Method for preparing beta-FeOOH nano granule suspension solution

A nanoparticle and suspension technology, applied in the direction of iron oxide/hydroxide, etc., can solve the problems of industrialization difficulties, high reactant prices, etc., and achieve the effect of broad market prospects, small particles, and less production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. According to the mass ratio of 6:1, respectively weigh 0.2021g (0.750mmol) of ferric chloride containing six crystal waters and 0.0074g (0.125mmol) of urea, and dissolve them in 50ml double distilled water at the same time.

[0023] 2. Add the above solution into a hydrothermal kettle equipped with a polytetrafluoroethylene liner, react at 80°C for 5 hours, stop heating, and let it cool down to room temperature naturally. A stable suspension of β-FeOOH nanoparticles was obtained.

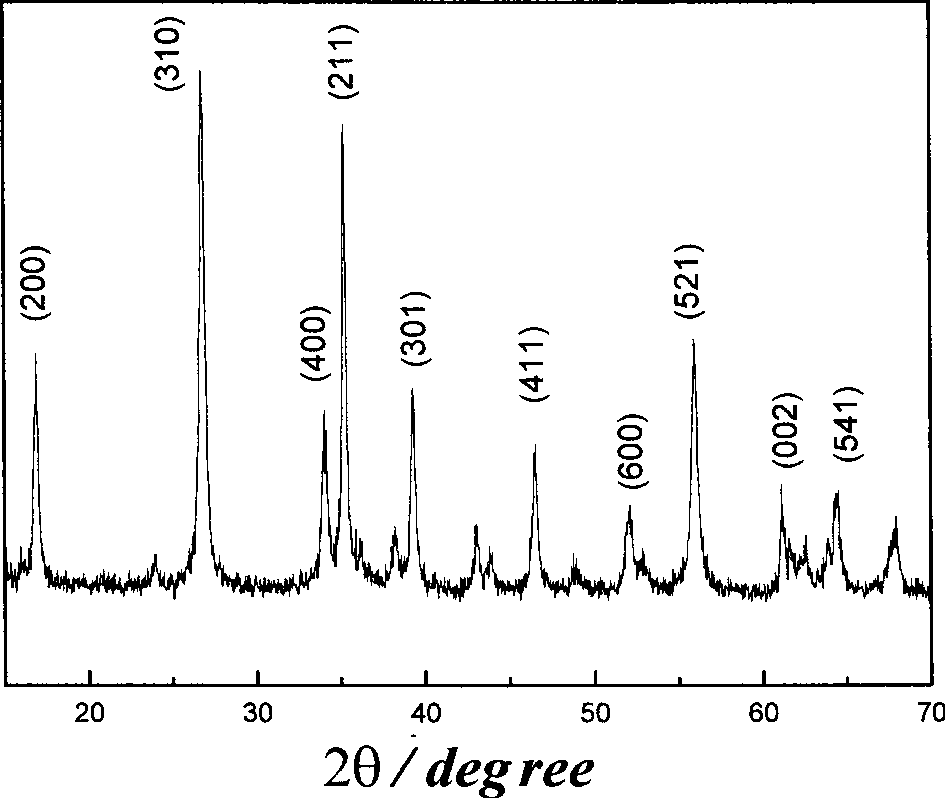

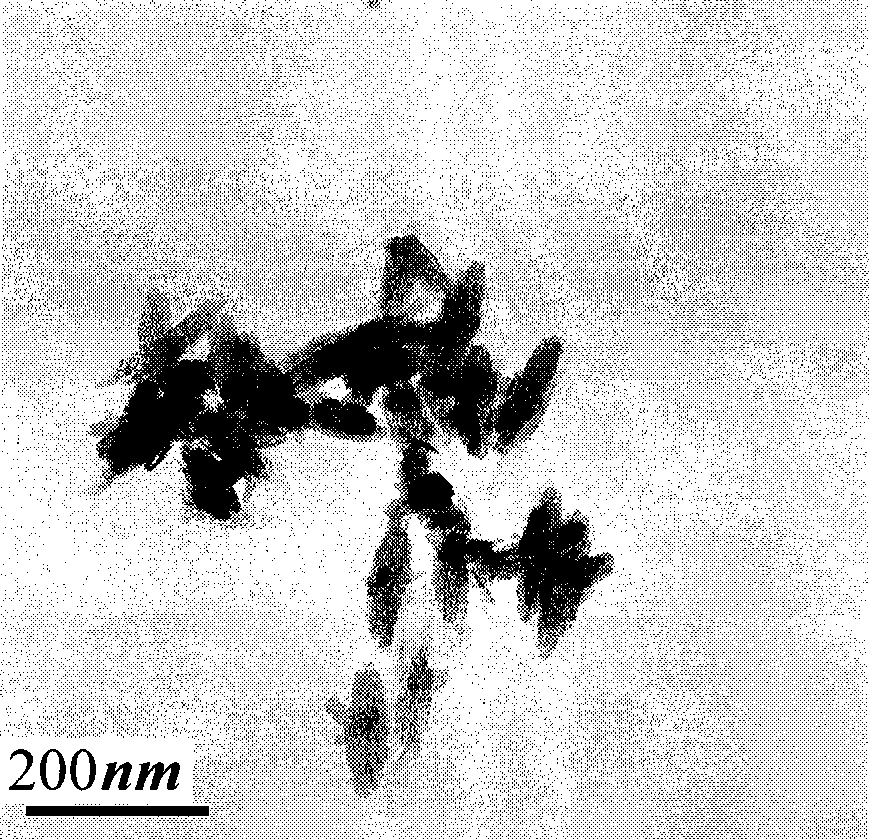

[0024] Such as figure 1 , figure 2 with image 3 shown. Photographs of the suspension were taken with a Canon 610 digital camera. The structure and phase identification of the product adopt German Bruker AXS D8 ADVANCE X-ray powder diffractometer (XRD, Cu K α Radiation, λ=1.54056 , 40kV, 200mA) for measurement. The morphology and particle size of the product were observed by JEM-2000EX transmission electron microscope.

[0025] The results showed that:

[0026] figure 1 : the u...

Embodiment 2

[0030] 1. According to the material ratio of 6:1, weigh 0.4042g of ferric chloride containing six crystal waters and 0.0148g (0.250mmol) of urea respectively, and dissolve them in 50ml of double distilled water at the same time.

