Phosphorus-nitrogen-containing polymer-coated beta-FeOOH nanoparticles, and preparation method and application thereof

A nanoparticle and polymer technology, applied in the field of flame retardant rubber, can solve problems such as the inability to meet the requirements of practical applications, the decline of rubber mechanical properties, etc., and achieve the effect of good smoke suppression, overcoming poor compatibility, and improving thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

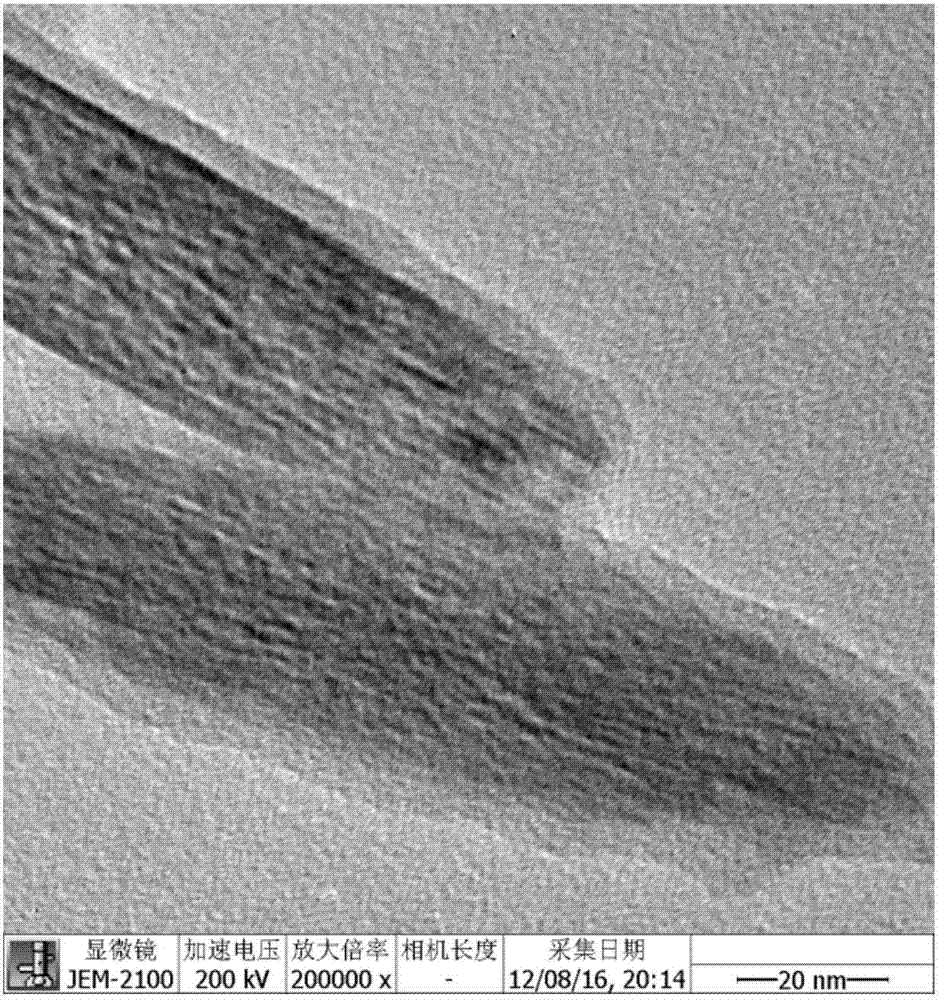

[0029] (1) Add 17.1g FeCl to the single-necked bottle in turn 3 ·6H 2 0. 15 g of polyvinylpyrrolidone and 600 mL of water were reacted at 80° C. for 10 h. After centrifugation, the supernatant was discarded to leave a precipitate, and the resulting precipitate was washed repeatedly with water and ethanol to obtain nanometer β-FeOOH.

[0030] (2) Get 10g of nanometer β-FeOOH obtained in step (1) and disperse it in the first solvent, add 20g of 3,4-dihydroxybenzaldehyde, stir at room temperature for 6h, pour off the clear liquid after centrifugation and leave the precipitate, the resulting precipitate The substance is reacted and washed with the first solvent to obtain 3,4-dihydroxybenzaldehyde-modified β-FeOOH.

