Patents

Literature

149results about How to "Save on rental costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

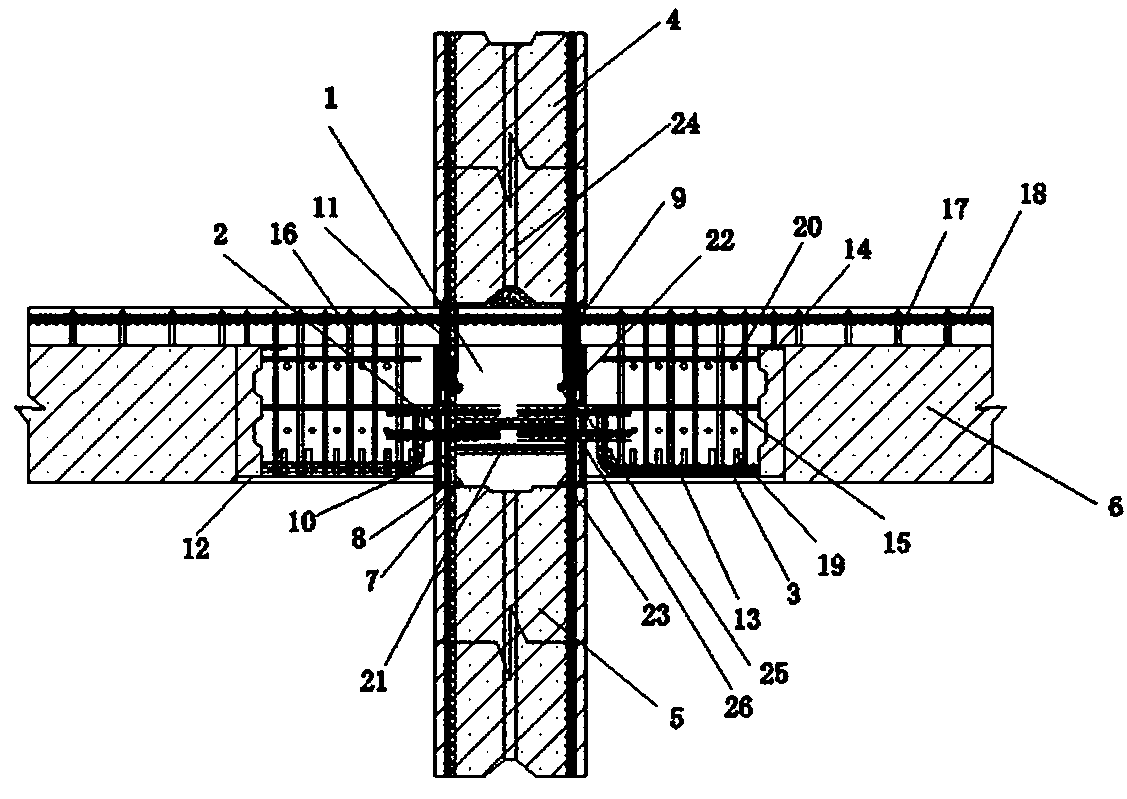

Extra-large fiber reinforced plastic (FRP) combined storage tank structure with floating roof, and construction method of storage tank structure

InactiveCN102877679AAids in lateral stabilityInsensitive to temperature changesBulk storage containerFiberPre stress

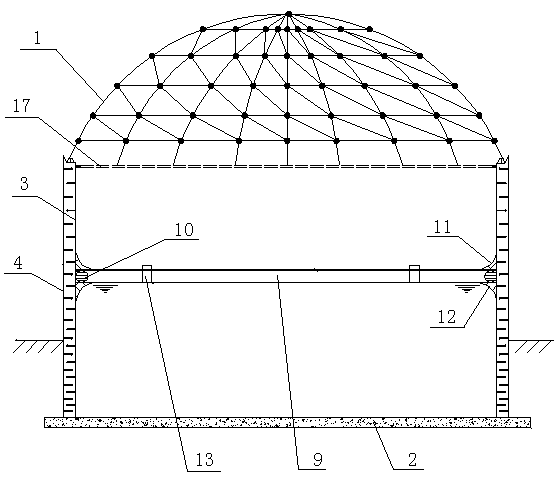

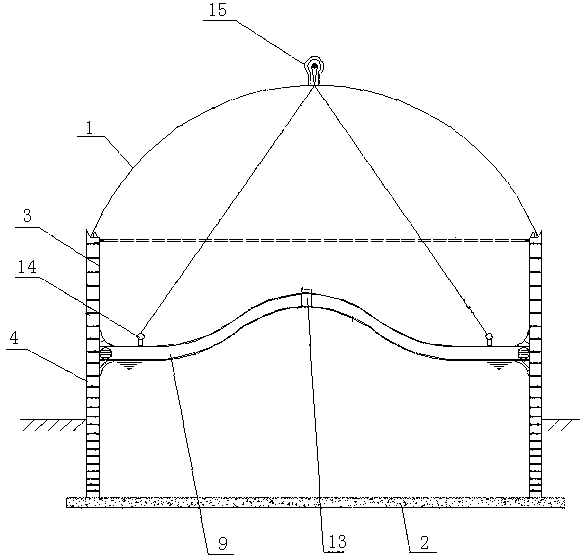

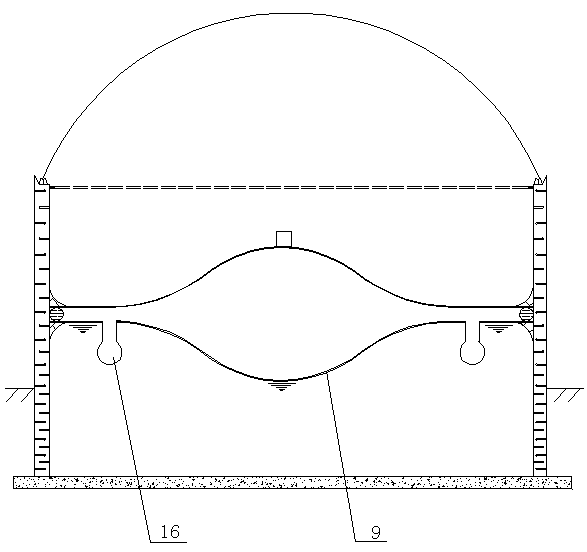

The invention relates to an extra-large fiber reinforced plastic (FRP) combined storage tank structure with a floating roof, and a construction method of the storage tank structure. The extra-large FRP combined storage tank structure comprises a tank top, a tank wall and a tank bottom, wherein the tank top has an FRP latticed shell structure; FRP plates are laid on the FRP latticed shell structure; the tank wall is composed of an inner layer FRP plate, an outer layer FRP plate and active powder concrete between the inner layer FRP plate and the outer layer FRP plate; the floating roof is arranged in the tank cover; a connection piece is arranged between the inner layer FRP plate and the outer layer FRP plate; concrete trapezoid grooves are sequentially formed between the inner layer FRP plate and the outer layer FRP plate along a circumferential direction; prestress bars are pulled between every two adjacent concrete trapezoid grooves section by section; and the inner layer FRP plate and the outer layer FRP plate are formed by connecting FRP spliced plates through tenon tongues and tenon grooves. The extra-large FRP combined storage tank structure is high in corrosion resistance and freezing resistance, insensitive to temperature change, low in heat transmission speed, favorable for keeping temperature in a tank body, high in compression strength, high in corrosion resistance and relatively high anti-permeability.

Owner:NORTHEAST GASOLINEEUM UNIV

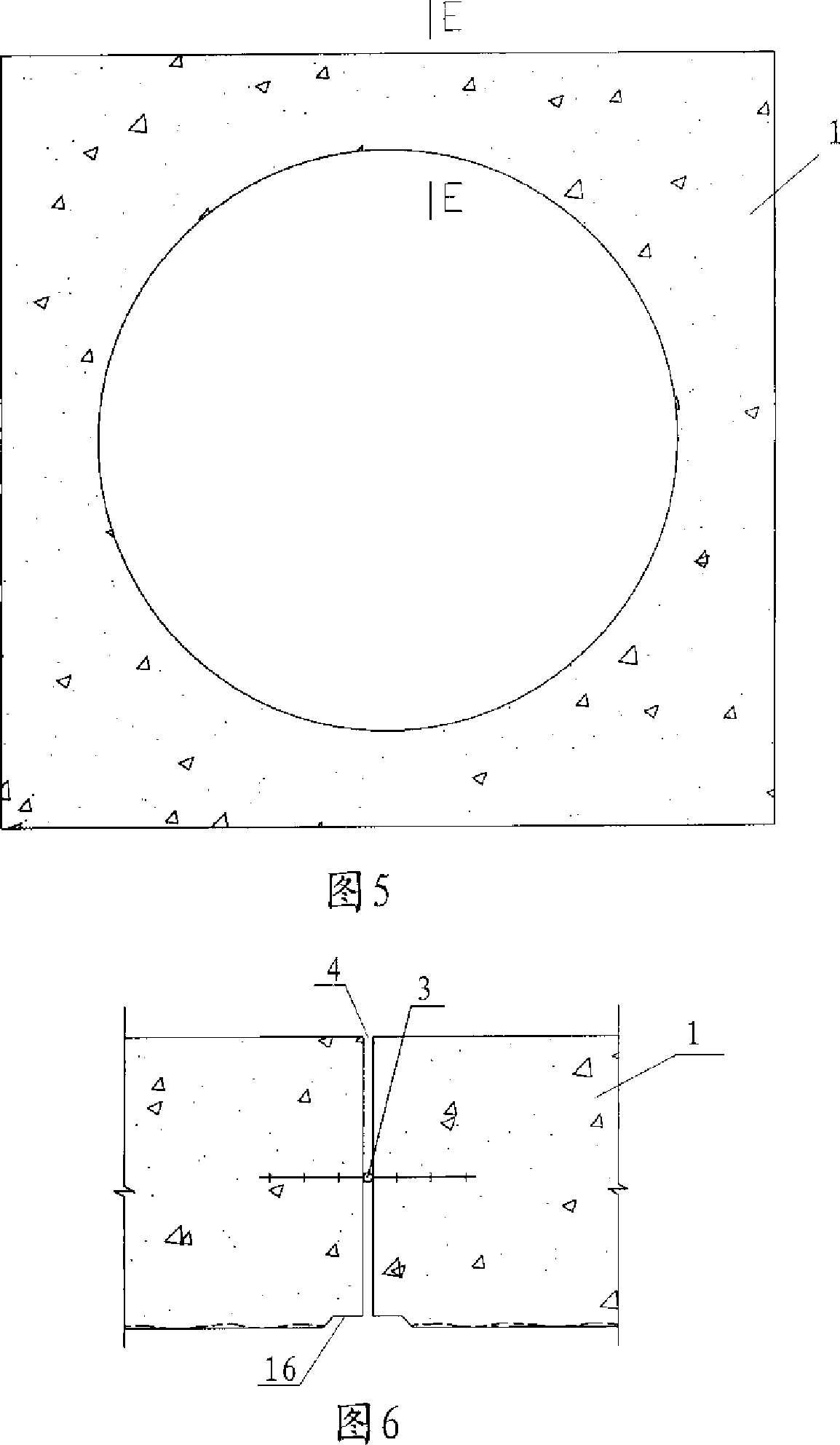

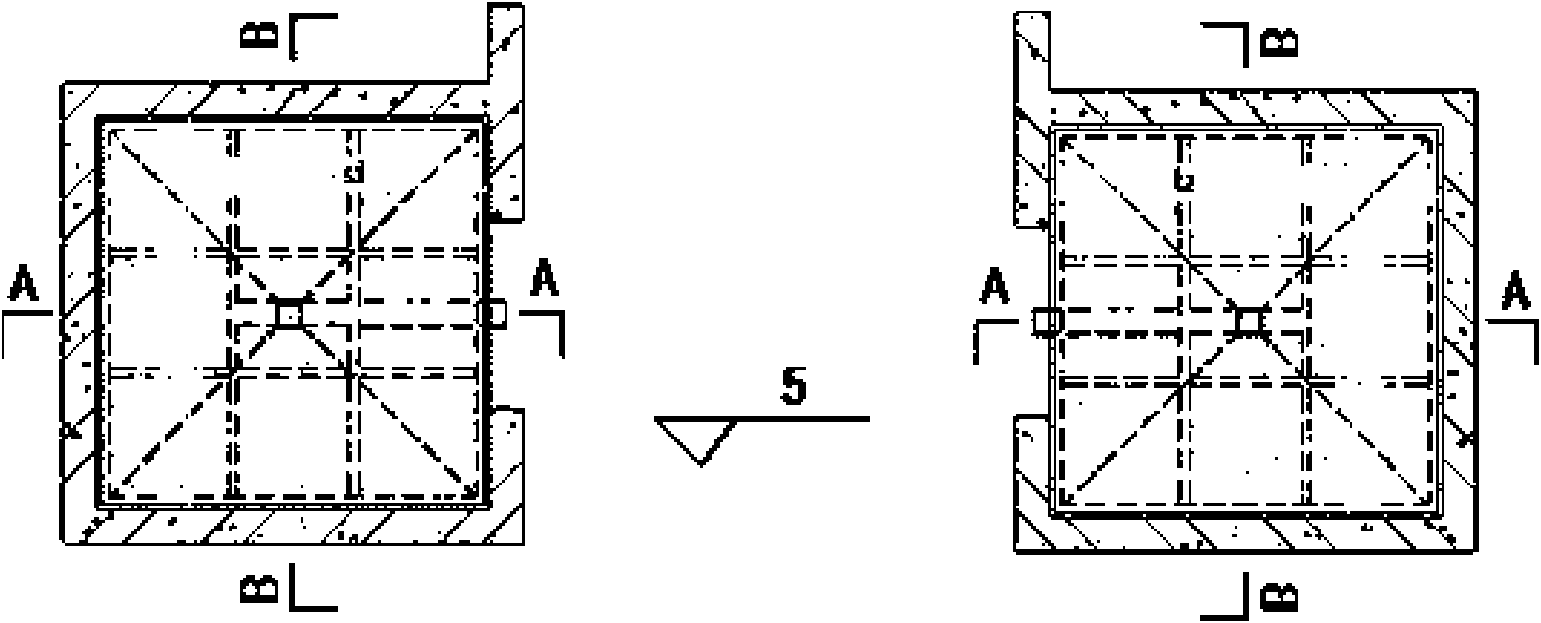

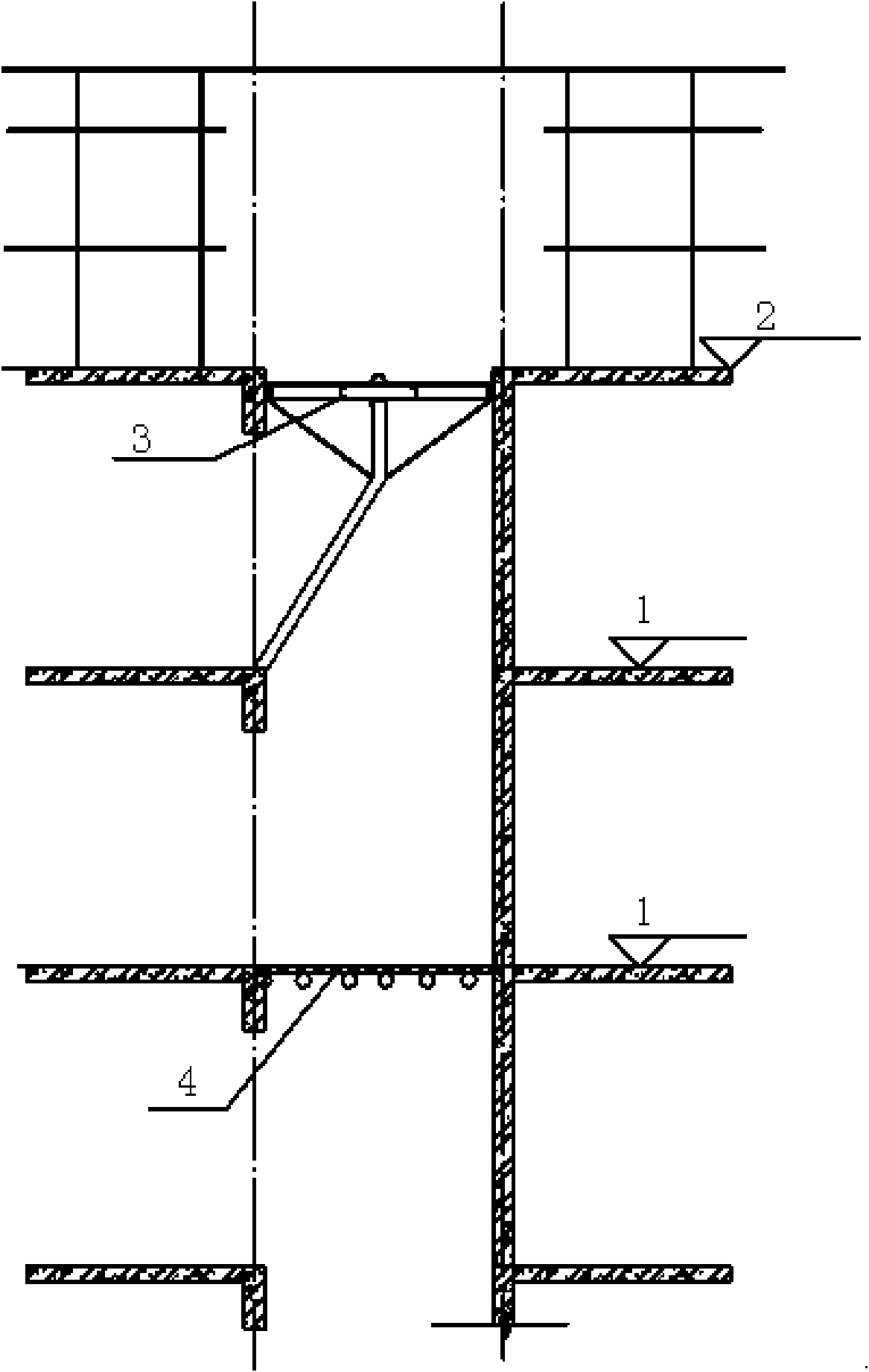

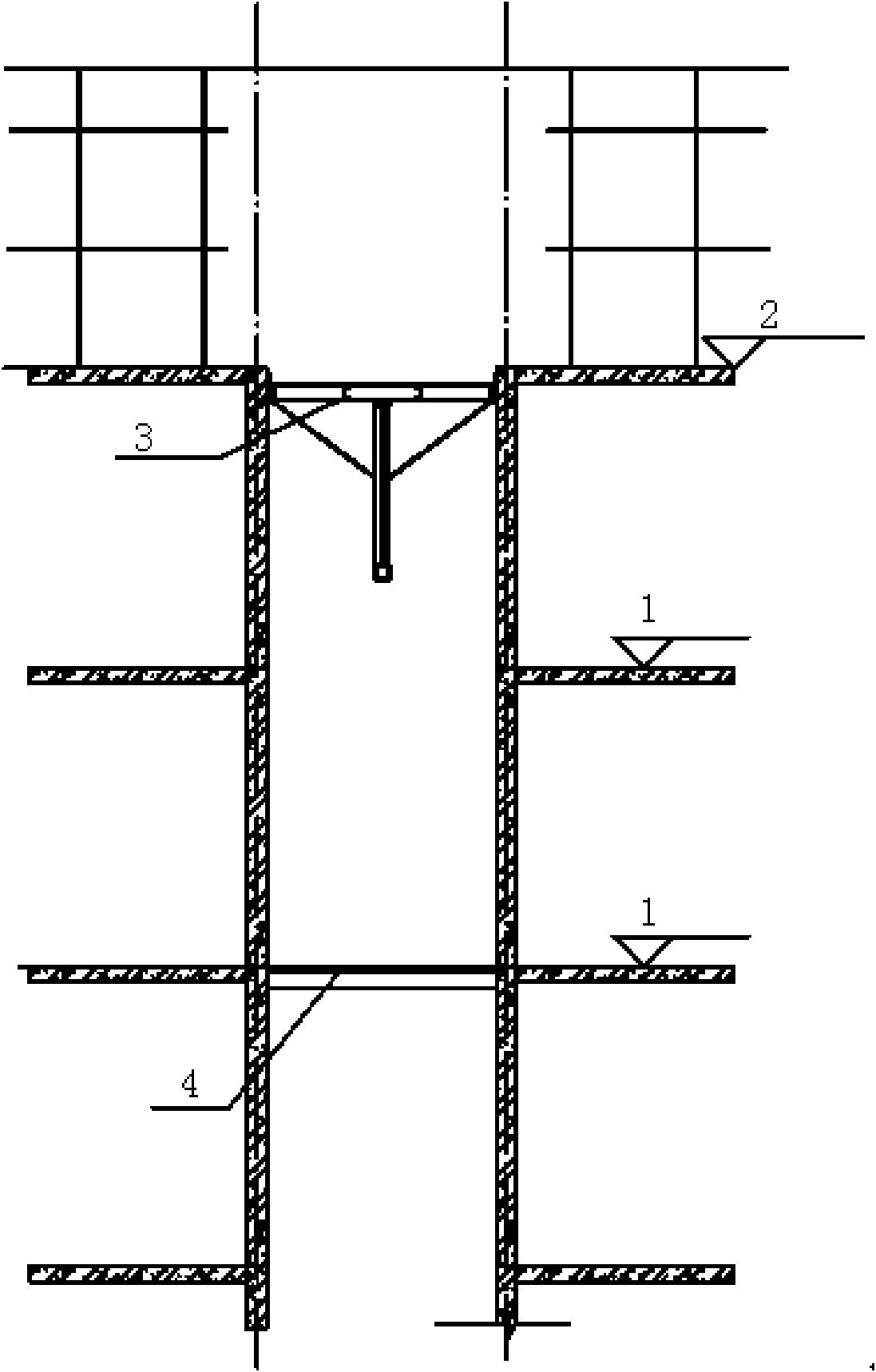

Construction method of cone-shaped top structure of large silo

ActiveCN104100122AShorten the total construction periodSave man hoursBulk storage containerEngineeringForming processes

