Nanometer multifunctional composite thin-membrane, its production and use

A composite film and multi-functional technology, applied in the direction of coating, etc., can solve the problem of high cost, achieve low cost, improve aging resistance, and improve wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1, the preparation of nanometer α-FeOOH particle

[0051] To 500mL of FeSO with a concentration of 0.3mol / L 4 FeSO was added to the solution 4 Quality 0.3% sodium hexametaphosphate, temperature control at 30°C, stirring speed 500 (r / min), after dissolution is complete, gradually add 3mol / L sodium hydroxide solution 50mL to it at a speed of 2mL / min by means of forced feeding , to obtain colloidal precipitates of dark green ferrous hydroxide, ultrasonically dispersed for 30min, with 0.15m 3 The speed of / h is oxidized by air, the color changes from dark green to bean green to dark gray, and then turns yellow quickly. After 30 minutes of crystal growth, add FeSO 4 3wt% sodium dodecylbenzene sulfonate, ultrasonically dispersed for 30min and then heated to 80°C, at 0.5m 3 Air was passed in at a speed of 1 / h to continue the oxidation reaction for 5 hours to obtain a yellow colloidal mixture, which was then centrifuged, and the filter cake was washed repeatedly u...

Embodiment 2

[0052] Embodiment 2, the preparation of nanometer β-FeOOH particle

[0053] To 540mL of FeSO with a concentration of 0.4mol / L 4 FeSO 4 Quality 0.45% sodium silicate and 0.1% sodium chloride, temperature control at 35 ° C, stirring speed 600 (r / min), after the dissolution is complete, 60 mL of 2 mol / L aqueous urea solution is added dropwise at a speed of 5 mL / min , ultrasonically disperse for 25 minutes, gradually increase the temperature to 85°C, the color changes from dark green to dark gray, maintain the system temperature, adopt the forced feeding method, gradually add 10% hydrogen peroxide 10mL at a speed of 1ml / min to oxidize, the color turns yellow quickly, add accounted for FeSO 4 Mass 4wt% sodium hexanoate, stir, continue to add 90mL of 10% hydrogen peroxide at a speed of 1ml / min to obtain a yellow colloidal mixture, then centrifuge, wash the filter cake repeatedly until the pH value is neutral, and filter the cake at 100 After drying at ℃ for 2 hours, it was ground...

Embodiment 3

[0054] Embodiment 3, nano-α-Fe 2 o 3 Granule preparation

[0055] The nano-α-FeOOH particles were heated to 450°C within 30 minutes and calcined for 3 hours to obtain red nano-α-Fe 2 o 3 particles. The nano-α-Fe 2 o 3 It is spindle-shaped, with uniform particle size and good dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

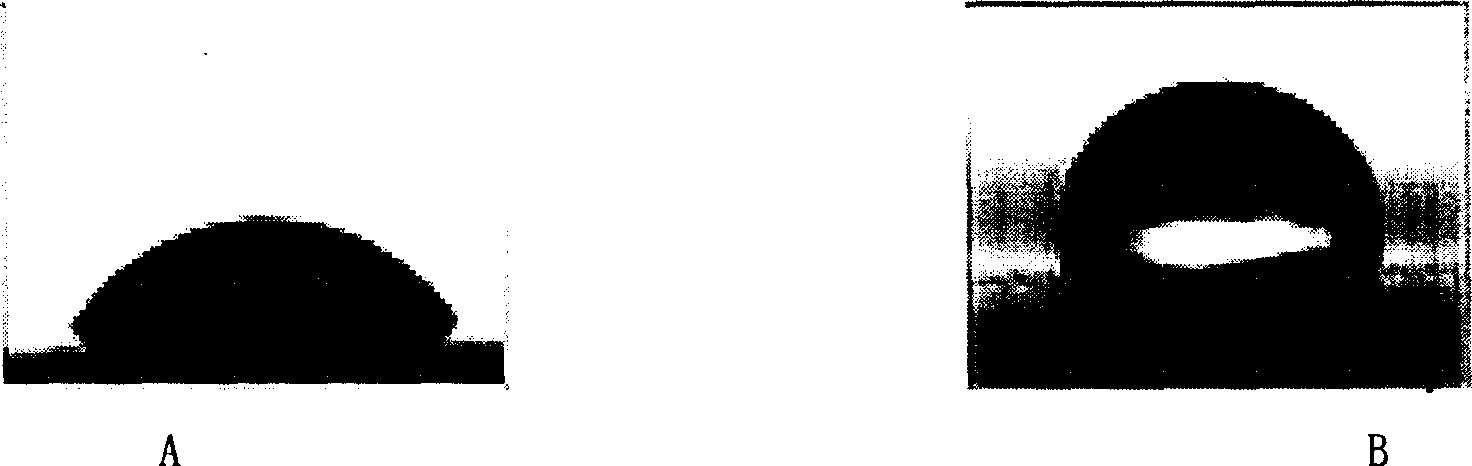

| Hydrophobic angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com