Double-functional Beta-FeOOH/eg-C3N4 composite nanomaterial and preparation method and application thereof

A composite nanomaterial, eg-c3n4 technology, applied in hydrogen/syngas production, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of acid consumption, iron leaching, small specific surface area, etc., and achieve simple and easy operation. performance, mild reaction conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1)eg-C 3 N 4 preparation of

[0024] Take 18g of melamine in a crucible, place it in a muffle furnace, heat it up to 550°C at a heating rate of 5°C / min, and calcinate for 4 hours to obtain yellow Bulk g-C 3 N 4 . Take 6g g-C 3 N 4 In a crucible, add an appropriate amount of water to sonicate for 1 hour, then dry in an oven at 120°C for 2 hours, then place it in a muffle furnace and heat it to 550°C, continue to calcine for 4 hours, and obtain eg-C after cooling 3 N 4 .

[0025] (2)β-FeOOH / eg-C 3 N 4 preparation of

[0026] Take 100mg of eg-C 3 N 4 Put the powder into a 100ml beaker, then add 50ml of deionized water, and then adjust the pH to 2 with 6mol / L hydrochloric acid. Then add 142mg of FeCl 3 ·6H 2 After O, it was sonicated for 6 hours, centrifuged, and the product was washed three times with ethanol and pure water, respectively, and dried in an oven at 60°C for 12 hours.

