Ferroferric oxide and zinc oxide nuclear shell nano-rod for absorbing high-frequency electromagnetic waves and manufacturing method thereof

A technology of ferroferric oxide and nanorods, which is applied in the field of nanomaterials, can solve problems such as coating thickness, and achieve the effect of simple operation and low thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

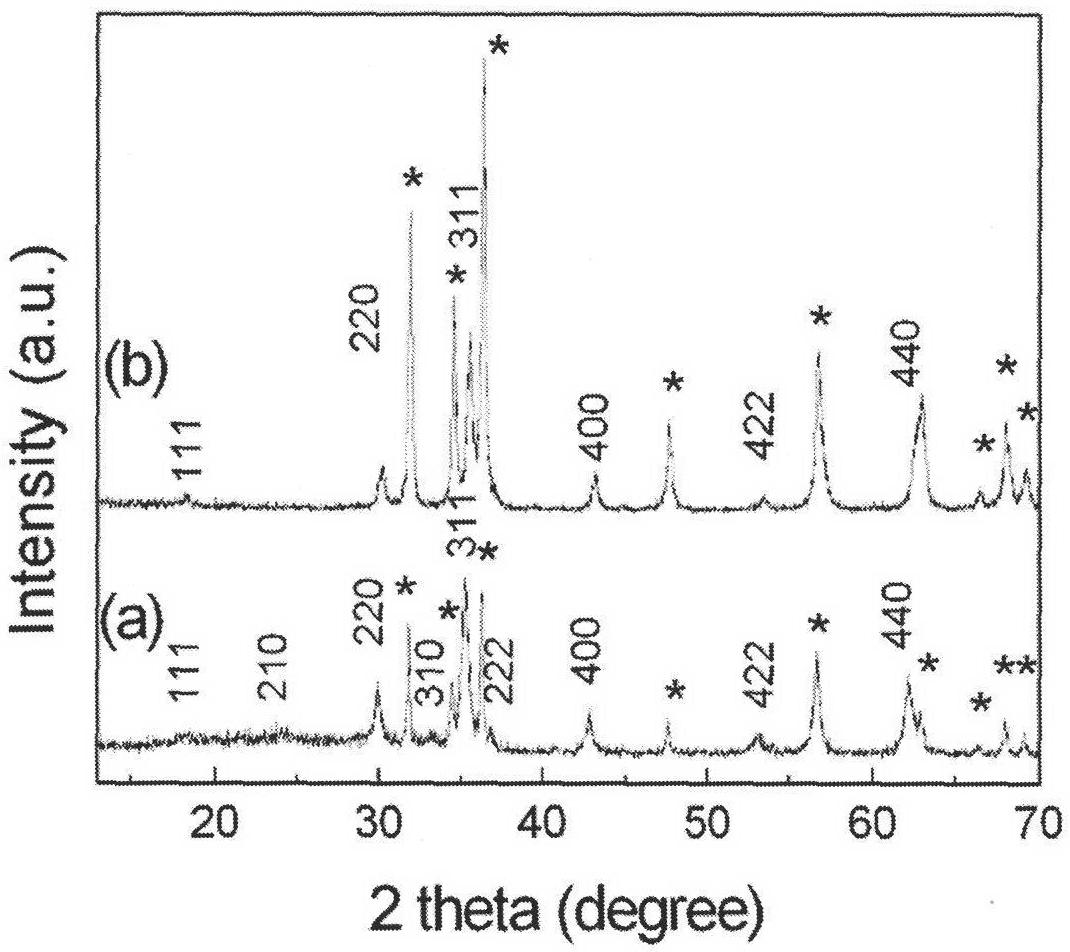

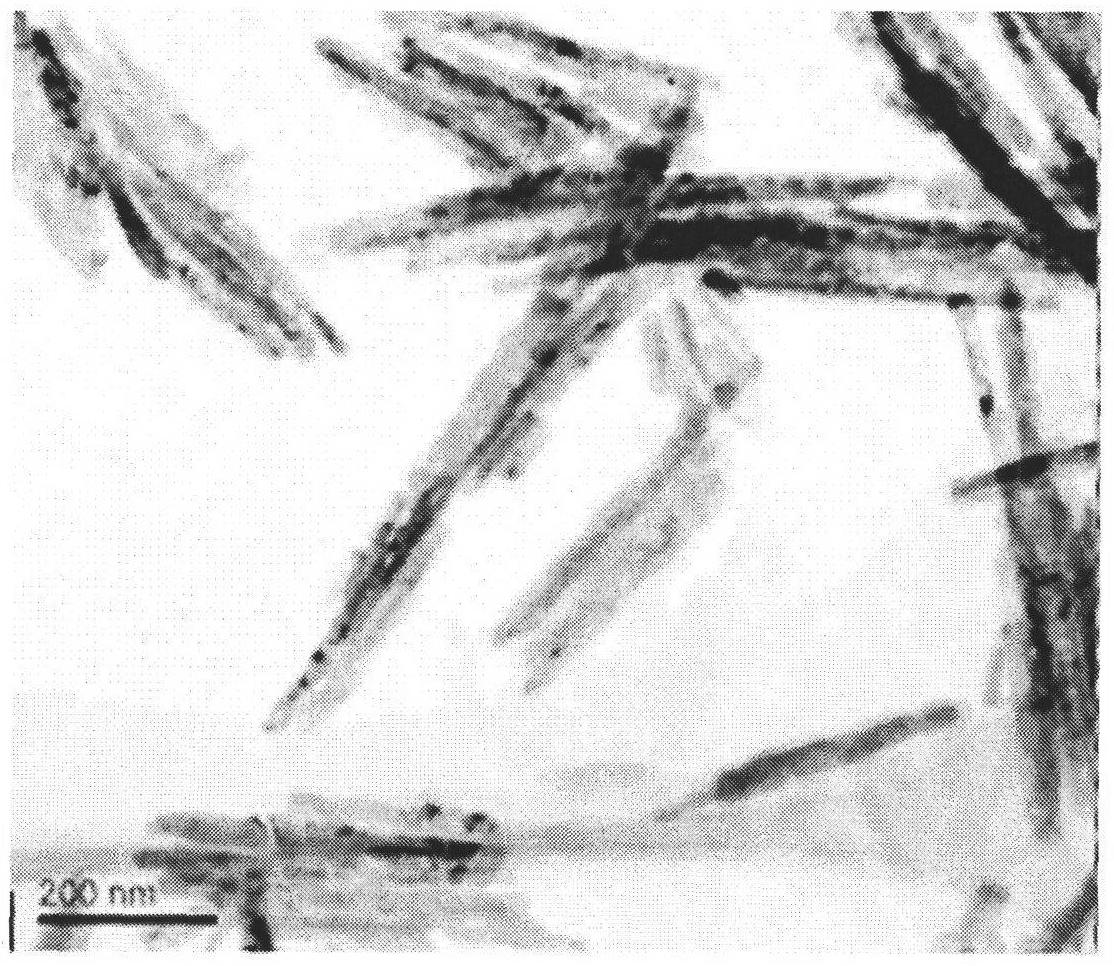

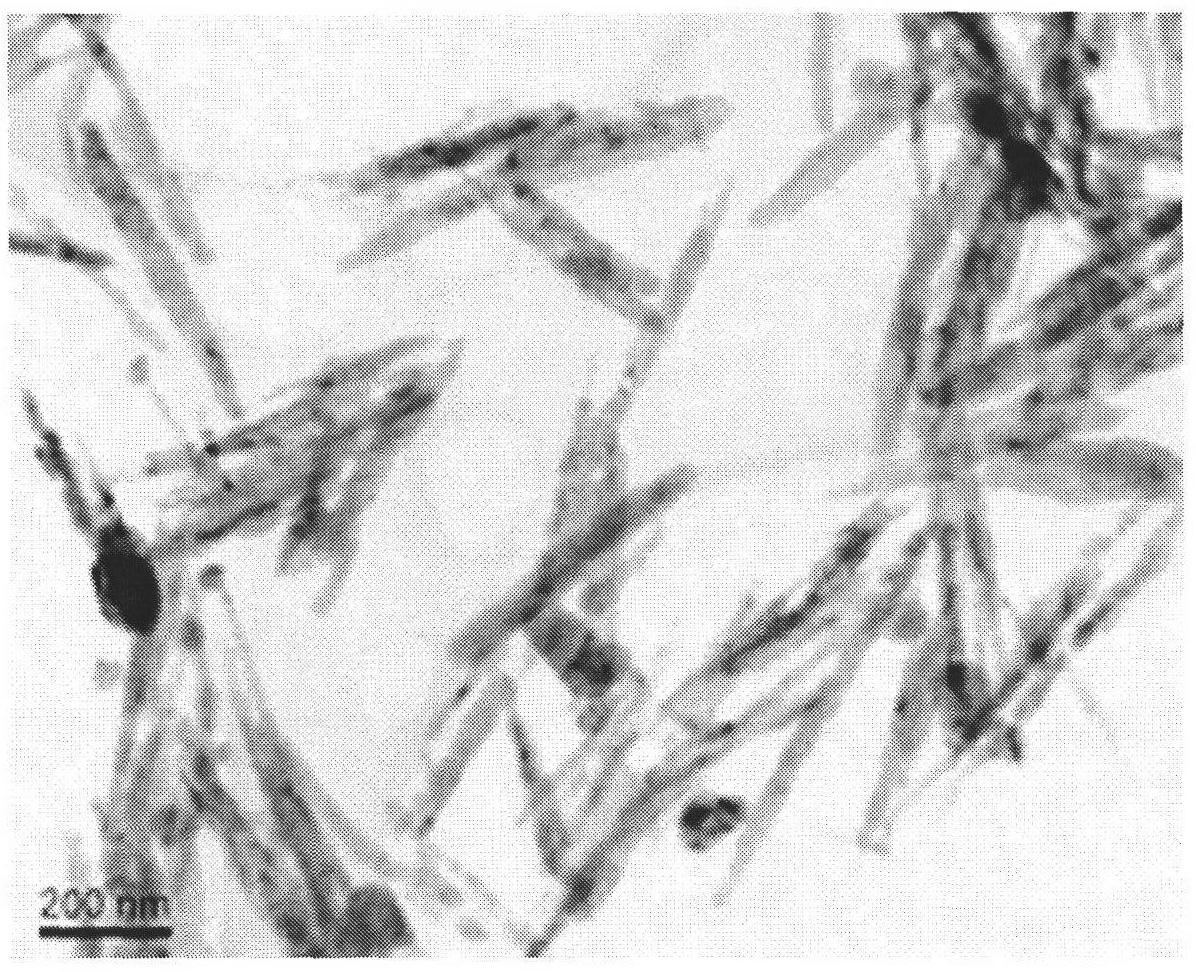

[0018] (1) Add 0.25-1.0mol / L FeCl 3 The solution was placed in a stainless steel sealed autoclave, and kept in an oven at 110°C for 12 hours. After the autoclave was naturally cooled to room temperature, the precipitate in the autoclave was washed with water and ethanol, and dried at 80°C to obtain β-FeOOH nanorods ;

[0019] (2) Ultrasonic dispersion of 0.05g β-FeOOH nanorods into 15ml ethylenediamine (0.15mol L -1 ) aqueous solution, then add 15ml of 0.1mol·L -1 Zn(AC) 2 After stirring the aqueous solution for 15 minutes, the mixed solution was poured into a sealed stainless steel autoclave liner, and the autoclave was put into an oven at 120° C. for 12 hours. After