps of: putting solution of FeCl3 into a stainless steel sealed autoclave, and keeping the temperature between 100 and 120 DEG C for 12 hours; when the autoclave is cooled to the room temperature naturally, washing a deposit in the autoclave by using water and ethanol; dying the deposit at the temperature of 80 DEG C to obtain a beta-FeOOH nano-rod; putting the beta-FeOOH nano-rod into aqueous solution of ethylene diamine through ultrasonic dispersion, then adding aqueous solution of Zn(AC)2 into the mixture, and reacting the mixture for 12 hours at the temperature of 120 DEG C; when the autoclave is cooled to the room temperature naturally, washing the deposit in the autoclave by using the water and the ethanol, drying the deposit in the air, and annealing the deposit for 3 hours at the temperature of 500 DEG C; performing a second treatment on the obtained powder in the aqueous solution of the ethylene diamine and the aqueous solution of the Zn(AC)2, filtering the mixture, and drying the deposit to obtain a Fe2O3 / ZnO nuclear shell nano-rod; and annealing the Fe2O3 / ZnO nuclear shell nano-rod for 5 to 7 hours at the temperature of between 360 and 380 DEG C under an 8 to 10 percent H2 / Ar atmosphere to obtain a ferroferric oxide / zinc oxide nano-rod. The manufacturing method is simple to operate and is suitable for industrial production.

Owner:HARBIN ENG UNIV

Nanometer multifunctional composite thin-membrane, its production and use

A multifunctional nanometer composite thin film, its production and use are disclosed. The thin film contains silicone, it is grafted with perfluoro-silicane 0.02í½0.1wt% on surface and doped with nanometer iron oxide particle 1í½4wt% in network, which is fusiform or needle alpha-FeOOH, beta-FeOOH, alpha-Fe2O3 or gamma-Fe2O3. The process is carried out by hydrolyzing for silane coupling agent and ethyl orthosilicate in water, alcohol and hydrolytic catalyst system, mixing, adding into alcohol, condensing and generating silicone polymer at 30í½60íÒC, adding into nanometer iron oxide particle and fluorosurfactant, reacting, obtaining thin-film sol, forming thin-film sol into film on treated substrate material, drying and curing. It achieves higher anti-aging and mechanical performances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

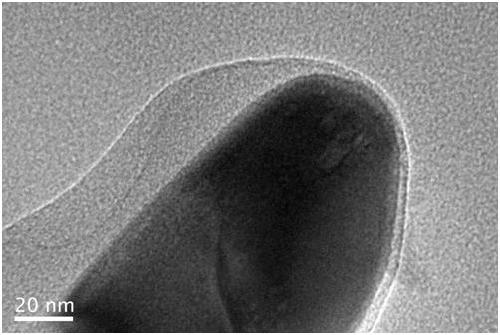

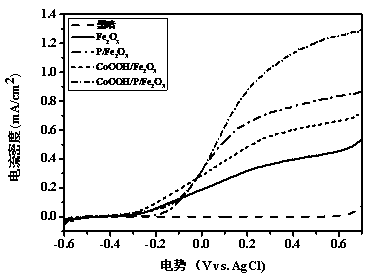

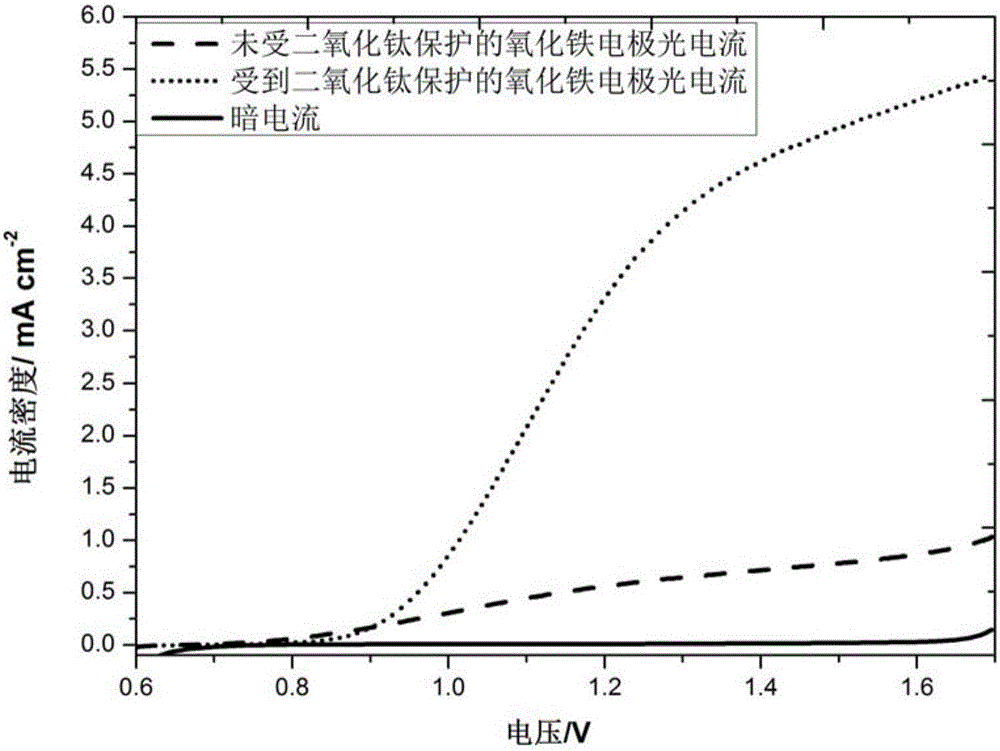

Preparation method of cobalt-oxygen-oxygen-hydrogen-modified phosphorus-doped iron oxide photo-anode

InactiveCN109504981AImprove performanceAchieve conversionSuperimposed coating processElectrodesTin dioxideNew energy

The invention relates to a preparation method of a cobalt-oxygen-oxygen-hydrogen-modified phosphorus-doped iron oxide photo-anode, and belongs to the technical field of new energy materials. The preparation method comprises the following steps that beta-FeOOH is generated on a F-doped tin oxide (FTO) conductive glass substrate through a hydrothermal method, then, the phosphorus-doped iron oxide photo-anode is generated by performing soaking in a phosphate solution and performing heat treatment, and finally, a layer of CoOOH is deposited on the surface of the phosphorus-doped iron oxide photo-anode by using a light-assisted electrodeposition method so as to obtain the cobalt-oxygen-oxygen-hydrogen-modified phosphorus-doped iron oxide photo-anode (CoOOH-P-Fe2O3). Due to phosphorus doping, the conductivity of the iron oxide photo-anode is improved; and furthermore, cobalt oxygen hydrogen is used as a catalyst for assistance in oxygen evolution, so that compared with basic iron oxide, thelight current density of the cobalt-oxygen-oxygen-hydrogen-modified phosphorus-doped iron oxide photo-anode prepared by using the method is improved by 200%.

Owner:CHANGZHOU UNIV

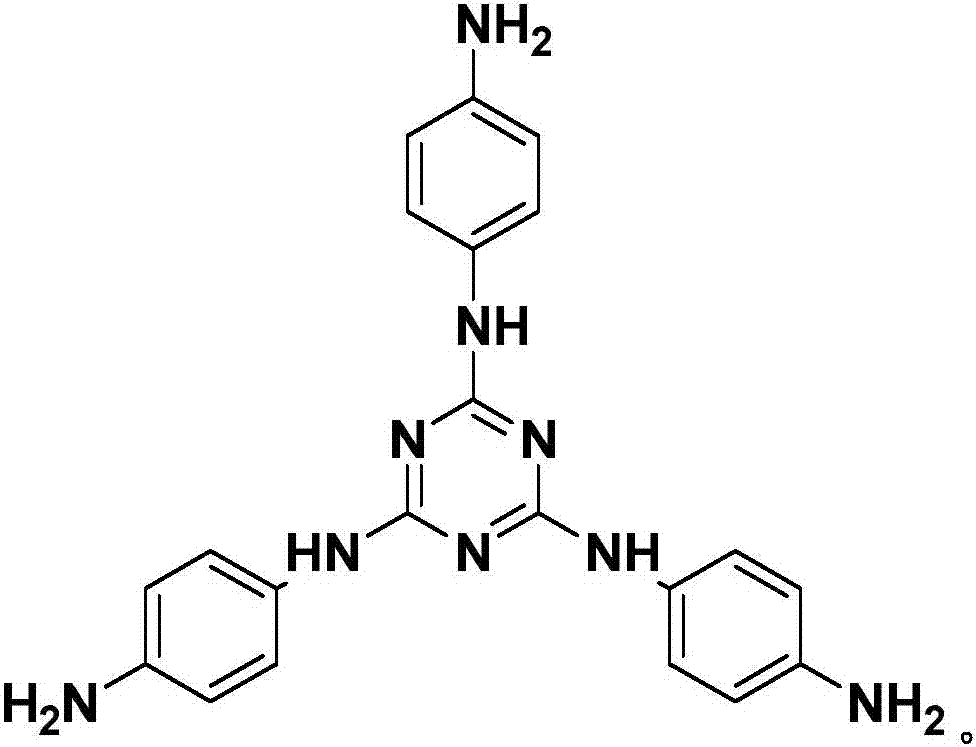

Phosphorus-nitrogen-containing polymer-coated beta-FeOOH nanoparticles, and preparation method and application thereof

ActiveCN107057121AImprove flame retardant performanceImprove thermal stabilityCarbon layerPolymer science

The invention discloses phosphorus-nitrogen-containing polymer coated beta-FeOOH nanoparticles and a preparation method and application thereof. The nanoparticles comprise nano beta-FeOOH and a polymer coated outside the nano beta-FeOOH and containing Schiff base structures; and DOPO is added to the polymer. According to the prepared phosphorus-nitrogen-containing polymer coated beta-FeOOH nanoparticles, two flame-retardant elements including a phosphorus element and a nitrogen element are introduced, the phosphorus element can catalyze the system to form a phosphorus-rich carbon layer when rubber is burnt, and the carbon layer can stop the burning of the rubber as a protective layer; the nitrogen element can generate non-combustible gas when the rubber is burnt, and further the burning process is slowed down; in addition, due to introduction of beta-FeOOH in the system, the thermal stability of the material can be improved and the smoke suppressing effect is good; and the two flame-retardant elements phosphorus and nitrogen and the beta-FeOOH have the synergistic flame-retardant effect, so that the effect for improving the flame-retardant property of the rubber is obvious.

Owner:万新(厦门)新材料有限公司

Preparation and application of different-crystal-phase FeOOH nanometer materials

ActiveCN104495946AEasy to addReduce usageMaterial nanotechnologyIron oxides/hydroxidesTobacco-specific nitrosaminesAlpha-FeOOH

The invention provides a preparation method of FeOOH nanometer materials. By preparing a solution A and a solution B, the solution A is used alone or in combination with the solution B at a certain ratio to respectively prepare different-crystal-phase FeOOH nanometer materials under a certain condition, namely, alpha-FeOOH, beta-FeOOH and delta-FeOOH. The invention further discloses a cigarette filter tip added with any one of the different-crystal-phase FeOOH nanometer materials. By adding the different-crystal-phase FeOOH nanometer materials prepared by the preparation method, which is disclosed by the invention, into the cigarette filter tip, the release amount of tobacco-specific nitrosamine in cigarette mainstream smoke can be effectively decreased. The additives for the cigarette filter tip are safe and non-toxic and low in cost and the preparation method is simple and high in yield and is suitable for industrial production.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

