Preparation method of cobalt-oxygen-oxygen-hydrogen-modified phosphorus-doped iron oxide photo-anode

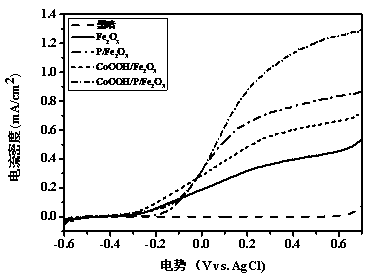

A technology of iron oxide light, cobalt oxygen oxygen hydrogen, applied in the direction of electrode, superimposed layer plating, coating, etc., can solve the problems of low flat band potential, short hole diffusion distance, slow oxygen evolution reaction kinetics, etc. To achieve the effect of conversion and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

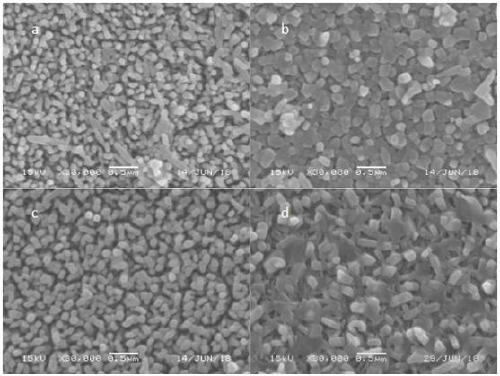

[0019] α-Fe 2 o 3 The preparation method of photoanode comprises the steps:

[0020] 1) The FTO was ultrasonically cleaned with isopropanol, acetone, ethanol and water in sequence. After the FTO was cleaned and dried, the back-to-back and vertical inner substrate surface (FTO's SnO 2 Facing the lining wall) placed on the PTFE lining. Add 0.81g FeCl to 20mL aqueous solution 3 •6H 2 O, and 1.69 g Na 2 NO 3 , stirred for 20min. The stirred solution was added into the polytetrafluoroethylene lining, and then the polytetrafluoroethylene lining was placed in an autoclave and sealed, and heated in a muffle furnace at 100° C. for 6 hours. After hydrothermal treatment, a light yellow translucent β-FeOOH film grew on the FTO, and the β-FeOOH film was washed with deionized water and air-dried.

[0021] 2) Put β-FeOOH in a muffle furnace for heat treatment. The heat treatment process is a two-step annealing method. First, the temperature is raised to 550°C for 2 hours, and then d...

specific Embodiment 2

[0022] P-Fe 2 o 3 The preparation method of photoanode comprises the steps:

[0023] 1) consistent with specific embodiment 1 step 1;

[0024] 2) Weigh 0.38g Na 3 PO 4 •12H 2 O and dissolved in 20mL deionized water, configured as a 0.05mol / L sodium phosphate solution, soaked the β-FeOOH prepared in step 1 in the sodium phosphate solution for 30s~480s, the results showed that the performance was optimal when the soaking time was 180s ;

[0025] 3) heat-treat the β-FeOOH after phosphorus treatment in step 2, and the heat treatment conditions are the same as step 2 in the specific example 1 to obtain phosphorus-doped iron oxide photoelectrode (P-Fe 2 o 3 ).

specific Embodiment 3

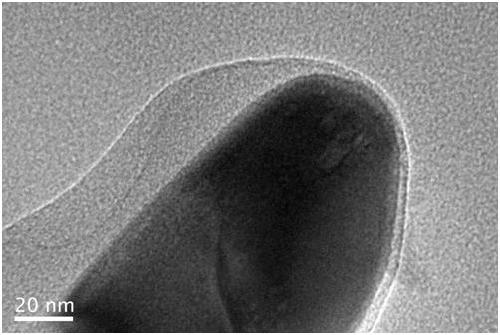

[0026] CoOOH-Fe 2 o 3 The preparation method of photoanode comprises the steps:

[0027] 1) Weigh 0.06g C 4 h 6 CoO 4 • 4H 2 O and dissolved in 25mL deionized water, configured as 0.01M cobalt acetate solution;

[0028] 2) Fe obtained in specific example 1 2 o 3 The photoanode is used as the working electrode, the platinum sheet electrode is used as the counter electrode, and the Ag / AgCl electrode is used as the reference electrode to form a three-electrode system. Using the cobalt acetate solution configured in step 1 as the electrolyte, under simulated sunlight (AM 1.5G, 100mWcm -2 ) for light-assisted electrodeposition with a deposition voltage of 0V (vs Ag / AgCl); 3) for a deposition time of 30s to 500s to obtain a cobalt oxyhydrogen modified iron oxide photoelectrode (CoOOH-Fe 2 o 3 ), the results show that the performance is optimal when the deposition time is 90s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com