the autoclave was naturally cooled to room temperature, the precipitate in the autoclave was washed with water and ethanol and dried in the air, then annealed at 500°C for 3 hours, and the obtained powder was mixed with ethylenediamine aqueous solution and Zn(AC) 2 The second treatment in aqueous solution, fi...

Embodiment 2

[0022] (1) Add 0.25-1.0mol / L FeCl 3 The solution was placed in a stainless steel sealed autoclave, and kept in an oven at 100°C for 12 hours. After the autoclave was naturally cooled to room temperature, the precipitate in the autoclave was washed with water and ethanol, and dried at 80°C to obtain β-FeOOH nanorods ;

[0023] (2) Ultrasonic dispersion of 0.05g β-FeOOH nanorods into 15ml ethylenediamine (0.15mol L -1 ) aqueous solution, then add 15ml of 0.1mol·L -1 Zn(AC) 2 After stirring the aqueous solution for 15 minutes, the mixed solution was poured into a sealed stainless steel autoclave liner, and the autoclave was put into an oven at 120° C. for 12 hours. After the autoclave was naturally cooled to room temperature, the precipitate in the autoclave was washed with water and ethanol and dried in the air, then annealed at 500°C for 3 hours, and the obtained powder was mixed with ethylenediamine aqueous solution and Zn(AC) 2 The second treatment in aqueous solution, fi...

Embodiment 3

[0026](1) Add 0.25-1.0mol / L FeCl 3 The solution was placed in a stainless steel sealed autoclave, and kept in an oven at 120°C for 12 hours. After the autoclave was naturally cooled to room temperature, the precipitate in the autoclave was washed with water and ethanol, and dried at 80°C to obtain β-FeOOH nanorods ;

[0027] (2) Ultrasonic dispersion of 0.05g β-FeOOH nanorods into 15ml ethylenediamine (0.15mol L -1 ) aqueous solution, then add 15ml of 0.1mol·L -1 Zn(AC) 2 After stirring the aqueous solution for 15 minutes, the mixed solution was poured into a sealed stainless steel autoclave liner, and the autoclave was put into an oven at 120° C. for 12 hours. After the autoclave was naturally cooled to room temperature, the precipitate in the autoclave was washed with water and ethanol and dried in the air, then annealed at 500°C for 3 hours, and the obtained powder was mixed with ethylenediamine aqueous solution and Zn(AC) 2 The second treatment in aqueous solution, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com