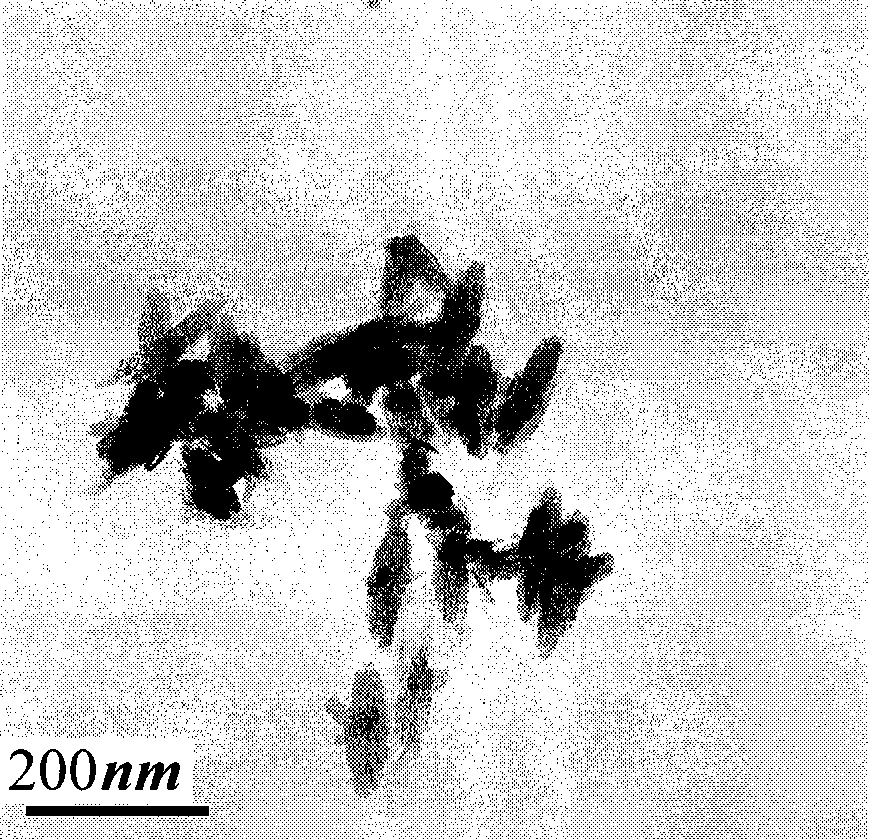

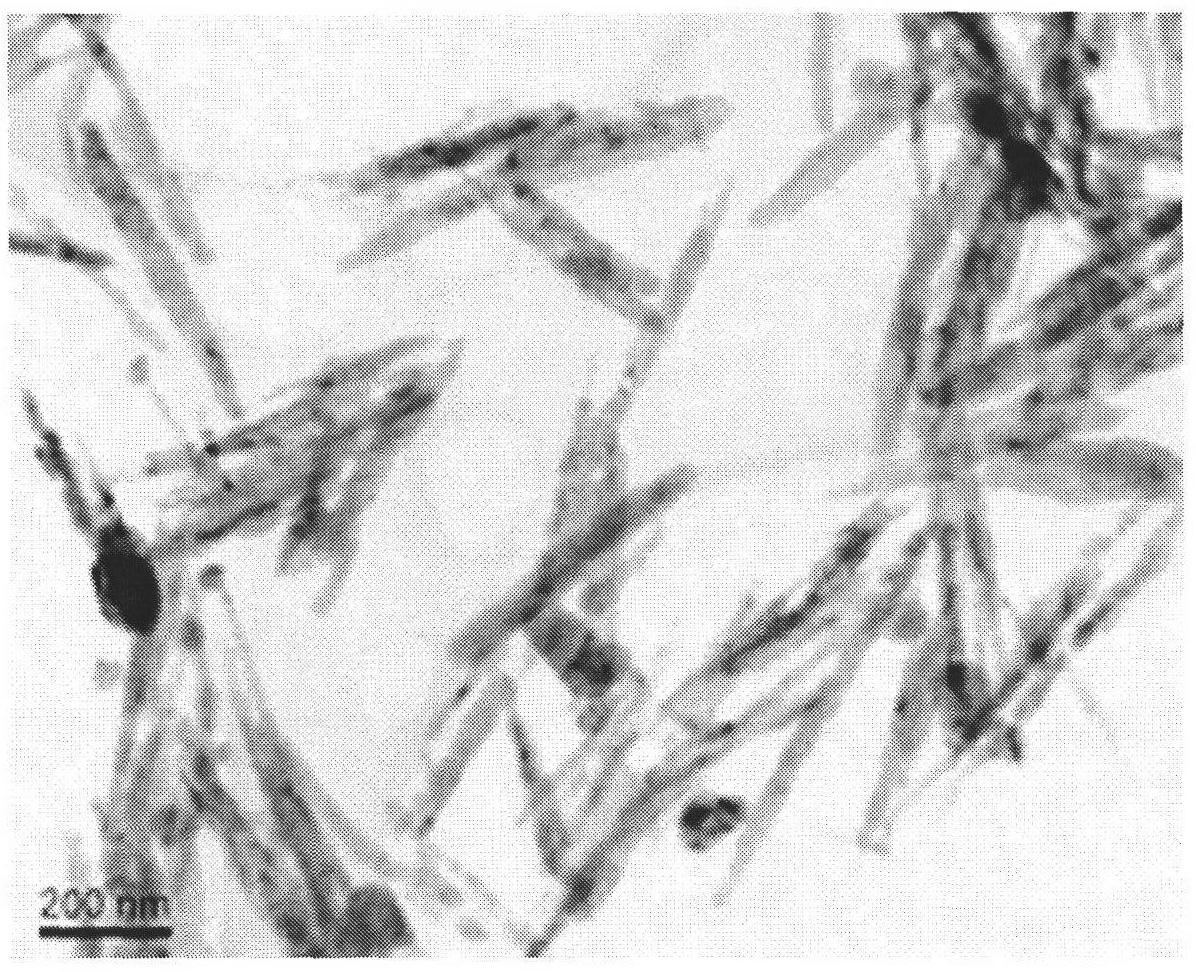

Cobweb-like graphene coated beta-FeOOH nano-rod aggregate lithium ion battery negative electrode material preparation method

ActiveCN107732168AImprove conductivityStructural recovery and stabilizationMaterial nanotechnologyCell electrodesFreeze-dryingMaterials science

The invention relates to a cobweb-like graphene coated beta-FeOOH nano-rod aggregate lithium ion battery negative electrode material preparation method, which comprises: dispersing graphene oxide in deionized water to obtain a suspension A; adding FeCl3.6H2O and NaNO3 into deionized water, and adding the obtained solution into the suspension A to obtain suspension B; pouring the suspension B intoa homogeneous phase hydrothermal reaction kettle, sealing the reaction kettle, placing the sealed reaction kettle into a homogeneous phase hydrothermal reaction instrument, and carrying out a reactionto obtain a product C; washing the product C respectively with water and alcohol, and dispersing the washed product in water to obtain a product D; and carrying out freeze drying on the product D toobtain the cobweb-like graphene coated beta-FeOOH nano-rod aggregate lithium ion battery negative electrode material. According to the present invention, the performance of beta-FeOOH is improved by compounding the graphene with the special structure, wherein graphene has advantages of good conductivity and large specific surface area, such that the poor conductivity of beta-FeOOH can be effectively solved by coating the beta-FeOOH with the special cobweb-like graphene while the volume expansion can be inhibited to achieve the stable battery structure so as to improve the cycle stability of the battery.

Owner:SHAANXI UNIV OF SCI & TECH

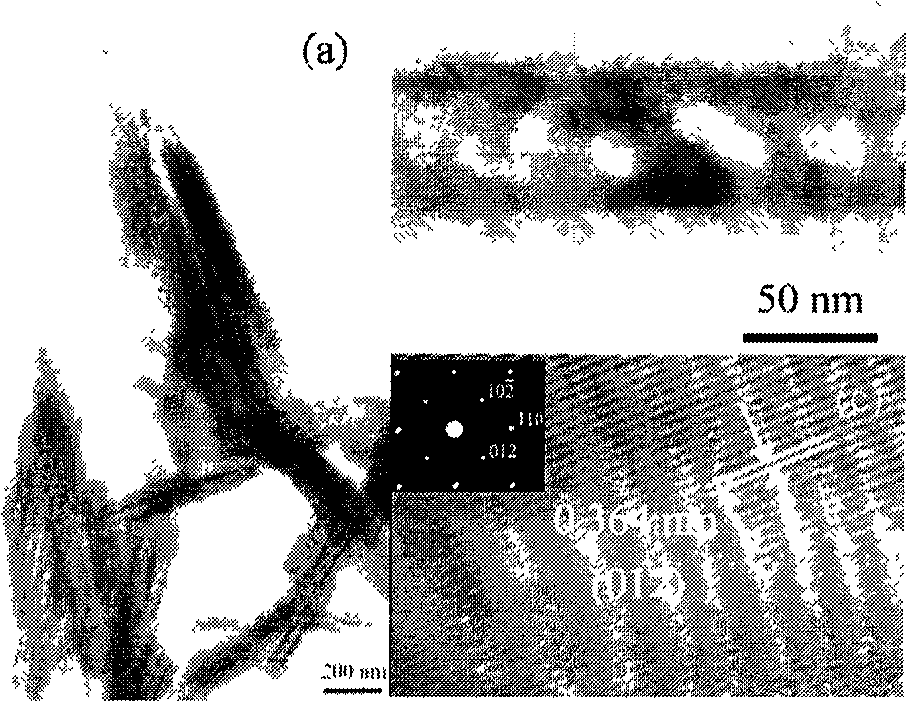

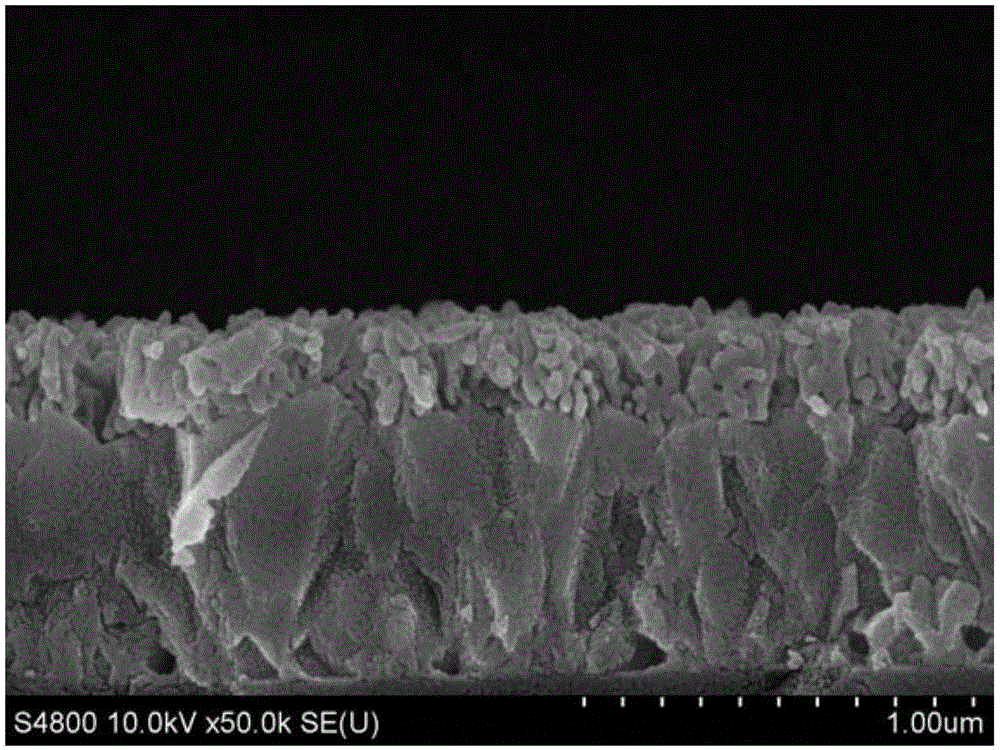

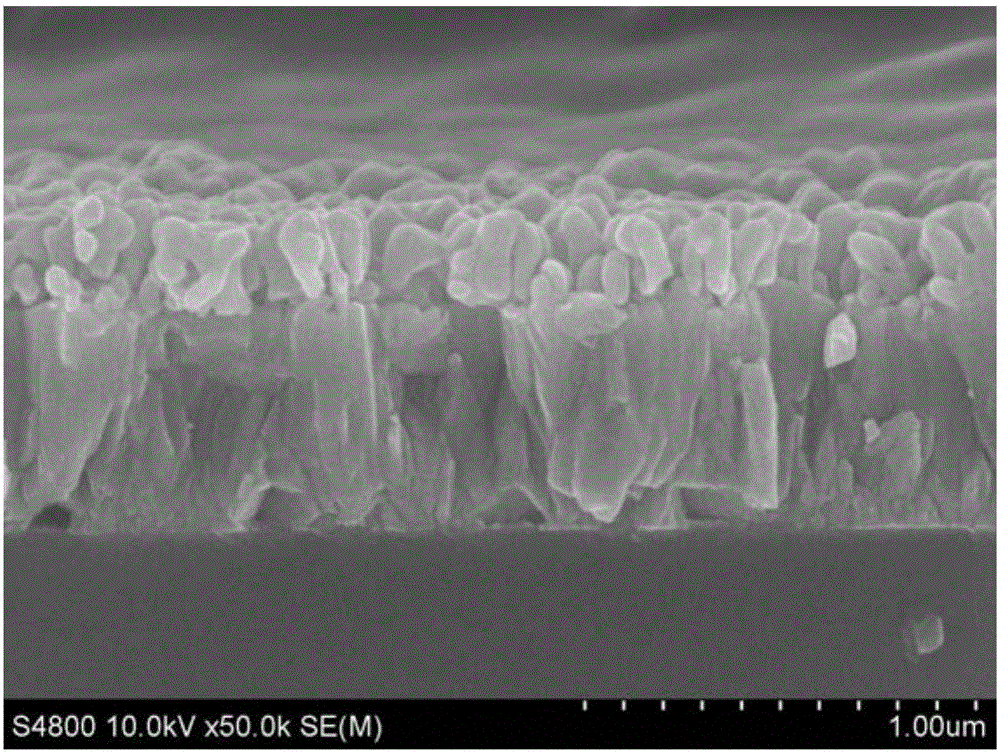

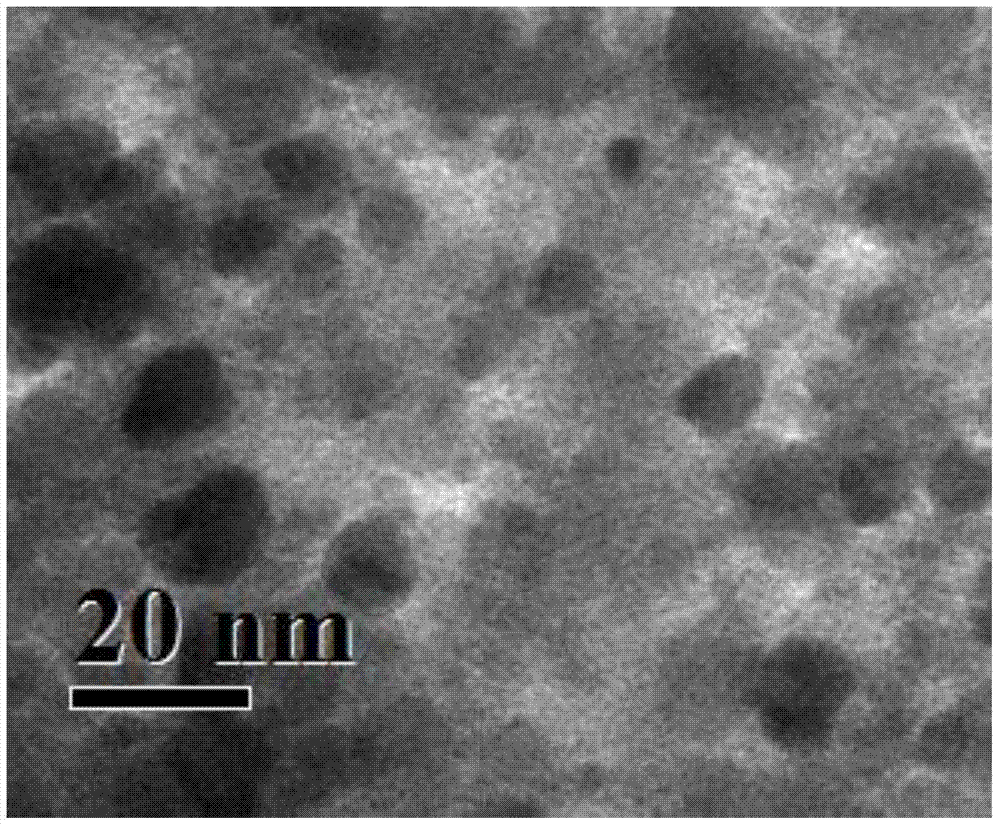

Titanium-doped alpha-iron oxide photo-anode, and preparation method and application thereof

The invention discloses a titanium-doped alpha-iron oxide photo-anode, and a preparation method and an application thereof. The method comprises the steps: coating the surface of a beta-FeOOH membrane with a titanium source solution, forming a TiO2 layer during high temperature annealing, and inhibiting grain coarsening of alpha-iron oxide; at the same time, in the process, diffusing titanium ions to the interior of alpha-iron oxide crystal lattices to realize titanium doping; and after annealing, using a hydrogen peroxide aqueous solution to remove the TiO2 layer, and thus obtaining the titanium-doped alpha-iron oxide photo-anode. The photo-anode has small particle size which is 30 nm-40 nm; the maximum photocurrent density can reach 3.62 mA / cm<2> under a 300 W xenon lamp light source and at the bias of 1.23 V[RHE]; compared with a un-doped alpha-iron oxide photo-anode without introduction of the TiO2 layer, the photocurrent is increased by 5 times, and a positive shift phenomenon of initial potential is not generated.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