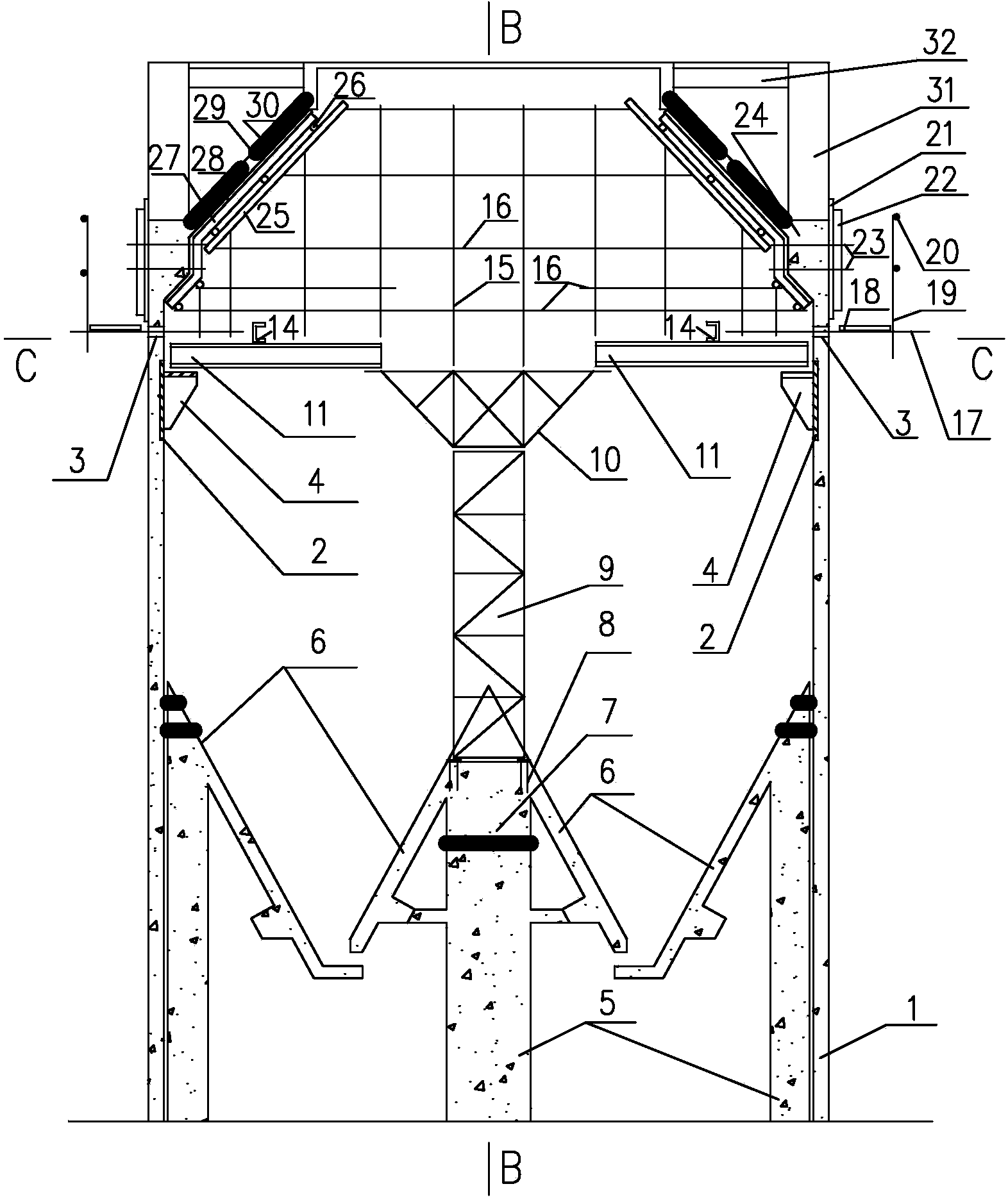

The invention provides a construction method of a cone-shaped top structure of a large silo. The construction method comprises the steps of burying embedded parts in the inner wall of the silo wall at the height close to the silo top in the slip form process of the silo wall of the large silo, forming reserved holes in the silo wall above the embedded parts, welding steel corbels on the embedded parts, and then constructing a concrete column, a funnel board and a column top beam in the silo, and burying a foundation bolt in the top of the concrete column, building a scaffold supporting platform on the steel corbels, arranging a silo top formwork support frame on the scaffold supporting platform, and then arranging a cone-shaped shell concrete structure supporting system of the silo top on the silo top formwork support frame, and finally, carrying out pouring. The construction method of the cone-shaped top structure of the large silo is capable of reducing the construction cost and increasing the construction progress, and the construction process is safer and more convenient.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

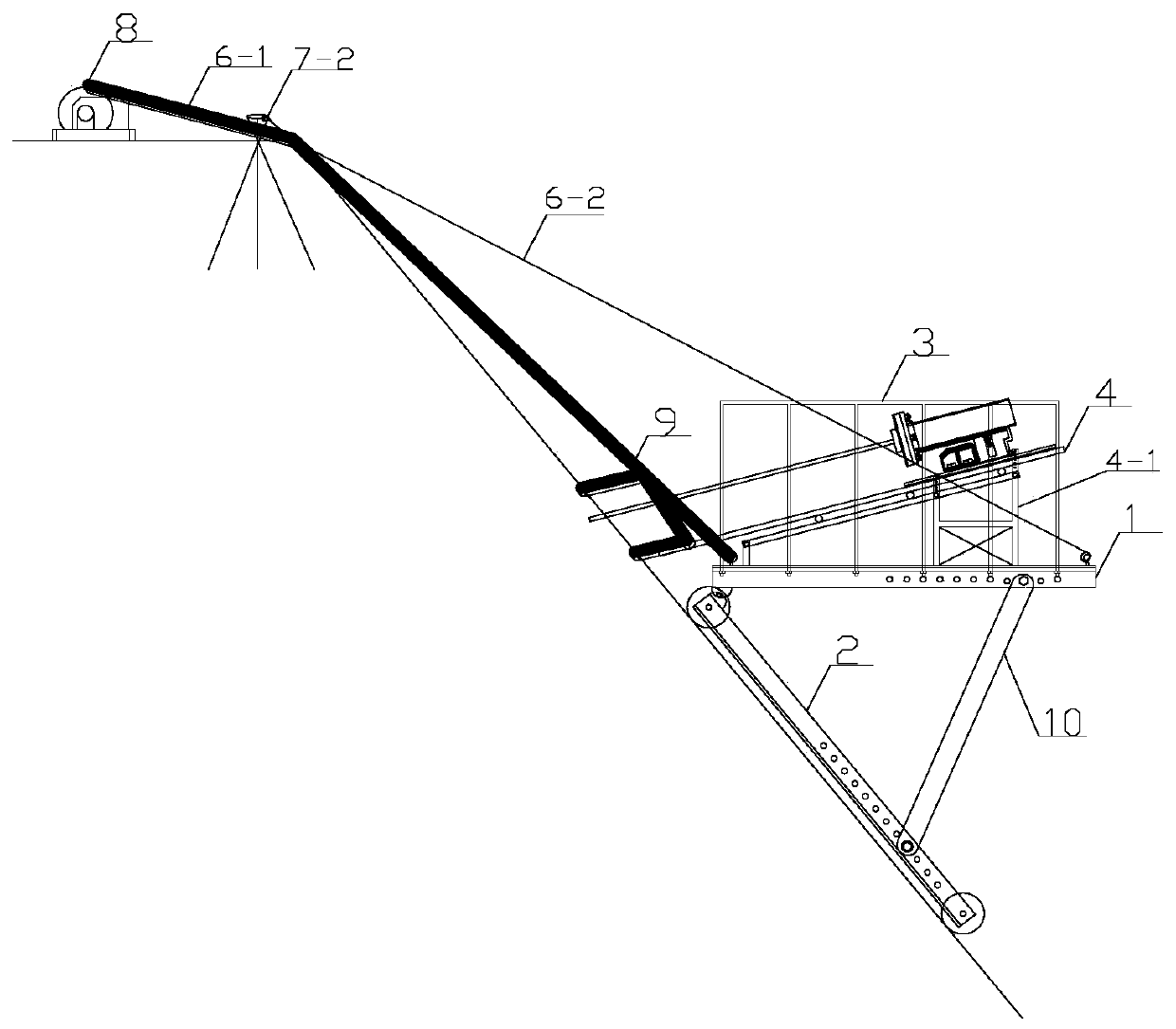

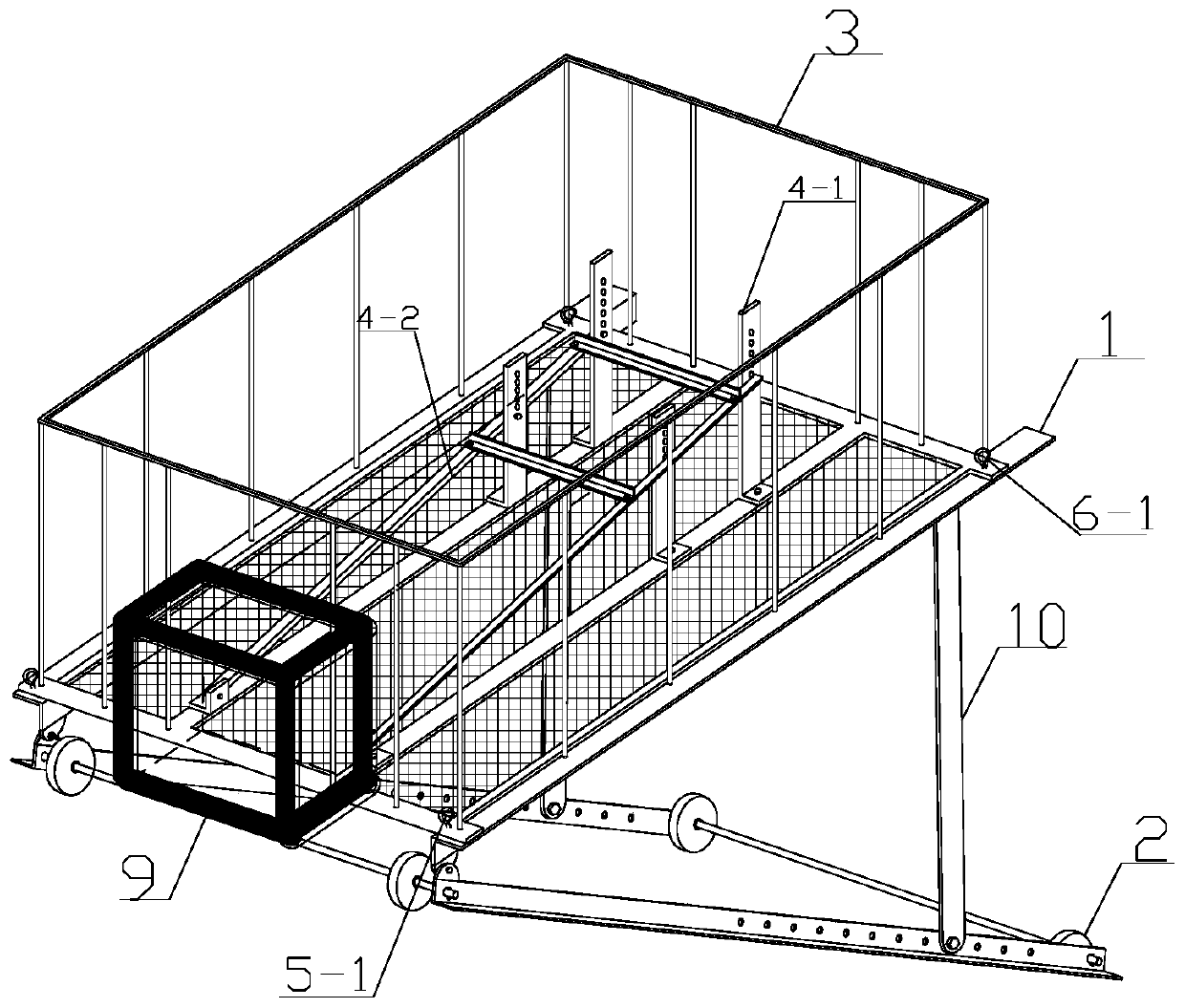

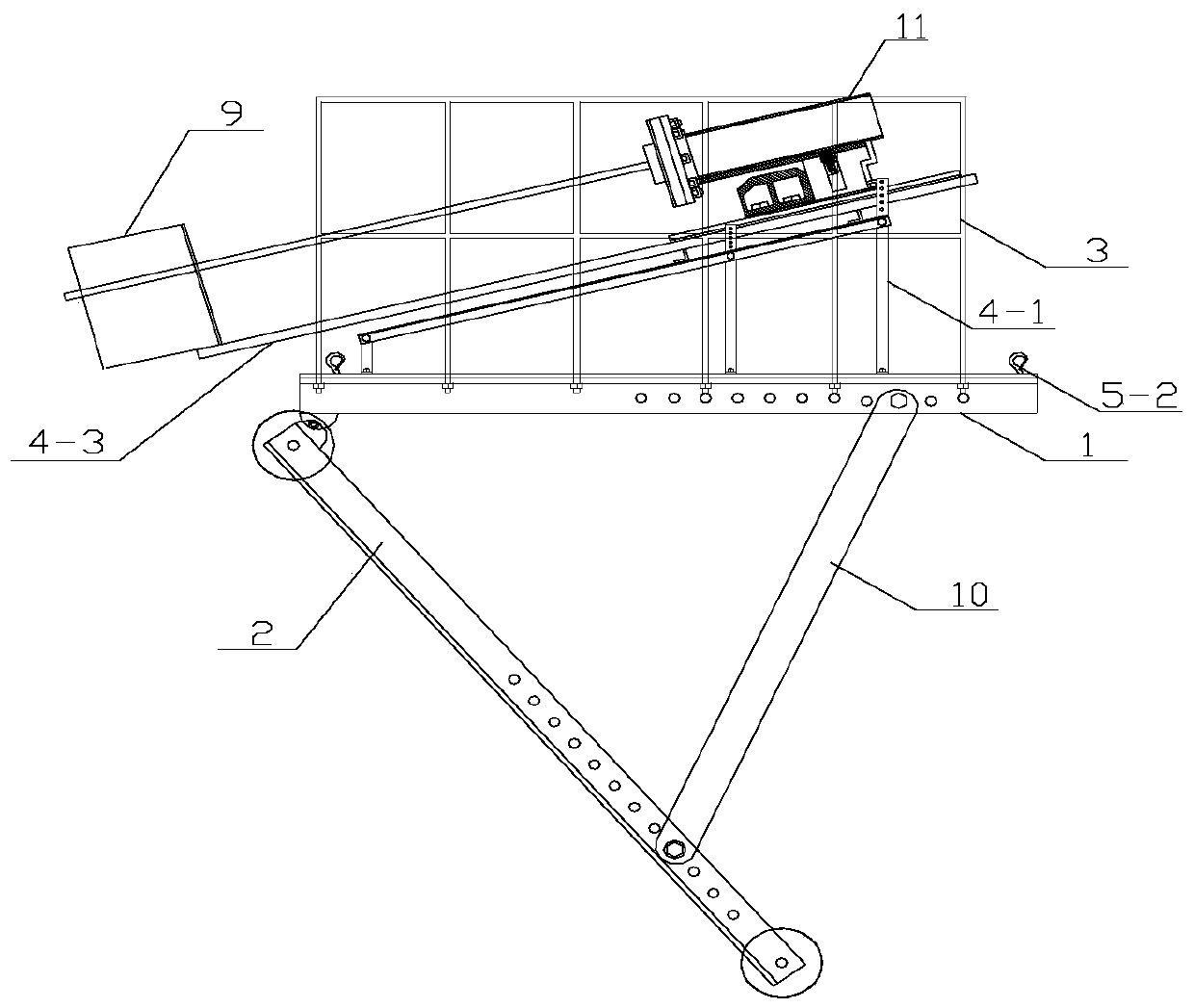

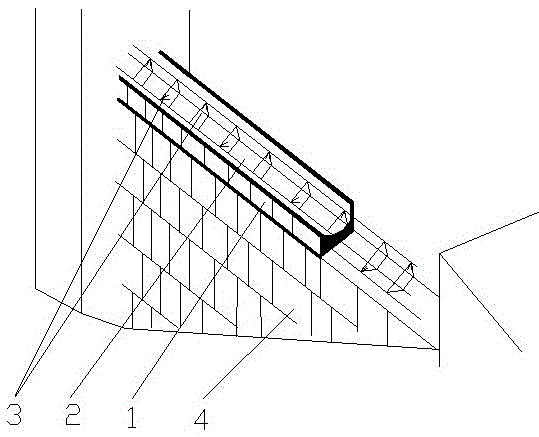

Operating platform for high slope anchor rod support construction

The invention discloses an operation platform for high slope anchor rod support construction. The operation platform comprises a mobile operation platform, wherein the mobile operation platform is provided with a horizontal operation platform and a slope walking trolley fixedly connected with the horizontal operation platform; a safety enclosure structure is arranged around the horizontal operation platform; a drill supporting frame is fixed on the horizontal operation platform, an anchor rod drill is installed on the drill supporting frame, and a guide rail of the anchor rod drill is fixed onthe drill supporting frame through a detachable connecting structure; a traction hook is arranged at the front end of the horizontal operation platform, and the traction hook is connected with a winch arranged at the top of the slope through a traction steel wire rope; and a safety hook is arranged at the rear end of the horizontal operation platform, and the safety hook is connected with an anchoring structure arranged at the top of the slope through a safety steel wire rope. According to the operation platform, the construction cost can be reduced, the construction safety can be ensured, the hole forming efficiency can be improved, the hole forming quality can be ensured conveniently, and the green and environmental protection construction concept can be implemented.

Owner:中建六局第一建设有限公司

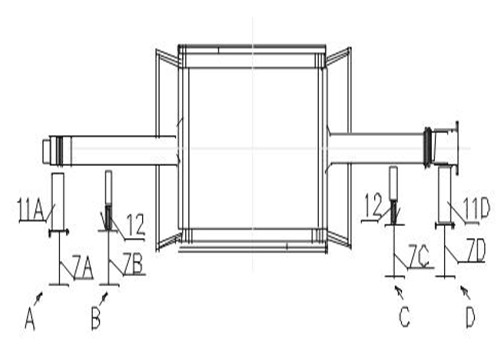

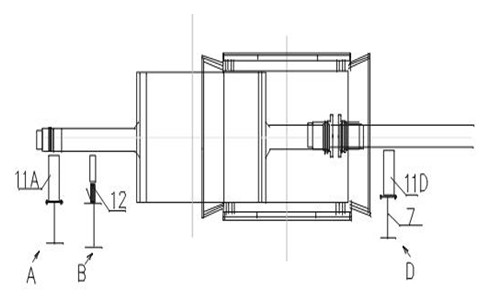

Core pulling and threading method for overhauling of large motor

ActiveCN102306979AAvoid damageNo dumping accidentsManufacturing dynamo-electric machinesEffective solutionNuclear engineering

The invention provides a core pulling and threading method for overhauling of a large motor, belonging to the technical field of the overhauling of the large motors. The method provided by the invention mainly comprises: preparing for core pulling: gantry processing and manufacturing, slideway laying and hoist placing; removing auxiliary devices, such as a bearing seat; pulling a core; overhauling for exfactory; and threading the core for recovery. According to the invention, the tonnage restriction on the core pulling and threading when a manual hoist is used for listing to cooperate with the moving of the gantry in the prior art is overcome effectively, the operation situation with small space is eliminated effectively, the core pulling and threading cost is lowered, the overhauling cycle is shortened greatly, and an effective solution is provided for the core pulling and threading of the large motor in a small plant. The method provided by the invention has the characteristics of capability of lead operation, safety and reliability and high economic benefit.

Owner:CHINA MCC17 GRP

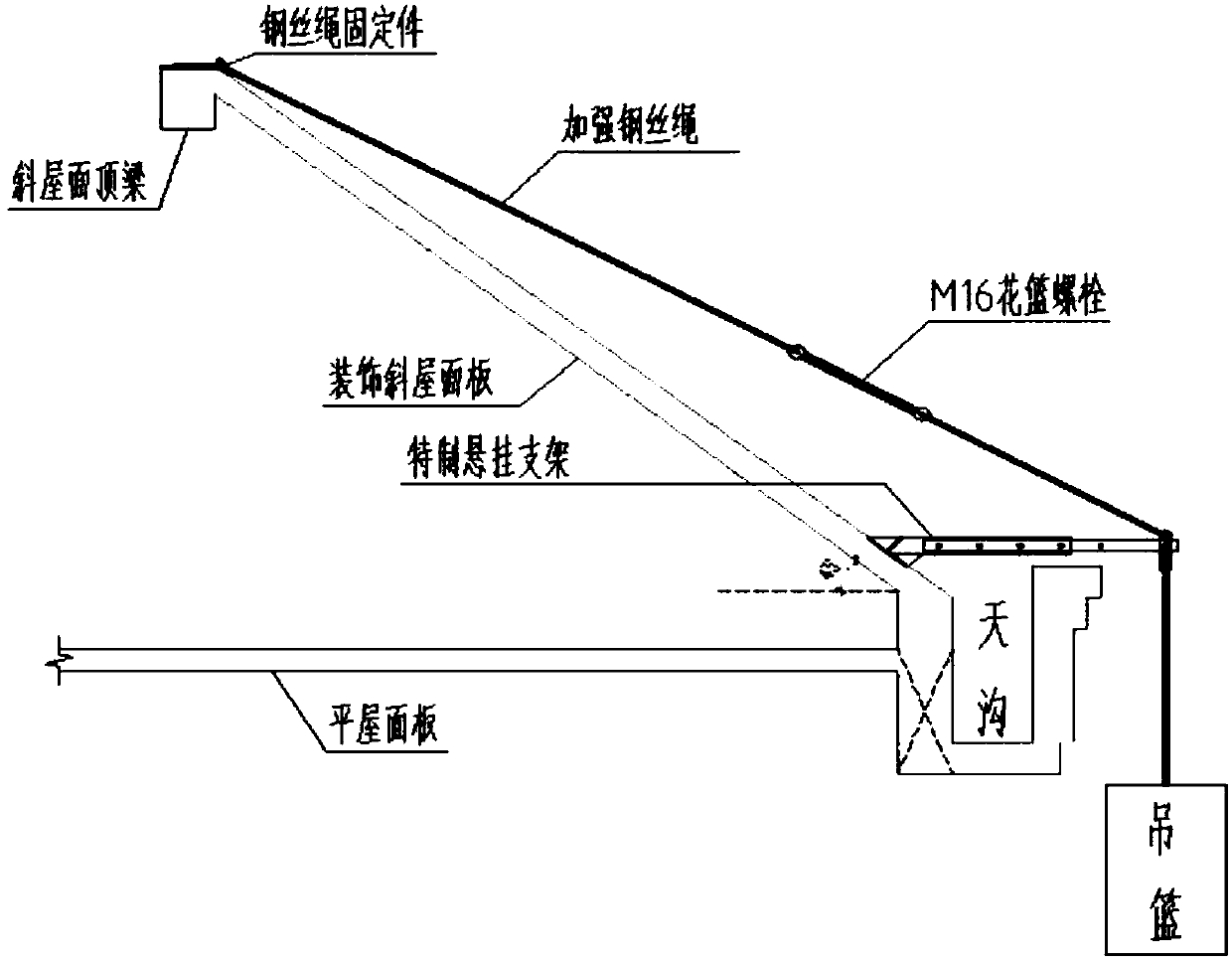

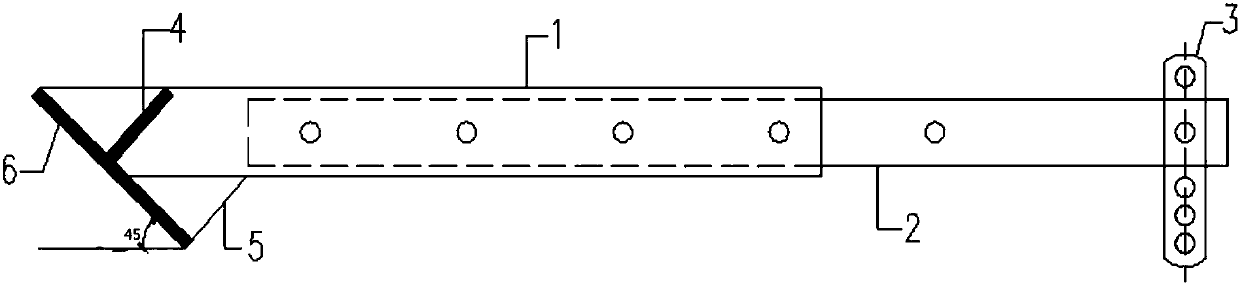

Manufacturing and mounting method of hanging basket suspension support for inclined roof

ActiveCN107558723ASimple structureLow costScaffold accessoriesBuilding support scaffoldsBiochemical engineeringHanging basket

The invention provides a hanging basket suspension support for an inclined roof. The hanging basket suspension support is mounted on a gutter of the inclined roof and used for hoisting a work platform. The hanging basket suspension support is characterized in that the hanging basket suspension support comprises an embedded part, a support body and a hoisting mechanism; the embedded part is arranged on the inclined roof; the support body is arranged on the gutter in a crossing mode and fixedly or detachably mounted on the embedded part; the support body comprises a support main rod and a suspension mechanism; one end of the support main rod is mounted on the embedded part; the other end of the support main rod is detachably provided with the suspension mechanism; and one end of the hoistingmechanism is provided with the work platform, and the other end of the hoisting mechanism is connected with the embedded part through the suspension mechanism. The hanging basket suspension support for the inclined roof has the characteristics of being simple in structure, safe, reliable, convenient to mount and low in cost.

