Porous Fe3O4/Fe/SiO2 core-shell nanorod absorbing high-frequency electromagnetic waves and a preparation method

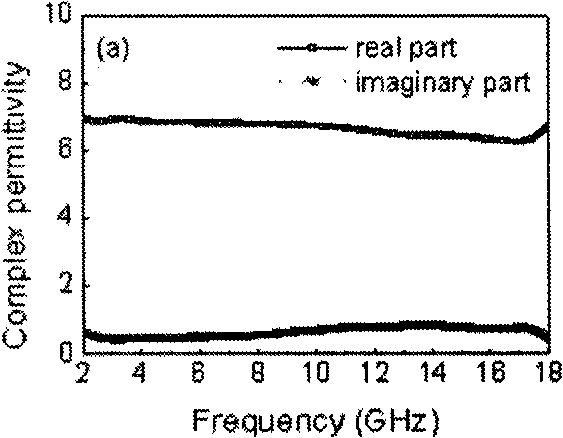

A technology of nano-rods and electromagnetic waves, applied in the field of nano-materials, can solve the problems of low width, only -12.28dB, etc., and achieve the effect of strong absorption characteristics and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) 40 milliliters of 0.5mol / L FeCl 3 The solution was placed in a 50ml stainless steel sealed autoclave. Keep in an oven at 120°C for 12 hours;

[0021] (2) After the autoclave is naturally cooled to room temperature, the precipitate in the autoclave is washed with water and ethanol several times. β-FeOOH nanorods were obtained after drying at 80°C;

[0022] (3) Hydrolyze the β-FeOOH nanorods obtained above in 60 ml tetraethyl orthosilicate / isopropanol solution to obtain β-FeOOH / SiO 2 Core-shell nanorods. Wherein, the volume ratio of ethyl tetrasilicate / isopropanol is 60:1;

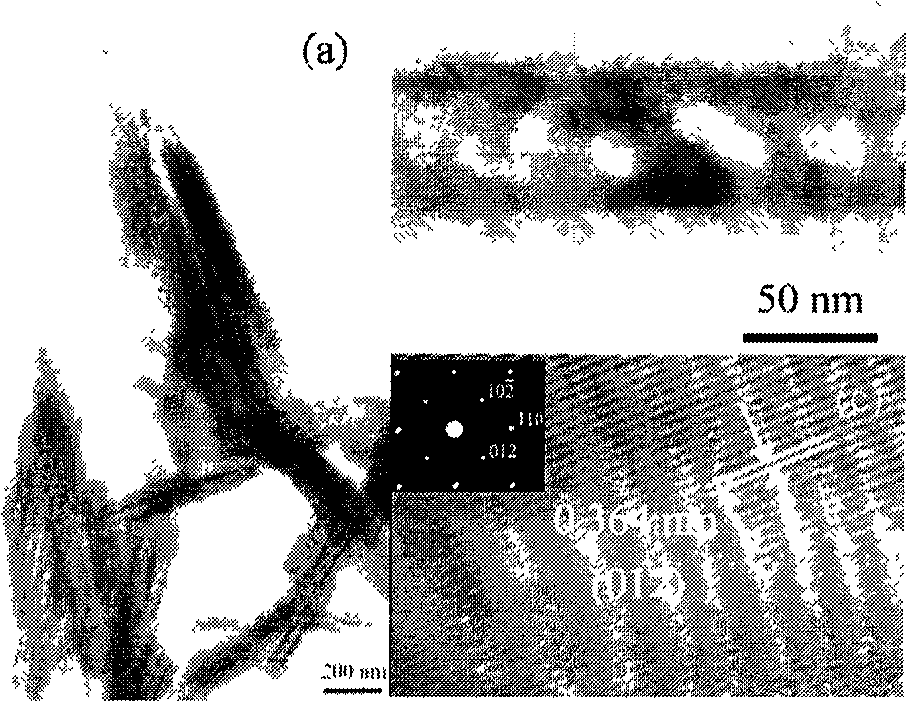

[0023] (4)β-FeOOH / SiO 2 Core-shell nanorods were annealed in air at 500 °C for 2.5 h to obtain α-Fe 2 o 3 / SiO 2 Core-shell nanorods. α-Fe 2 o 3 / SiO 2 Core-shell nanorods are porous structures, and their morphology and microstructure are characterized by transmission electron microscopy, as shown in figure 1 shown;