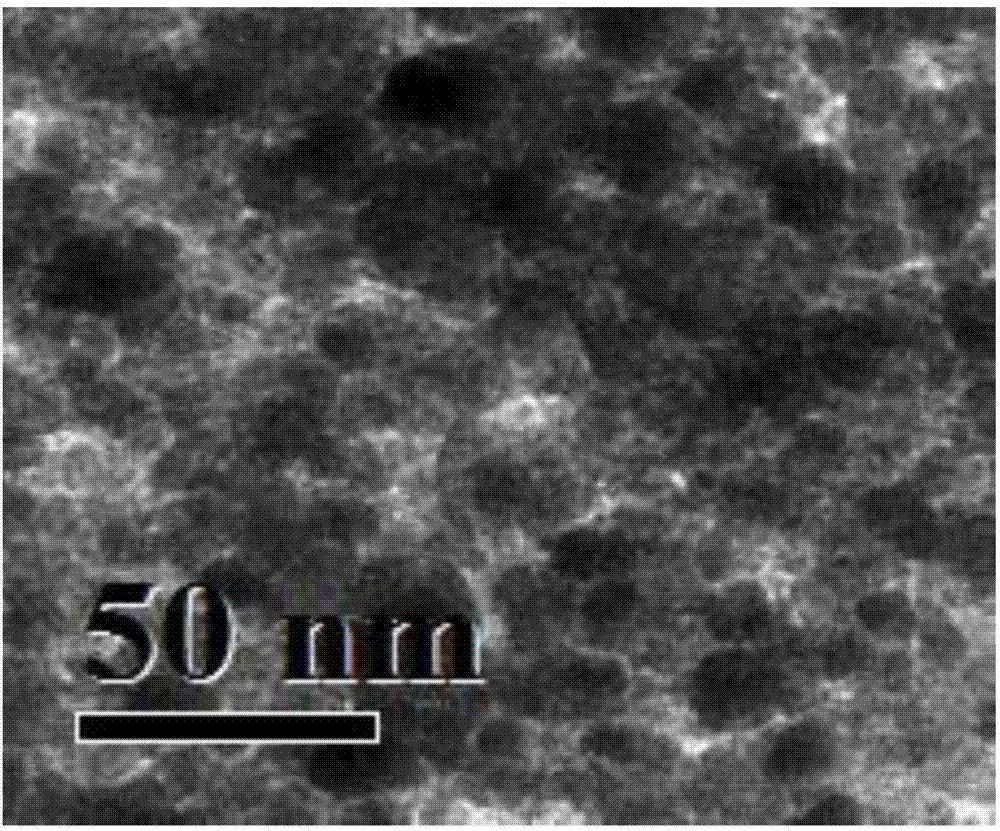

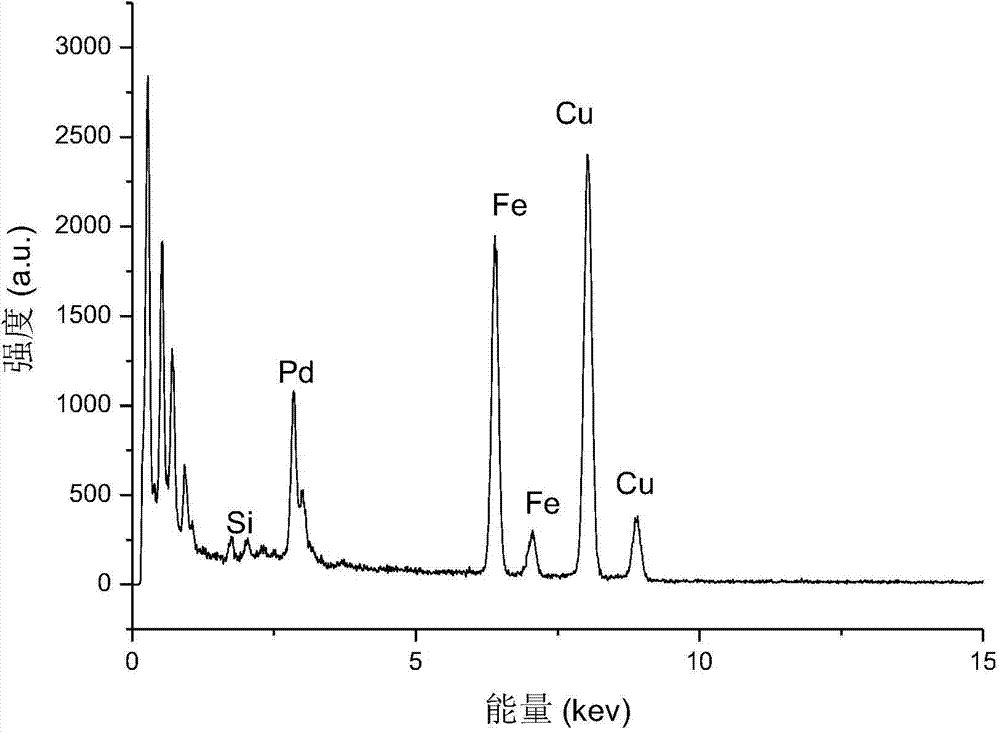

Biosynthesis method of magnetic Pd nanocomposite material

InactiveCN103710389AShort reaction timeMild conditionsMicroorganism based processesFermentationNanoparticleNanocomposite

The invention discloses a biosynthesis method of a magnetic Pd nanocomposite material and belongs to the field of nano-material bio-preparation. The biosynthesis method comprises that biological magnetic nano-particles are synthesized by a reaction of Shewanella oneidensis MR-1 and beta-FeOOH; and the biological magnetic nano-particles, Na2PdCl4 and AuCl3.HCl.4H2O are synthesized into the magnetic Pd nanocomposite material at a normal temperature. The biosynthesis method has mild reaction conditions, simple processes, short reaction time and a low cost, is a preparation technology of the green pollution-free Pd nanocomposite material, and can be used for catalytic degradation of environmental pollutants.

Owner:DALIAN UNIV OF TECH

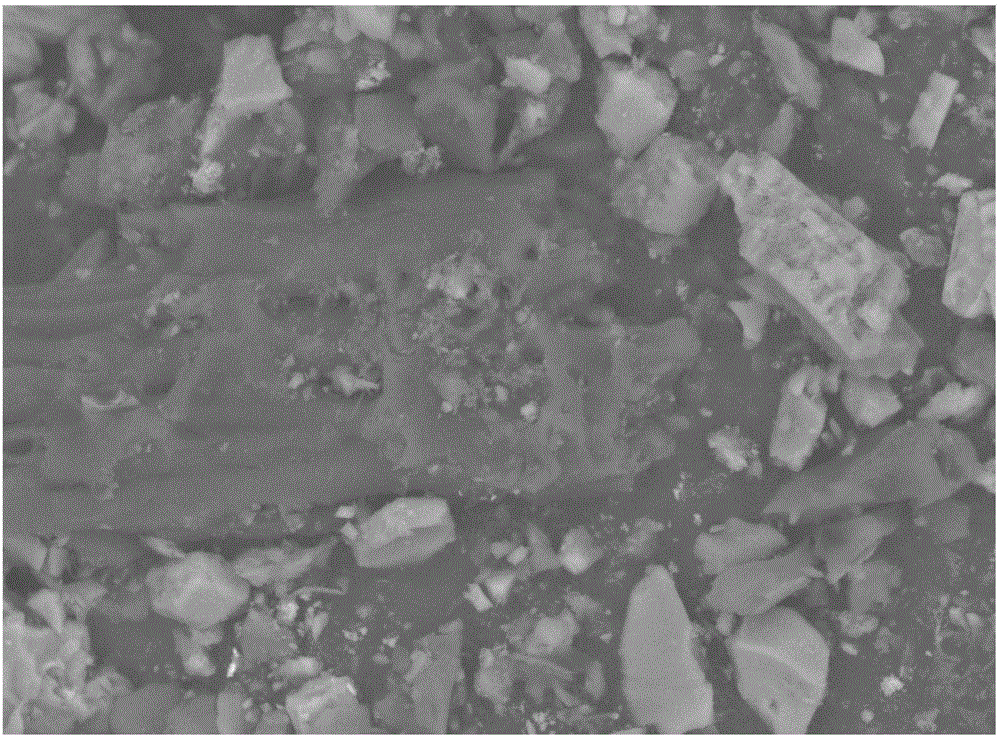

Beta-FeOOH particles, preparation method and application thereof

ActiveCN101696037ALow priceSimple manufacturing methodTobacco treatmentIron oxides/hydroxidesRoom temperatureChloride

The invention discloses beta-FeOOH particles, a preparation method and application thereof. The beta-FeOOH particles have spindle-shape microstructure and are prepared by the following method: (1) adding ferric chloride and ethanol to an autoclave, slowly adding water while stirring, sealing the autoclave after adding is finished, raising temperature to between 78 and 82 DEG C and keeping for 71 to 73 hours; and (2) cooling the autoclave to room temperature, washing and drying obtained precipitates and obtaining finished products. When the beta-FeOOH particles are used as cigarette additives, the beta-FeOOH particles can effectively reduce the nitrosamine content of cigarette smoke, are dissolved in water and then added to cut tobacco in a spraying way, use no toxic reagents, do not affect the appearance and taste of cigarettes, and do not affect the burning of the cigarettes or conventional composition of cut cigarette.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Simple preparation method for Fe3O4@C@TiO2 magnetic separation photocatalyst

InactiveCN106964350AUniform sizeEasy to operateMaterial nanotechnologyWater/sewage treatment by irradiationDispersityMagnetic response

