Titanium-doped alpha-iron oxide photo-anode, and preparation method and application thereof

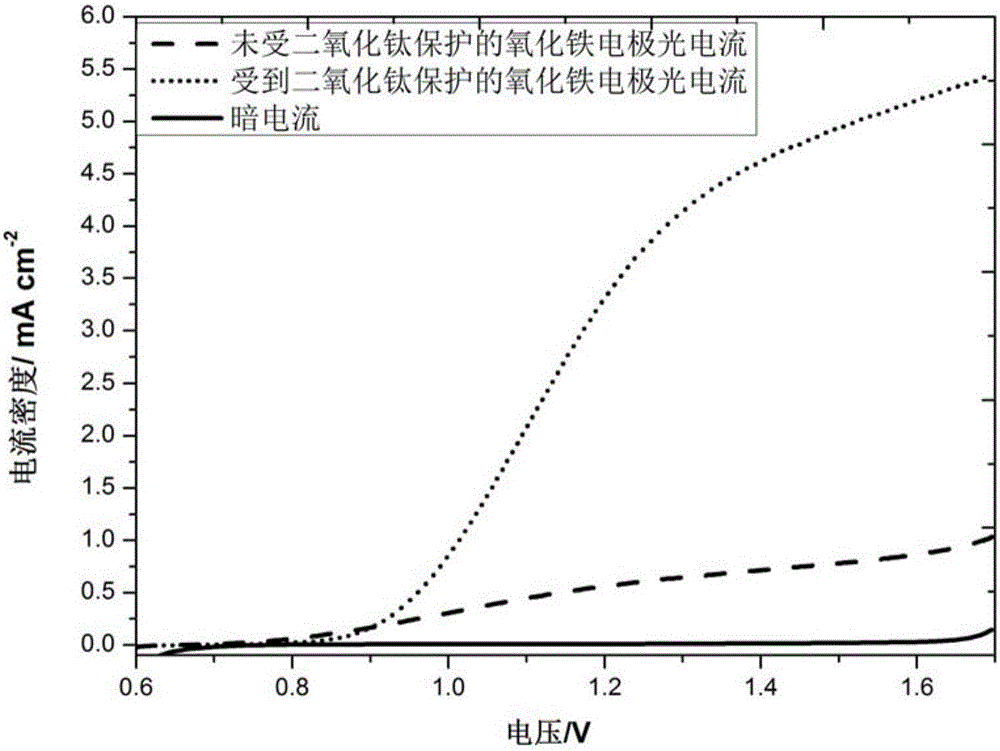

A technology of iron oxide light and titanium doping, which is applied in the field of nanomaterial preparation and application, can solve the problems of increase in grain size, positive shift of photoelectrode initial potential, coarsening of iron oxide grains, etc., and achieve an increase in photocurrent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

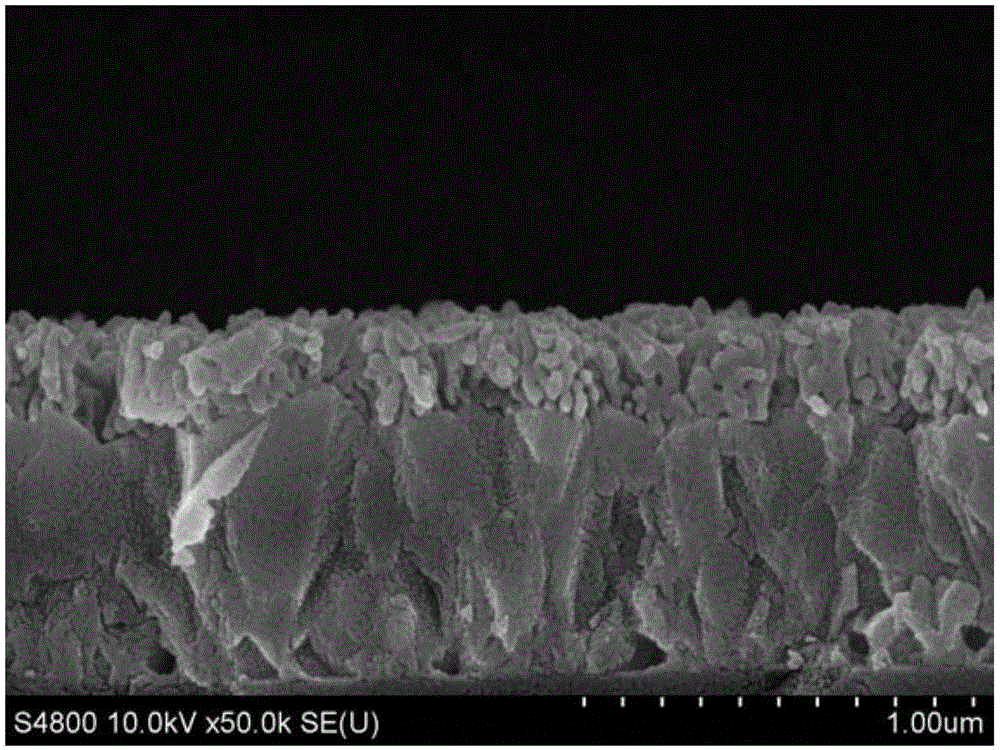

[0071] (1) Prepare the substrate used for preparing the titanium-doped α-iron oxide photoanode, cut it into a size of 2cm*4cm, and clean it with isopropanol, acetone, ethanol and water in sequence. After the FTO was cleaned and dried, the back-to-back and vertical inner substrate surface (FTO's SnO 2 Facing the lining wall) placed on the PTFE lining. Add 0.54058g FeCl to 20mL aqueous solution 3 ·6H 2 O, and 0.36036gNH 2 CONH 2 , stirred for 60min. The stirred solution was poured into the polytetrafluoroethylene lining, and then the polytetrafluoroethylene lining was placed in an autoclave and sealed, and heated at 70° C. for 6 hours in a blast drying oven. After hydrothermal treatment, a light yellow translucent β-FeOOH film grew on the FTO. The β-FeOOH film was cleaned with deionized water and dried with nitrogen.

