BiOCl/beta-FeOOH composite nanomaterial and preparation method thereof

A technology of composite nanomaterials and nanorods, applied in the field of BiOCl/β-FeOOH composite nanomaterials and its preparation, to achieve the effects of controllable product composition, less by-products, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1), the FeCl of 27g 3 ·6H 2 O was dissolved in 100 mL of distilled water, and magnetically stirred for 2 minutes at room temperature to fully dissolve it to obtain solution a.

[0022] (2), weigh 48.5g of Bi(NO 3 ) 3 ·5H 2 O was added to the above solution a, and magnetic stirring was continued for 1 minute to obtain solution b.

[0023] (3) Add 0.35 g of glucose into solution b, adjust the pH of the solution to 3 with HCl solution, and obtain solution c.

[0024] (4) Put the solution c into the reactor to carry out the hydrothermal synthesis reaction, the reaction time is 24 hours, and the reaction temperature is 100°C.

[0025] (5) After the reaction, the product was taken out, washed, centrifuged and dried to obtain the target product. The drying temperature was 70° C. and the drying time was 4 hours.

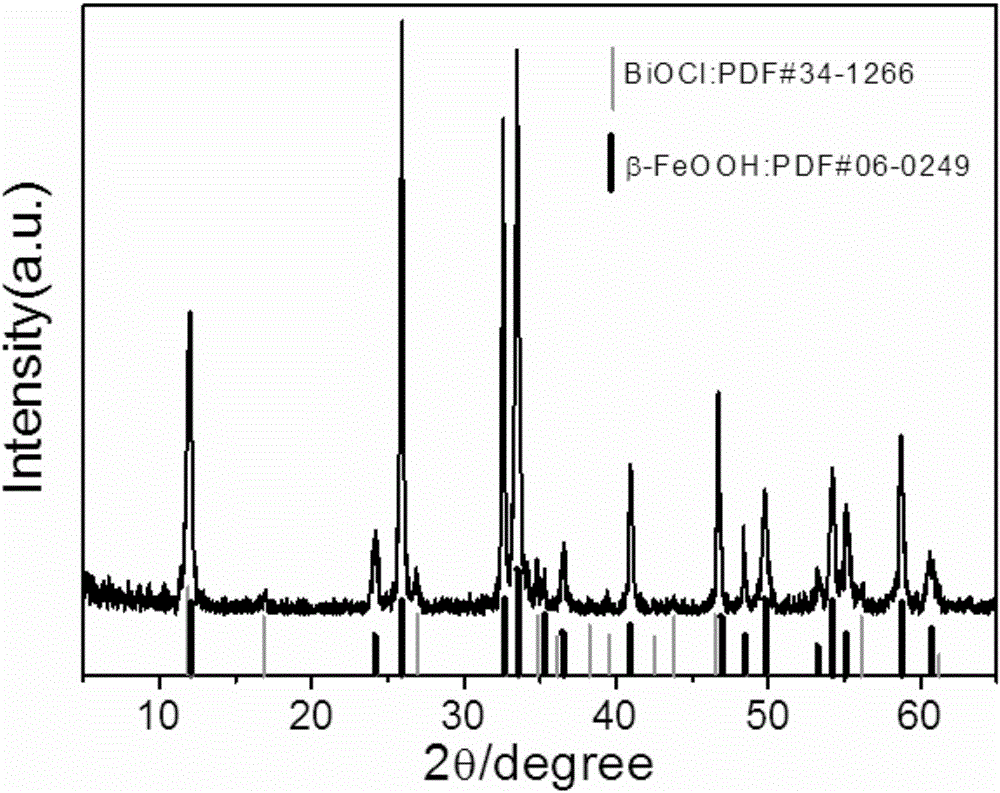

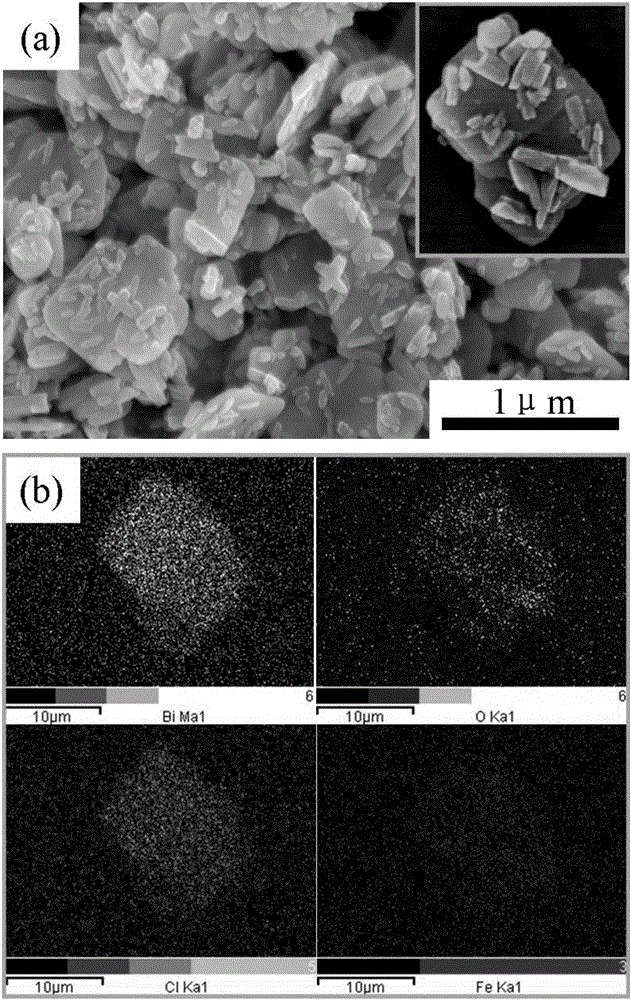

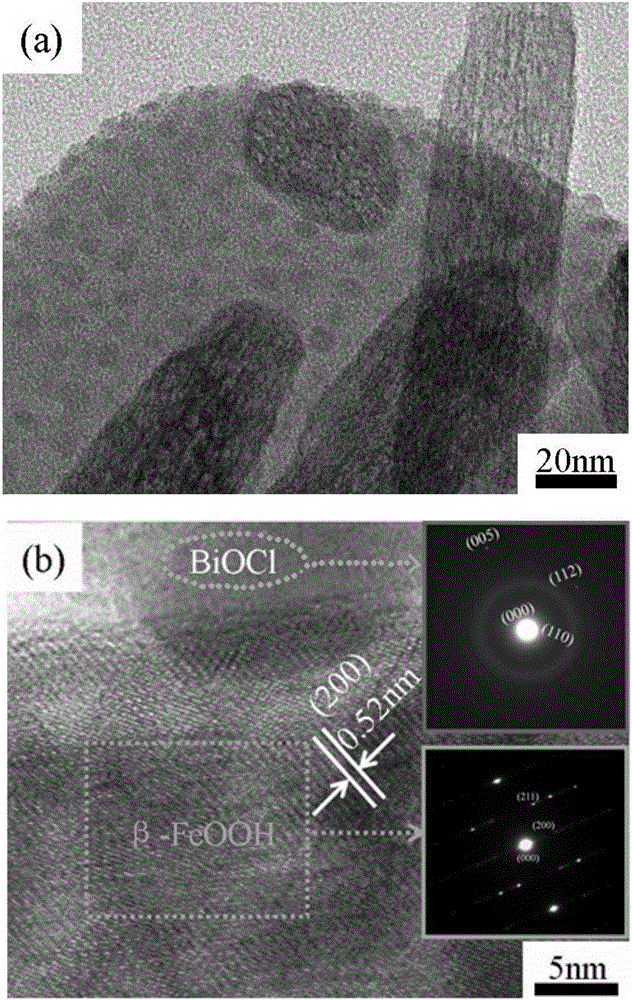

[0026] figure 1 It is the XRD spectrum pattern of the product obtained in Example 1. Comparing and analyzing all the XRD diffraction peaks of the product wit...

Embodiment 2

[0031] (1), the FeCl of 135g 3 ·6H 2 O was dissolved in 100 mL of distilled water, and magnetically stirred for 3 minutes at room temperature to fully dissolve it to obtain solution a.