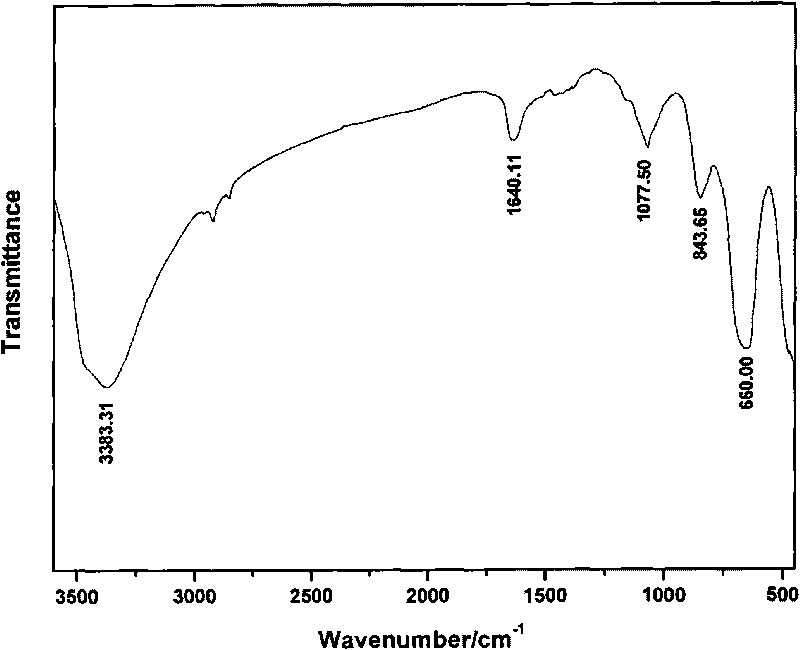

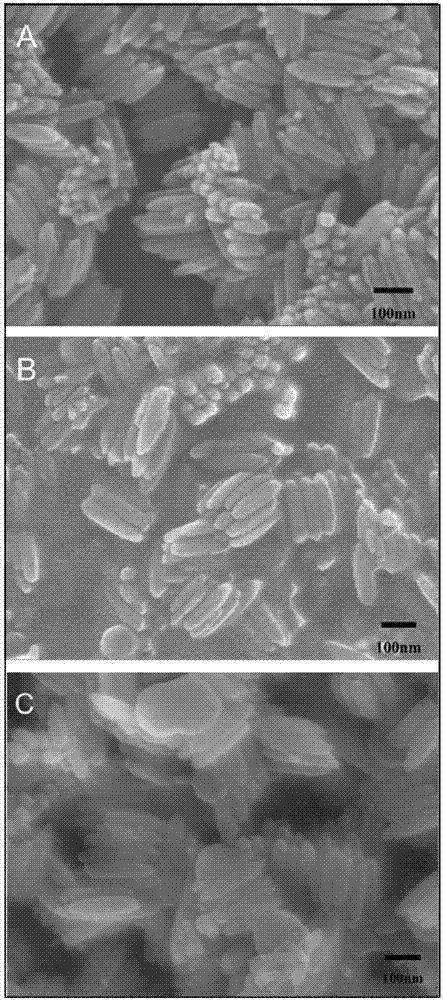

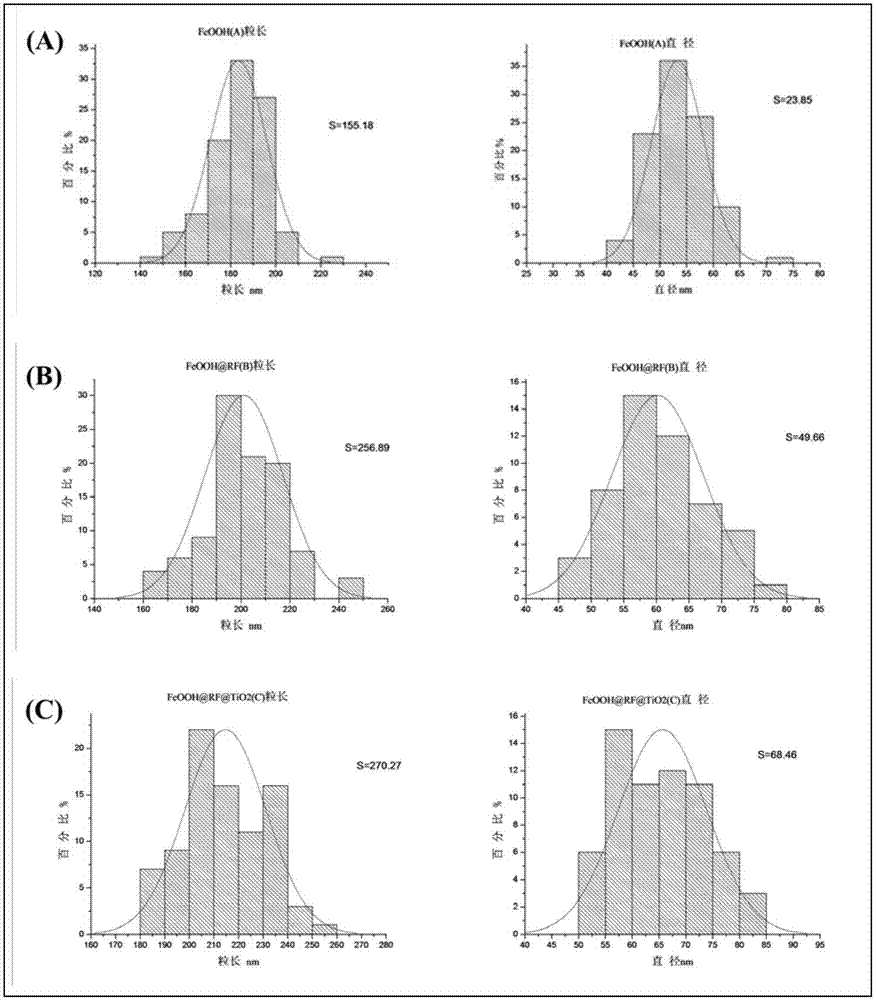

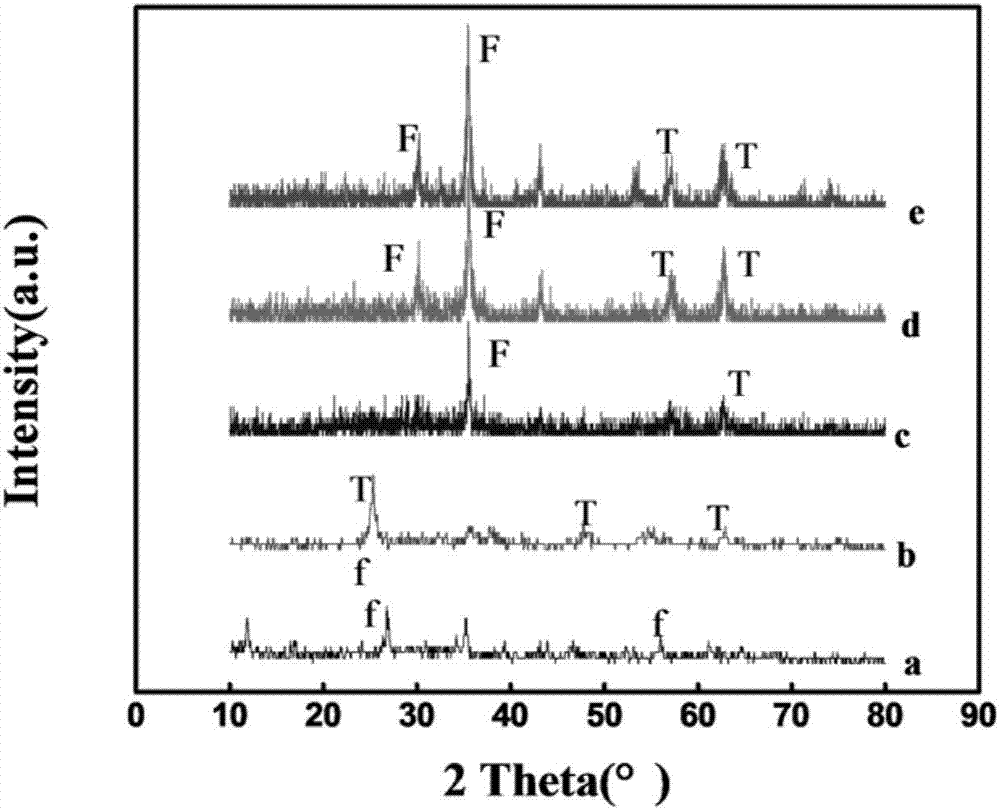

The invention relates to a simple preparation method for a Fe3O4@C@TiO2 magnetic separation photocatalyst. The method includes steps: 1) taking beta-FeOOH nanorods, and dispersing into water to form dispersion liquid; 2) adopting resorcinol and formaldehyde for synthesizing FeOOH@RF core-shell nanorods, and dispersing into ethyl alcohol to form dispersion liquid; 3) adding ethyl alcohol, CH3CN and ammonium hydroxide, and well stirring and mixing to form liquid A; taking ethyl alcohol and CH3CN again, well mixing, and adding TBOT to form liquid B; mixing for room-temperature reaction for a certain time to obtain the nanorods; 4) performing high-temperature calcinations to obtain the Fe3O4@C@TiO2 magnetic separation photocatalyst. The method has advantages that the magnetic-response recyclable Fe3O4@C@TiO2 visible-light nanometer photocatalyst is prepared according to the simple and mild method; the method is simple in operation and low in equipment requirement, and the prepared Fe3O4@C@TiO2 core-shell nanorods are high in dispersity and uniform in nanoparticle size.

Owner:WUHAN UNIV OF TECH

Preparation method of NaCl-modified graphene net-coated Beta-FeOOH lithium ion battery negative electrode material

ActiveCN107910506AImprove conductivityLarge specific surface areaCell electrodesSecondary cellsLithium intercalationVolume expansion

Owner:SHAANXI UNIV OF SCI & TECH

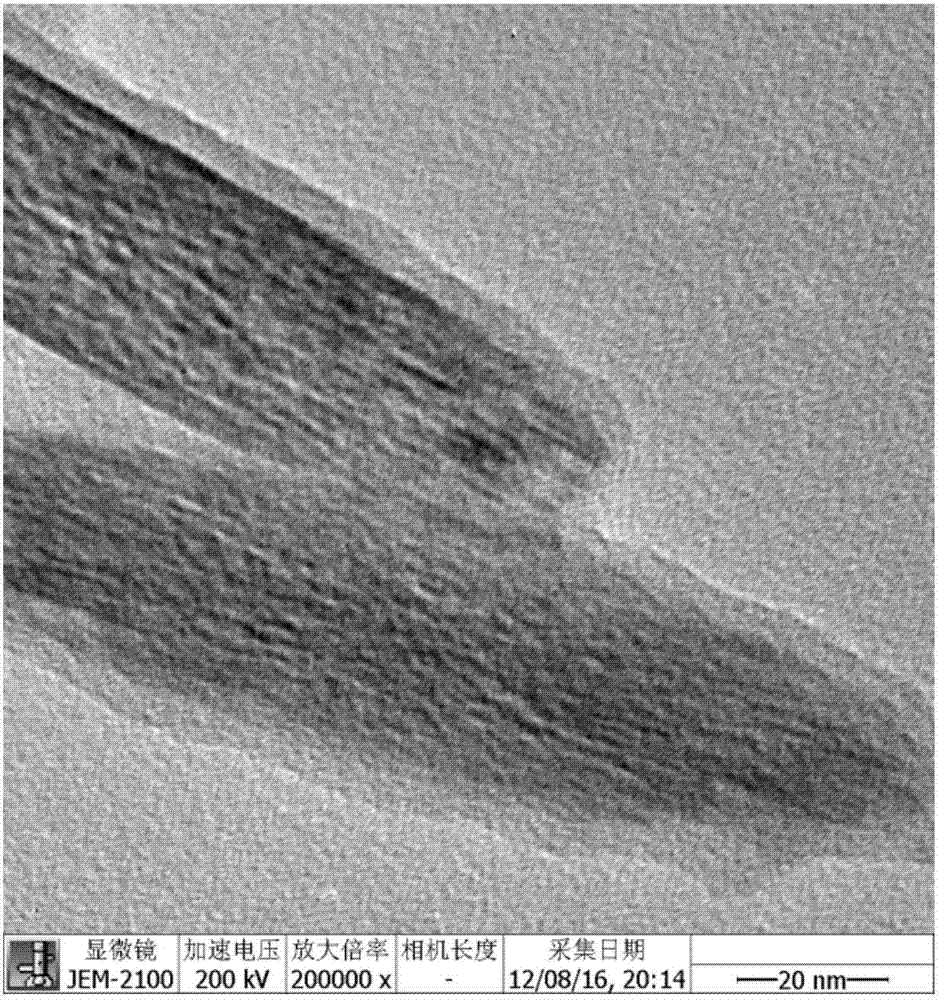

Preparing method and application of alpha-Fe2O3 porous nano bar array photo-anode material

ActiveCN107268022AIn situ preparationImprove performanceLiquid/solution decomposition chemical coatingElectrodesHydrolysisHeat treated

The invention relates to an alpha-Fe2O3 porous nano bar photo-anode material for photoelectric hydrolysis hydrogen production. The liquid-solid chemical method is used for in-situ preparing of an FTO conductive glass base body loaded alpha-Fe2O3 porous nano bar and the photo-anode material comprising the above alpha-Fe2O3 porous nano bar. According to the specific preparing method, in-situ growing of a beta-FeOOH nano bar array is conducted on an FTO conductive glass base body in an FeCl3 containing dicyandiamide and sulphonated acetone-formaldehyde plymer water solution, high-temperature heat treatment is conducted, and the one-dimension alpha-Fe2O3 porous nano bar array photo-anode material is obtained. By adoption of the alpha-Fe2O3 porous nano bar array photo-anode material prepared through the method, wetting of an electrolyte in the photo-anode material can be improved, the transmission distance of photon-generated carriers is shortened, and the photoelectric hydrolysis hydrogen production efficiency is improved. According to the preparing method, operation is convenient, simple and easy to control, and the prepared photo-anode material has important application potentials in the aspects such as photoelectric catalysis.