[0072] (2) Take 100μL TiCl 4 Add 20mL ethanol solution to get TiCl 4 ethanol solution, take 10 μL TiCl 4 The ethanol solution was used as a spin coating ...

Embodiment 2

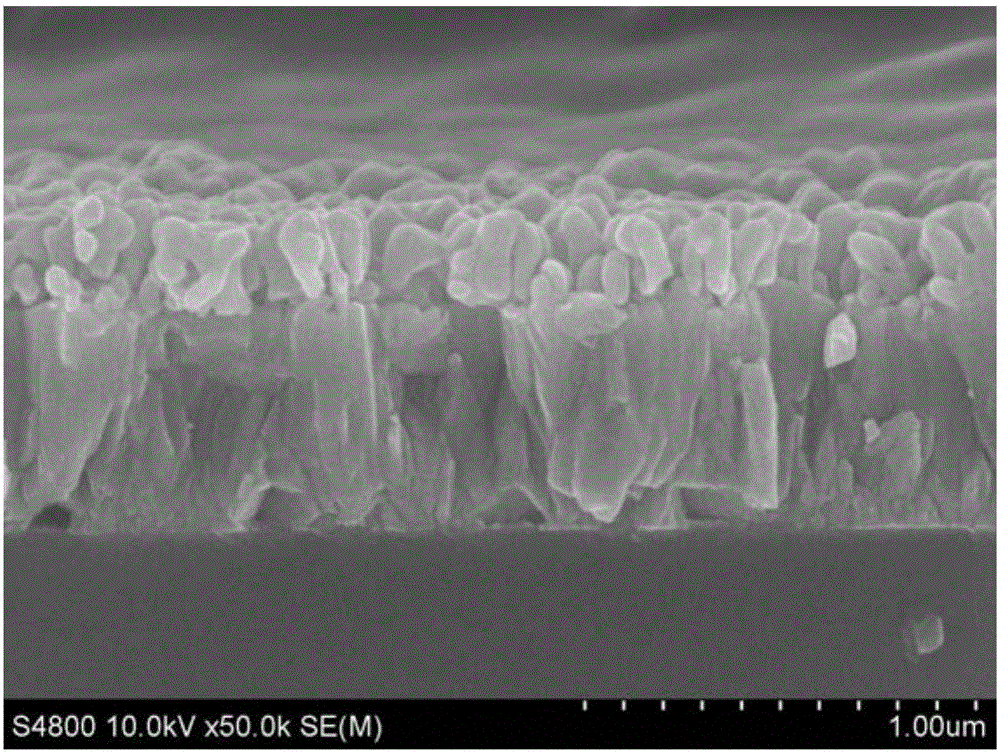

[0077](1) Prepare the substrate used for preparing the titanium-doped α-iron oxide photoanode, cut it into a size of 2cm*4cm, and clean it with isopropanol, acetone, ethanol and water in sequence. After the FTO was cleaned and dried, the back-to-back and vertical inner substrate surface (FTO's SnO 2 Facing the lining wall) placed on the PTFE lining. Add 0.54058g FeCl to 20mL aqueous solution 3 ·6H 2 O, and 0.36036gNH 2 CONH 2 , stirred for 60min. The stirred solution was poured into the polytetrafluoroethylene lining, and then the polytetrafluoroethylene lining was placed in an autoclave and sealed, and heated at 70° C. for 6 hours in a blast drying oven. After hydrothermal treatment, a light yellow translucent β-FeOOH film grew on the FTO. The β-FeOOH film was cleaned with deionized water and dried with nitrogen.

[0078] (2) Take 200μL TiCl 4 Add 20mL ethanol solution to get TiCl 4 ethanol solution, take 10 μL TiCl 4 The ethanol solution was used as a spin coating s...

Embodiment 3

[0083] (1) Prepare the substrate used for preparing the titanium-doped α-iron oxide photoanode, cut it into a size of 2cm*4cm, and clean it with isopropanol, acetone, ethanol and water in sequence. After the FTO was cleaned and dried, the back-to-back and vertical inner substrate surface (FTO's SnO 2 Facing the lining wall) placed on the PTFE lining. Add 5.4058g FeCl to 40mL aqueous solution 3 ·6H 2 O, and 3.6036g NH 2 CONH 2 , stirred for 50min. The stirred solution was poured into the polytetrafluoroethylene lining, and then the polytetrafluoroethylene lining was placed in an autoclave and sealed, and heated at 80° C. for 6.5 hours in a blast drying oven. After hydrothermal treatment, a light yellow translucent β-FeOOH film grew on the FTO. The β-FeOOH film was cleaned with deionized water and dried with nitrogen.

[0084] (2) Take 150μL TiCl 4 Add 20mL ethanol solution to get TiCl 4 ethanol solution, take 20 μL TiCl 4 The ethanol solution was used as a spin coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com