Iron compound particles, method of producing iron compound particles, and oxidation catalyst using iron compound particles

A technology of iron compounds and particles, applied in the field of oxidation catalysts, to achieve the effect of excellent oxidation catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

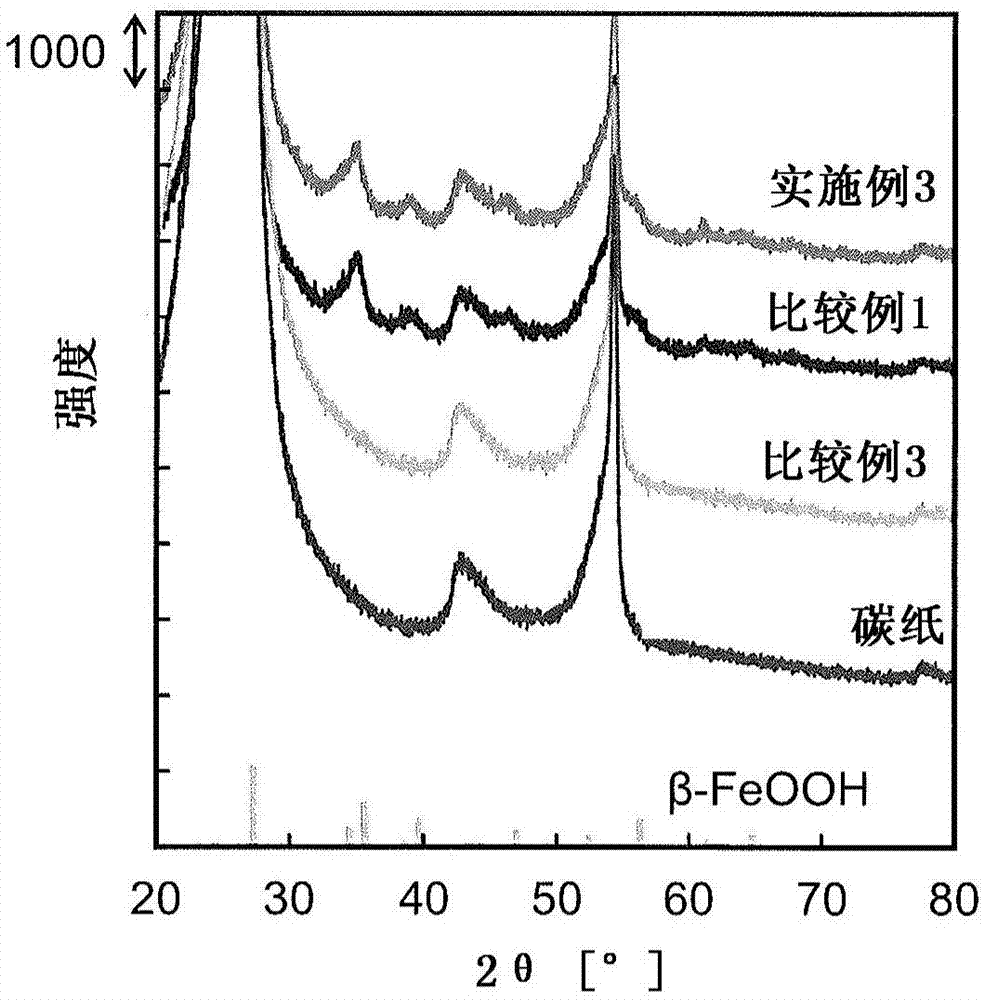

Embodiment 1

[0080] In a beaker, FeCl 3 ·6H 2 O (27.30g, 101mmol) and Zn (NO 3 ) 2 ·6H 2 O (1.25g, 4.20mmol) was dissolved in ion-exchanged water (500ml). Thus, a raw material aqueous solution containing metal ions (raw material solution A) having an Fe ion concentration of 0.2 mol / L was prepared. Also, in a beaker, an ethylenediamine solution (11 ml) diluted to 1 / 2 with ion-exchanged water was dissolved in ion-exchanged water (500 ml). Thus, a raw material aqueous solution (raw material solution B) containing a neutralizing agent was prepared. Raw material solutions A and B were mixed in a beaker with a magnetic stirrer using a stirring bar (rotational speed: 400 rpm) and stirred together for 30 minutes at room temperature (25° C.). Thus, a colloidal solution of an iron compound was prepared. By using a pH meter, the pH of the resulting colloid solution was measured and found to be 2.2.

Embodiment 2

[0082] The colloidal solution of iron compound was prepared in the same manner as in Example 1, except that Co(NO 3 ) 2 ·6H 2 O (1.22g, 4.19mmol) instead of Zn(NO 3 ) 2 ·6H 2 O. The pH of the obtained colloidal solution was 2.2.

Embodiment 3

[0084] The colloidal solution of iron compound is prepared in the same manner as in Example 1, except that Ni(NO 3 ) 2 ·6H 2 O (1.21g, 4.16mmol) instead of Zn(NO 3 ) 2 ·6H 2 O. The pH of the obtained colloidal solution was 2.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Crystallite diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com