Owner:SHANGHAI TONGJI CONSTR CO LTD

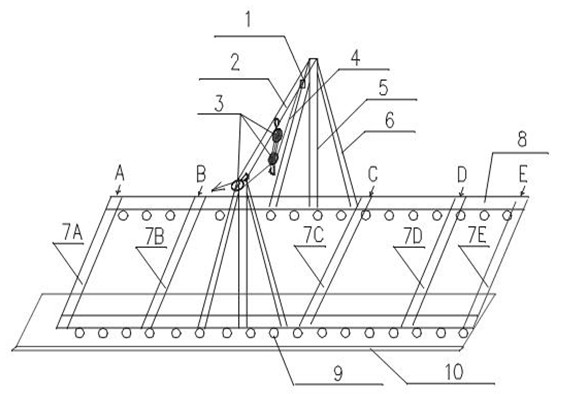

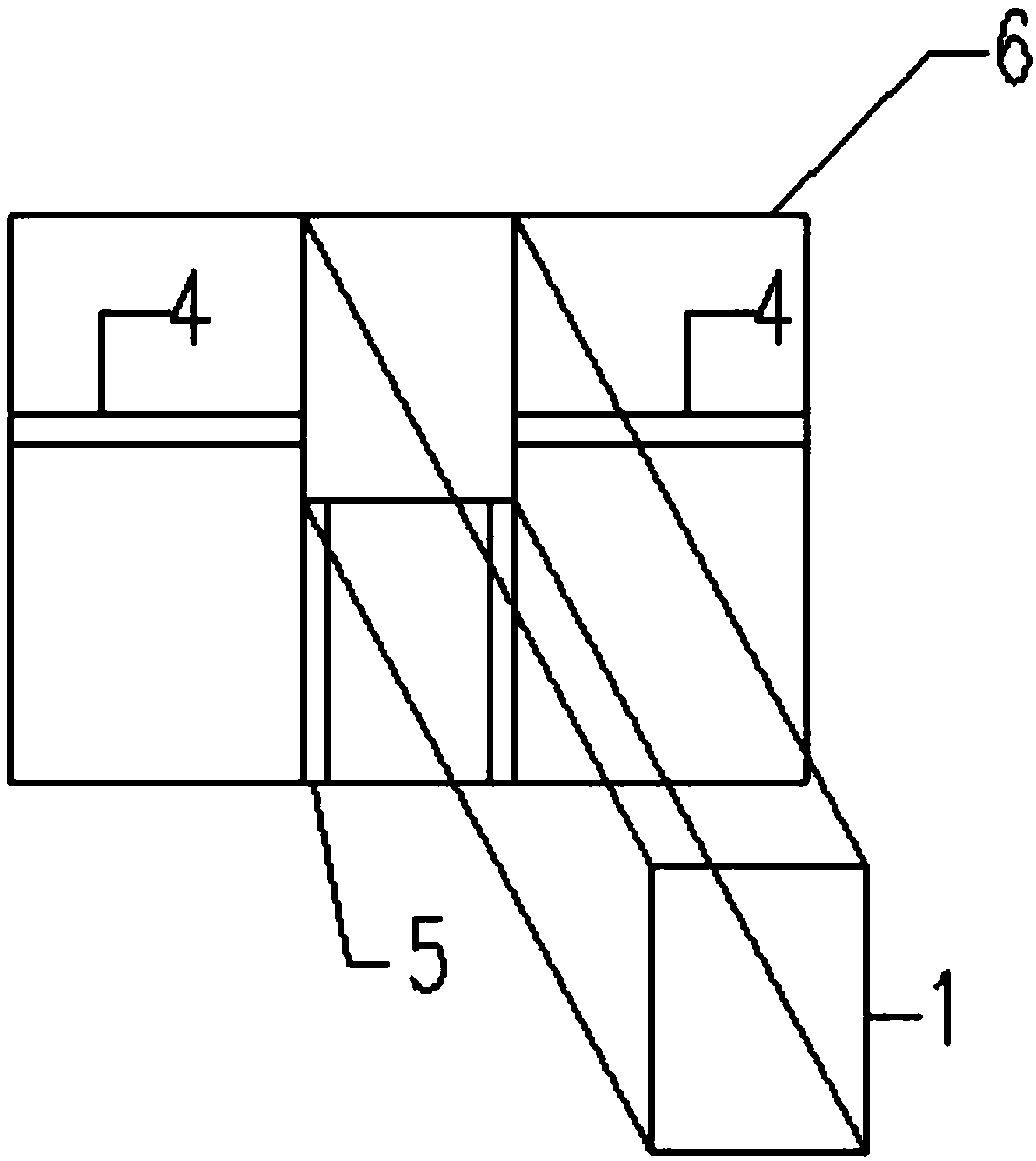

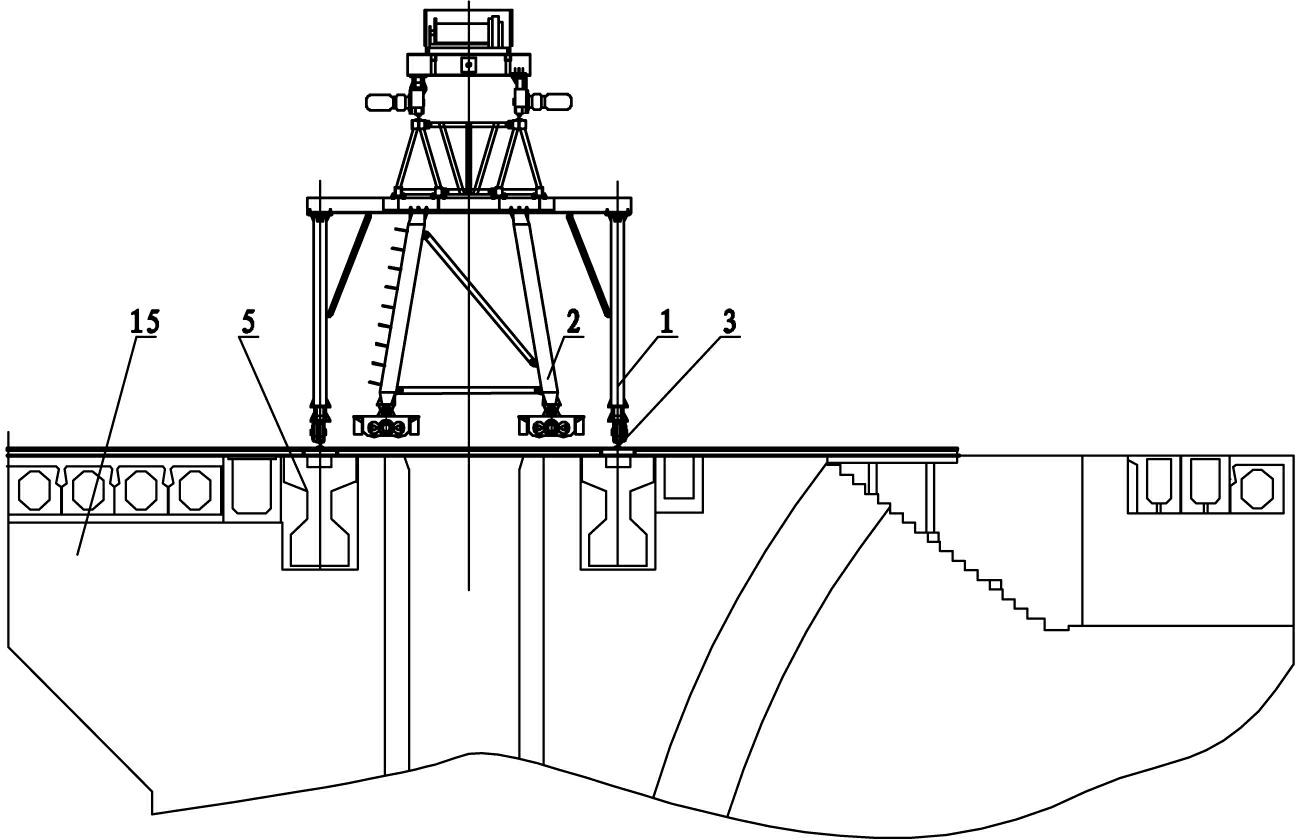

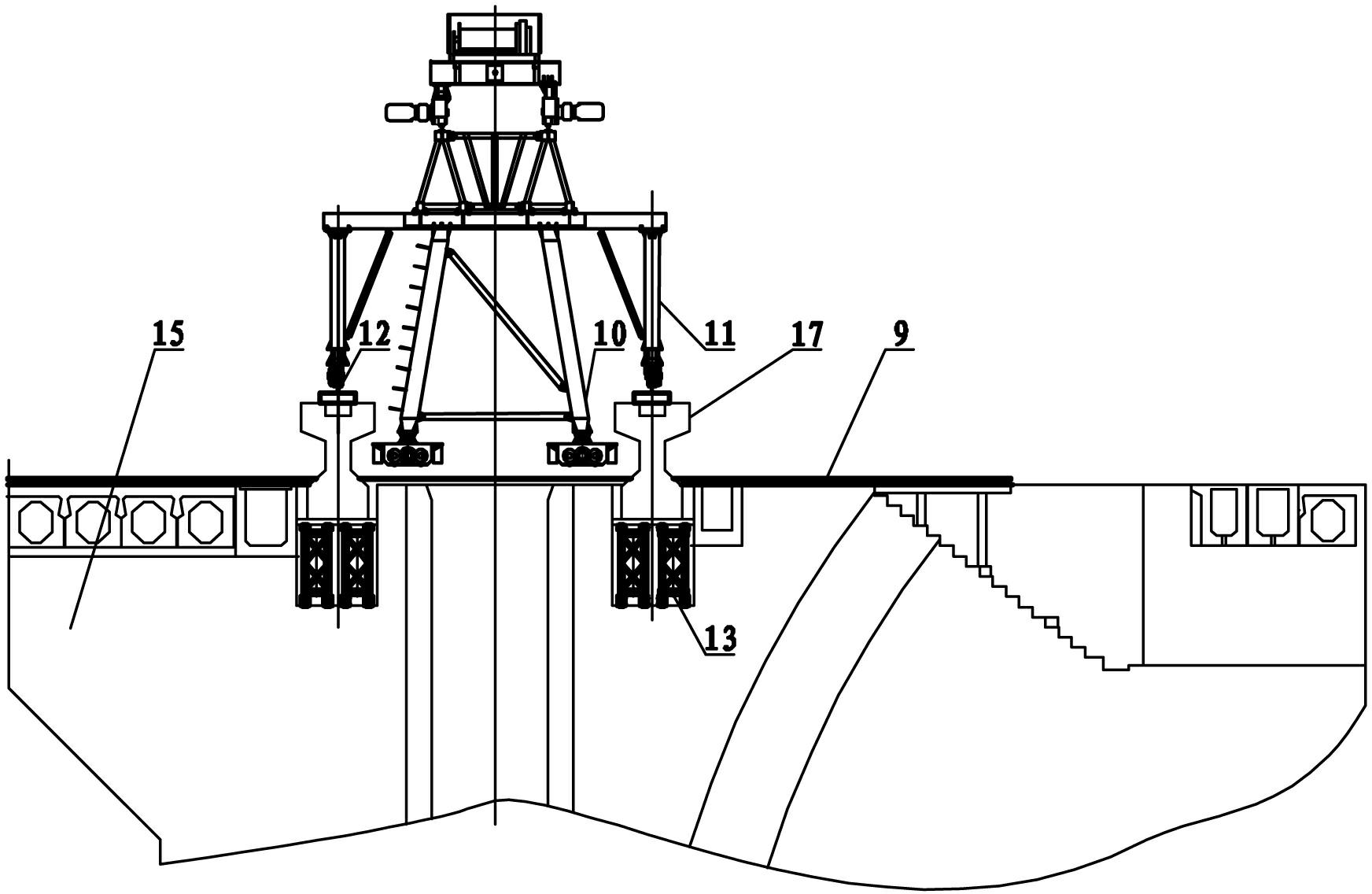

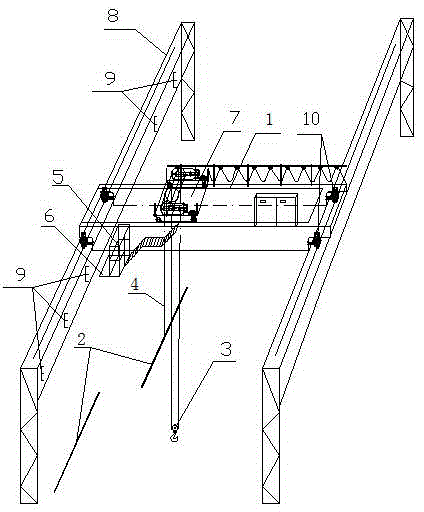

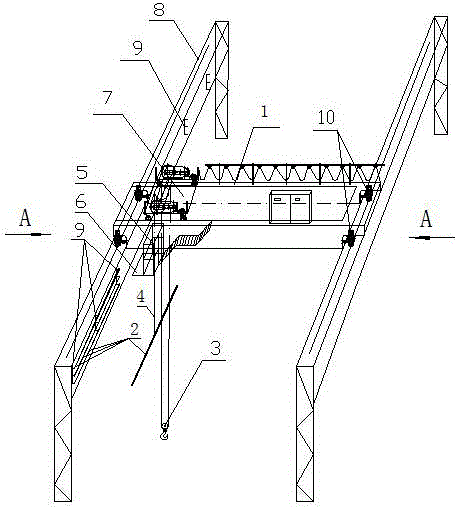

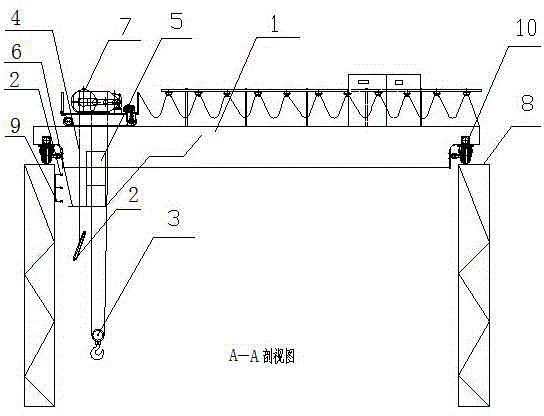

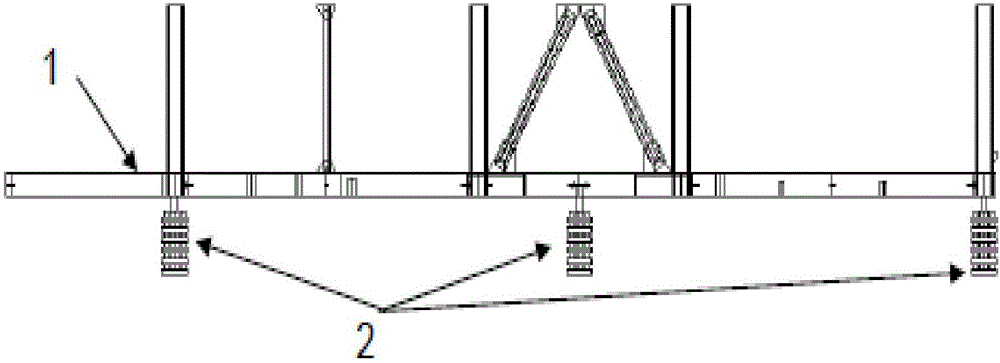

Gantry crane device with lengthways and transverse traveling functions and hoisting method

InactiveCN102139832ASave on rental costsImprove the safety of hoisting constructionBase supporting structuresBraking devices for hoisting equipmentsEngineeringMechanical engineering

The invention discloses a gantry crane device with lengthways and transverse traveling functions. The gantry crane device comprises a main steel girder and a hoisting mechanism, wherein a first auxiliary supporting leg, a first main supporting leg, a second main supporting leg and a second auxiliary supporting leg are arranged on the main steel girder in turn; the roller box traveling direction of the first main supporting leg and the second main supporting leg is vertical to that of the first auxiliary supporting leg and the second auxiliary supporting leg; and the roller box height of the first main supporting leg and the second main supporting leg is different from that of the first auxiliary supporting leg or the second auxiliary supporting leg. The gantry crane device has the advantages of high hoisting capacity, novel concept, and simple structure and is convenient to operate, is safe and reliable and is not affected by a rainy season and a flood season. In the water conservancyproject flood discharge gate hoisting construction technology, compared with the normal large crane, the gantry crane device has great advantages in economy and technology, and can simplify construction procedures to adapt to various hoisting working conditions, speed up a construction progress and highly reduce a safety hazard.

Owner:CHINA GEZHOUBA GROUP CO LTD +1

Cast-in-situs steel reinforced concrete raceway water pressure testing method

InactiveCN101013073ASimple processQuality and safety are easier to guaranteeMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumRebarPiping

It is a water pressure test method for the cast-in-place reinforced concrete pipes, and firstly, constructing the aqueducts, and in the joint of the pipe installed the water stop strip, and in the pipe inner wall reserved a lap notch; then, clean up the water pipes inside wall, and in two grooves relative to the aqueduct joints, spreading the viscose layer, and then slit-covered oak stick belt, and the joints, the water stop strip, the inner wall notch and the rubber ring closed to form a sealed space. With top-pressure component and supporting skeleton, it guarantees the sealing surface compact and solid; the input water pipe imports the water to the sealed space, and after excluding the air of the sealed space, controlling the drainage flow, and observing the pressure gauge at the same time, until the pressure reaching the test standard requirements, and inspecting the aqueduct having no leakage, and then pilot qualified. The invention no need to add a separate compressor or pressure pump, no need large loading equipment, the installation and removal is convenient, and the technique is simple, reliable and easy to operate, and effect is visual and intuitive, and the test device can be re-use, lower cost, not occupying the civil engineering project time of cast-in-place reinforced concrete pipes.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Beam-slab framework early removal construction method

InactiveCN102121314AReduce consumption costsShorten the construction period of the structureForms/shuttering/falseworksBuilding material handlingSupporting systemKeel

The invention provides a beam-slab framework early removal construction method. The method comprises the following steps: (1) span changing treatment is performed, wherein a technical measure of adding a single row of upright poles under a secondary joist of 10*10cm square lumber at the bottom of a longitudinal mid-span part of a slab for supporting is adopted, the square lumber secondary joist separates the slab with the span more than 4m into a bidirectional plate structure with the early removal span between 2 and 4m in a beam support mode; and in the same way, the technical measure that double poles are vertically added at the bottom of the beam every other 2.6 to 4m for a supporting is adopted, and the beam is turned into a framework removal structure with the early removal span between 2.6 and 4m; (2) the structure strength, rigidity and crack width in framework early removal are determined and calculated according an existing formula, and when the calculation results meet requirements at the same time, early removal construction is permitted; and (3) framework early removal construction is performed, wherein after the lowest permitted framework removal strength is determined, the actual early removal strength of concrete is calculated on the basis of the pressure testing strength of a test block is maintained under the same condition; whether the actual early removal strength is more than the calculated early removal strength or not is judged, and if the actual early removal strength is more than the calculated early removal strength, a later removal support system can be maintained, and other framework supports are removed.

