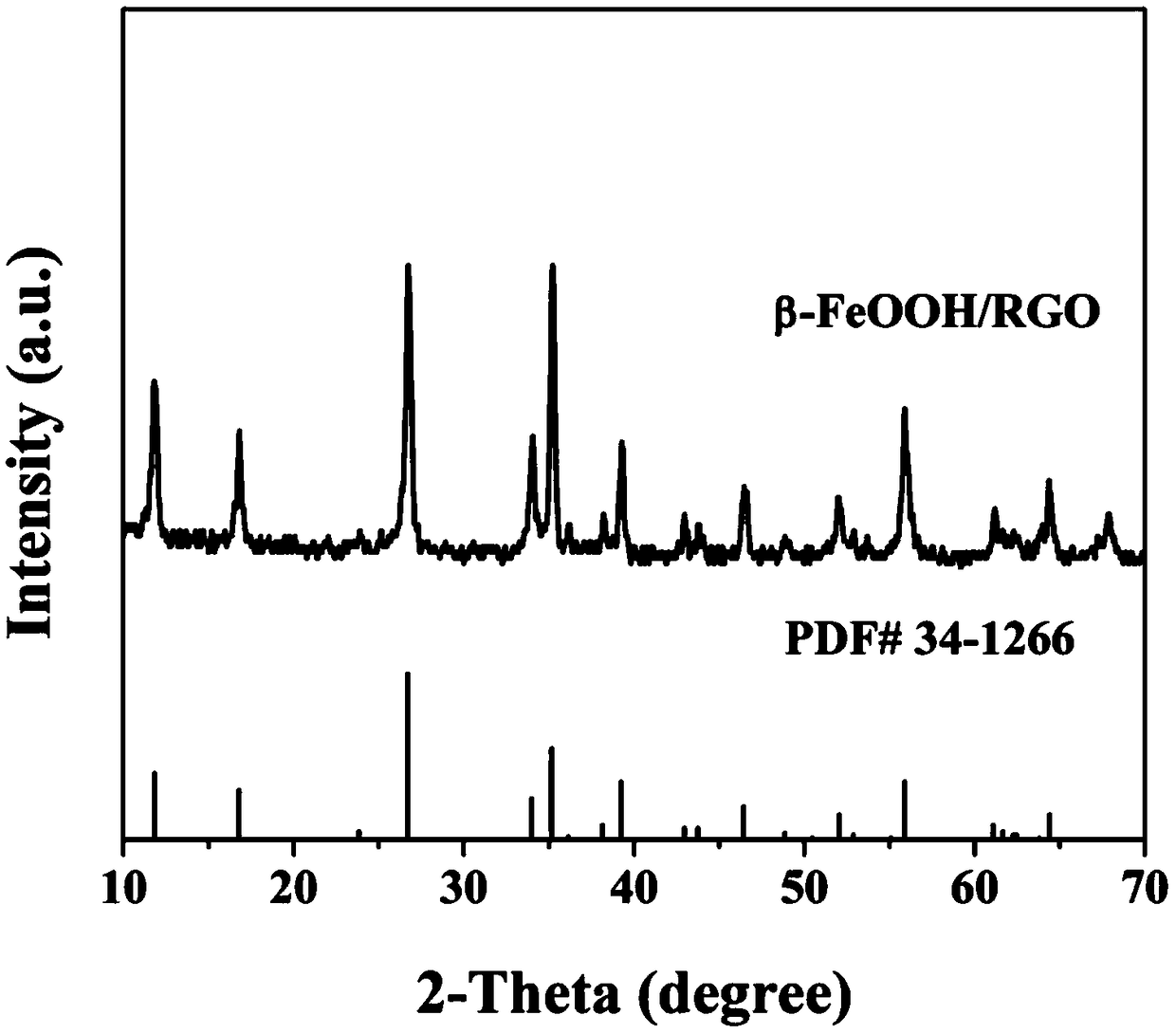

Preparation method of super large lamella RGO loaded ultrafine beta-FeOOH nanometer particle lithium ion battery negative electrode material

A lithium-ion battery and nanoparticle technology, which is applied in the field of electrochemistry, can solve the problems of further improvement of specific capacity and poor conductivity, and achieves the effects of easy implementation, improved conductivity and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Disperse commercially available graphene oxide in 25mL deionized water to form a 1mg / mL solution, and then disperse it with a 300W ultrasonic generator for 1h to form a uniformly dispersed graphene oxide suspension A;

[0031] 2) Add analytically pure soluble iron salt ferric chloride hexahydrate, sodium chloride and 0.3g urea to 25mL absolute ethanol and 10mL deionized water, stir well to dissolve the salt, and then add to suspension A, Configure a mixed solution of salt and graphene oxide, wherein the concentration of the iron salt is 0.05mol / L, and the concentration of the sodium salt is 2 / 3 of the concentration of the iron salt, and then the mixed solution is dispersed by an ultrasonic generator to obtain a suspension B;

[0032] 3) Pour the suspension B prepared above into the polytetrafluoroethylene lining of the homogeneous hydrothermal reactor, the filling degree is 30%, then seal the reactor, and put it into the homogeneous hydrothermal reactor Carry out hyd...

Embodiment 2

[0039] 1) Disperse commercially available graphene oxide in 30mL deionized water to form a 2mg / mL solution, and then disperse it with a 300W ultrasonic generator for 3h to form a uniformly dispersed graphene oxide suspension A;

[0040] 2) Add analytically pure soluble iron salt ferrous sulfate heptahydrate, sodium chloride and 0.35g urea to 25mL of absolute ethanol and 12mL of deionized water, stir well to dissolve the salt, then add it into the suspension A, configure A mixed solution of salt formation and graphene oxide, wherein the concentration of the iron salt is 0.2mol / L, the concentration of the sodium salt is 2 / 3 of the concentration of the iron salt, and then the mixed solution is dispersed by an ultrasonic generator to obtain a suspension B;

[0041] 3) Pour the suspension B prepared above into the polytetrafluoroethylene lining of the homogeneous hydrothermal reactor, the filling degree is 80%, then seal the reactor, and then put it into the homogeneous hydrothermal...

Embodiment 3

[0045] 1) Disperse commercially available graphene oxide in 35mL deionized water to form a 5mg / mL solution, then disperse it with a 300W ultrasonic generator for 2h to form a uniformly dispersed graphene oxide suspension A;

[0046] 2) Add analytically pure soluble iron salt ferric nitrate nonahydrate, sodium chloride and 0.4g urea into 25mL of absolute ethanol and 14mL of deionized water, stir well to dissolve the salt, then add it into the suspension A, and configure it as A mixed solution of salt and graphene oxide, wherein the concentration of the iron salt is 0.3mol / L, the concentration of the sodium salt is 2 / 3 of the concentration of the iron salt, and then the mixed solution is dispersed by an ultrasonic generator to obtain a suspension B;

[0047] 3) Pour the suspension B prepared above into the polytetrafluoroethylene lining of the homogeneous hydrothermal reactor, the filling degree is 60%, then seal the reactor, and then put it into the homogeneous hydrothermal reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com