[0032] (2), weigh 48.5g of Bi(NO 3 ) 3 ·5H 2 O was added to the above solution a, and magnetic stirring was continued for 1 minute to obtain solution b.

[0033] (3) Add 0.55 g of glucose into solution b, adjust the pH of the solution to 4 with HCl solution, and obtain solution c.

[0034] (4) Put the solution c into the reactor to carry out the hydrothermal synthesis reaction, the reaction time is 48 hours, and the reaction temperature is 80°C.

[0035] (5) After the reaction, the product was taken out, washed, centrifuged and dried to obtain the target product. The drying temperature was 80° C. and the drying time was 2 hours.

Embodiment 3

[0037] (1), the FeCl of 27g 3 ·6H 2 O was dissolved in 100 mL of distilled water, and magnetically stirred at room temperature for 1 minute to fully dissolve to obtain solution a.

[0038] (2), weigh 727.6g of Bi(NO 3 ) 3 ·5H 2 O was added to the above solution a, and magnetic stirring was continued for 3 minutes to obtain solution b.

[0039] (3) Add 0.85 g of glucose into solution b, adjust the pH of the solution to 6 with HCl solution, and obtain solution c.

[0040] (4) Put the solution c into the reactor to carry out the hydrothermal synthesis reaction, the reaction time is 36 hours, and the reaction temperature is 90°C.

[0041] (5) After the reaction, the product was taken out, washed, centrifuged and dried to obtain the target product. The drying temperature was 60° C. and the drying time was 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com