Owner:李万山 +2

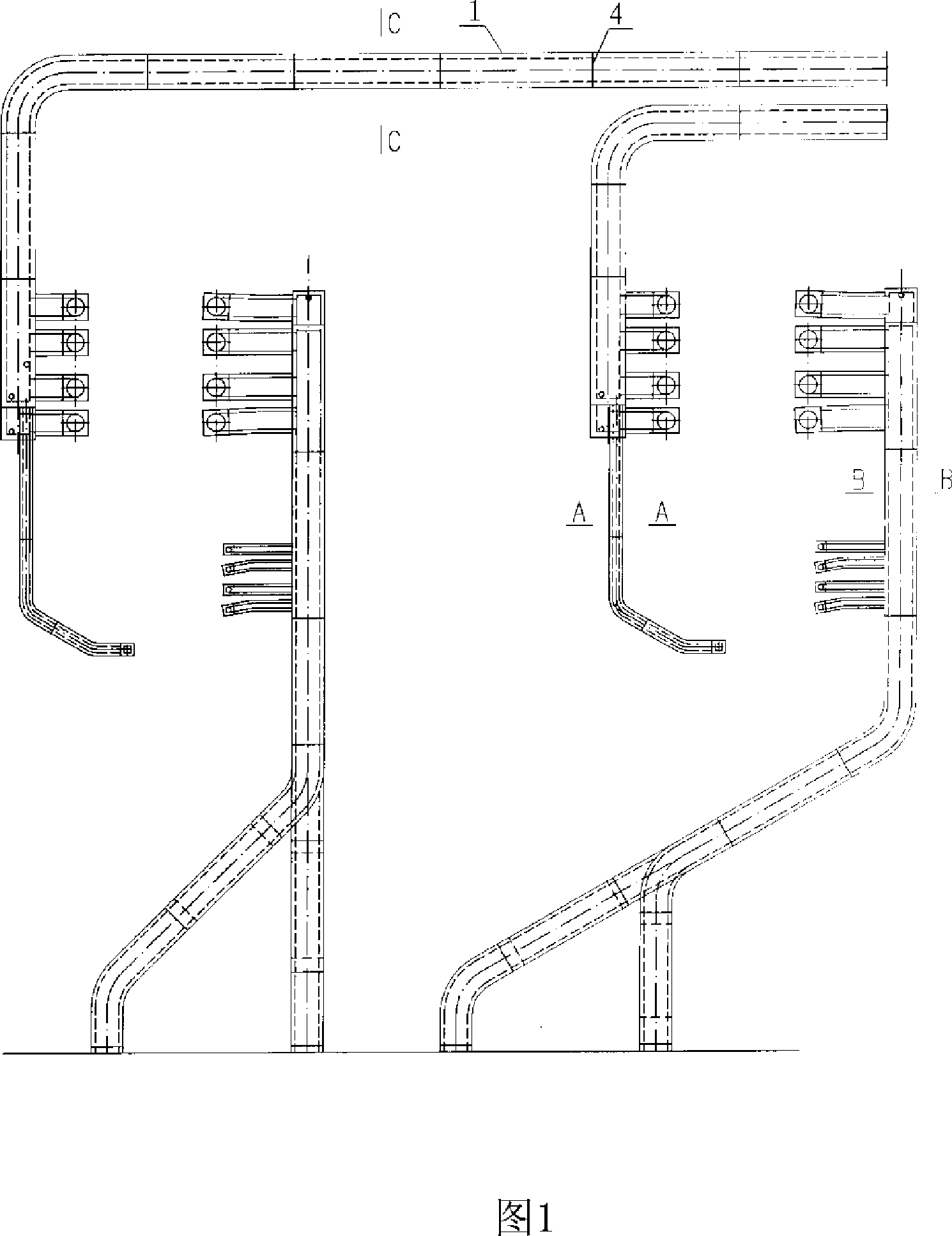

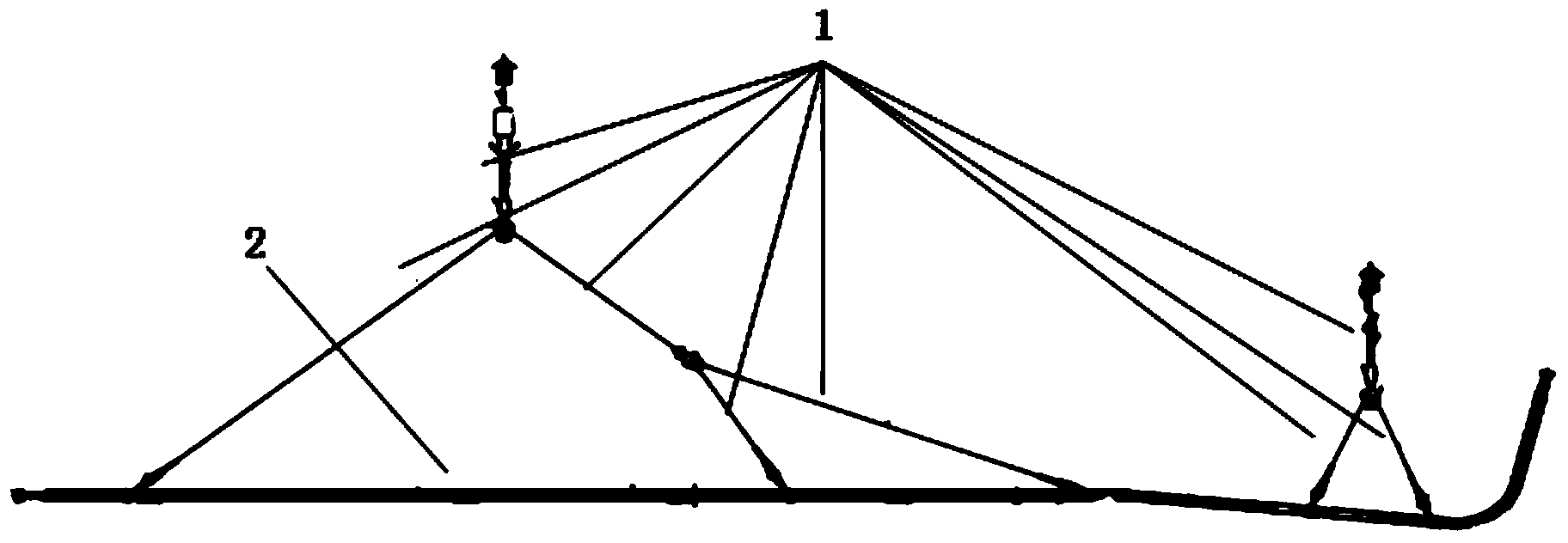

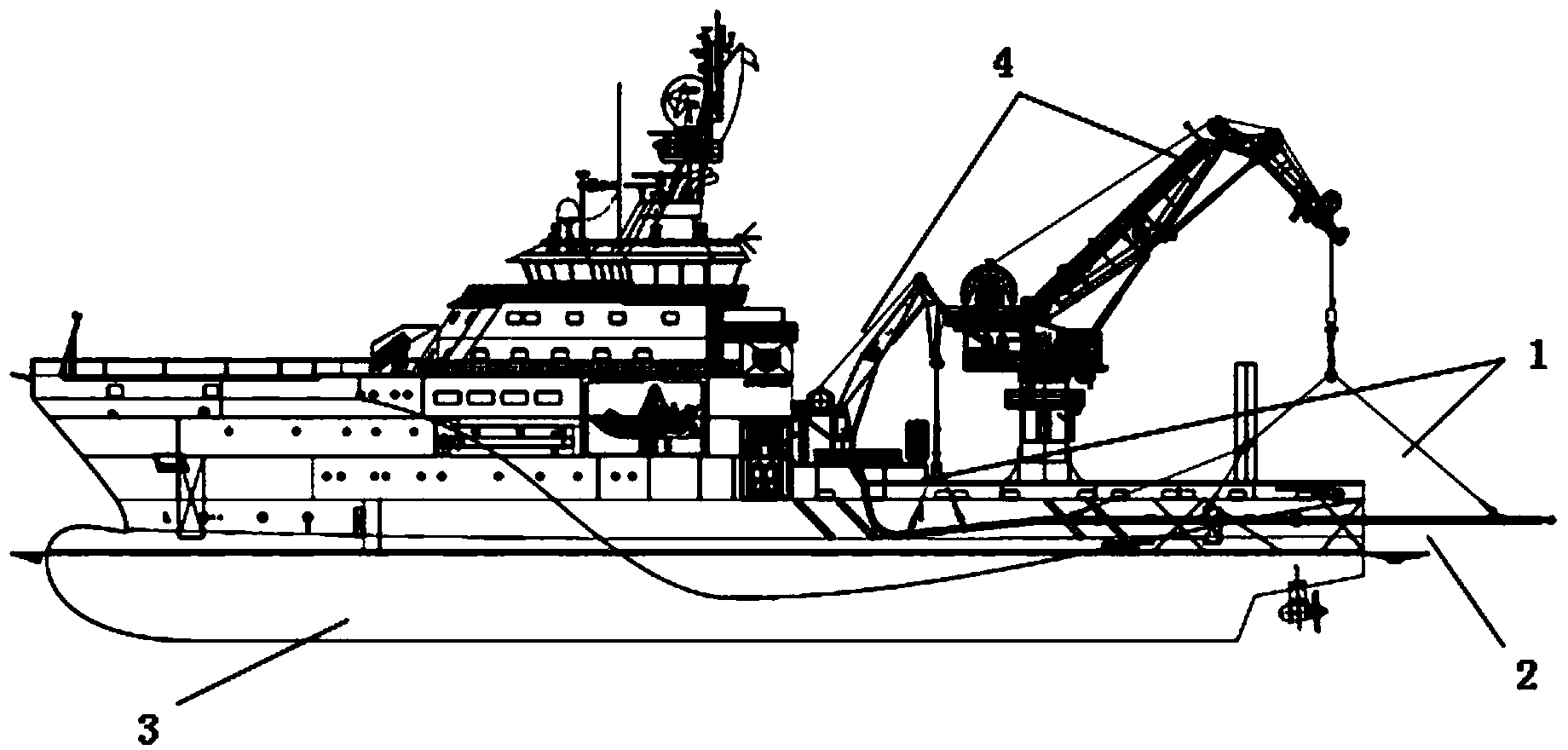

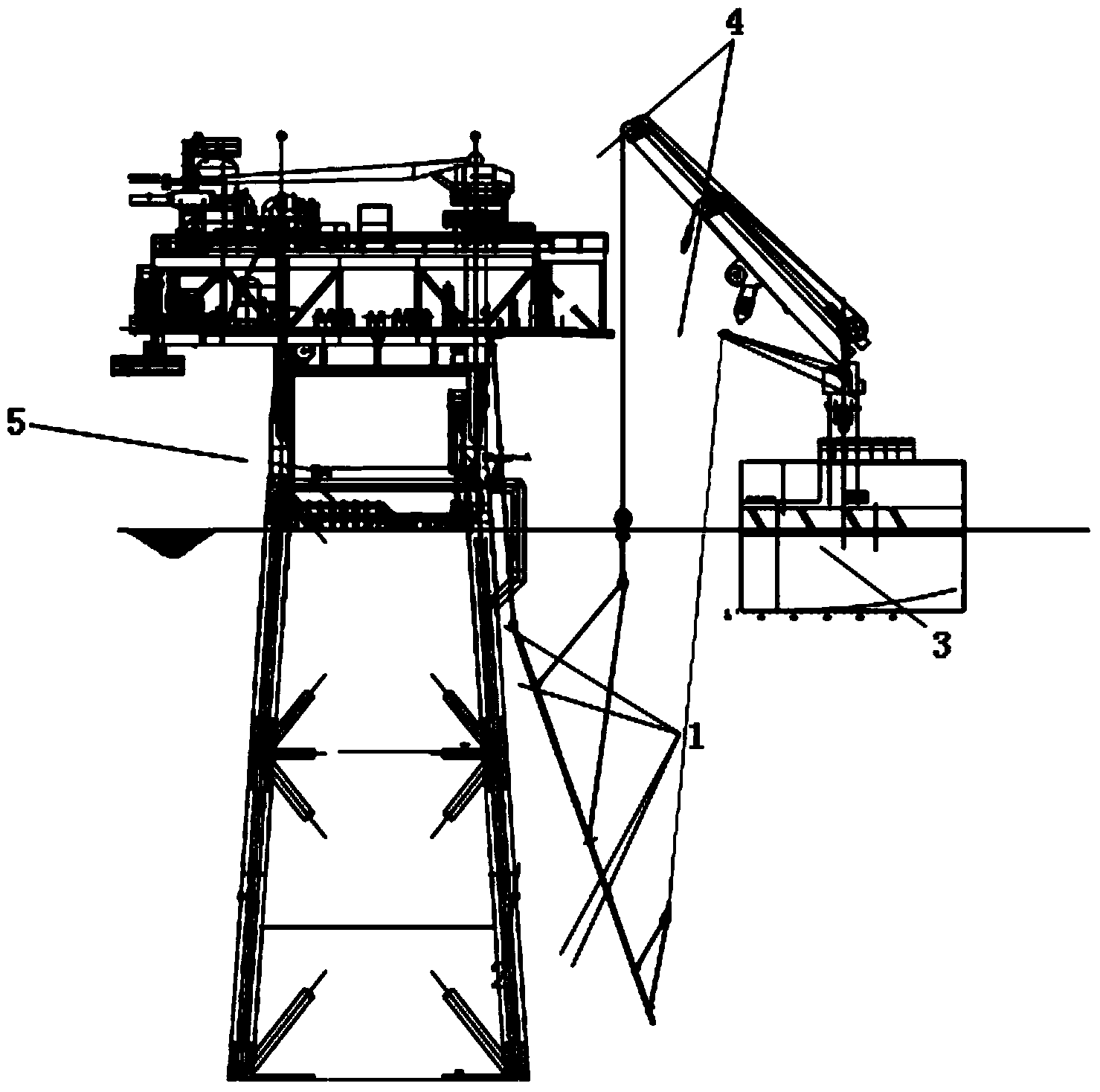

Method for utilizing two cranes on saturation diving support vessel to mount vertical pipe

ActiveCN103883273ASave on rental costsReduce manufacturing costDrilling rodsDrilling casingsBARGESaturation diving

The invention discloses a method for utilizing two cranes on a saturation diving support vessel to mount a vertical pipe. The method is characterized by including the following steps: 1, transferring operating personnel to a barge; 2, mounting lower-section vertical pipe rigging; 3, experimentally hoisting the lower section of the vertical pipe by the cranes; 4, transferring the operating personnel back; 5, lifting the lower section of the vertical pipe by the cranes, and moving the barge out; 6, fixing the lower section of the vertical pipe on a rail of the barge by the cranes; 7, lowering the lower section of the vertical pipe into water, and maintaining the lower section of the vertical pipe vertical in the water; 8, loosening a main crane; 9, enabling an underwater robot to dive; 10, embedding the lower-section of the vertical pipe into a vertical pipe clamp for fixing; 11, repeating the above steps until the whole vertical pipe is mounted completely. By the method, only the saturation diving support vessel and a self-propelled barge are needed to perform mounting of a deepwater vertical pipe, so that requirements on vessel resources are greatly lowered, and working efficiency and economic benefit are improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

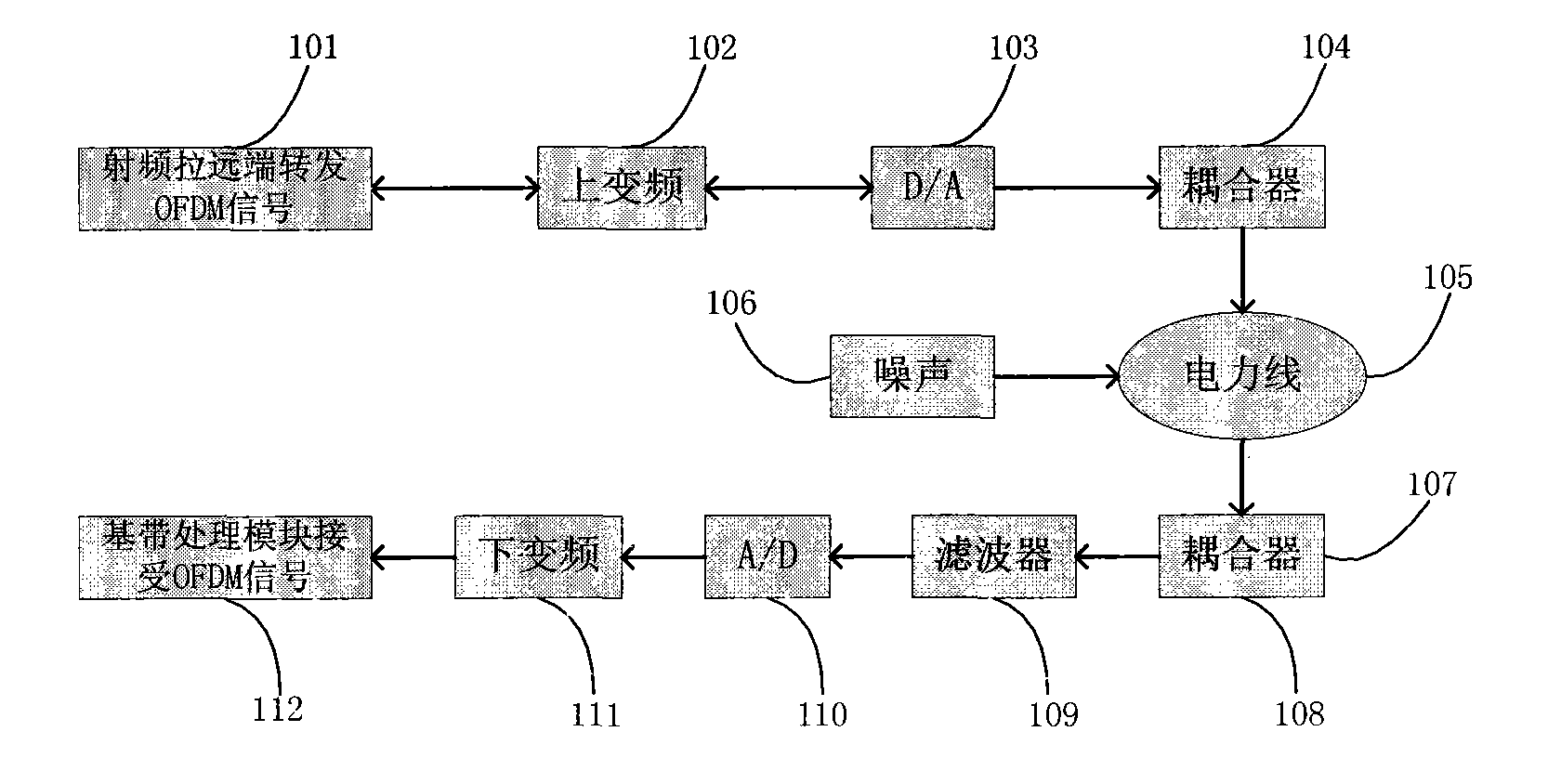

OFDM (orthogonal frequency division multiplexing)-based high-speed rail mobile communication method and system

