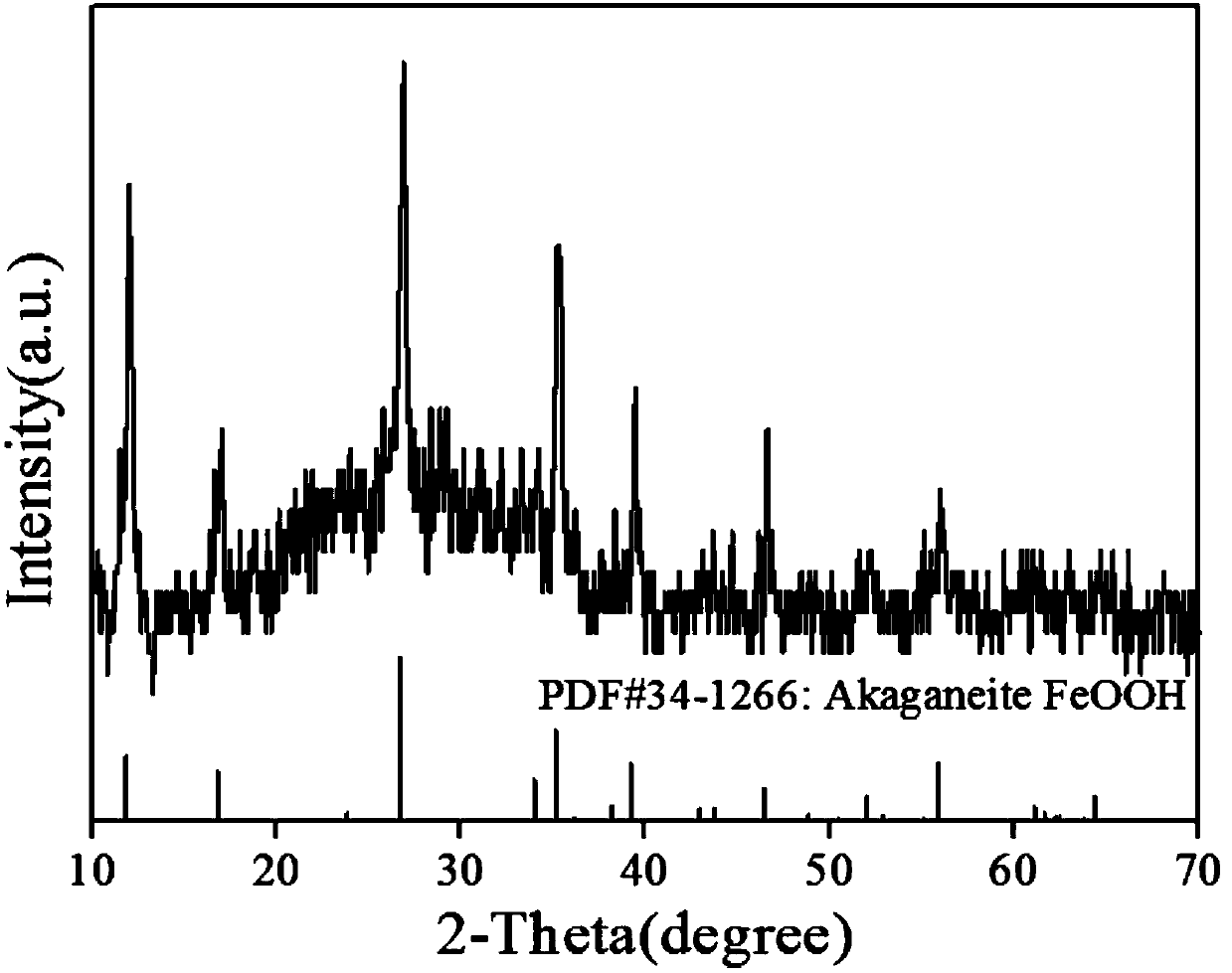

Cobweb-like graphene coated beta-FeOOH nano-rod aggregate lithium ion battery negative electrode material preparation method

A graphene-wrapped, lithium-ion battery technology, applied in the field of electrochemistry, can solve problems such as poor conductivity, and achieve the effects of improving conductivity, inhibiting volume expansion, and improving cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Disperse commercially available graphene oxide in 25 mL of deionized water to form a solution with a graphene oxide concentration of 1 mg / mL, and then use an ultrasonic generator to form a uniformly dispersed graphene oxide suspension A;

[0019] 2) The analytically pure FeCl 3 ·6H 2 O and NaNO 3 Add it into 25mL deionized water, stir to make it fully dissolve, and then add it to suspension A to form a mixed solution of iron salt and graphene oxide, wherein the concentration of iron salt is 0.05mol / L, and the concentration of sodium salt is 0.05mol / L. 2 / 3 of the salt concentration, and then disperse the mixed solution with an ultrasonic generator to obtain a suspension B;

[0020] 3) Pour the suspension B prepared above into a homogeneous hydrothermal reaction kettle, control the filling degree to 30%, then seal the reaction kettle, and put it into a homogeneous hydrothermal reactor at 50°C for hydrothermal reaction , naturally cooled to room temperature after the...

Embodiment 2

[0027] 1) Disperse commercially available graphene oxide in 30mL deionized water to form a solution with a graphene oxide concentration of 2mg / mL, and then use an ultrasonic generator to form a uniformly dispersed graphene oxide suspension A;

[0028] 2) The analytically pure FeCl 3 ·6H 2 O and NaNO 3 Add it into 20mL deionized water, stir it to fully dissolve, then add it into suspension A, and configure it as a mixed solution of iron salt and graphene oxide, wherein the concentration of iron salt is 0.3mol / L, and the concentration of sodium salt is 0.3mol / L. 2 / 3 of the salt concentration, and then disperse the mixed solution with an ultrasonic generator to obtain a suspension B;

[0029] 3) Pour the suspension B prepared above into a homogeneous hydrothermal reaction kettle, control the filling degree to 80%, then seal the reaction kettle, put it into a homogeneous hydrothermal reactor at 70°C for hydrothermal reaction , naturally cooled to room temperature after the reac...

Embodiment 3

[0033] 1) Disperse commercially available graphene oxide in 35mL deionized water to form a solution with a graphene oxide concentration of 5mg / mL, and then use an ultrasonic generator to form a uniformly dispersed graphene oxide suspension A;

[0034] 2) The analytically pure FeCl 3 ·6H 2 O and NaNO 3 Add it into 15mL deionized water, stir to make it fully dissolve, and then add it to suspension A to form a mixed solution of iron salt and graphene oxide, wherein the concentration of iron salt is 0.5mol / L, and the concentration of sodium salt is 0.5mol / L. 2 / 3 of the salt concentration, and then disperse the mixed solution with an ultrasonic generator to obtain a suspension B;

[0035] 3) Pour the suspension B prepared above into a homogeneous hydrothermal reactor, control the filling degree to 60%, then seal the reactor, put it into a homogeneous hydrothermal reactor at 150°C for hydrothermal reaction , naturally cooled to room temperature after the reaction to obtain produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com