Owner:TAIYUAN UNIV OF TECH

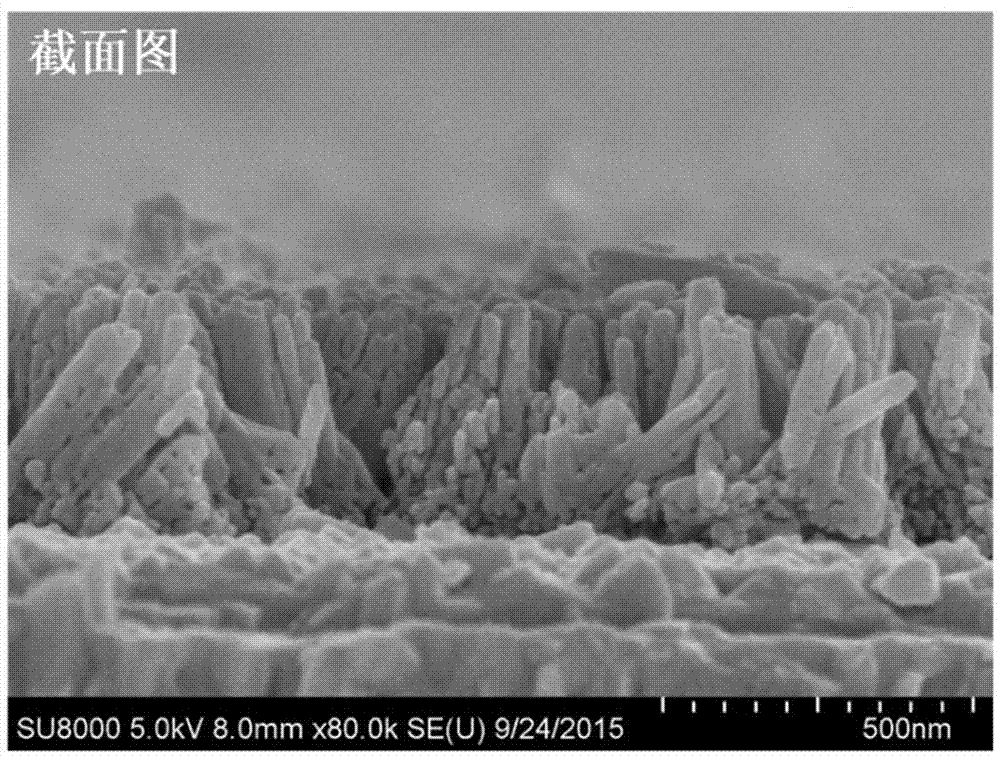

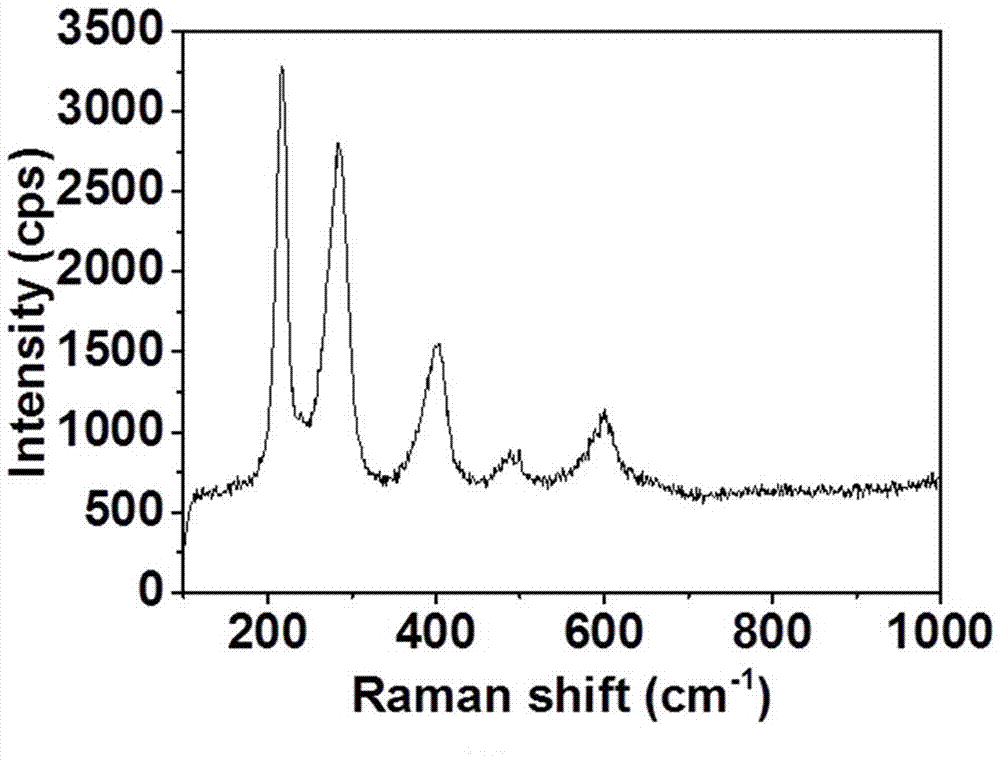

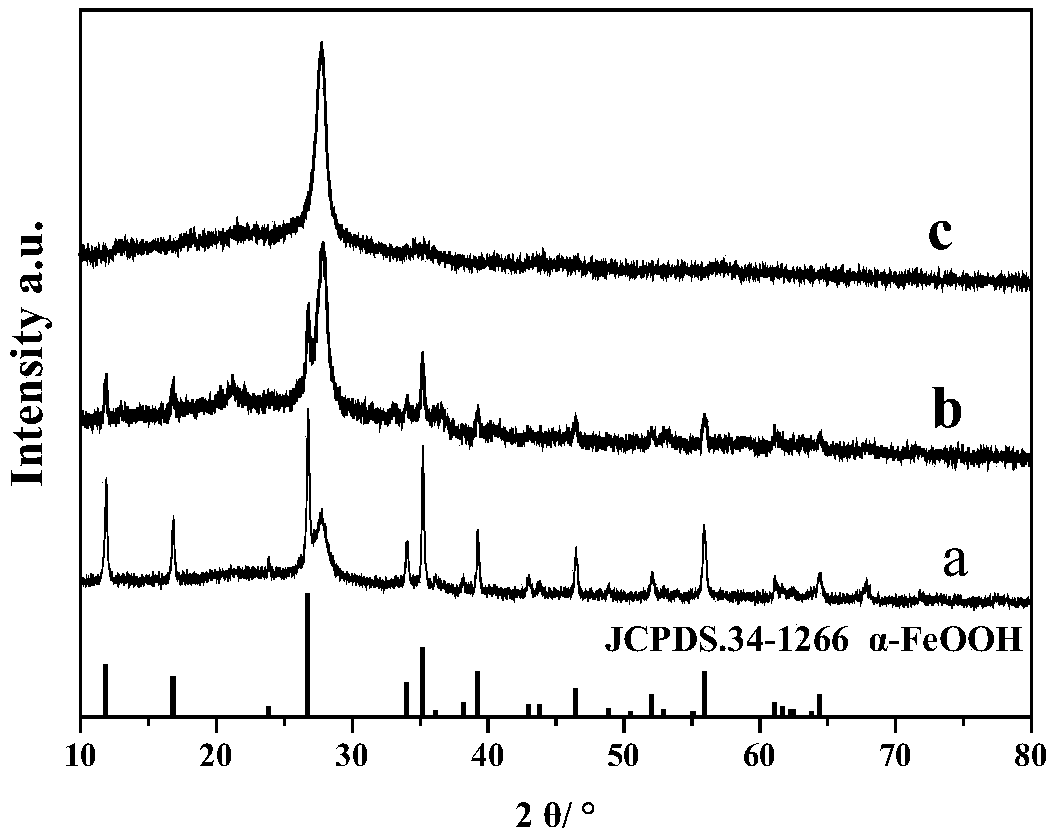

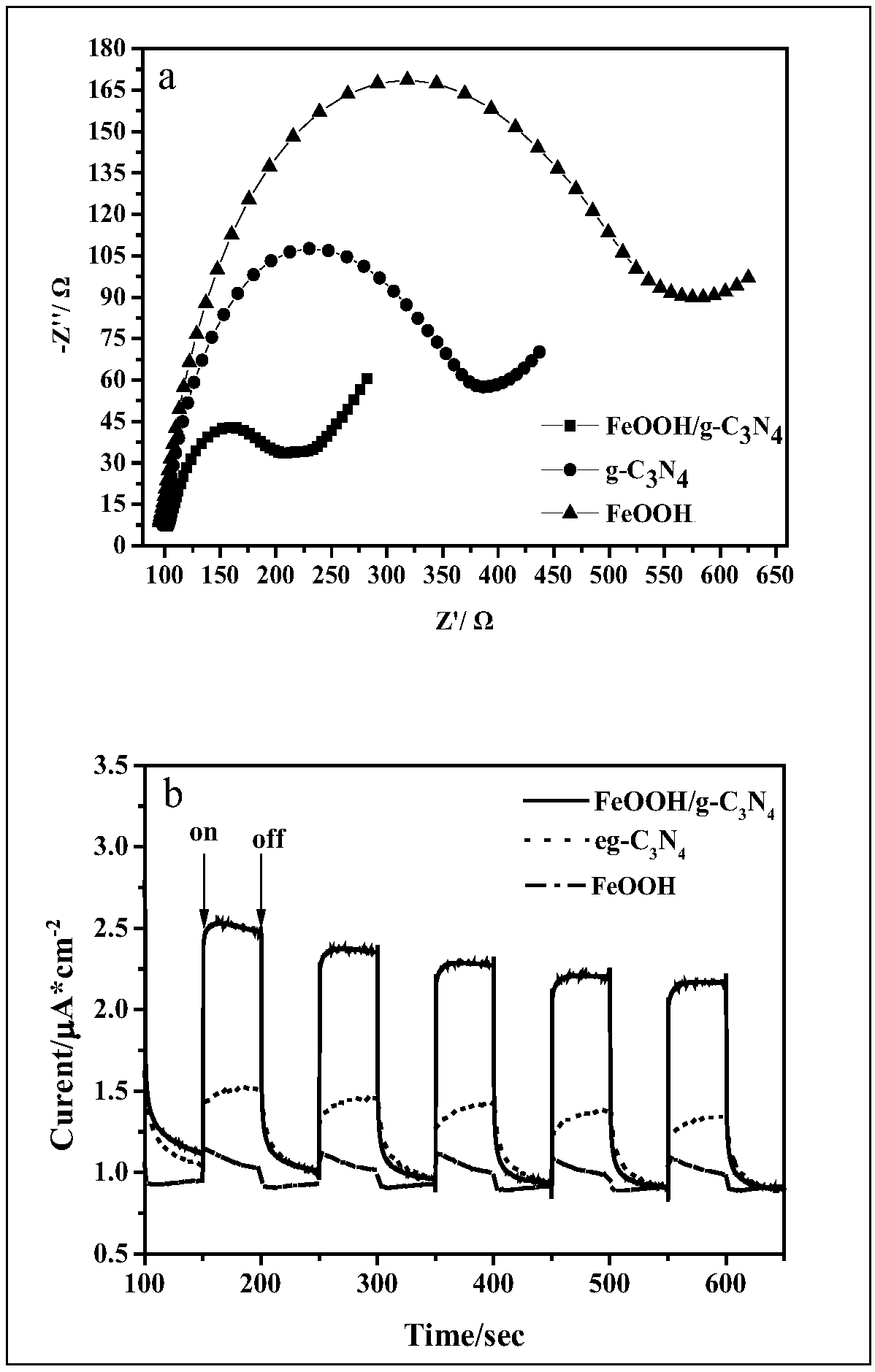

Double-functional Beta-FeOOH/eg-C3N4 composite nanomaterial and preparation method and application thereof

InactiveCN109317184AReduce usageNo generationPhysical/chemical process catalystsWater/sewage treatment by irradiationSolventPhotocatalytic degradation

The invention relates to a preparation method for a double-functional Beta-FeOOH / eg-C3N4 composite nanomaterial. The method comprises the following steps: using water as a solvent, adding a suitable amount of eg-C3N4, adjusting a solution pH, and adding a suitable amount of ferric salt, performing ultrasonic-processing, washing, and drying, to obtain the Beta-FeOOH / eg-C3N4 composite nanomaterial.The advantage of the method is that operation is simple and easy, a reaction condition is moderate, other chemical reagents and solvents except a raw material are prevented from being used in a wholeprocess, no by-product is generated, synchronization of combination and nano-crystalline growth is realized, cost is low, and the process environmentally friendly, and a requirement for industrializedapplication can be satisfied. A Beta-FeOOH / eg-C3N4 nano rod-like compound catalyst prepared by the method disclosed by the invention has performance of photocatalytic-degrading a pollutant in visiblelight, and capacity of generating hydrogen by electrocatalytically decomposing water.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

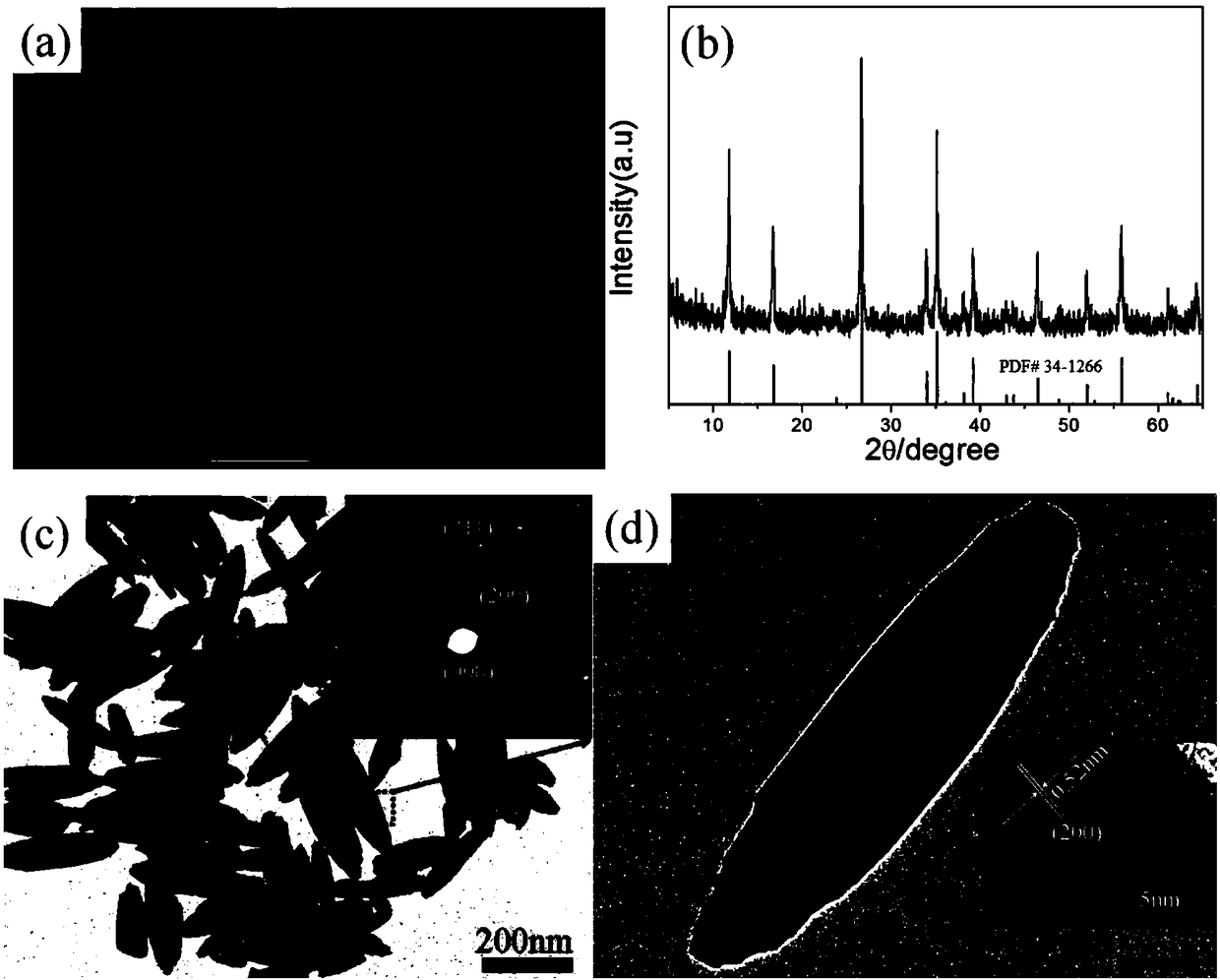

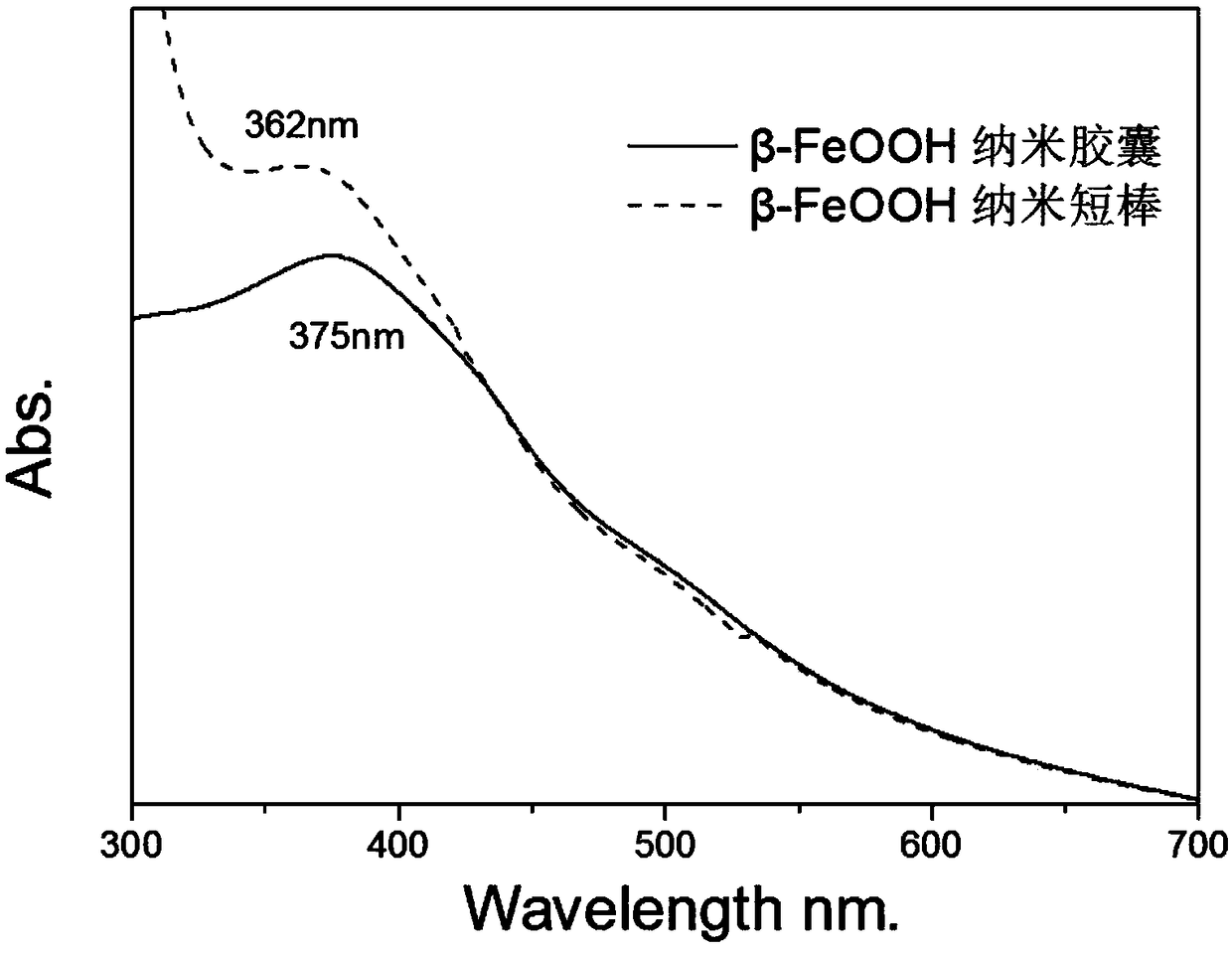

Preparation method of beta-FeOOH nano-capsules

ActiveCN108910960AImprove visible light absorptionEasy to operateIron oxides/hydroxidesNanotechnologyAlcoholIron(III) chloride

The invention discloses a preparation method of beta-FeOOH nano-capsules, and relates to the technical field of preparation of nano-capsules. The method comprises the following steps: performing hydrolysis by using an aqueous solution of ferric chloride to generate beta-FeOOH nano-rods, and carrying out heating alcohol thermalmaturation on the beta-FeOOH nano-rods, glycerin and water to prepare the beta-FeOOH nano-capsules. The beta-FeOOH nano-capsules are successfully obtained by adopting an alcohol thermalmaturation technology with green and environmentally-friendly glycerin as a reaction medium and the beta-FeOOH nano-rods as a precursor. The method has the characteristics of simplicity in operation, low cost, and excellent visible light absorption performance of the product, and provides a simple and environmentally-friendly method for preparing capsule type nanoparticles.