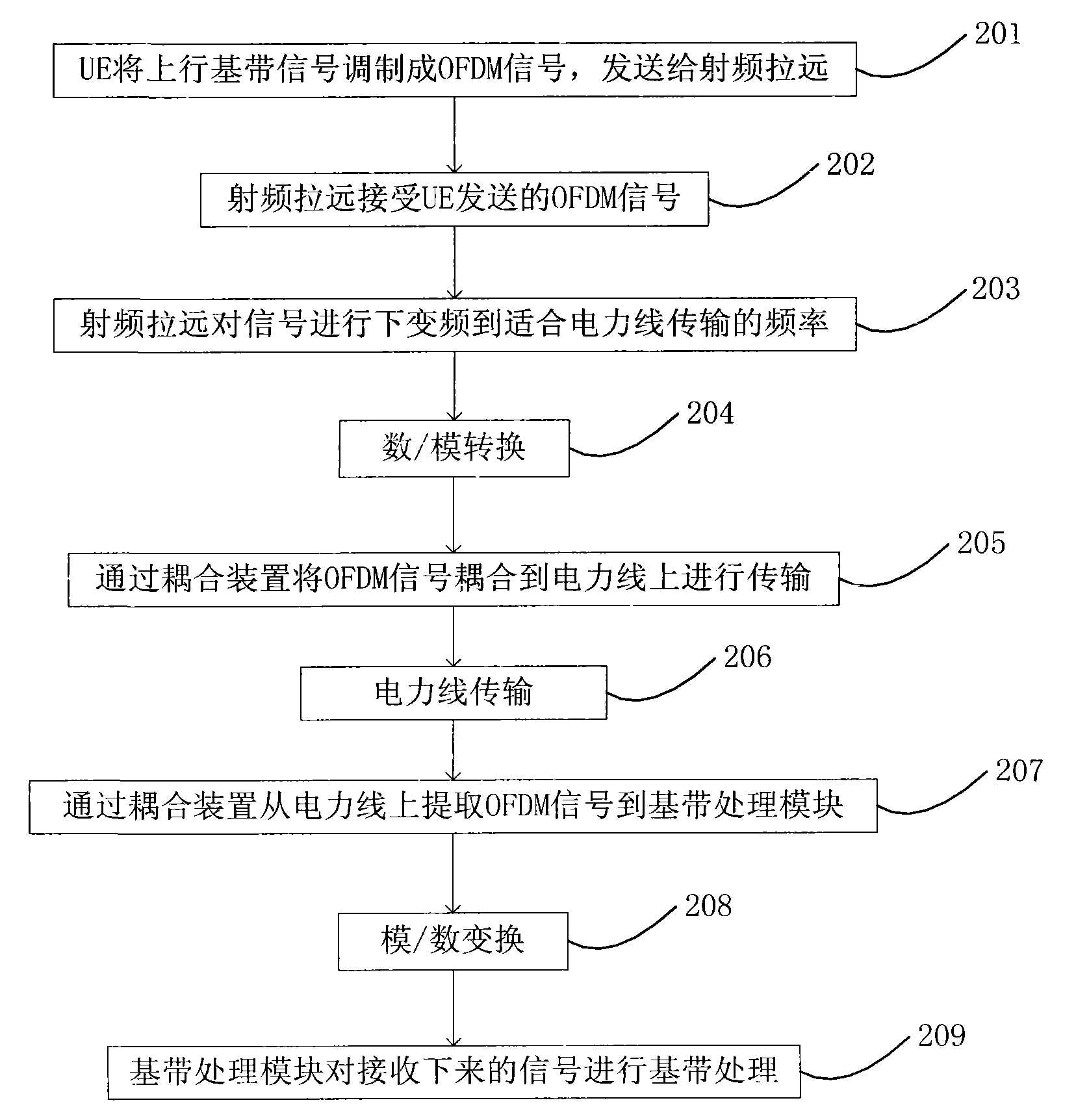

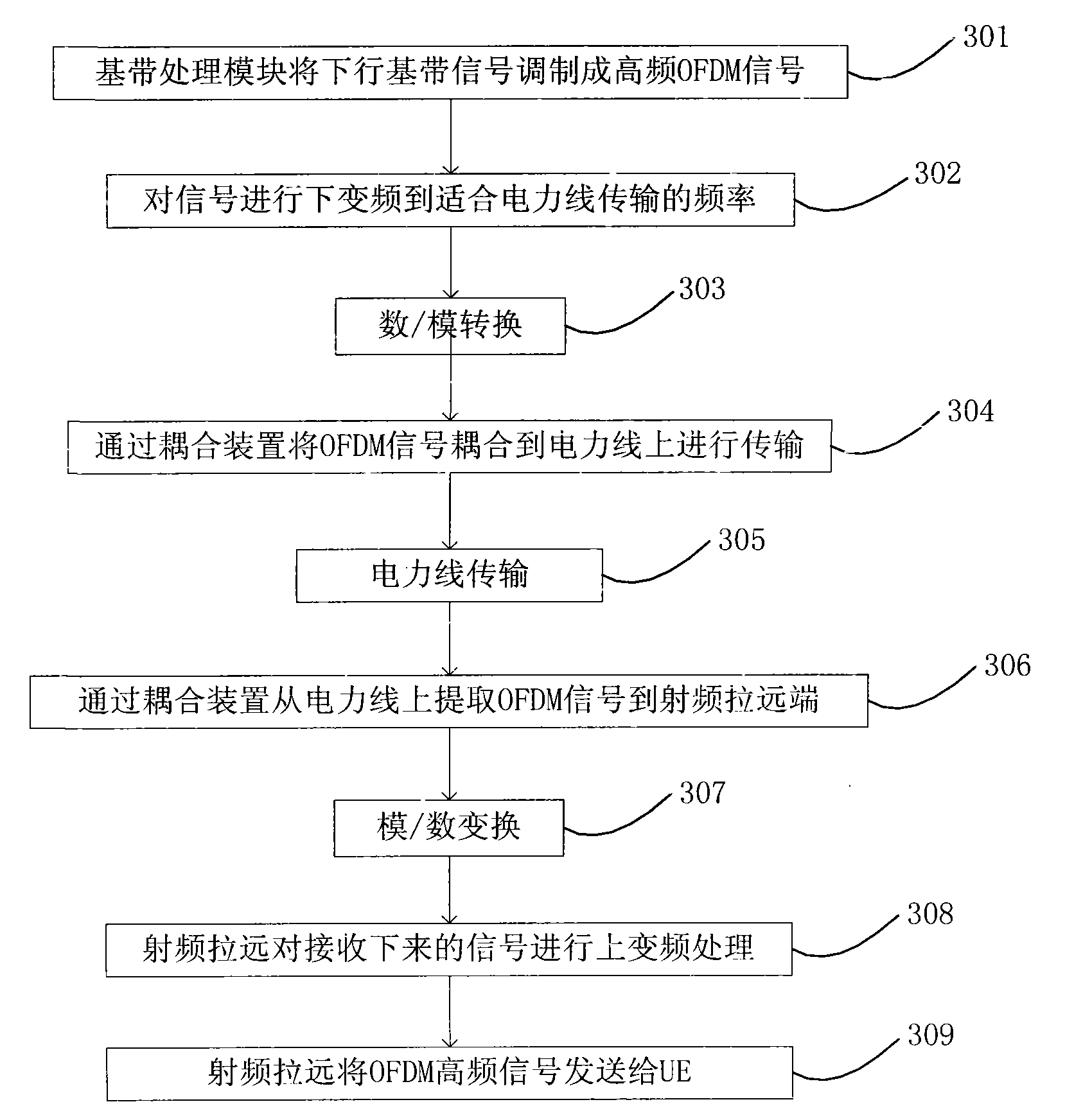

InactiveCN102130882ASolve the shielding effectTroubleshooting Tunnel Communication IssuesPower distribution line transmissionActive radio relay systemsMobile stationUp conversion

The invention discloses an OFDM (orthogonal frequency division multiplexing) modulation-based high-speed rail mobile communication method and system. An RRU (radio remote unit) is arranged in a train compartment, and the RRU is communicated with a far-end machine room by a power line connected with a train; the communication between the machine room and the far end of the RRU adopts an OFDM modulation mode; along with an up direction, a signal which is transmitted by a mobile station is transmitted to the far end of the RRU by means of OFDM, is converted by means of down-conversion and D / A (digital-to-analogy) conversion, is coupled to the power line to be transmitted, and is subjected to base band processing in the far-end machine room; and along with a down direction, the machine room is used for modulating a baseband signal into an OFDM signal, wherein the OFDM signal is coupled to the power line to be transmitted, is received at a radio remote end of a base station, is converted by means of A / D (analogy-to-digital) conversion and up-conversion, and is transmitted to the mobile station by the radio remote end of the base station, so that the voice / data communication can be realized.

Owner:BEIJING UNIV OF POSTS & TELECOMM

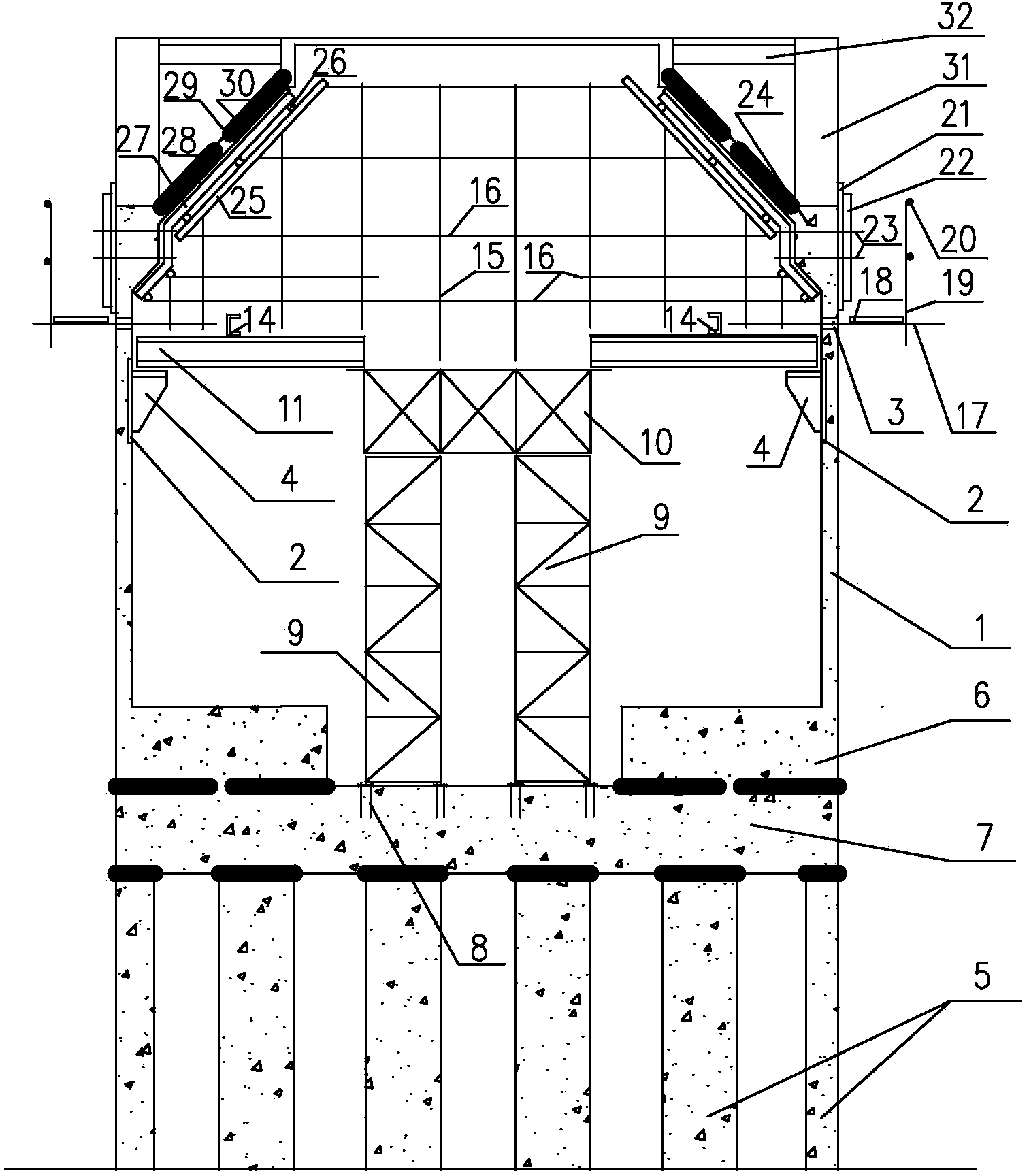

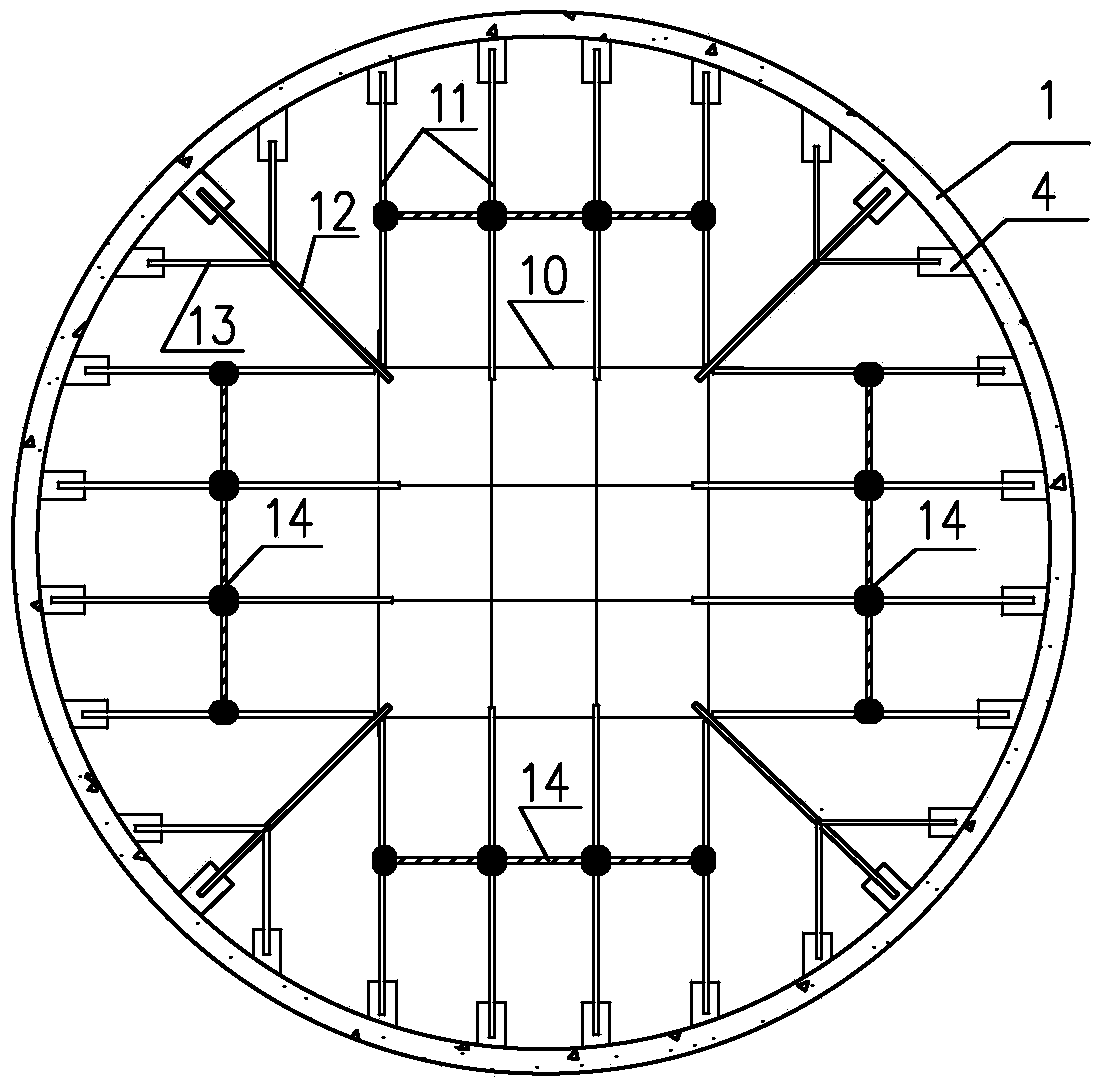

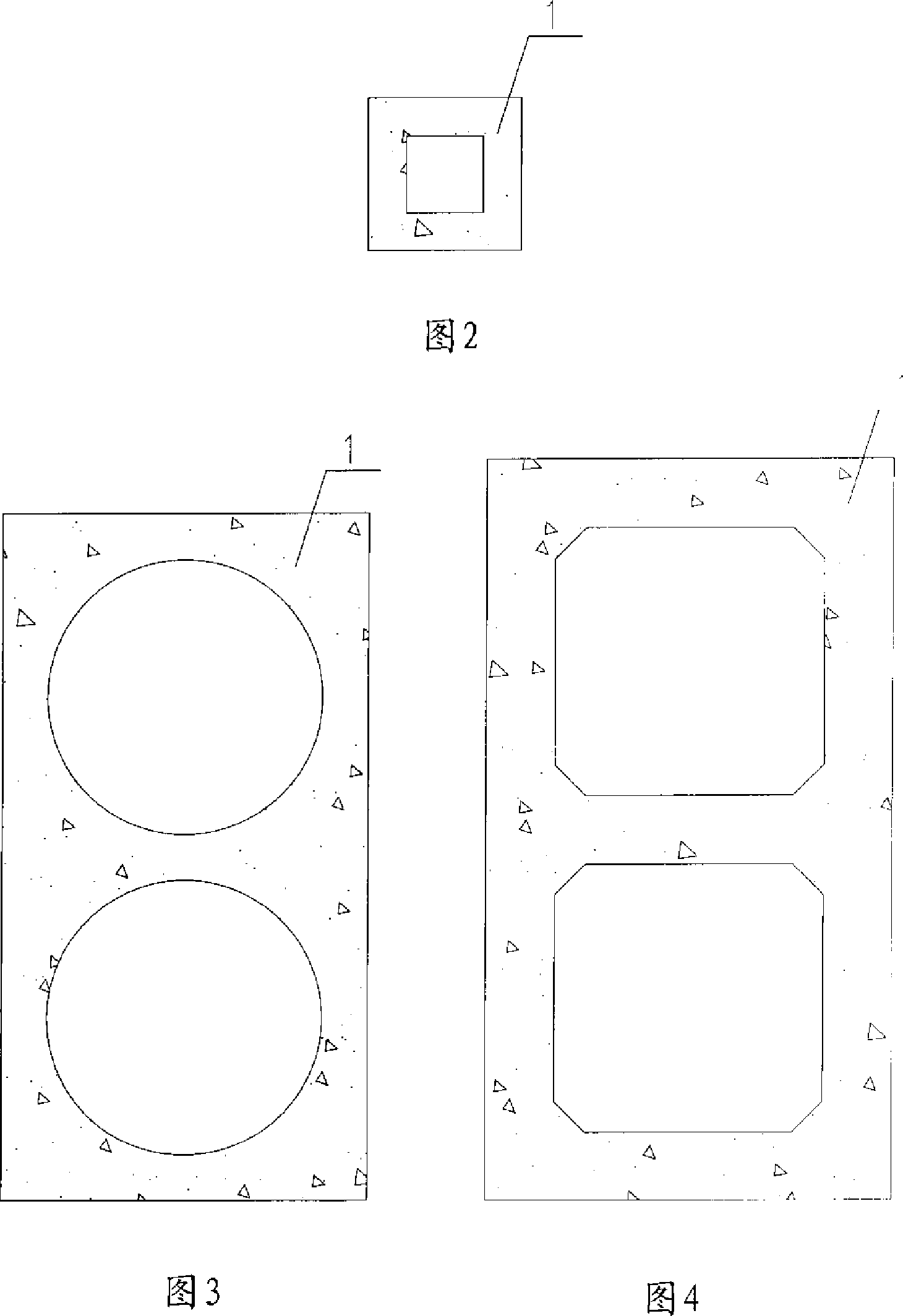

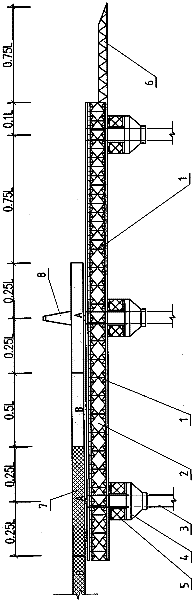

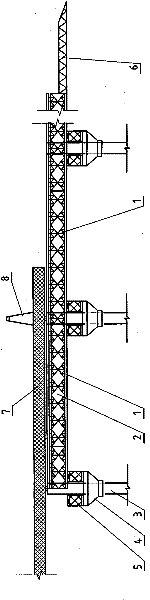

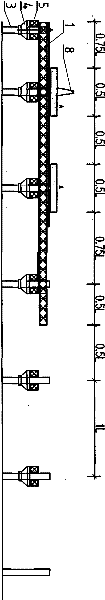

Rapid construction process for sinking vertical shaft pit shaft with large diameter on deep surface soil layer by utilizing freezing method

InactiveCN101694160ASave on rental costsReduce manual labor intensityShaft sinkingShaft liningBedding supportHigh strength concrete

The invention discloses a rapid construction process for sinking a vertical shaft pit shaft with large diameter on a deep surface soil layer by utilizing a freezing method. Aiming to overcome the defect of the prior art, the invention provides the following key technologies: a borehole deviational survey deviation correction technology, a freezing refrigerating capacity guaranteeing technology, a centrally control technology of a shaft sinking winch, a multifunctional hanging scaffold fixing technology, an automatically and centrally stirring technology of high-strength concrete, application of an improved rock rake in a frozen loose bed, application of a small excavator in the frozen loose bed and a thick expanded clay bed supporting technology. The process meets the policy requirement of low power consumption in China, lowers the working intensity of workers, simplifies the operation procedures and shortens the period of construction.

Owner:中煤第一建设有限公司第四十九工程处

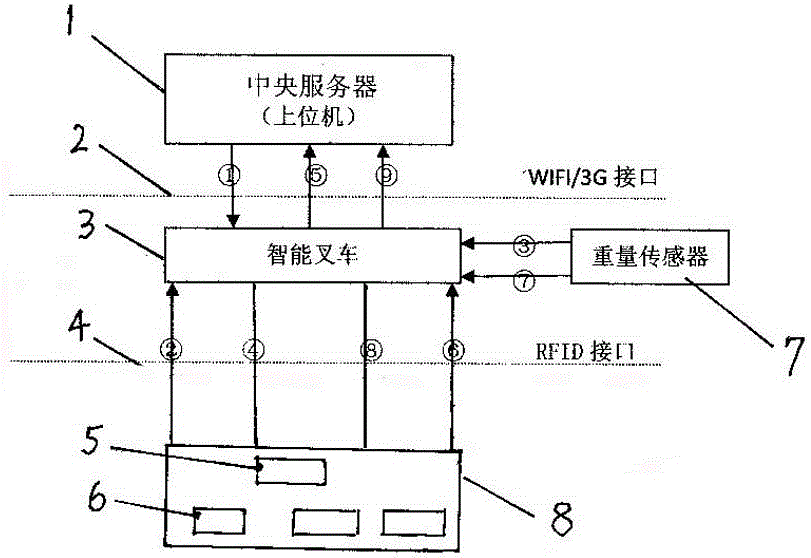

Method for achieving intelligent warehousing through RFID/industry WIFI technology

InactiveCN105858039AHigh application promotion valueImprove efficiencyStorage devicesWifi networkServer-side

The invention discloses a method for achieving intelligent warehousing through an RFID / industry WIFI technology. The method includes the following steps that firstly, a central server is deployed in a warehousing management center, and intelligent warehousing system software (a server side) and a warehousing database are installed; secondly, a traditional forklift is intelligently transformed based on the RFID / industry WIFI technology; thirdly, an industry WIFI network covers a warehouse working area, and an industry WIFI wireless network which is stable, reliable and short in time delay is laid in a warehouse range; and fourthly, an intelligent mark based on RFID is arranged on a warehouse location / goods packaging box. The method conforms to the development trend of the industry 4.0 and intelligent manufacturing, the problems about reliability and stability of RFID fast reading and writing in the warehousing logistics environment are solved, and in addition, intelligent control and management of warehousing are automatically achieved through the functions of system integrating, automatic reading and writing, acousto-optical early-warning and the like; and the utilization rate of a warehouse can be increased, the input of labor force is reduced, and the logistics cost of an integral industry chain especially the manufacturing industry is reduced. The method is suitable for application of warehousing logistics enterprises.

