Method for preparing Ge-doped alpha-phase iron trioxide nanosheet array membrane

A nano-sheet array and ferric oxide technology, which is applied in the field of preparation of α-phase ferric oxide nano-sheet array films, can solve the problems of dependence, expensive instruments and the like, and achieve the effects of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

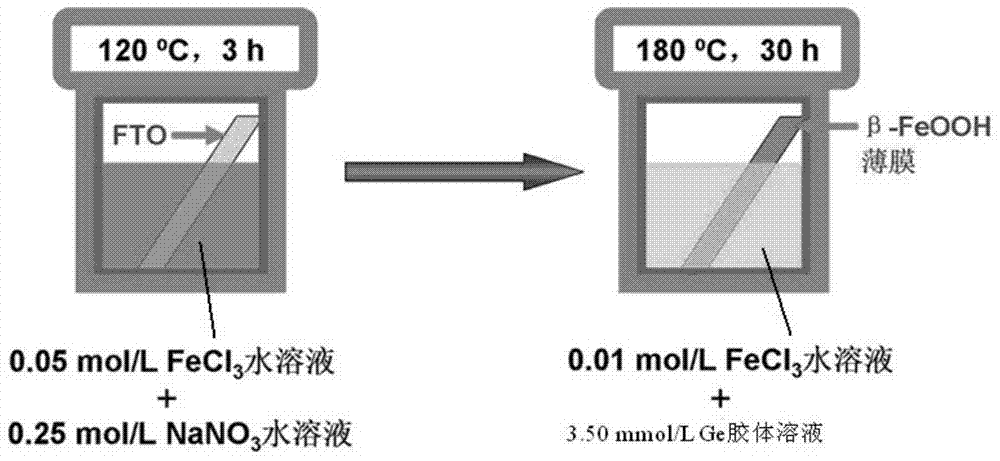

[0031] Such as figure 1 As shown, the β-FeOOH nanorod array film is firstly obtained by hydrothermal reaction, and then used as a template to provide Ge colloid solution with high reactivity as a doping precursor by using LAL technology. After hydrothermal treatment, it can conduct electricity in FTO. In situ construction of Ge-doped α-Fe on glass substrate 2 o 3 Nanosheet array films. Ge-doped α-Fe 2 o 3 The doping concentration of the nanosheet array thin film depends on the concentration of Ge colloidal solution added, and the thickness of the thin film can be controlled by the thickness of the β-FeOOH template, and the relationship between the two is proportional.

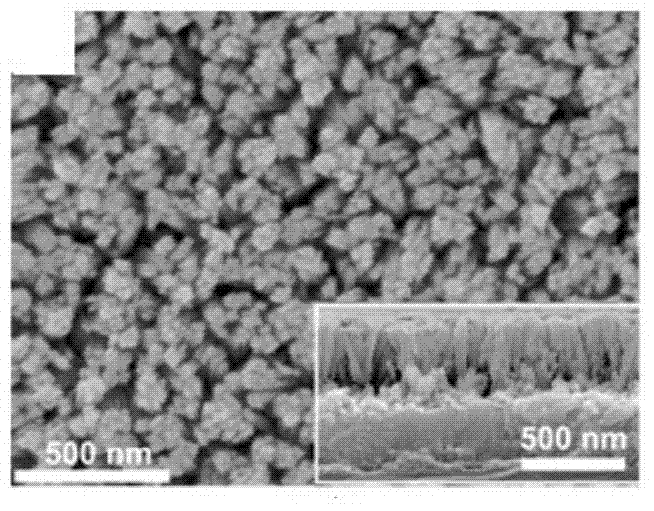

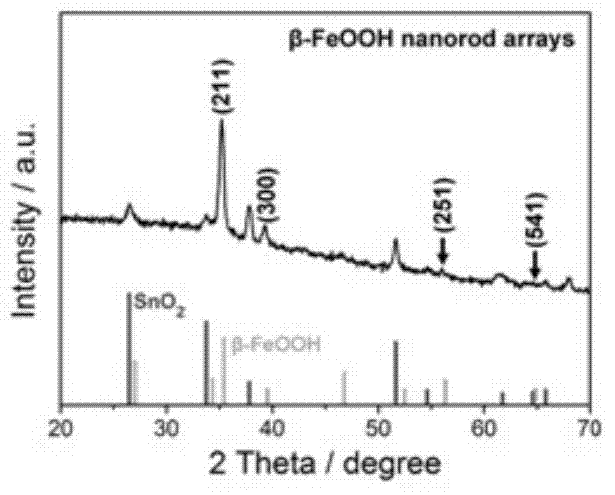

[0032] Figure 2a It is the SEM photo of the obtained β-FeOOH nanorod array. From the top view, it can be clearly seen that β-FeOOH is composed of a large number of dense nanorod arrays. Figure 2a The inset in the lower right corner of the center is a side SEM photo of the β-FeOOH nanorod array, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com