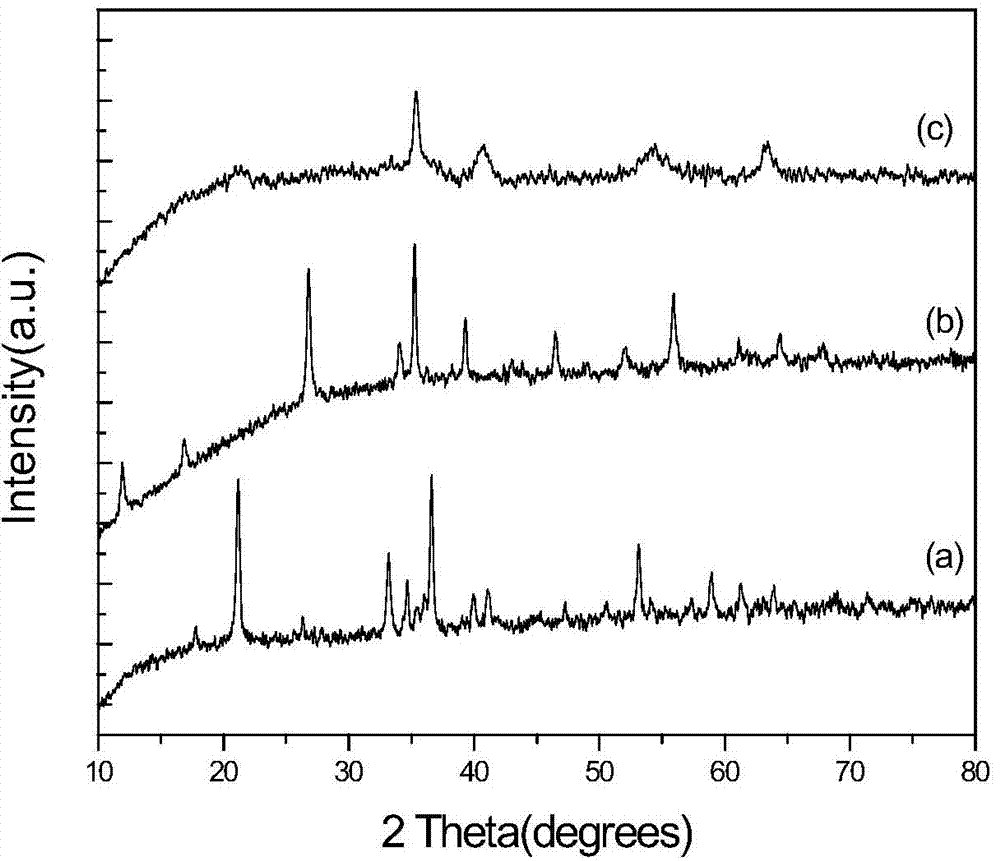

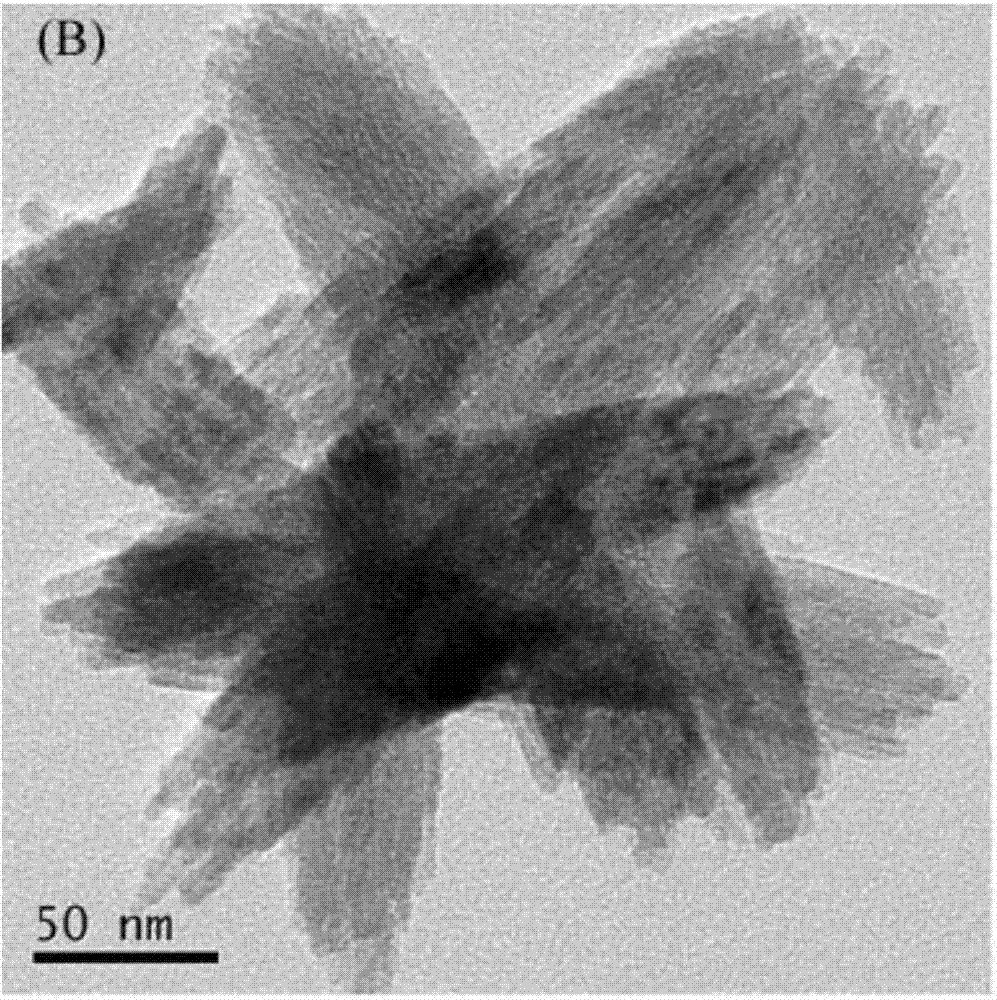

Preparation and application of different-crystal-phase FeOOH nanometer materials

A technology of nanomaterials and PH value, applied in the fields of application, nanotechnology, nanotechnology, etc., can solve the problems of large amount of adsorption materials used and complicated addition, and achieve the effect of low cost, simple preparation method, and small amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Weigh 7.9696g of sodium dodecylbenzene sulfonate dissolved in 100ml of absolute ethanol and add it to 2000ml of deionized water after completely dissolving; then weigh 222.416g of ferrous sulfate heptahydrate and add it to the above system, fully stir to make The ferrous sulfate is completely dissolved, and nitrogen is blown into the mixed system for 15-20 minutes to drive off the air in the system, and the solution A is prepared, sealed and stored for later use. Weigh 80g of urea and dissolve it in deionized water to prepare solution B for use.

[0070] After mixing the two solutions of solution A and solution B, transfer them to a 5L three-necked flask, stir, heat to 90℃, keep for 1 hour to fully hydrolyze the urea, add hydrogen peroxide to the system, control the dropping rate so that it does not produce a lot of foam , The amount of adding hydrogen peroxide is about 200ml, which is used to test whether the ferrous ion in the system is completely oxidized. Finally, use...

Embodiment 2

[0072] Weigh 6.9696g of sodium dodecylbenzene sulfonate and dissolve it in 70ml of absolute ethanol, and add it to 1400ml of deionized water after completely dissolving; then weigh 222.416g of ferrous sulfate heptahydrate and add it to the above system, fully stir to make