Owner:HUNAN ZHONGSHIFA ELECTRONICS TECH CO LTD

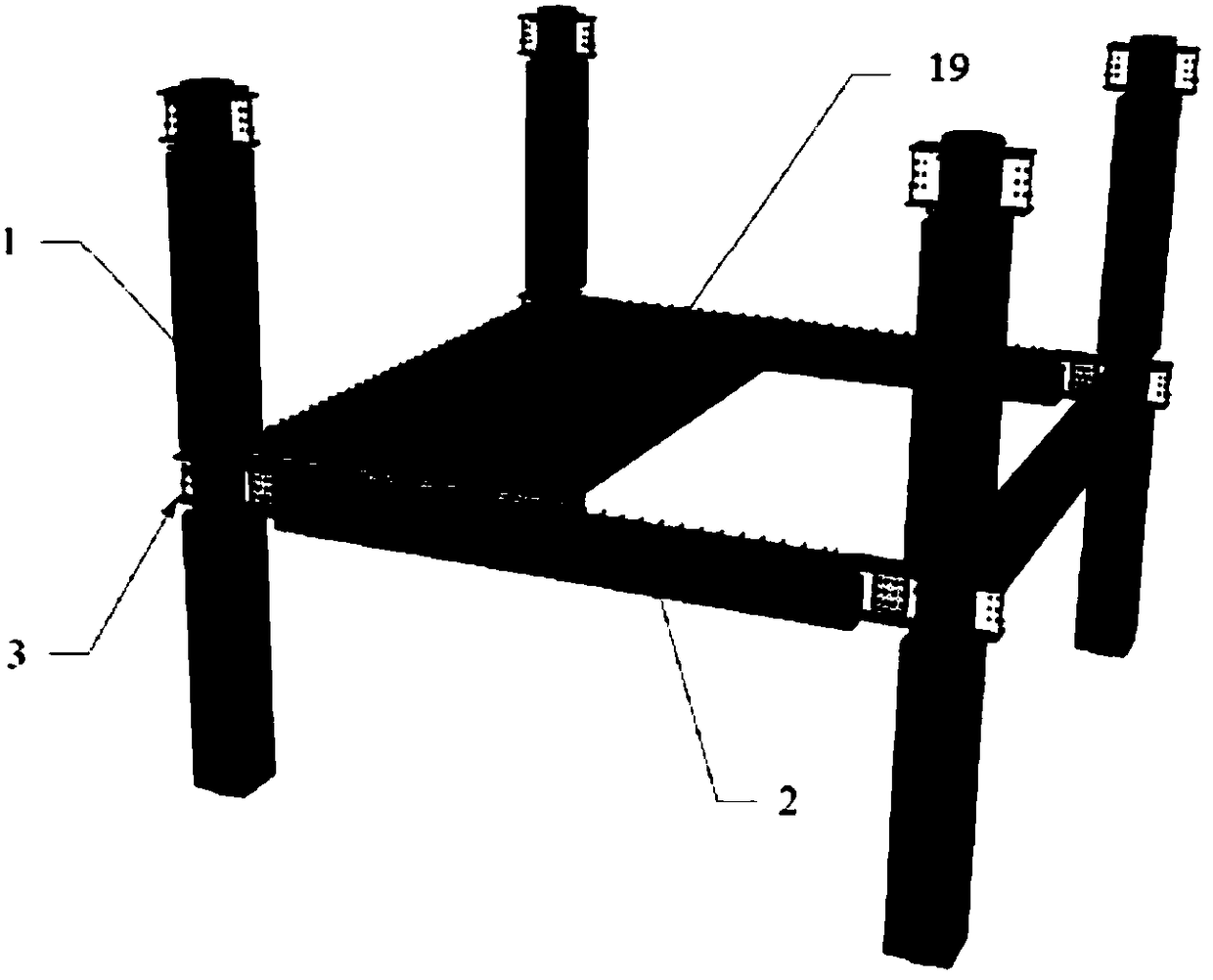

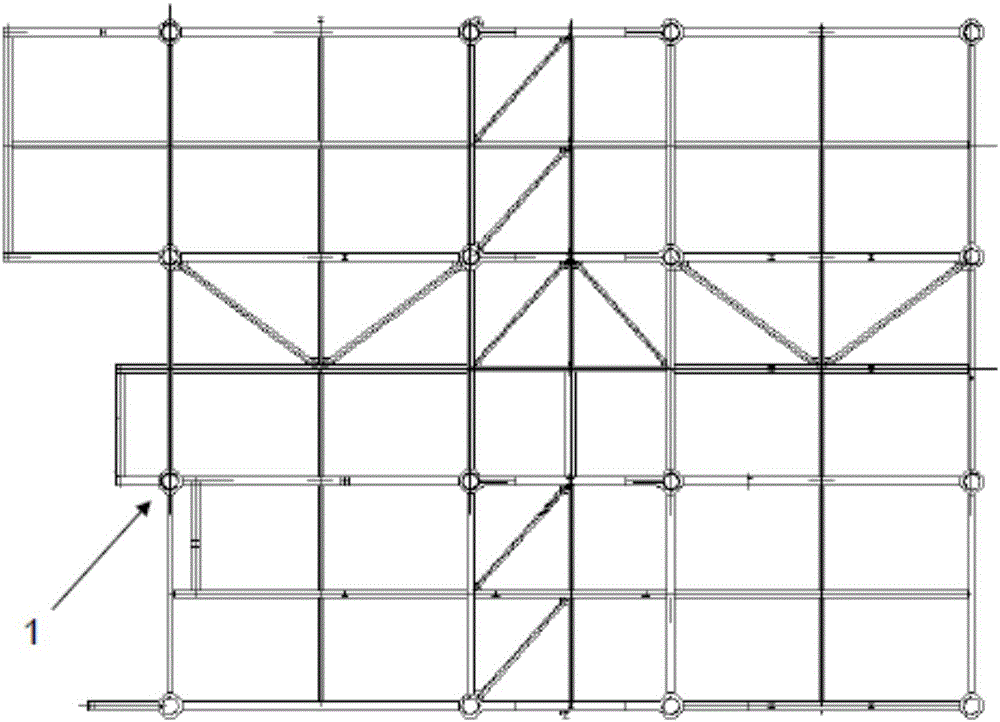

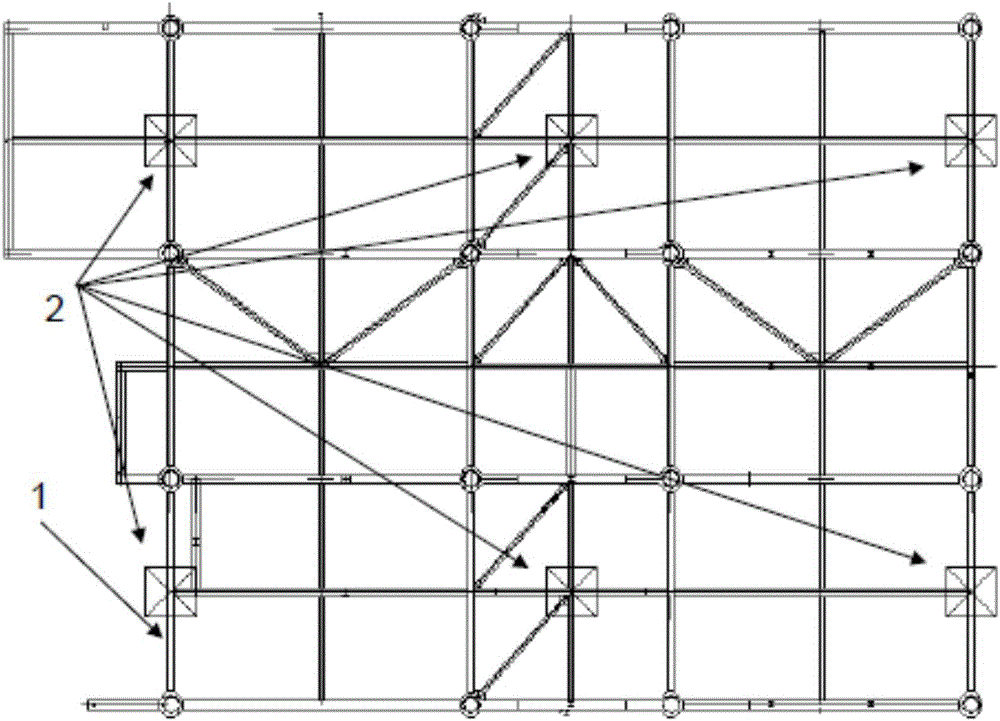

Prefabricated pre-stressed beam member, fabricated combined frame structure and installation method of fabricated combined frame structure

PendingCN108457422AReduce shipping weightSave on rental costsLoad-supporting elementsFloor slabSurface layer

The invention discloses a prefabricated pre-stressed beam member, a fabricated combined frame structure and an installation method of the fabricated combined frame structure. The fabricated combined frame structure comprises prefabricated column members with hollow steel pipes inside, prefabricated pre-stressed beam members, cast-in-place concrete inside the prefabricated column hollow steel pipes, a laminated floor slab prefabricated base plate and laminated surface layer concrete. The middle sections of the hollow steel pipes of the prefabricated column members are covered with concrete, anda beam-column joint zone provided with short H-shaped steel beams is arranged at both ends of each middle section. The prefabricated pre-stressed beam member comprises a concrete laminated pre-stressed beam and interposed H-shaped steel beams at both ends of the pre-stressed beam. The short H-shaped steel beams in the beam-column joint zone and the interposed H-shaped steel beams of the prefabricated pre-stressed beam member are combined by bolt welding or connected by bolting. Joints of the hollow steel pipes of the upper and lower sections of the prefabricated column members are connected by welding. The fabricated combined frame structure integrates the advantages of a steel structure and a prefabricated concrete structure, and has high installation efficiency and good safety, and manpower and material resources are greatly saved.

Owner:SOUTHEAST UNIV +2

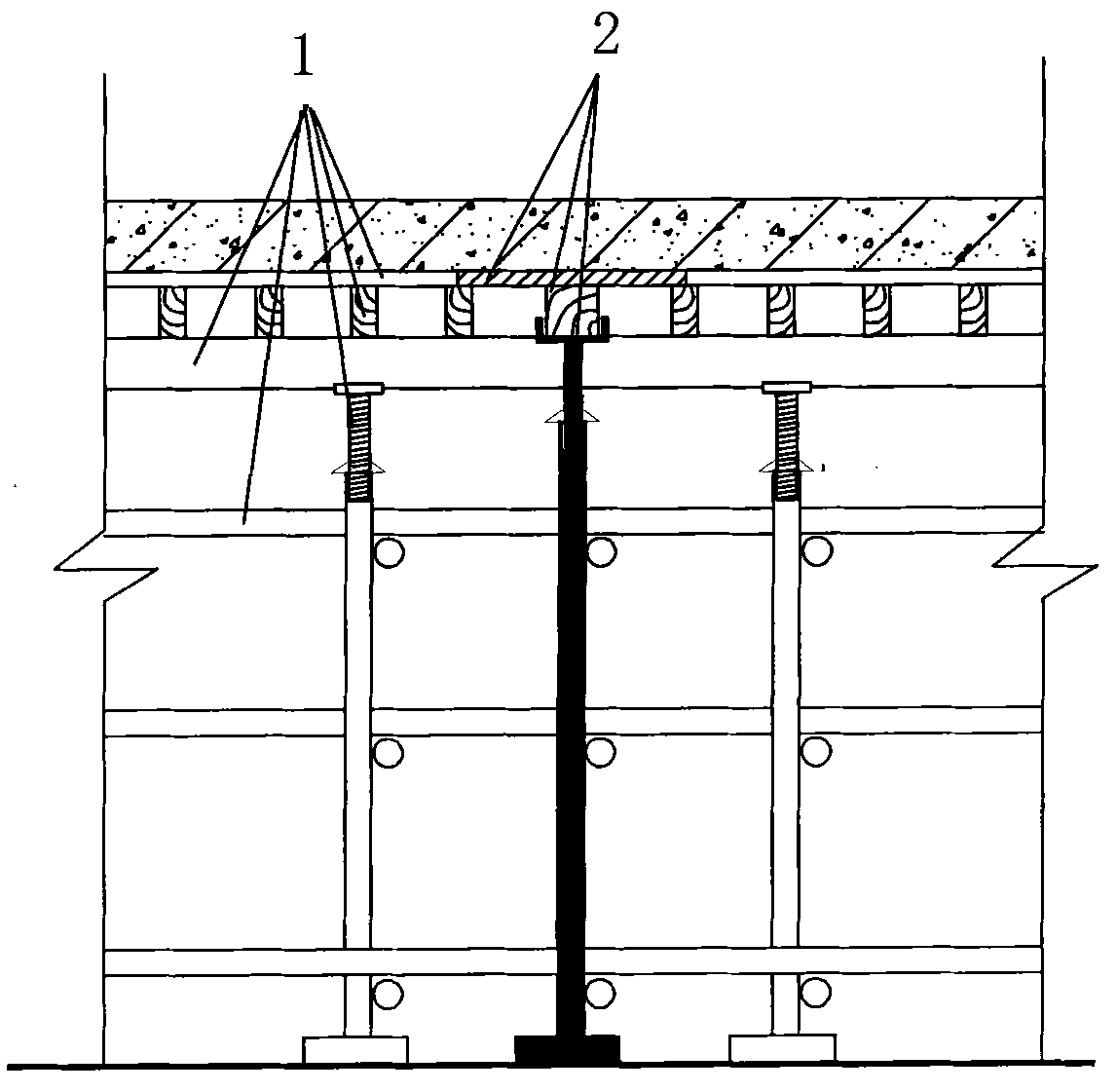

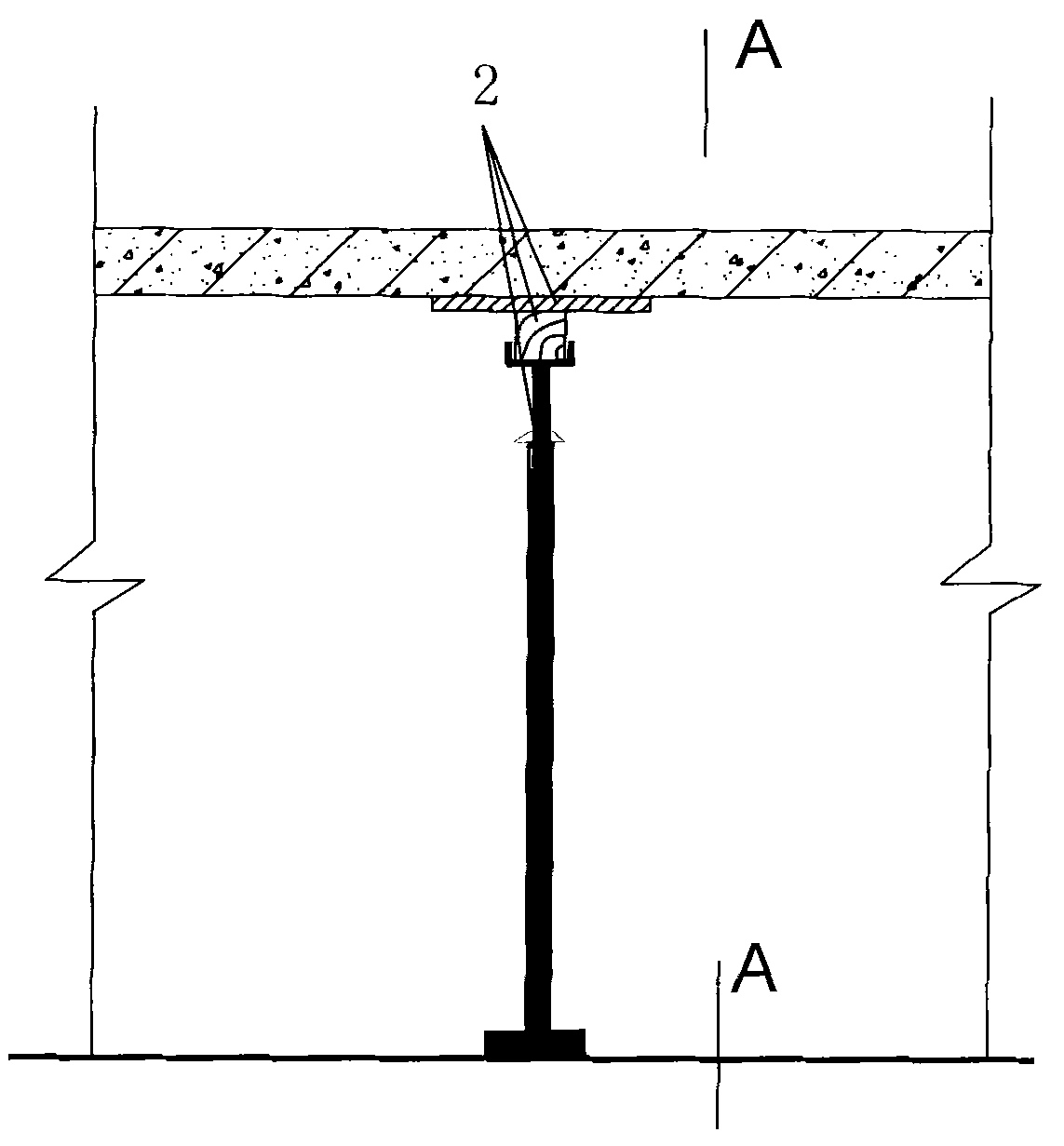

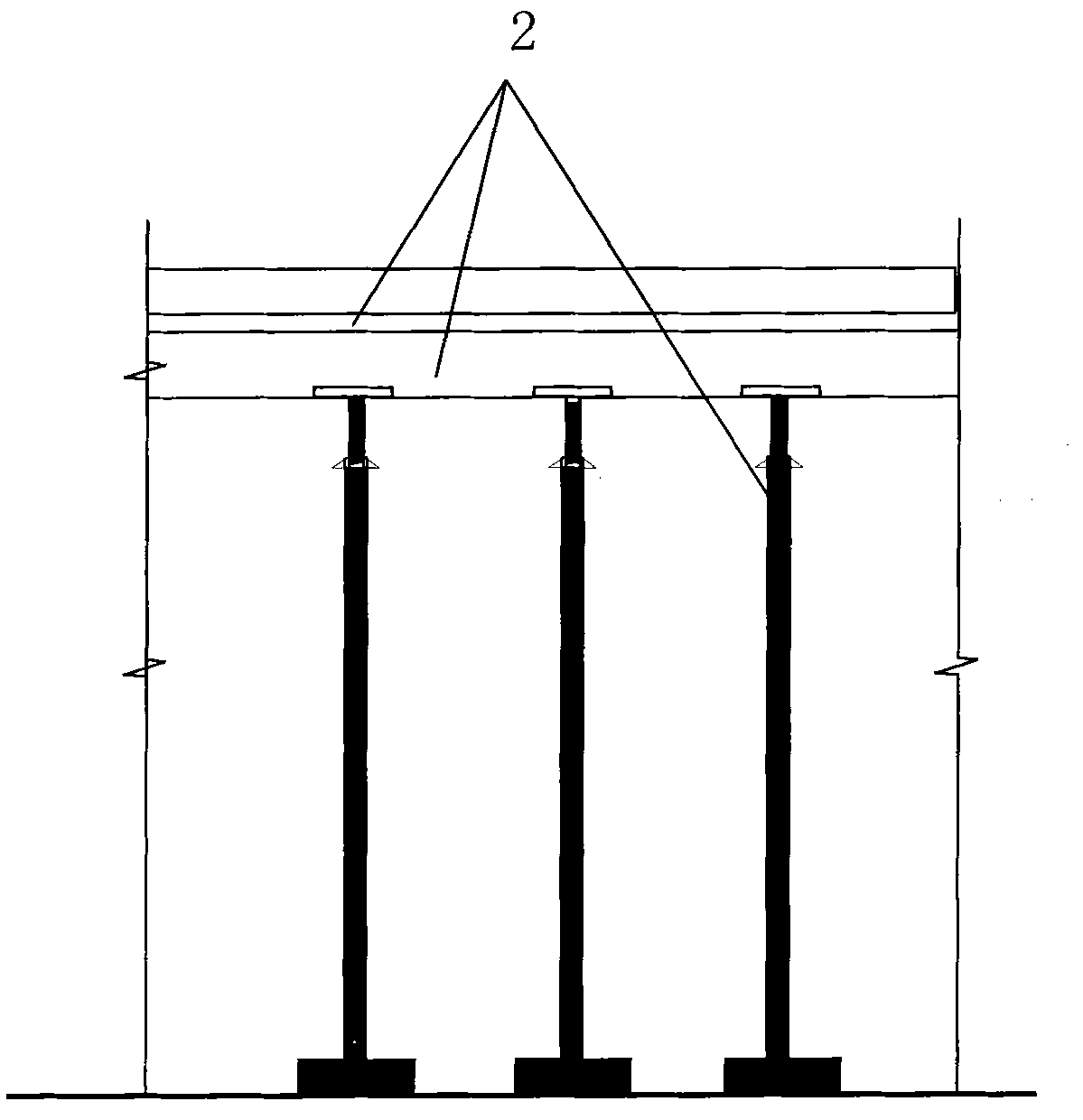

Profile steel framework structure concrete floor slab suspension mould pouring construction method

ActiveCN103758348AFast constructionShorten the construction periodBuilding material handlingFloor slabRebar

The invention relates to a profile steel framework structure concrete floor slab suspension mould pouring construction method. The profile steel framework structure concrete floor slab suspension mould pouring construction method comprises the steps of installing and correcting profile steel components, measuring a released line, designing and manufacturing a suspension mould system, manufacturing and installing a hoisting bar, installing main rods, installing secondary rods, laying formwork panels, tying floor slab steel bars, pouring and maintaining concrete, and detaching the suspension mould system. Compared with the prior art, the profile steel framework structure concrete floor slab suspension mould pouring construction method has the advantages of being high in construction speed, being stable in quality of a concrete structure, reducing the use of circulation materials, relieving vertical conveying pressure, improving labor efficiency and relieving labor intensity. Compared with a traditional steel pipe whole-building supporting frame, the profile steel framework structure concrete floor slab suspension mould pouring construction method improves the labor efficiency by about 2.5 times. Due to the fact that labor intensity is largely relieved, the work of operators is continuous.