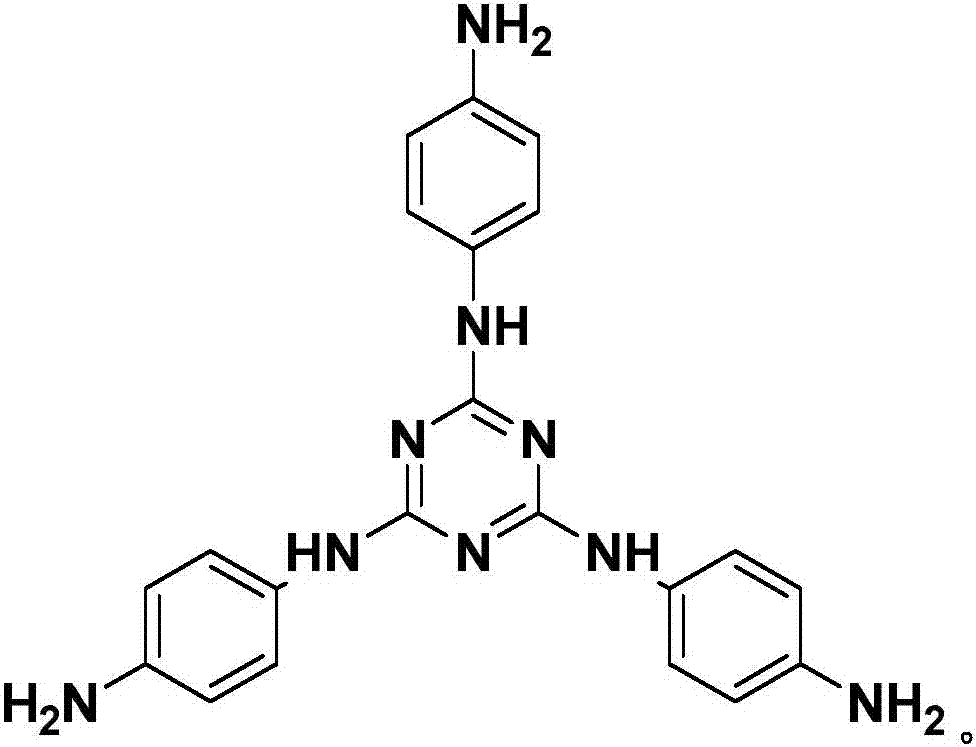

[0031] (3) Disperse 1 g of 3,4-dihydroxybenzaldehyde-modified β-FeOOH obtained in step (2) and 0.2 g of terephthalaldehyde in 600 mL of tetrahydrofuran, and then slowly add 720 mL of 0.01 g / mL dissolved in 2,4,6-tris(p-N'-octadecylureido-anilino)-1,3,5-triazine solut...

Embodiment 2

[0034] (1) The preparation of nanometer β-FeOOH is the same as in Example 1.

[0035] (2) The preparation of 3,4-dihydroxybenzaldehyde-modified β-FeOOH is the same as in Example 1.

[0036] (3) The preparation of β-FeOOH nanoparticles coated with phosphorus and nitrogen polymer is the same as that in Example 1.

[0037] (4) Take 0.5g of phosphorus-nitrogen-containing polymer-coated β-FeOOH nanoparticles and blend them with 100g of rubber, ultrasonically treat them for 0.5-3 hours, add 2g of DCP, mix them on an open mill for 5-10 minutes, and then mold and vulcanize them to obtain phosphorus-containing Nitrogen polymer coated β-FeOOH nanoparticles functionalized flame retardant rubber.

Embodiment 3

[0039] (1) The preparation of nanometer β-FeOOH is the same as in Example 1.

[0040] (2) The preparation of 3,4-dihydroxybenzaldehyde-modified β-FeOOH is the same as in Example 1.

[0041] (3) The preparation of β-FeOOH nanoparticles coated with phosphorus and nitrogen polymer is the same as that in Example 1.

[0042] (4) Take 0.25g of phosphorus-nitrogen-containing polymer-coated β-FeOOH nanoparticles and blend them with 100g of rubber, ultrasonically treat them for 0.5-3 hours, add 2g of DCP, mix them on an open mill for 5-10 minutes, and then mold and vulcanize them to obtain phosphorus-containing Nitrogen polymer coated β-FeOOH nanoparticles functionalized flame retardant rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com