The ferrous sulfate is completely dissolved, and nitrogen is blown into the mixed system for 15-20 minutes to drive off the air in the system, and the solution A is prepared, sealed and stored for later use. Weigh 80g of urea and dissolve it in deionized water to prepare solution B for use.

[0073] Mix the two solutions of solution A and solution B and transfer to a 5L three-necked flask, stir, heat to 85°C, keep for 0.5 hours to fully hydrolyze the urea, add hydrogen peroxide to the system dropwise, control the dropping rate so that it does not produce a lot of foam , Add hydrogen peroxide dropwise to check whether the ferrous ion in the system is completely oxidized. Finally, use a dropping funnel to drop a ...

Embodiment 3

[0075] Weigh 8.3635g of sodium dodecylbenzene sulfonate and dissolve it in 127ml of absolute ethanol, and add it to 2500ml of deionized water after completely dissolving; then weigh 313.712g of ferrous ammonium sulfate and add it to the above system, stir fully to make the sulfuric acid The ferrous iron is completely dissolved. Blow nitrogen into the mixed system for 15-20 minutes to drive off the air in the system, prepare solution A, seal it and store it for later use. Weigh 80g of urea and dissolve it in deionized water to prepare solution B for use.

[0076] After mixing the two solutions of solution A and solution B, transfer them to a 5L three-necked flask, stir, heat to 95℃, keep for 1.5 hours to fully hydrolyze the urea, add hydrogen peroxide to the system, control the dropping rate so that it does not produce a lot of foam , Add hydrogen peroxide dropwise to check whether the ferrous ion in the system is completely oxidized. Finally, use a dropping funnel to drop a 1M s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com