Owner:芜湖立宇建设有限公司

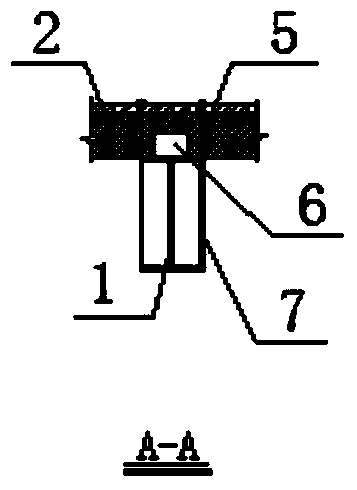

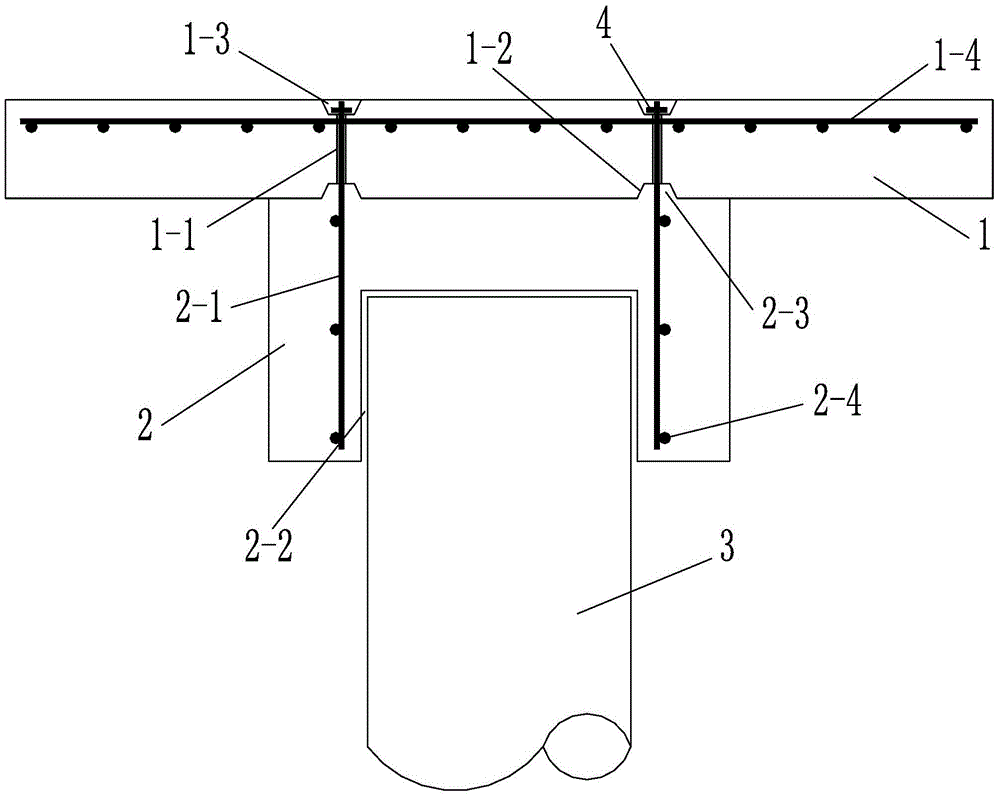

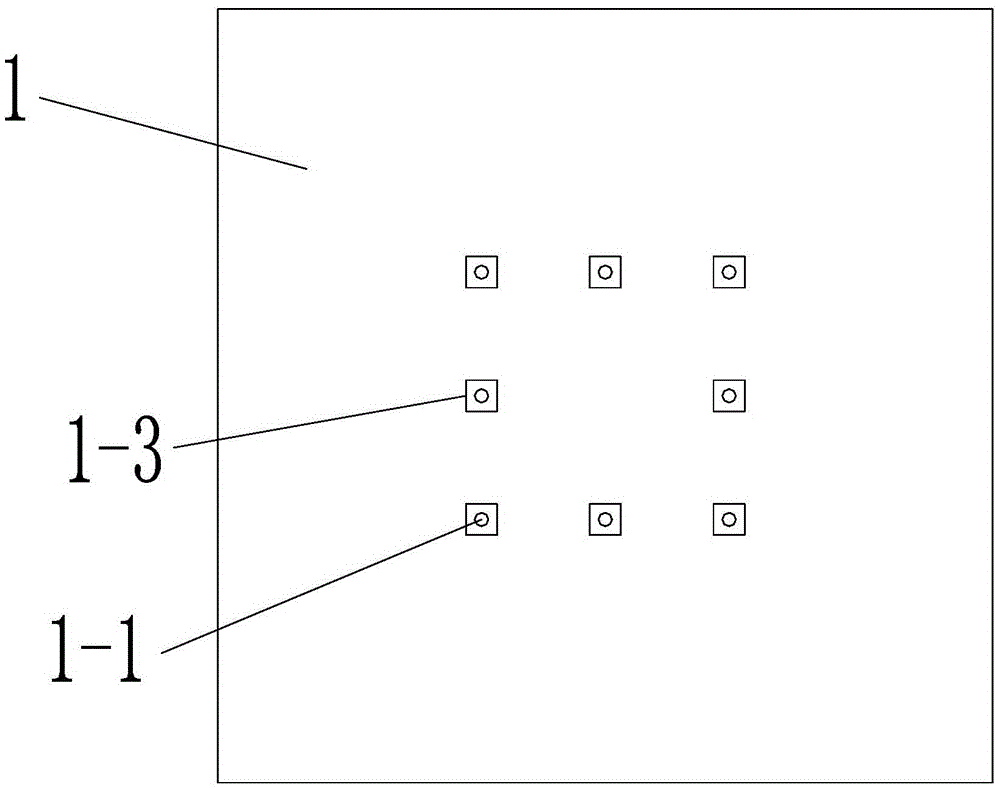

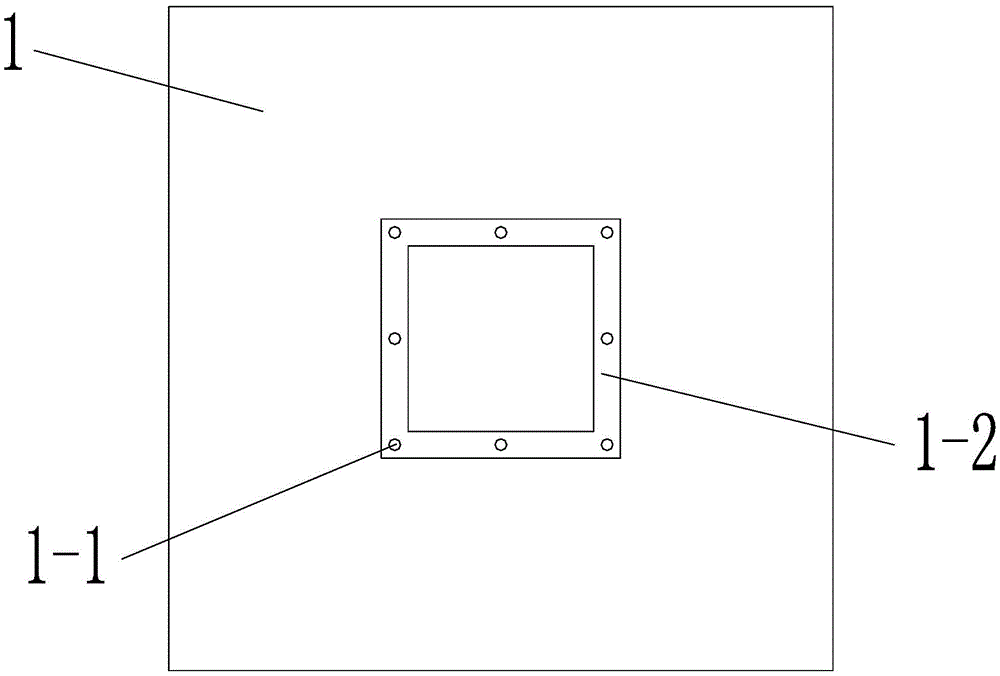

Prefabricated pile cap for composite foundation

The invention relates to a prefabricated pile cap for a composite foundation. The prefabricated pile cap comprises a top plate and a fixing sleeve connected onto the lower side surface of the top plate, wherein a plurality of locking rods are vertically distributed in the fixing sleeve and extend out of the upper end surface of the fixing sleeve, and a blind hole for sleeving a prefabricated pile is formed in the lower end of the fixing sleeve; locking through holes allowing the locking rods to penetrate through are correspondingly formed in the top plate, the top plate and the fixing sleeve are fixedly connected by the aid of locking nuts, and the locking nuts are rotationally arranged on the locking rods penetrating through the upper side surface of the top plate. With the adoption of the prefabricated pile cap for the composite foundation, the engineering construction speed and quality can be effectively increased, and the cost can be reduced. The prefabricated pile cap for the composite foundation has the advantages as follows: 1, the prefabricated pile cap for the composite foundation can be disassembled into the top plate and the fixing sleeve, so that all components cannot be overweight, construction is facilitated, and the rent of machinery can be reduced.

Owner:ARCHITECTURAL DESIGN INST FUKIEN PROV

Constructing method for high-rise building elevator shaft through elevating type safety protection steel platform

InactiveCN102031862AEasy to processSave leaseBuilding material handlingBuilding support scaffoldsEconomic benefitsArchitectural engineering

The invention discloses a constructing method for a high-rise building elevator shaft through an elevating type safety protection steel platform, comprising the steps of: firstly, manufacturing a steel platform matched with the size of an elevator shaft, then installing the steel platform inside the bottom layer of the elevator shaft, carrying out elevator shaft construction operation by constructors standing on the steel platform, elevating the steel platform layer by layer after the construction on the current operation layer is completed until the steel platform is elevated to the elevator shaft of the upper floor to facilitate the elevator shaft construction operation, sealing the lower elevator shaft after the steel platform is elevated, and repeating the steps until the elevator shaft construction on all the floors of the whole building is completed. The construction method is featured by safety, simplicity and convenience for operation, easiness for construction, obvious economic benefits and the like, has the greatest advantages of saving lease expense of raw materials and facilitating cost control, and is particularly suitable for high-rise buildings and multistoried buildings with longer construction periods.

Owner:THE THIRD CONSTR & ENG OF CCFED

Rapid installation method of crane light rail sliding conducting wire

The present invention discloses a rapid installation method of a crane light rail sliding conducting wire. According to the present invention, according to the load of an installed and debugged crane, a temporary crane power supply electric cable is laid so as to ensure normal operation of the crane; a light rail sliding conducting wire to be installed is lifted onto a position below the installation position by using the crane; one end of a lifting belt is fixed on a crane small hook, the other end of the lifting belt contacts the ground surface, and the height of the crane small hook is adjusted before fixing the lifting belt so as to make the crane small hook do not affect the lifting and the installing of the light rail sliding conducting wire during the lifting operation; and an operation platform is built on the crane current collector maintenance hanging cage side surface close to the sliding conducting wire bracket, and can not contact the crane beam and the sliding conducting wire bracket. The method of the present invention has the following advantages that: the rapid installation construction progress of the crane light rail sliding conducting wire is accelerated, the safety and the reliability are provided, the influential factors are less, and the economic benefits are high.

Owner:CHINA MCC17 GRP

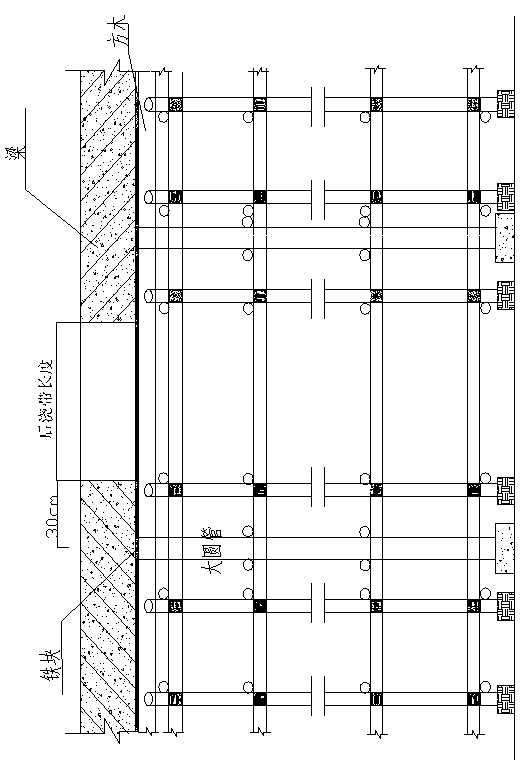

Construction process for implementing post-cast strip casting by post-cast strip stiff steel pipe support system

ActiveCN103061509ASave on rental costsGood economic benefitsBuilding material handlingPipe supportEngineering

The invention relates to a construction process for implementing post-cast strip casting by a post-cast strip stiff steel pipe support system and relates to the construction technique of post-cast strip casting for buildings. Arranging two rows of holes on spread beam-bottom form boards, and a straight stiff steel pipe is allowed to penetrate through each hole. A hoop steel pipe is disposed between the two rows of straight stiff steel pipes below the two rows of holes. Floor concrete is cast on the beam-bottom form boards. After the cast floor concrete solidifies, the hoop steel pipe is removed and concrete casting and maintenance are performed to post-cast strips. The beam-bottom form boards and the straight rigid steel pipes are removed finally. Cost of secondary form erecting materials is low, cost in renting the material is lowered greatly, and the total cost is about two times of that of the existing construction method. The straight stiff steel pipes are reusable. The construction segments are mutually communicated, so that effective and fast turnover of the materials is guaranteed, engineering cost is reduced greatly and construction period is shortened greatly.

Owner:扬州市江都区仙女基础设施建设有限公司

Method for block-by-block casting of concrete continuous beam bridge by using military truss shift mould

InactiveCN102206934ALight weightEasy to assemble and disassembleBridge erection/assemblyBridge materialsContinuous beamPre stress

The invention relates to a method for block-by-block casting of a concrete continuous beam bridge by using a military truss shift mould. The method is characterized by comprising the following steps of: firstly, dividing a full-span concrete continuous beam with span of L into two segmented box girders, casting the segmented box girder A located on a bridge pier and tensioning the prestress on the upper edge of the segmented box girder A; secondly, transferring withdrawn templates to the segmented box girder B located at the middle span and pouring after the segmented box girder A is cast completely, tensioning the linkage prestress of the segmented box girder A and the segmented box girder B and the prestress on the lower edge of the segmented box girder B after the strength is achieved, finally, transferring the withdrawn templates to the segmented box girder A of the next span to cast. The cross section of the concrete continuous beam can be of a single-box single-chamber type, a single-box two-chamber type, a single-box three-chamber type, a single-box four-chamber type, a single-box fifth-chamber type or a single-box six-chamber type; the bridge pier adopts a non-cover beam column structure comprising a single-column bridge pier, a dual-column bridge pier or a three-column bridge pier. Due to the adoption of the method for block-by-block casting of the concrete continuous beam bridge by using the military truss shift mould, only one set of military truss beam construction equipment with light weight, convenience in mounting / dismounting and good universality is used in construction, high construction speed and a short construction period are realized, and the majority of the members can be used repeatedly, so that good quality, cost reduction and investment saving are realized.

Owner:COMM DESIGN INST CO LTD OF JIANGXI PROV

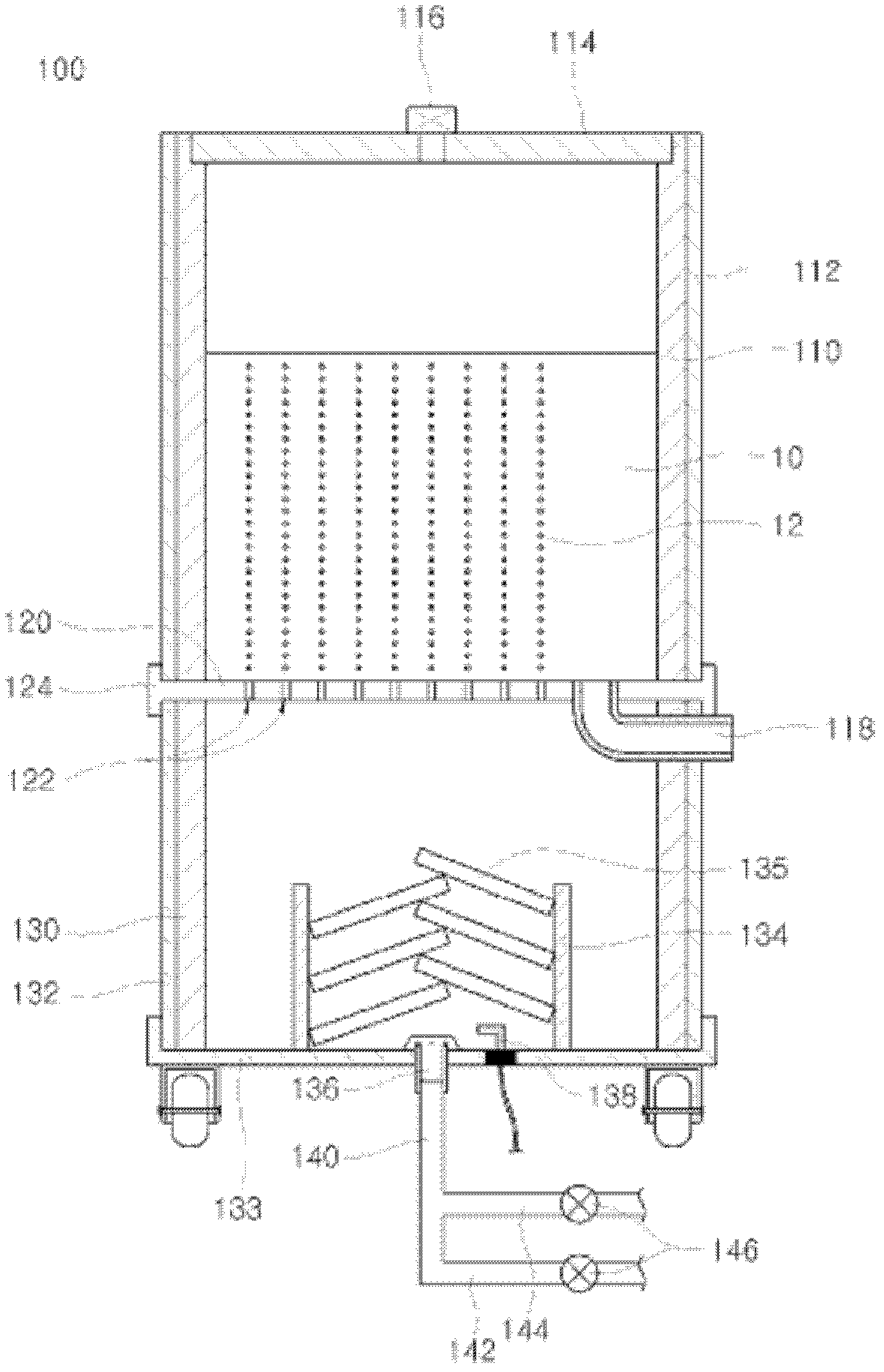

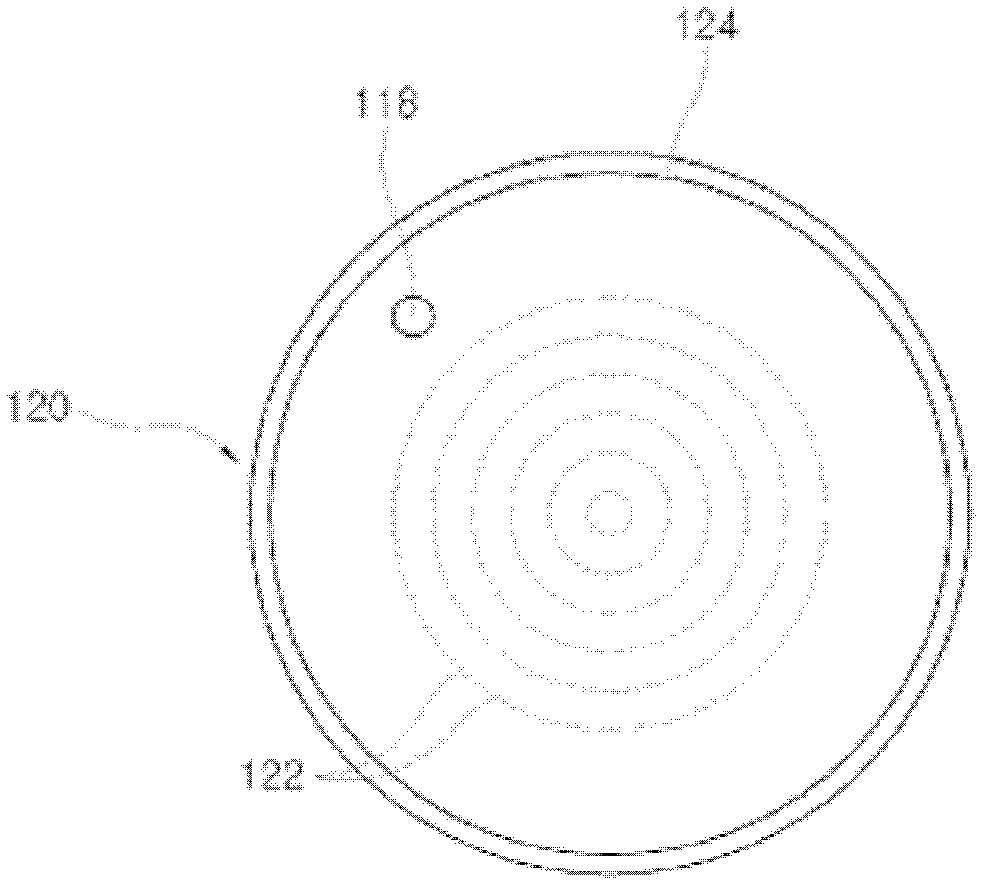

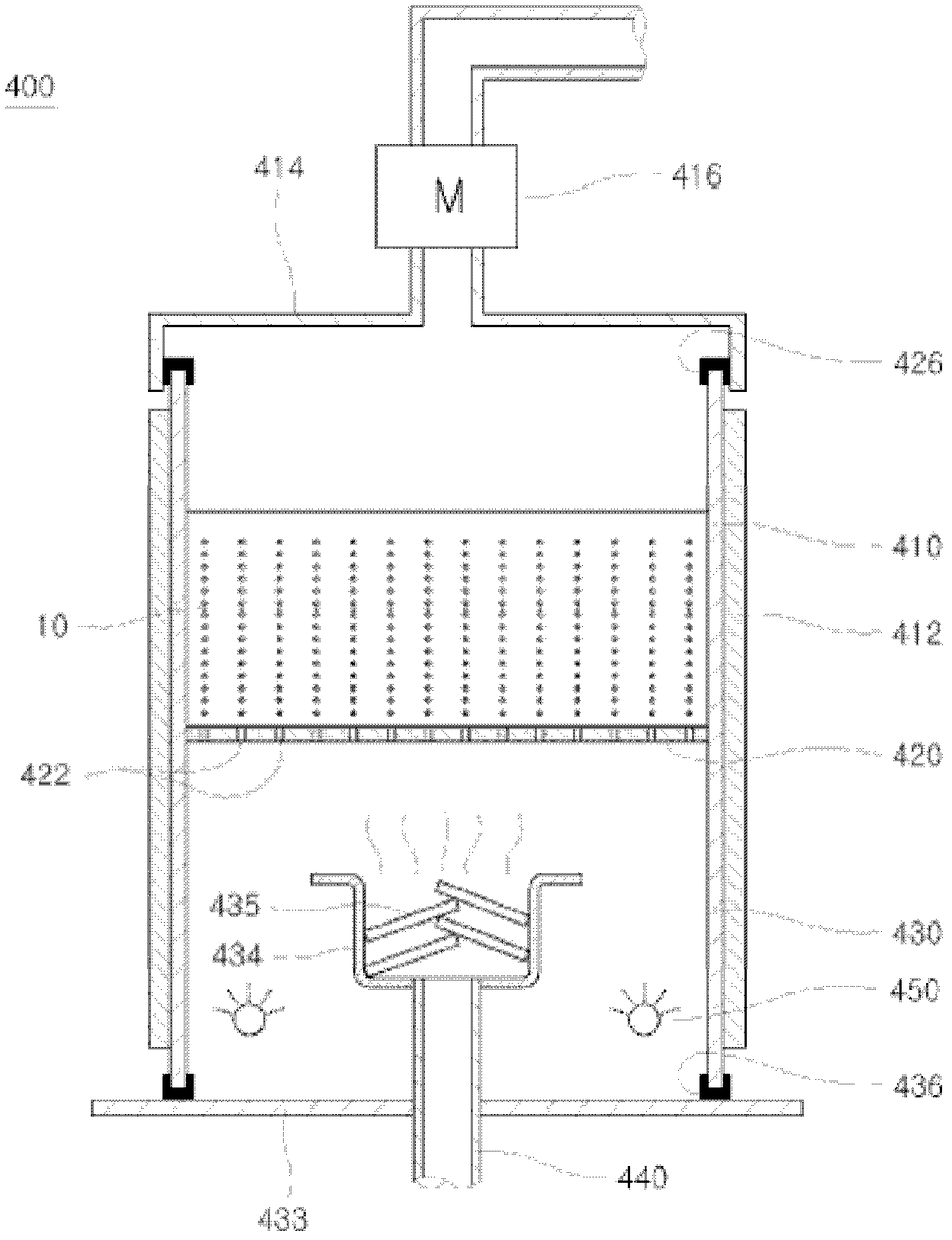

Food cooking method and device and food made using the method

InactiveCN102427749AHigh thermal efficiencyEasy cookingDomestic stoves or rangesLighting and heating apparatusCombustion chamberLiquid state

Owner:辛昶根 +1

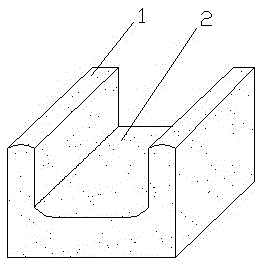

Ring beam formwork bricks and building secondary structure filler wall ring beam construction method

The invention discloses a building secondary structure filler wall ring beam construction method. The method comprises the following steps that a lower wall is built to reach the design height; formwork bricks are built on the top of the lower wall, and a groove penetrating through a beam formwork brick body is formed in the middle of each formwork brick body; the cross section of the formwork brick bodies is in a U shape; the opening end of each formwork brick faces upwards, and a ring beam steel reinforcing bar is arranged inside each annular groove; ring beam concrete is poured into the annular groove. According to the building secondary structure filler wall ring beam construction method, construction is easy and convenient, and no damage is caused to the wall below a ring beam during construction; materials are saved, the construction cost is lowered, waste of formworks and wood beams is avoided, the lease or purchase cost of a formwork clamp is lowered, and the ring beam formwork assembly and disassembly labor cost is lowered; no potential quality hazard is caused during construction, quality defects such as ring beam concrete formwork expansion are avoided, the construction progress is improved, and continuous construction can be performed on the upper and lower walls of the ring beam.