Owner:HEFEI UNIV

Preparation method of super large lamella RGO loaded ultrafine beta-FeOOH nanometer particle lithium ion battery negative electrode material

ActiveCN109390573AImprove conductivityAlleviate volume expansionMaterial nanotechnologyCell electrodesFreeze-dryingLithium-ion battery

The invention discloses a preparation method of a super large lamella RGO loaded ultrafine beta-FeOOH nanometer particle lithium ion battery negative electrode material. The preparation method comprises following steps: oxidized graphene is dispersed in deionized water so as to obtain a suspending liquid A; a certain amount of a soluble salt, sodium chloride, and urea are added into absolute ethylalcohol and deionized water, and then are mixed with the suspending liquid A so as to obtain a suspending liquid B; the suspending liquid B is introduced into a homogeneous hydro-thermal reaction vessel, the homogeneous hydro-thermal reaction vessel is sealed, and is introduced into a homogeneous hydro-thermal reaction equipment for hydro-thermal reaction, and then natural cooling to room temperature is carried out so as to obtain a product C; the product C is washed with water and alcohol respectively; and after washing, the product is dispersed in water so as to obtain a product D; the product D is subjected to freeze-drying so as to obtain the super large lamella RGO loaded ultrafine beta-FeOOH nanometer particle lithium ion battery negative electrode material. According to the preparation method, graphene combination and particle size reduction are adopted to improve the performance of beta-FeOOH, so that more electrochemical active sites and ion transmission channels are provided, battery reversible capacity is increased, the reversible capacity at 5000mA g<-1> is larger than 1000mAh g<-1>, and the potential capacity of the super large lamella RGO loaded ultrafine beta-FeOOHnanometer particle lithium ion battery negative electrode material is excellent.

Owner:SHAANXI UNIV OF SCI & TECH

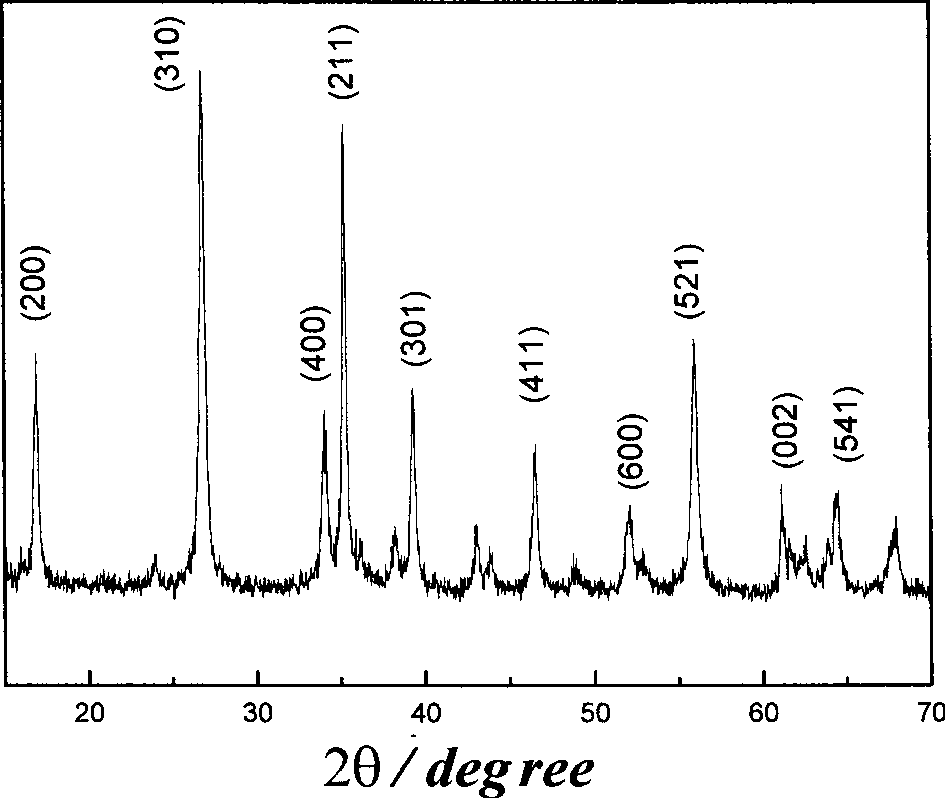

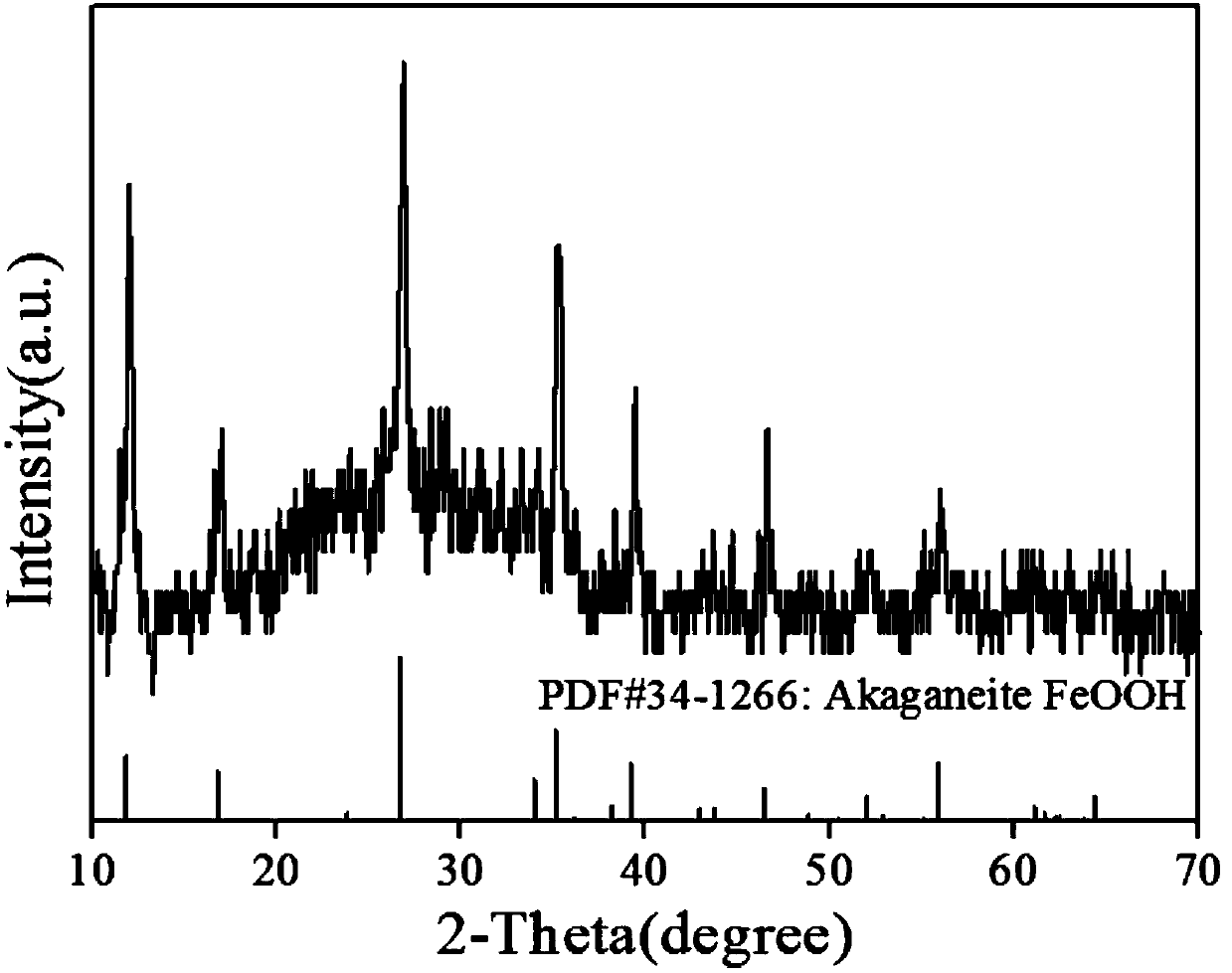

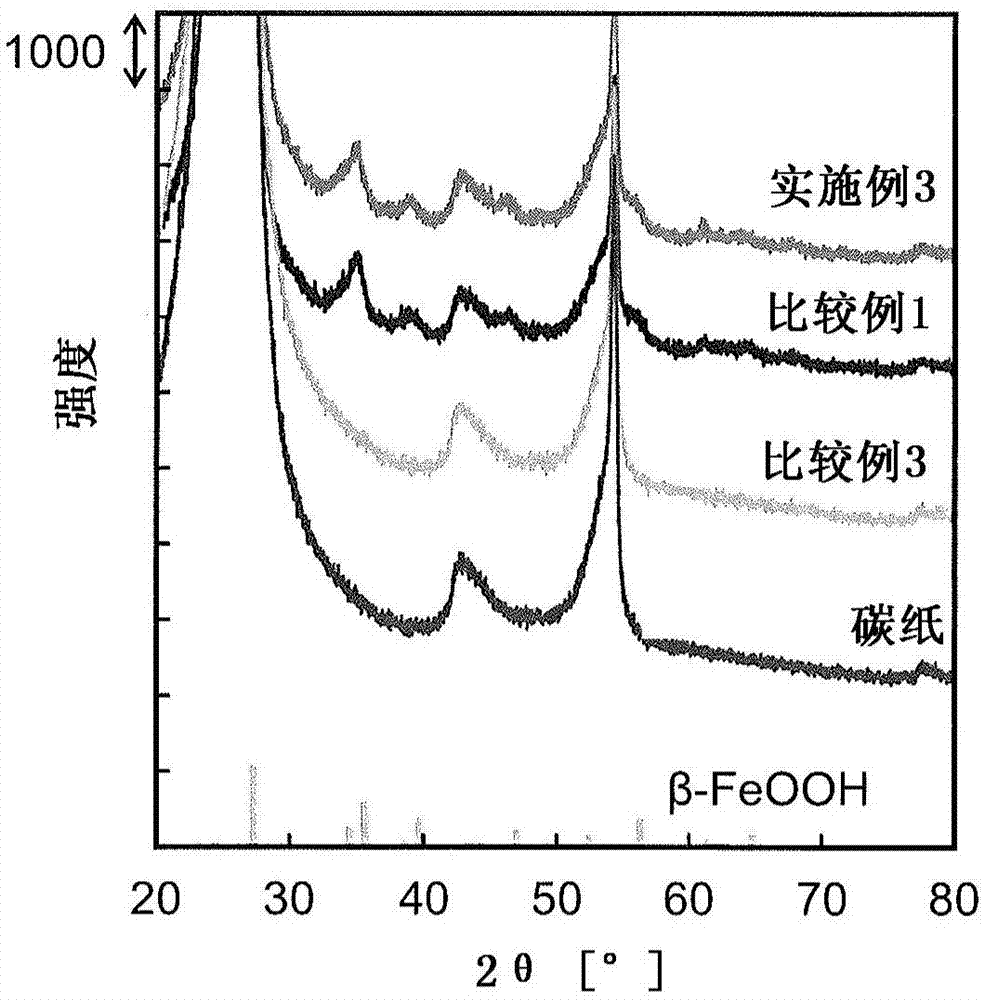

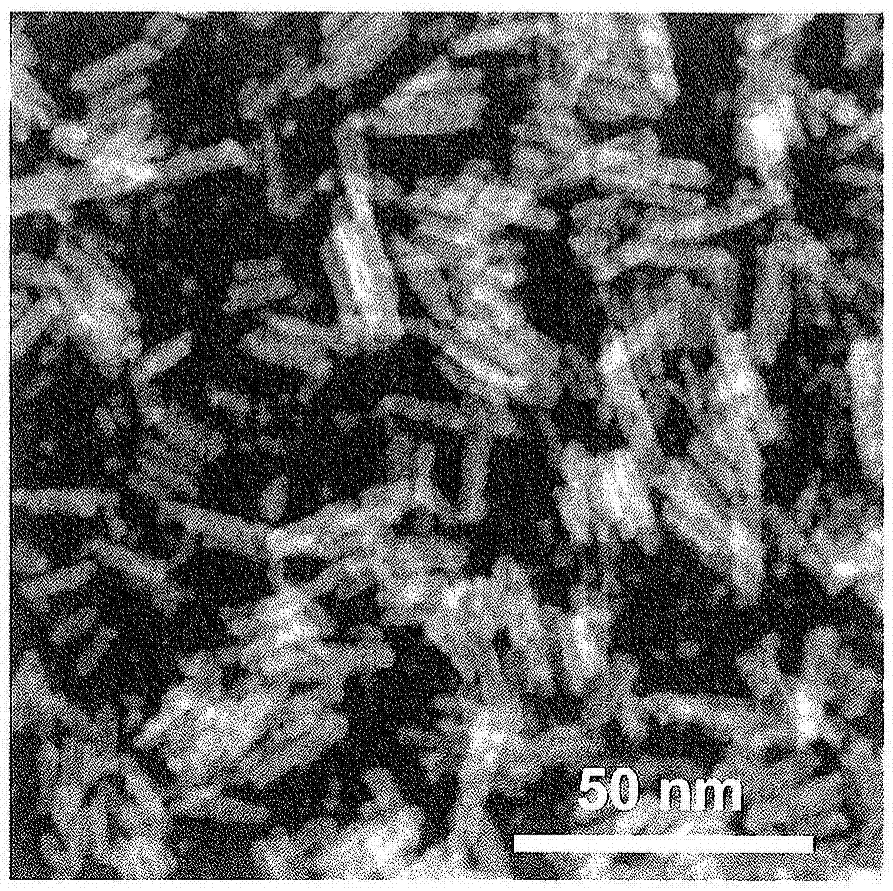

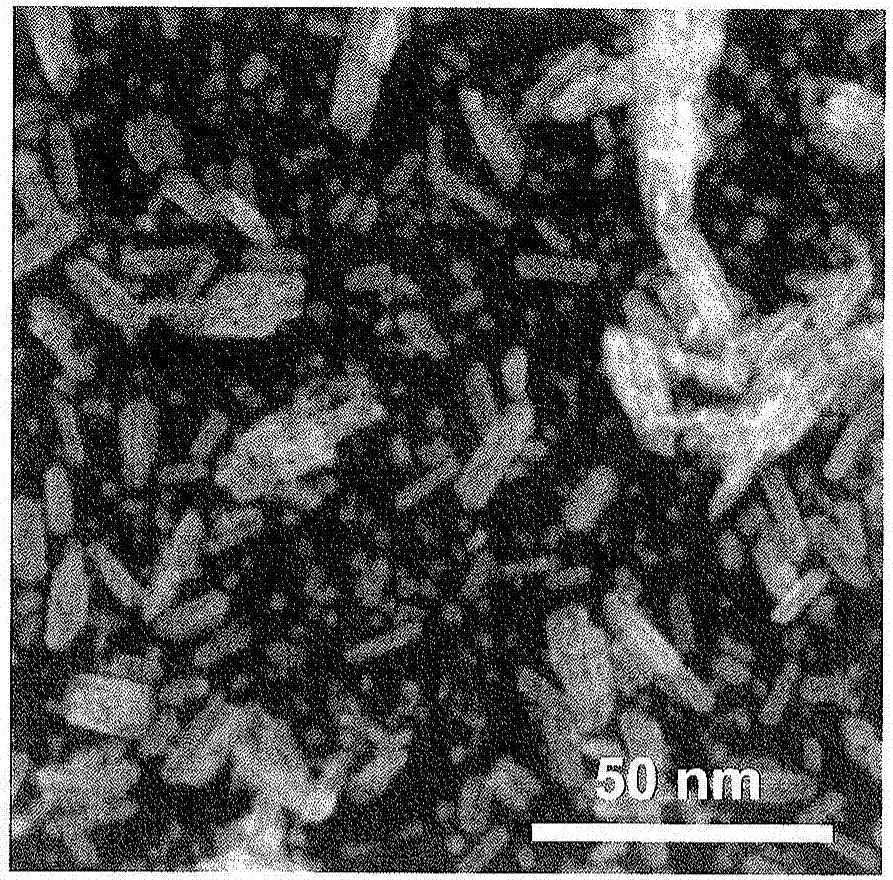

Iron compound particles, method of producing iron compound particles, and oxidation catalyst using iron compound particles