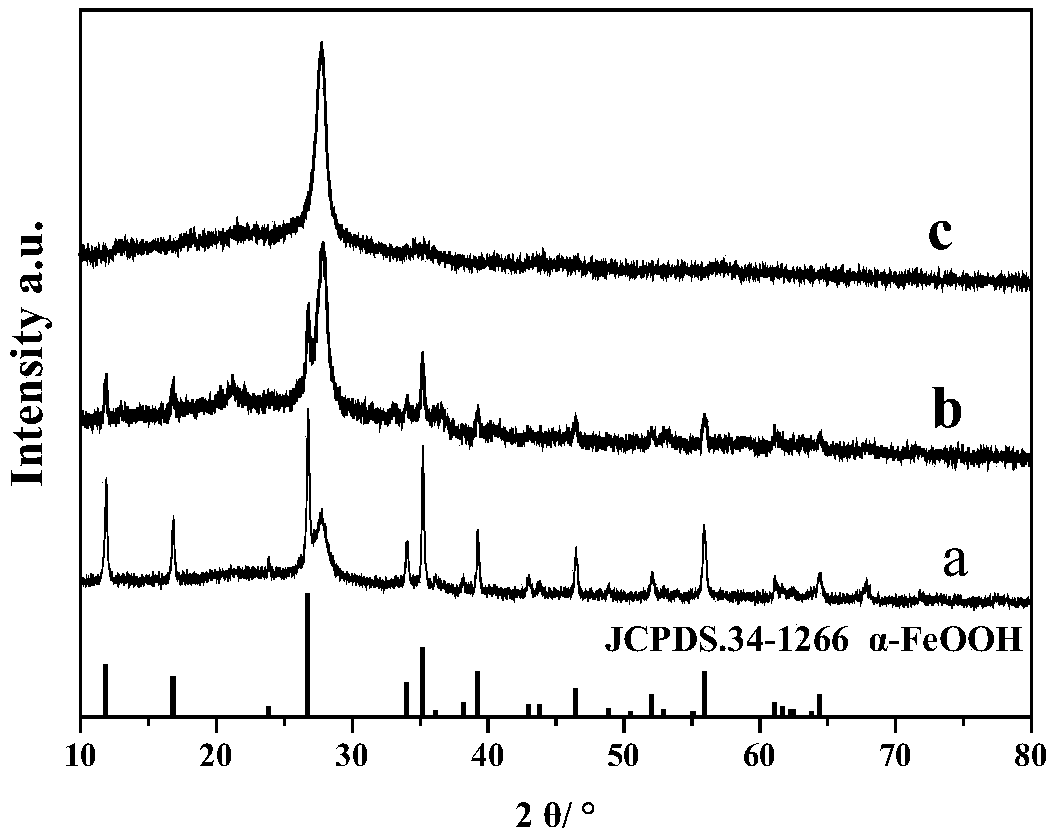

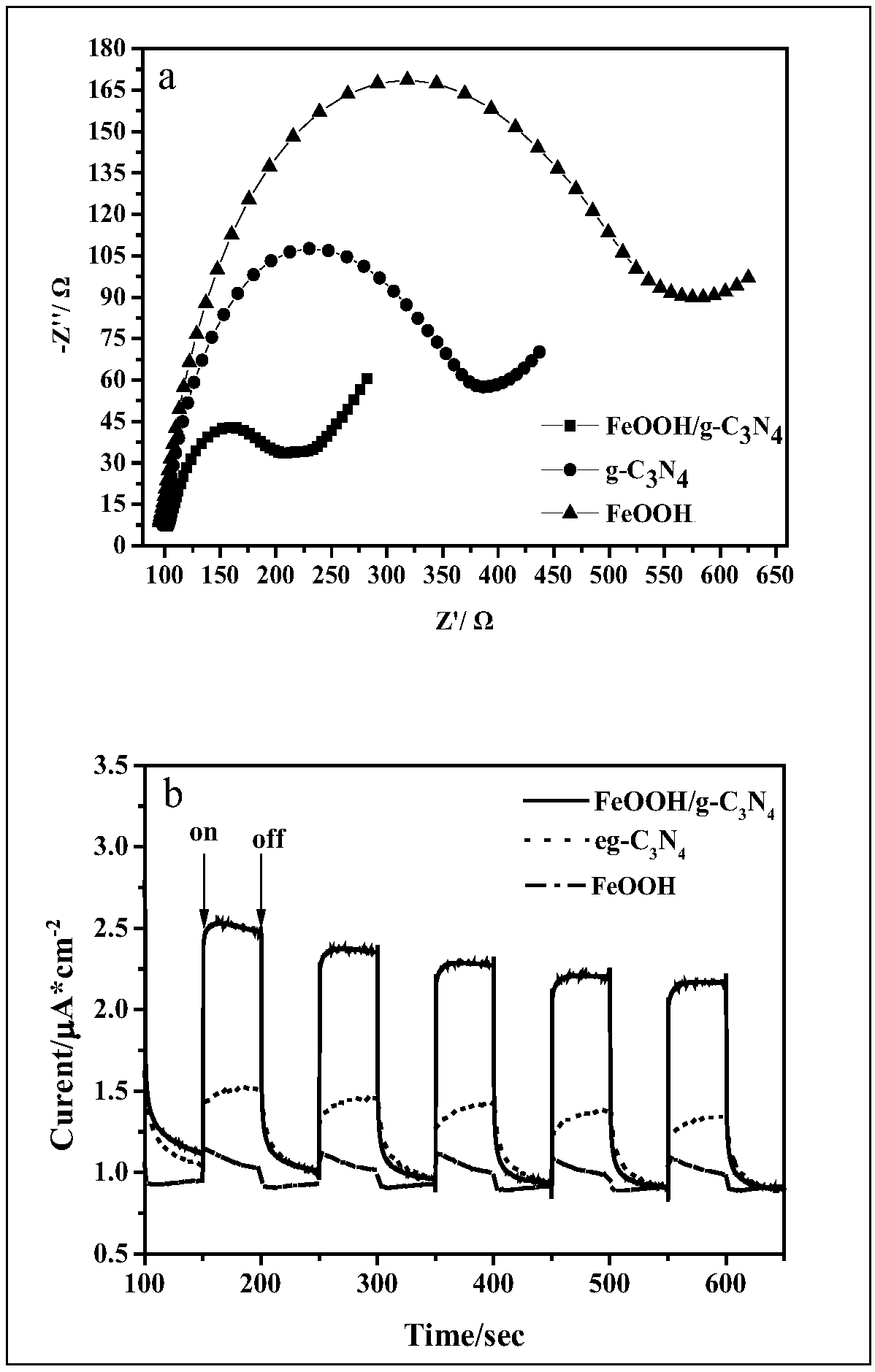

[0027] The morphology, structure and composition of the product were chara...

Embodiment 2

[0030] (1)eg-C 3 N 4 preparation of

[0031] Take 6g of melamine in a crucible, place it in a muffle furnace, heat it up to 550°C at a heating rate of 5°C / min, and calcinate for 4 hours to obtain yellow eg-C 3 N 4 . Take 3g-C 3 N 4 In a crucible, add an appropriate amount of water for ultrasonication for 1 hour, then dry in an oven at 120°C for 2 hours, then place it in a muffle furnace and heat it to 550°C, continue calcination for 5 hours, and obtain eg-C after cooling 3 N 4 .

[0032] (2)β-FeOOH / eg-C 3 N 4 preparation of

[0033] Take 50mg eg-C 3 N 4 Put the powder into a 100ml beaker, add 50ml of deionized water, then use 6mol / L hydrochloric acid to adjust the pH of the solution to 1, after ultrasonication for 1h, add 94mg of FeCl 3 ·6H 2 O, continue to sonicate for 4 hours, centrifuge, wash the product with ethanol and pure water three times, and put it in a 60°C oven to dry for 12 hours.

Embodiment 3

[0035] (1)eg-C 3 N 4 preparation of

[0036] Take 9g of melamine in a crucible, place it in a muffle furnace, heat it up to 550°C at a rate of 5°C / min, and calcinate for 4 hours to obtain yellow Bulk g-C 3 N 4 . Take 3g-C 3 N 4 In a crucible, add an appropriate amount of water to sonicate for 1 hour, then dry in an oven at 120°C for 2 hours, then place it in a muffle furnace and heat it to 550°C, continue to calcine for 4 hours, and obtain eg-C after cooling 3 N 4 .

[0037] (2)β-FeOOH / eg-C 3 N 4 preparation of

[0038] Take 200mg of eg-C 3 N 4 Put the powder into a 100ml beaker, add 100ml of deionized water, and then adjust the pH of the solution to 0.5 with 6mol / L hydrochloric acid. After ultrasonication for 1h, add 378mg of FeCl 3 ·6H 2 O, ultrasonication for 6 hours, centrifugation, the product was washed three times with ethanol and pure water, and dried in an oven at 60°C for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com