[0031] 2. Add the above solution into a hydrothermal kettle equipped with a polytetrafluoroethylene liner, react at 80°C for 5 hours, stop heating, and let it cool down to room temperature naturally. A stable suspension of β-FeOOH nanoparticles was obtained.

[0032] Such as figure 2 , Figure 4 with Figure 5 shown. Photographs of the suspension were taken with a Canon 610 digital camera. The structure and phase identification of the product adopt German Bruker AXS D8 ADVANCE X-ray powder diffractometer (XRD, Cu K α Radiation, λ=1.54056 , 40kV, 200mA) for measurement. The morphology and particle size of the product were observed by JEM-2000EX transmission electron microscope.

[0033] The results showed that:

[0034] Figure 4 : the uni...

Embodiment 3

[0038] 1. According to the mass ratio of 6:1, respectively weigh 0.6063g (2.250mmol) of ferric chloride containing six crystal waters and 0.0222g (0.375mmol) of urea, and dissolve them in 50ml double distilled water at the same time.

[0039] 2. Add the above solution into a hydrothermal kettle equipped with a polytetrafluoroethylene liner, react at 80°C for 5 hours, turn off the power, stop heating, and let it cool down to room temperature naturally. A stable suspension of β-FeOOH nanoparticles was obtained.

[0040] Such as figure 2 , Image 6 with Figure 7 shown. Photographs of the suspension were taken with a Canon 610 digital camera. The structure and phase identification of the product adopt German Bruker AXS D8ADVANCE X-ray powder diffractometer (XRD, Cu K α Radiation, λ=1.54056 , 40kV, 200mA) for measurement. The morphology and particle size of the product were observed by JEM-2000EX transmission electron microscope.

[0041] The results showed that:

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com