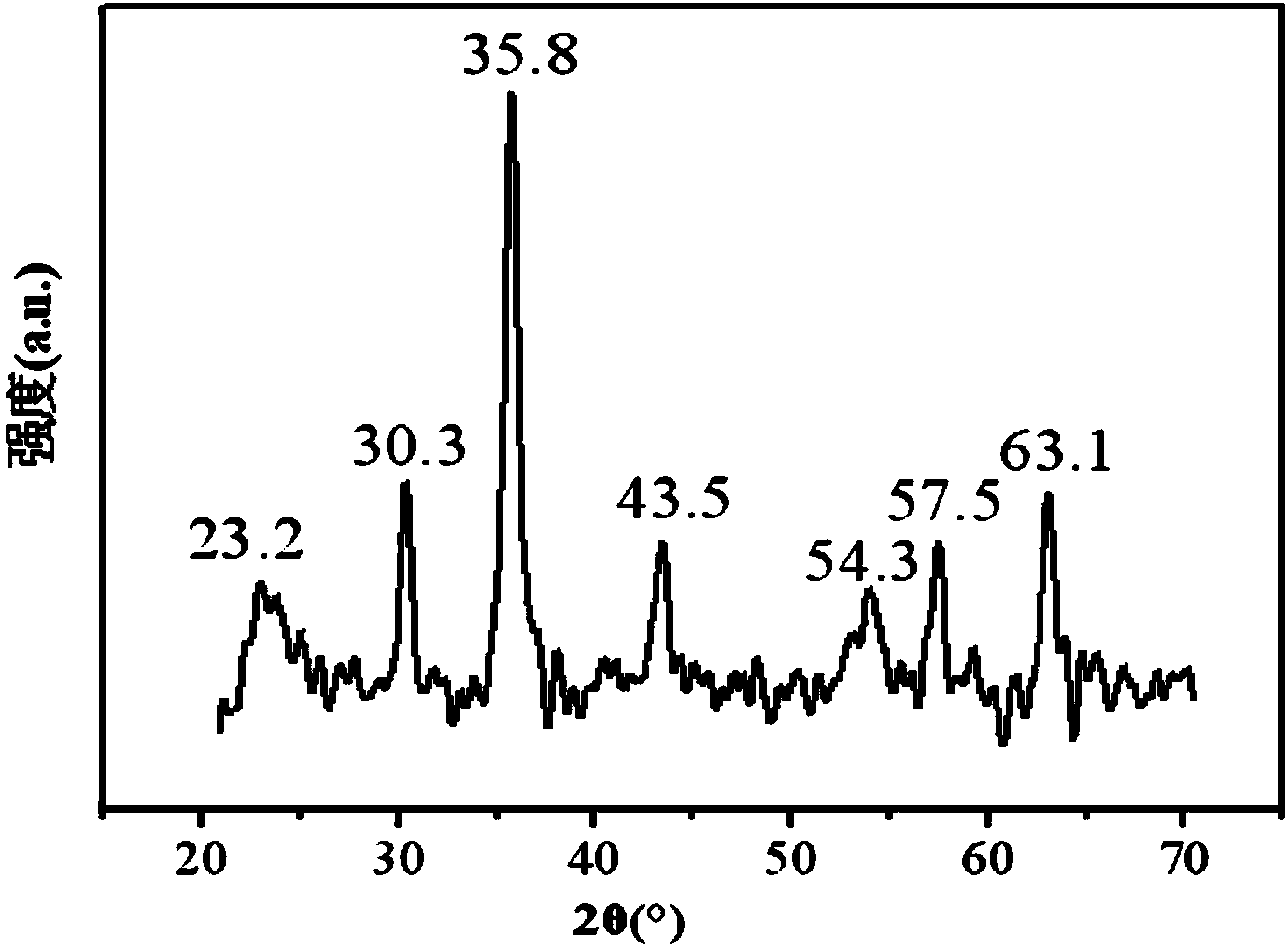

ActiveCN106975490AExcellent oxidation catalytic activityMetal/metal-oxides/metal-hydroxide catalystsElectrodesX-raySolvent

The invention relates to iron compound particles, a method of producing the iron compound particles, and an oxidation catalyst using the iron compound particles. The iron compound particles comprise a beta-FeOOH crystal phase and a metal element other than Fe for doping the beta-FeOOH crystal phase, wherein the metal element other than Fe is at least one metal element selected from the group consisting of : Al and transition metals of 3d and 4d other than Fe belonging to Groups 4 to 12 of the periodic table, the atomic ratio of the metal element to Fe element (metal element other than Fe / Fe element) ranges from 0.001 to 0.5, and said iron compound particles satisfy at least one of the following requirements (A) and (B): (A) the iron compound particles have a crystallite diameter of 1 to 60 nm when measured by X-ray diffraction; and (B) the iron compound particles have an average particle diameter of 1 to 600 nm as measured by dynamic light scattering in the solvent.

Owner:TOYOTA CENT RES & DEV LAB INC

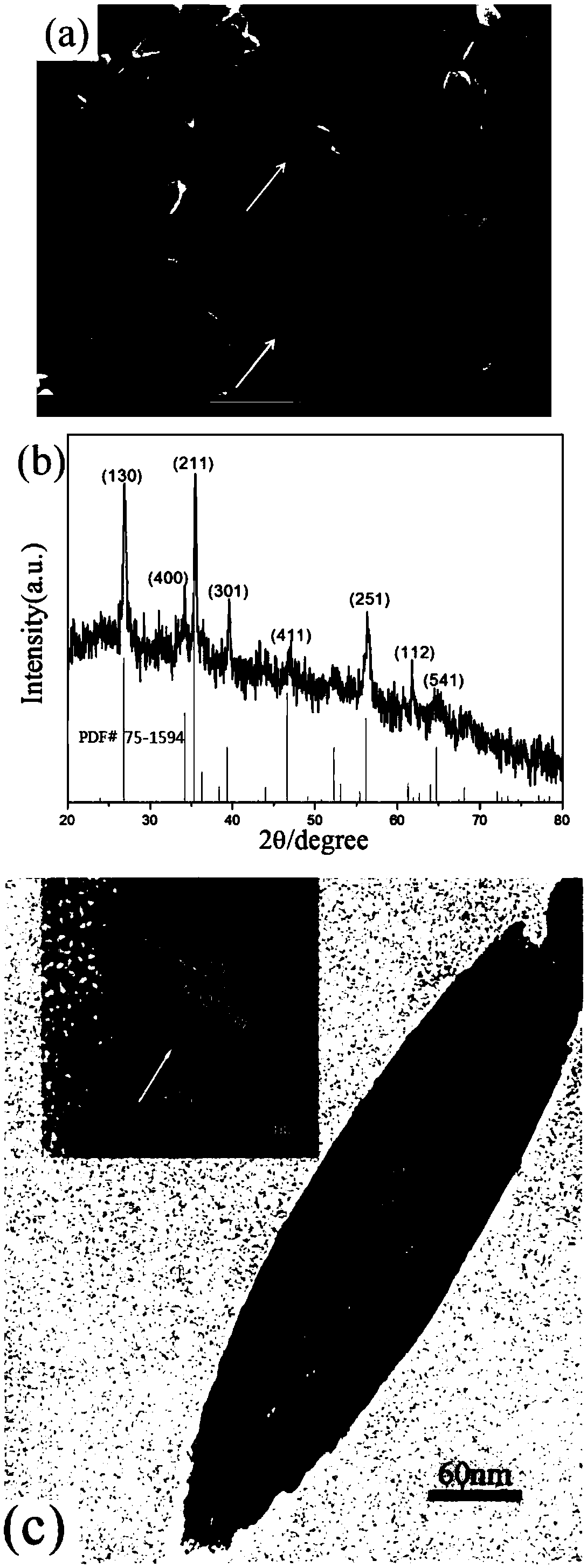

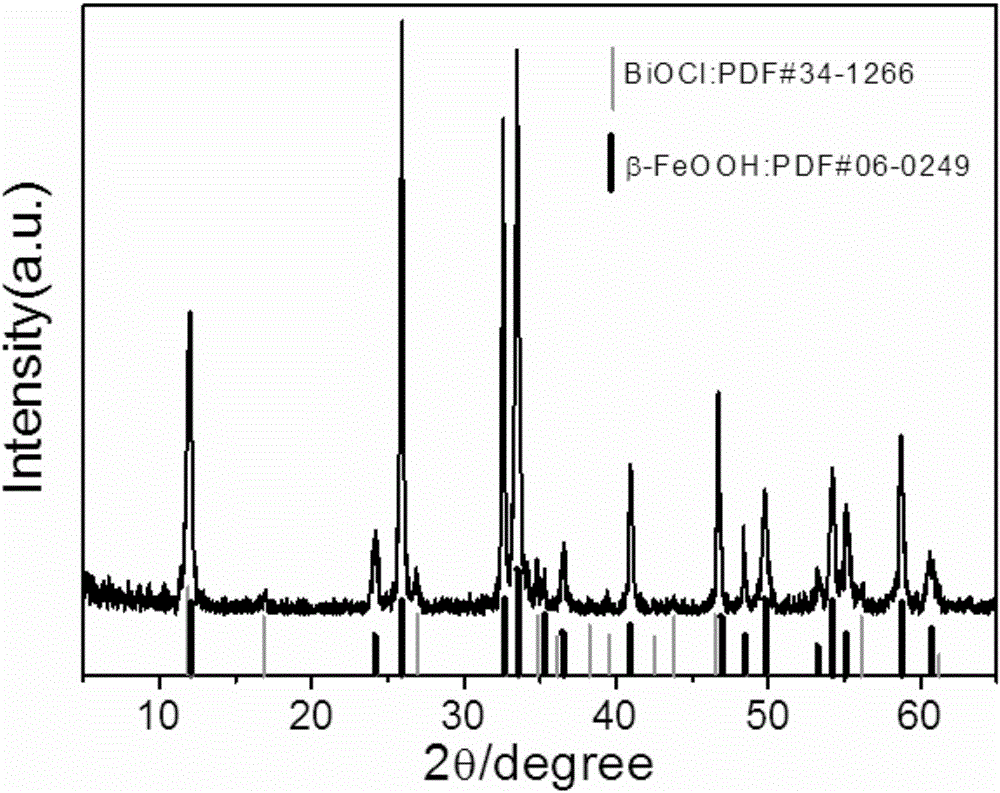

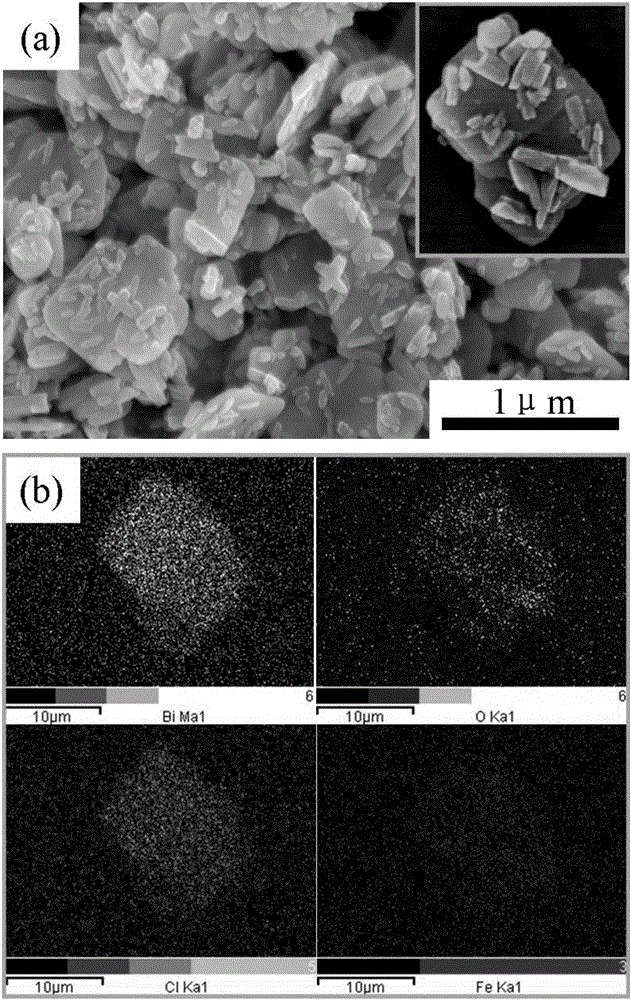

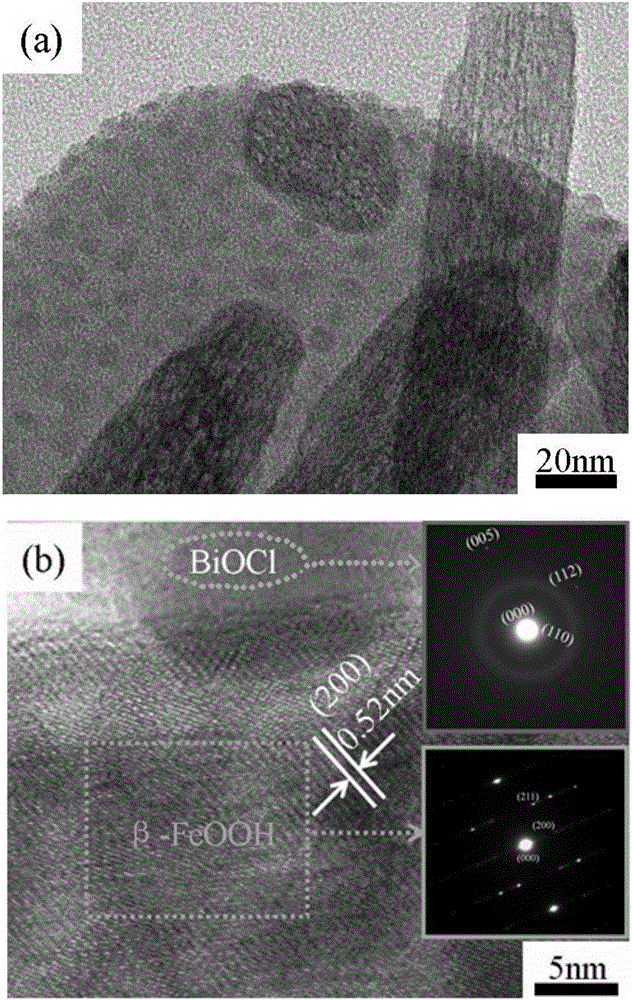

BiOCl/beta-FeOOH composite nanomaterial and preparation method thereof

ActiveCN105833887ALarge specific surface areaGood photocatalysisPhysical/chemical process catalystsWater/sewage treatment by irradiationDistilled waterSewage

The invention relates to a BiOCl / beta-FeOOH composite nanomaterial and a preparation method thereof, and relates to the technical field of composite nanomaterials. The method comprises the following steps: dissolving FeCl3.6H2O in distilled water, sequentially adding Bi(NO3)3.5H2O and glucose, uniformly mixing, adjusting the pH value of the above obtained mixture to 3-6, and carrying out a hydrothermal synthesis reaction to obtain the BiOCl / beta-FeOOH composite nanomaterial. Low temperature hydrothermal synthesis is adopted, glucose biomacromolecules are used to control attached growth of beta-FeOOH nanorods on BiOCl nanosheets, and spindly BiOCl / beta-FeOOH nanorods are distributed on the sheet BiOCl in the structure of the BiOCl / beta-FeOOH composite nanomaterial, so the composite nanomaterial has the advantages of high specific surface area, and excellent photocatalytic and Fenton-like catalytic activity, and is hopeful to be used as an effective catalyst for removing various organic pollutants from sewage.