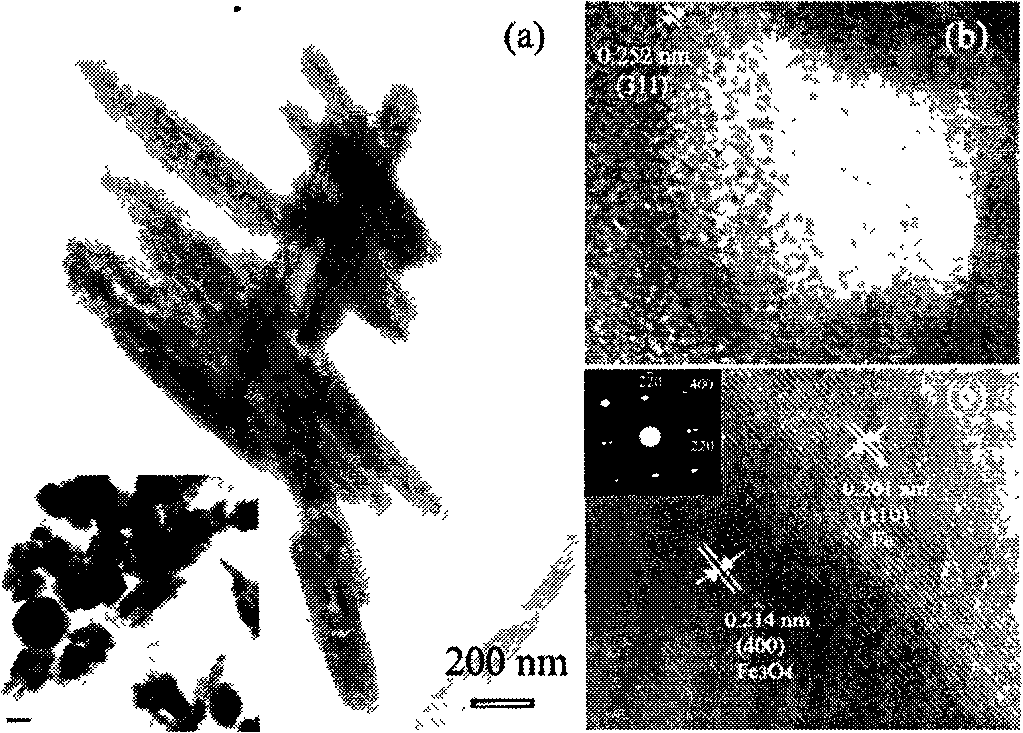

[0024] (5) α-Fe 2 o 3 / SiO 2 Core-shell nanorods in N 2 / H 2 ...

Embodiment 2

[0027] (1) 40 milliliters of 1.0mol / L FeCl 3 The solution was placed in a 50ml stainless steel sealed autoclave. Keep in the oven at 100°C for 12 hours;

[0028] (2) After the autoclave is naturally cooled to room temperature, the precipitate in the autoclave is washed with water and ethanol several times. β-FeOOH nanorods were obtained after drying at 80°C;

[0029] (3) Hydrolyze the β-FeOOH nanorods obtained above in tetraethyl orthosilicate / isopropanol solution to obtain β-FeOOH / SiO 2 Core-shell nanorods. Wherein, the volume ratio of ethyl tetrasilicate / isopropanol is 60:1;

[0030] (4)β-FeOOH / SiO 2 Core-shell nanorods were annealed in air at 500 °C for 2.5 h to obtain α-Fe 2 o 3 / SiO 2 Core-shell nanorods;

[0031] (5) α-Fe 2 o 3 / SiO 2 Core-shell nanorods in N 2 / H 2 (8% / H 2 ) atmosphere, annealed at 400 ° C for 7 hours, and finally obtained porous Fe 3 o 4 / Fe / SiO 2 Nano stave.

Embodiment 3

[0033] (1) 40 milliliters of 0.25mol / L FeCl 3 The solution was placed in a 50ml stainless steel sealed autoclave. Keep in an oven at 110°C for 12 hours;

[0034] (2) After the autoclave is naturally cooled to room temperature, the precipitate in the autoclave is washed with water and ethanol several times. β-FeOOH nanorods were obtained after drying at 80°C;

[0035] (3) Hydrolyze the β-FeOOH nanorods obtained above in tetraethyl orthosilicate / isopropanol solution to obtain β-FeOOH / SiO 2 Core-shell nanorods. Wherein, the volume ratio of ethyl tetrasilicate / isopropanol is 60:1;

[0036] (4)β-FeOOH / SiO 2 Core-shell nanorods were annealed in air at 500 °C for 2.5 h to obtain α-Fe 2 o 3 / SiO 2 Core-shell nanorods;

[0037] (5) α-Fe 2 o 3 / SiO 2 Core-shell nanorods in N 2 / H 2 (8% / H 2 ) atmosphere, annealed at 400 ° C for 7 hours, and finally obtained porous Fe 3 o 4 / Fe / SiO 2 Nano stave.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com