Infrared absorbing fine particle-containing masterbatch pulverized product, dispersion containing infrared absorbing fine particle-containing masterbatch pulverized product, infrared absorbing fine particle-containing ink, anti-counterfeiting ink employing same, anti-counterfeiting print film, and method for manufacturing infrared absorbing fine particle-containing masterbatch pulverized product

A manufacturing method and technology of absorbing materials, applied in the printing, ink, and printing of special types of printed matter, can solve the problems of insufficient infrared absorption characteristics and insufficient functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0269] Dissolve cesium carbonate (Cs 2 CO 3 )7.43kg to obtain a solution. This solution was added to tungstic acid (H 2 WO 4 ) 34.57kg, after fully stirring and mixing, dry while stirring (corresponding to the molar ratio of W and Cs 1:0.33). One side is supplied with N 2 The gas is 5 volume % H of the carrier gas 2 While heating the dried product, it was fired at 800°C for 5.5 hours. Then, replace this supply gas with only N 2 gas, cooled to room temperature to obtain cesium tungsten oxide particles.

[0270] 20% by mass of cesium tungsten oxide particles, 75 parts by weight of toluene, and 5 parts by weight of polyacrylate polymer resin (hereinafter referred to as "resin a" in this embodiment and comparative examples) were mixed to prepare 30kg slurry. This slurry was added to a media agitation mill together with balls, and pulverization and dispersion treatment was performed for 10 hours. In addition, the media agitation mill used the horizontal cylindrical ring t...

Embodiment 2、3

[0282] Except that polyethylene resin or acrylic resin was used instead of polypropylene resin, the same procedure as in Example 1 was carried out to obtain the infrared-absorbing particle dispersions, powders in which infrared-absorbing particles were dispersed, and infrared-absorbing particles containing Fine particle masterbatch pulverization, anti-counterfeiting ink, printing film for anti-counterfeiting.

[0283] The same evaluation as in Example 1 was performed on the infrared-absorbing fine particle dispersion liquid, the masterbatch pulverized product containing infrared-absorbing fine particles, and the anti-counterfeiting printed film of Examples 2 and 3.

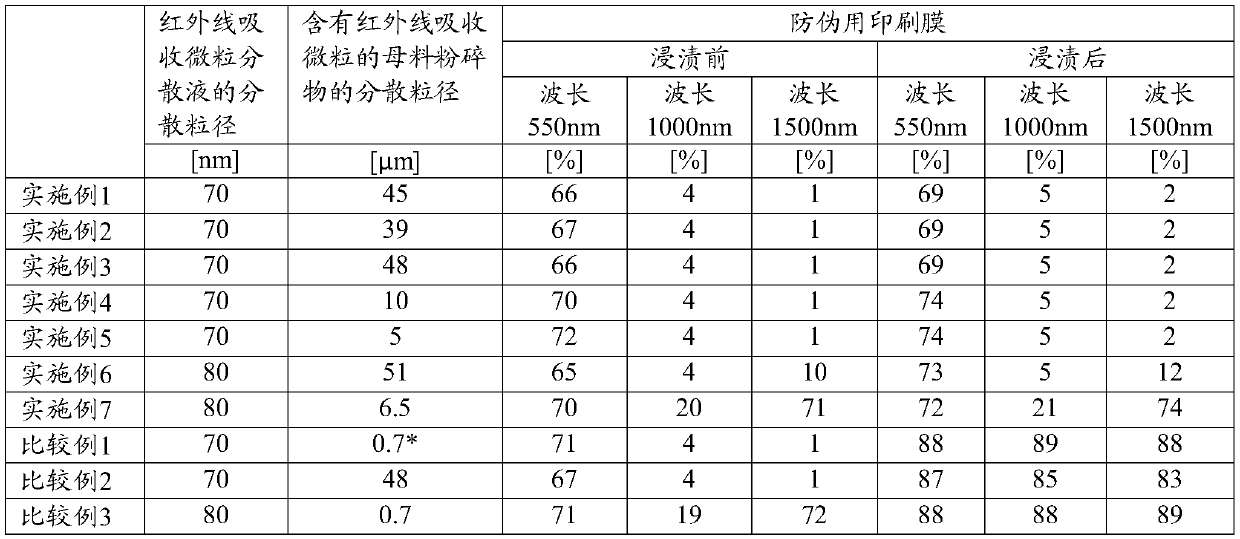

[0284] The manufacturing conditions and evaluation results are shown in Tables 1 and 2.

Embodiment 4

[0286] When pulverizing the masterbatch containing infrared-absorbing microparticles, a jet-grinding pulverizer was used instead of a hammer mill. In the same manner as in Example 1, the powder in which infrared-absorbing microparticles were dispersed in Example 4, containing Crushed masterbatch of infrared absorbing particles, anti-counterfeiting inks, printing films for anti-counterfeiting.

[0287] The same evaluation as in Example 1 was performed on the infrared-absorbing fine particle dispersion liquid, the masterbatch pulverized product containing infrared-absorbing fine particles, and the anti-counterfeiting printing film of Example 4.

[0288] The manufacturing conditions and evaluation results are shown in Tables 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com