Owner:HEFEI UNIV

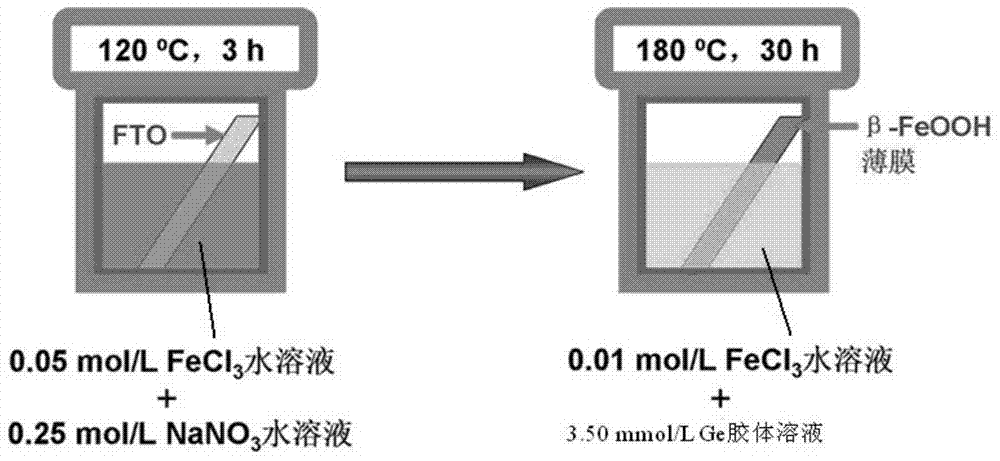

Method for preparing Ge-doped alpha-phase iron trioxide nanosheet array membrane

InactiveCN103693861ASimple processLow costMetal/metal-oxides/metal-hydroxide catalystsNanostructureImpurity

The invention discloses a method for preparing a Ge-doped alpha-phase iron trioxide nanosheet array membrane. According to the method, a beta-FeOOH nanorod array membrane is firstly prepared on a FTO (fluorine-doped tin oxide) conductive glass substrate through a hydrothermal method, then the array membrane is taken as a substrate template, Ge nanometer colloidal solution obtained through liquid phase laser corrosion (LAL) is taken as a reaction precursor of impurity atom Ge, and the Ge doped alpha-Fe2O3 nanosheet array membrane is obtained through hydrothermal treatment. The method is simple, has low cost, realizes doping and can effectively control the nanostructure of alpha-Fe2O3.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

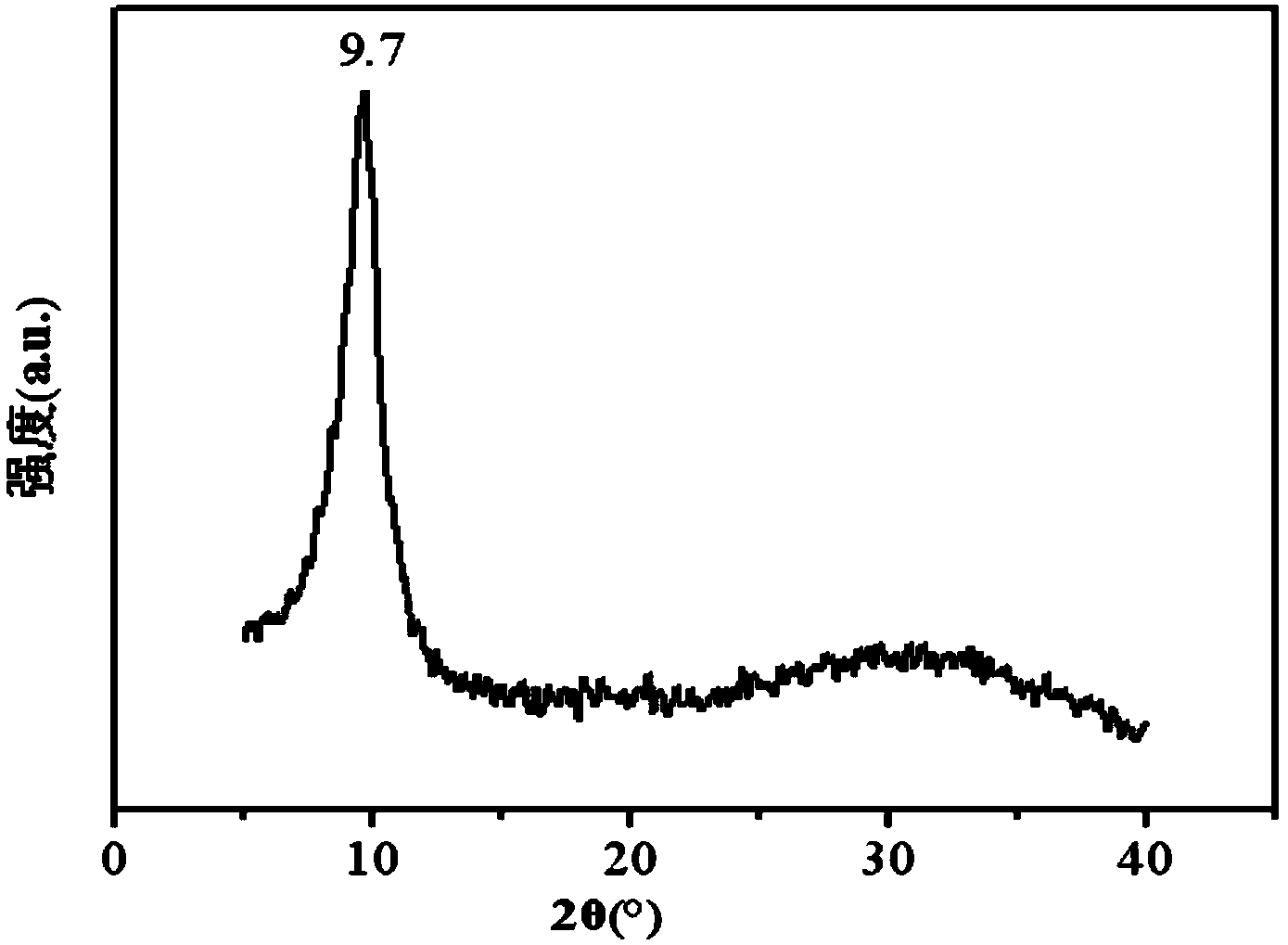

Biosynthesis method of magnetic graphene composite material

InactiveCN104046652AAchieve recyclingMild reaction conditionsMicroorganism based processesFermentationSodium lactateMaterials science

The invention belongs to the field of biosynthesized nano materials, and relates to a biosynthesis method of a magnetic graphene composite material. The method comprises the following steps: regulating the pH value of 10-30 mmol / L piperazinyl-1,4-diethylsulfonic acid and 10-30 mmol / L sodium lactate to 7.0, deoxidizing and sterilizing; adding graphene oxide into a culture solution, wherein the concentration of the graphene oxide is 0.4-0.6 g / L; carrying out ultrasonic treatment for 30-80 minutes, and adding beta-FeOOH until the concentration of the beta-FeOOH is 30-80 mmol / L; carrying out anaerobic magnetic stirring for 12-36 hours; collecting the dissimilatory metal reducing bacteria in the later logarithmic growth phase; and adding the dissimilatory metal reducing bacteria into the mixed solution, and culturing at 30 DEG C under anaerobic conditions for 132-156 hours to obtain the magnetic graphene composite material. The method has the advantages of mild technical reaction conditions and low energy consumption, and is simple to operate; and the prepared magnetic graphene composite material can be used for adsorption, magnetic catalysis and the like.

Owner:DALIAN UNIV OF TECH

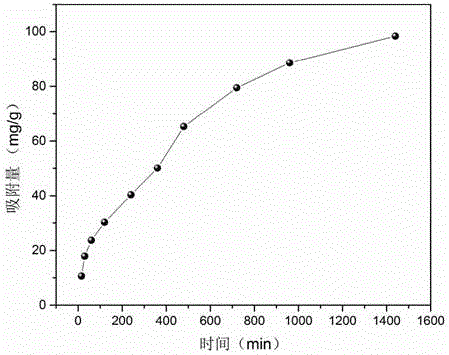

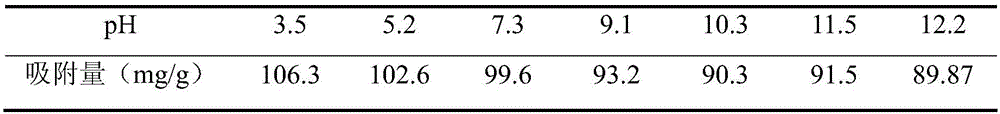

Preparation and application of hydrothermal carbon/attapulgite/beta-FeOOH composite adsorbent

InactiveCN106732374AEasy to collectLow costOther chemical processesWater contaminants17beta estradiolSorbent

The invention relates to a hydrothermal carbon modified material capable of removing an environmental estrogen pollutant 17beta-estradiol, in particular to a hydrothermal carbon / attapulgite / beta-FeOOH composite material. A preparation method of the material comprises the following steps: performing hydrothermal carbonization on attapulgite and biomass; assembling the attapulgite on the surface of hydrothermal carbon; activating with KOH; loading beta-FeOOH onto the surface of the material; increasing the specific surface area to prepare a high-performance hydrothermal carbon / attapulgite / beta-FeOOH composite adsorption material. The modified hydrothermal carbon material prepared by the method has a large quantity of adsorption sites, and can be used for efficiently removing the environmental estrogen 17beta-estradiol. Moreover, the hydrothermal carbon modified material is easy to prepare, is low in cost, has high adsorption performance, and is an adsorbent with a wide market prospect.

Owner:HUNAN UNIV

Method for removing bromate in water through Fe<2+> and beta-FeOOH supported red mud ceramsite

ActiveCN105152258AEfficient removalIncrease the areaWater/sewage treatment by ion-exchangeWater/sewage treatment by sorptionRed mudBromate

The invention relates to a method for removing bromate in water, particularly to a method for removing bromate in water through Fe<2+> and beta-FeOOH supported red mud ceramsite, and aims to solve problems that the drug dosage is large and Fe<2+> and beta-FeOOH are loose in a powder shape and easy to hydrolyze when Fe<2+> and beta-FeOOH are added separately to remove the bromate in the water according to existing methods. The method comprises steps as follows: a certain amount of the Fe<2+> and beta-FeOOH supported red mud ceramsite is added to a to-be-treated bromate solution, a treated solution is obtained after vibration at a certain temperature, and the bromate concentration of the solution is measured. The bromate in the water is removed with the method.

Owner:哈尔滨学博环保科技有限责任公司

Preparation method of PEDOT@beta-FeOOH/rGO array type lithium ion battery negative electrode material

ActiveCN108288700AGood chemical stabilityGood dispersionSecondary cellsNegative electrodesConductive polymerFreeze-drying

Provided is a preparation method of a PEDOT@beta-FeOOH / rGO array type lithium ion battery anode material. The method comprises the steps that graphene oxide is dispersed in deionized water to obtain suspension A; soluble ferric salt and 3, 4-ethylenedioxythiophene (EDOT) are added into the suspension for intensive mixing to obtain suspension B; the suspension B is poured into a homogeneous phase hydrothermal reactor, then the reactor is sealed and put into a homogeneous phase hydrothermal reaction apparatus for a hydrothermal reaction, and then is naturally cooled to room temperature to obtaina product C; the product C is respectively washed with water and alcohol, and the washed product is dispersed in water to obtain a product D; and the product D is freeze-dried to obtain the PEDOT@beta-FeOOH / rGO self-assembled louver array type lithium ion battery negative electrode material. The preparation method of the PEDOT@beta-FeOOH / rGO array type lithium ion battery anode material has the advantages that the conductivity of reduced graphene oxide is good, the specific surface area is larger, the surface functional groups are more, the composition of ferric oxide and graphene significantly improves the dispersion of ferric oxide and avoids agglomeration, the conductive polymer PEDOT is used to coat the reduced graphene oxide, and the shape is conducted with self-assembled adjustmentand control to further improve the electrochemical performance of the product.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of ultra-fine Beta-FeOOH nanorod self-assembly hollow microspheres under urea action

ActiveCN109411747AEasy self-assemblyThe experimental method is simpleCell electrodesNanotechnologyElectrochemical responseMicrosphere

The invention discloses a preparation method of ultra-fine Beta-FeOOH nanorod self-assembly hollow microspheres under urea action. The preparation method comprises the following steps: adding solublesalt ferric trichloride, sodium chloride and urea of certain amount into absolute ethyl alcohol and deionized water to obtain suspension A; pouring the suspension A into a homogeneous-phase hydrothermal reaction kettle, and sealing the reaction kettle; putting the reaction kettle in a homogeneous-phase hydrothermal reaction instrument for a hydrothermal reaction; then naturally cooling to room temperature to obtain a product B; washing the product B with water and alcohol respectively, and dispersing the washed product in water to obtain a product C; performing freeze drying on the product C to obtain the ultra-fine Beta-FeOOH nanorod self-assembly hollow microspheres under urea action. Through the homogeneous-phase hydrothermal process, the preparation method disclosed by the invention has the advantages of simplicity, short time, low cost and easiness in implementation; with a larger specific surface area, the ultra-fine Beta-FeOOH nanorod self-assembly hollow microspheres under ureaaction can provide more electrochemical reaction active sites to improve the reaction activity of a Beta-FeOOH conversion reaction.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com