Owner:二十二冶集团第一建设有限公司

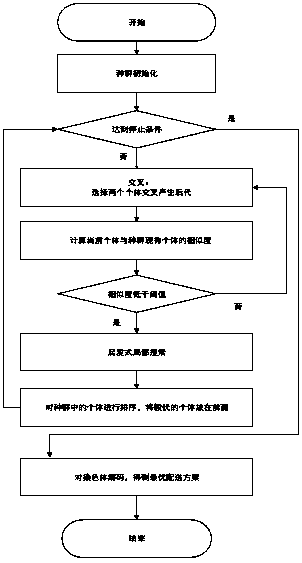

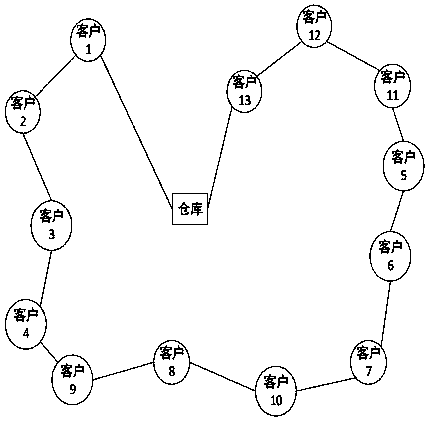

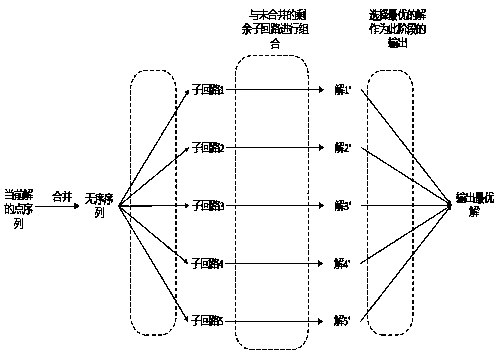

Intelligent culture gene logistics distribution method based on similarity learning

ActiveCN108921326ASave manpower and material costsSave on rental costsForecastingLogisticsLocal optimumLogistics management

The invention relates to the field of intelligent logistics distribution, and particularly relates to an intelligent culture gene logistics distribution method based on similarity learning. The methodcomprises the following steps of uploading data such as cargo data, customer coordinates, road states and the like to a database; initializing a population; checking whether stopping conditions are met or not; performing roulette selection on two individuals in the population to perform crossing to generate offspring; calculating the similarity between the current individuals; if the similarity between the individuals and existing individuals in the population is lower than a threshold value, performing heuristic local searching on the individuals; and sorting the individuals in the population, thereby selecting out the optimal individuals. A similarity concept is adopted, so that the diversity of the population is controlled to a certain degree in an iteration process of an algorithm, the situation that the population is subject to premature convergence and falls into local optimum is avoided, the searching range of the population is greatly expanded, computing resources can be usedfor more potential solutions as more as possible through the population, and the optimization capability of the population is improved.

Owner:GUANGDONG UNIV OF TECH

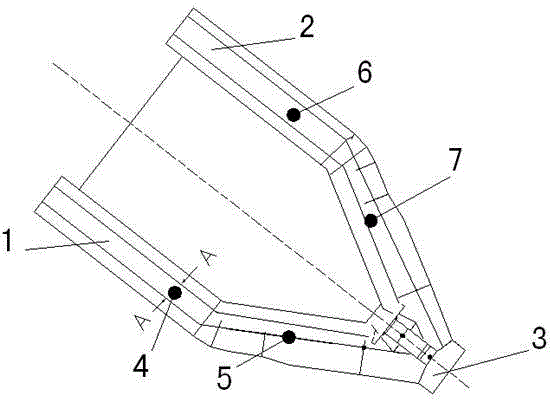

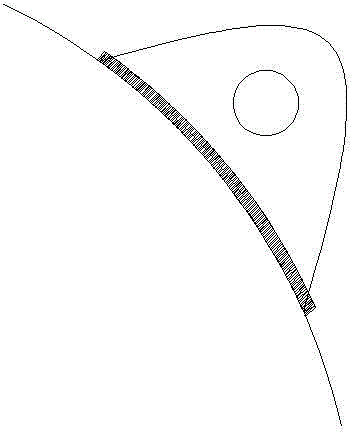

One-step integral hoisting method for Y-shaped three-way-type downcomer of blast furnace

ActiveCN104878139AIncrease in sizeLarge spanBlast furnace componentsBlast furnace detailsTurning radiusBlast furnace

The invention discloses a one-step integral hoisting method for a Y-shaped three-way-type downcomer of a blast furnace. The one-step integral hoisting method includes the technological steps of 1, welding of the Y-shaped three-way-type downcomer of the blast furnace, 2, hoisting preparation and 3, hoisting completion. According to one-step integral hoisting method, reasonable structure and safety and reliability in use are achieved; compared with conventional hoisting modes (hoisting at upper and lower positions), the one-step integral hoisting method has the advantages that the turning radius of a crane is reduced, tonnage of the crane is reduced, rent expense of a large crane and project cost are saved, construction period is shortened, mounting quality of the Y-shaped three-way-type downcomer of the blast furnace is improved effectively, and construction cost is reduced.

Owner:CHINA MCC17 GRP

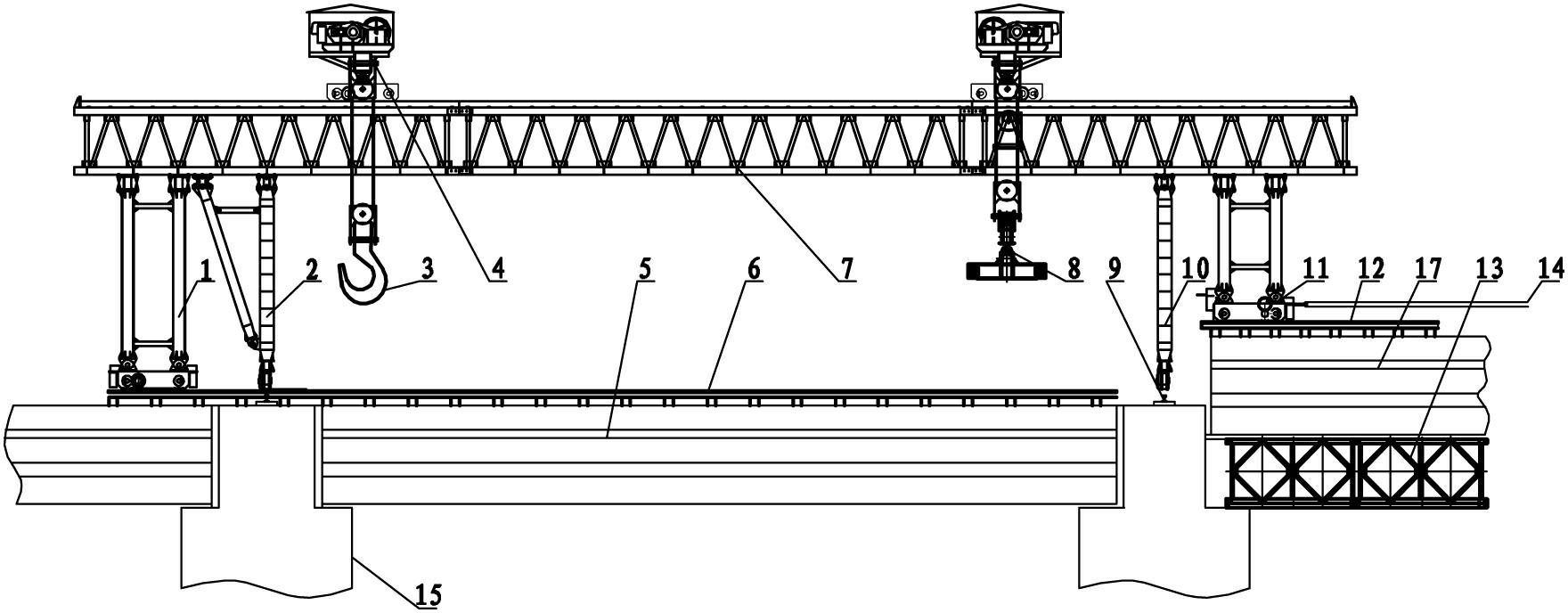

Transporting technology of large-span structural sheet

ActiveCN105109939ASolve the problem of transportation operations that cannot realize large-span structural piecesReduce inputMechanical conveyorsEngineeringMechanical engineering

A transporting technology of a large-span structural sheet comprises the following steps: 1, prefabricating the large structural sheet; 2, laying a plurality of hydraulic jacking devices at a jacking point below the large structural sheet; 3, after jacking the large structural sheet to an appointed height, mounting a temporary support below the large structural sheet; 4, connecting a transporting framework with a trolley axis of a self-powered hydraulic flat car; 5, driving the self-powered hydraulic flat car below the large structural sheet, and after jacking the large structural sheet, transporting the large structural sheet out of a workshop to an advanced outfitting site; 6, driving the self-powered hydraulic flat car away, and supporting by the temporary support; 7, driving the self-powered hydraulic flat car below the large structural sheet, and after jacking the large structural sheet, transporting the large structural sheet to a spraying workshop; and 8, after finishing spraying the large structural sheet, transporting the sprayed large structural sheet out of the spraying workshop to an assembly site, and carrying out assembly operation. The transporting technology solves the problem that the existing site transporting vehicle cannot realize the transporting operation of the large-span structural sheet and realizes safe and efficient transporting operation.

Owner:CHINA NAT OFFSHORE OIL CORP +2

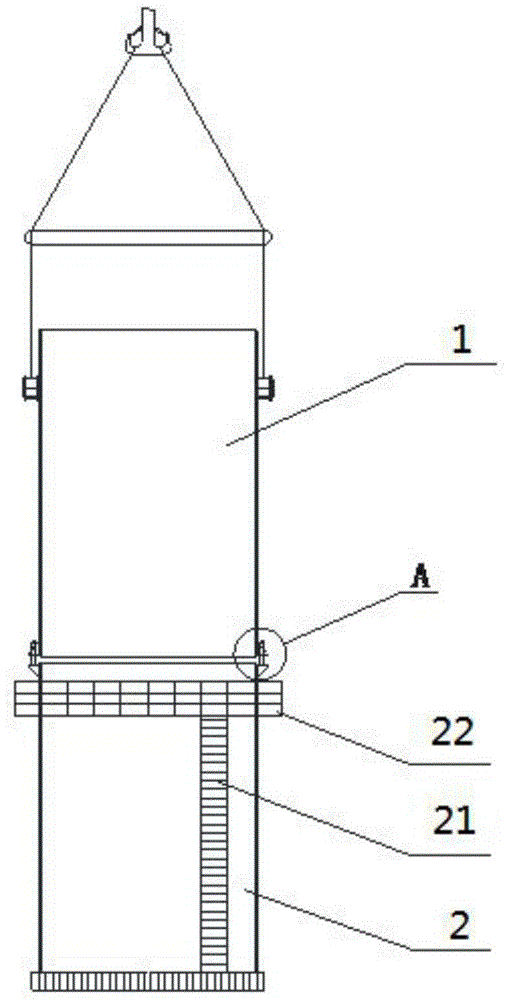

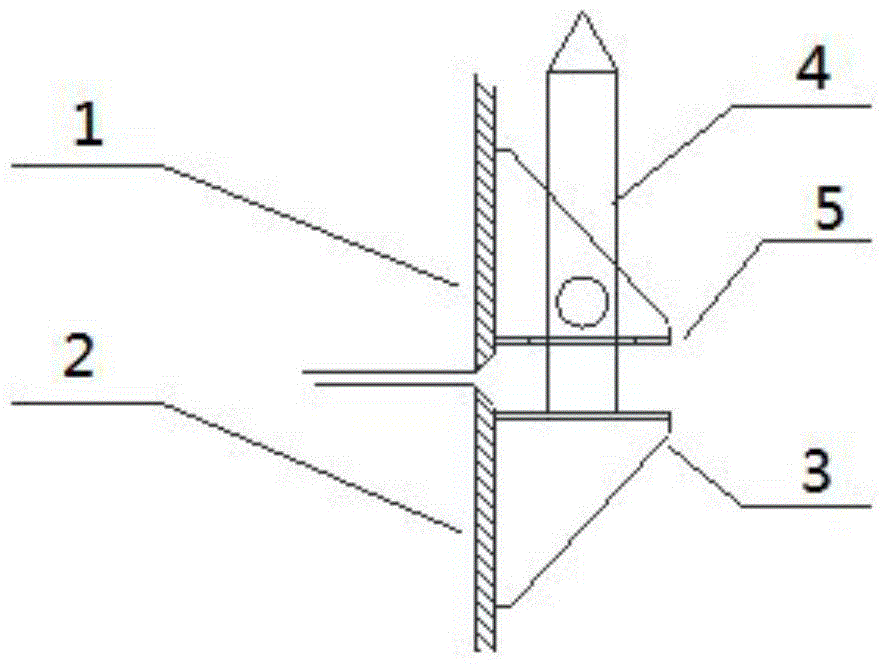

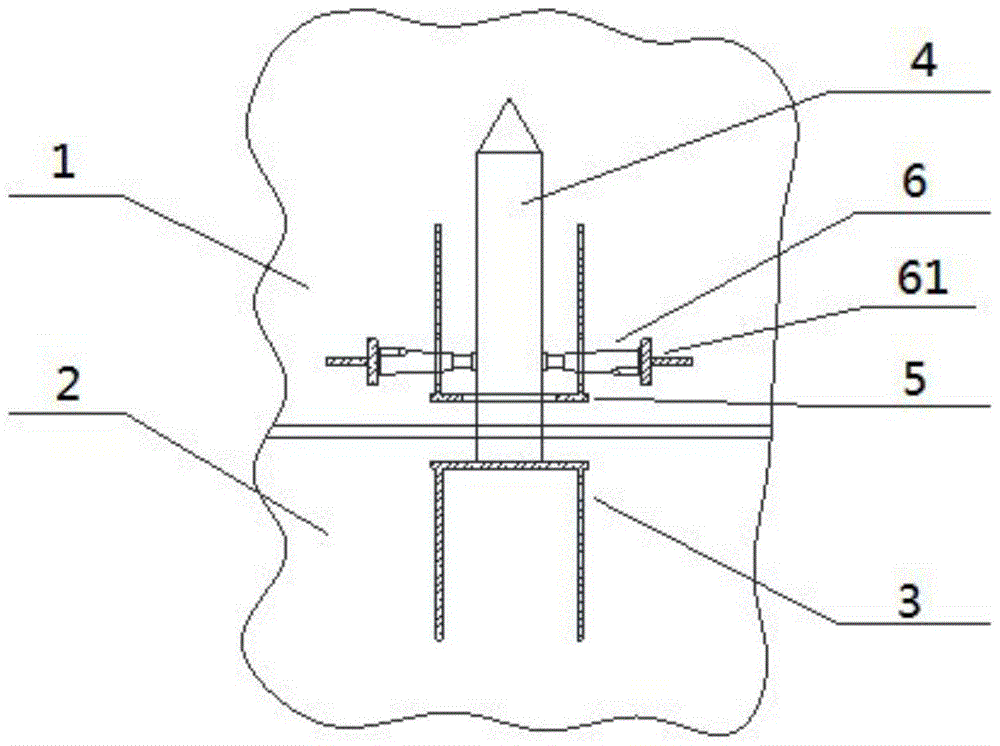

In-place guiding device for segmented hoisting and air pairing of heavy tower equipment

The invention discloses an in-place guiding device for segmented hoisting and air pairing of heavy tower equipment and belongs to the technical field of equipment manufacturing and installation. According to the in-place guiding device, supporting tools are installed on the peripheral wall of the portion, close to a paired welding position, of a lower section of a tower, and guide columns are welded to the tools; guiding rings are installed on the portion, located above a paired weld joint, of the tower section to be hoisted; the guiding rings are uniformly distributed on the peripheral wall of the portion, close to the welding position, of an upper section of the tower and correspond to the guiding columns of the lower section of the tower; and the upper section of the tower is hoisted to the position above the lower section of the tower, the position of the upper section of the tower is adjusted and controlled by drawing hemp ropes tied in advance, the guiding columns installed on the upper portion of the lower section of the tower are sleeved with the guiding rings installed on the lower portion of the upper section of the tower by descending hoisting rings, and the upper section and the lower section of the tower are guided to be aligned rapidly and accurately. A brand-new method for segmented hoisting and vertical pairing of the heavy tower equipment is designed. By the adoption of the technical scheme, pairing of the upper section and the lower section of the equipment can be completed more safely, rapidly and accurately.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

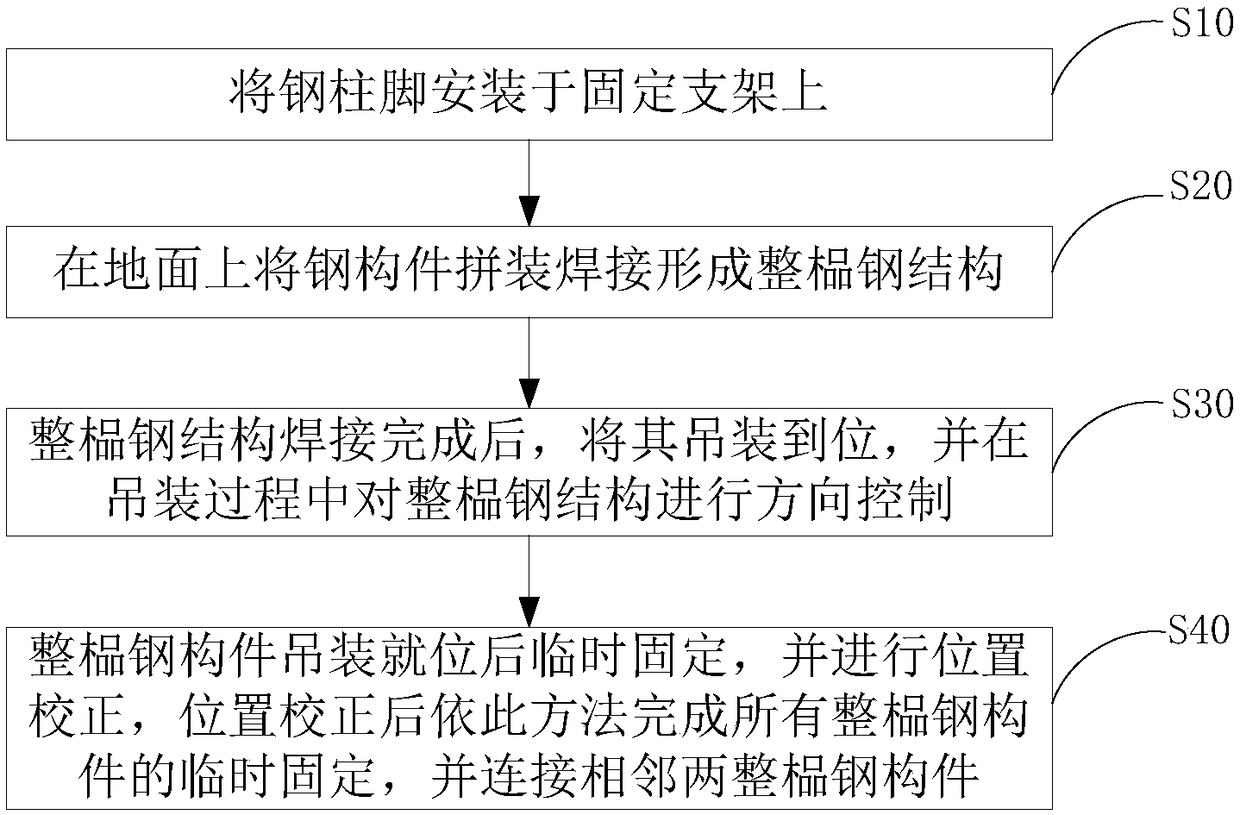

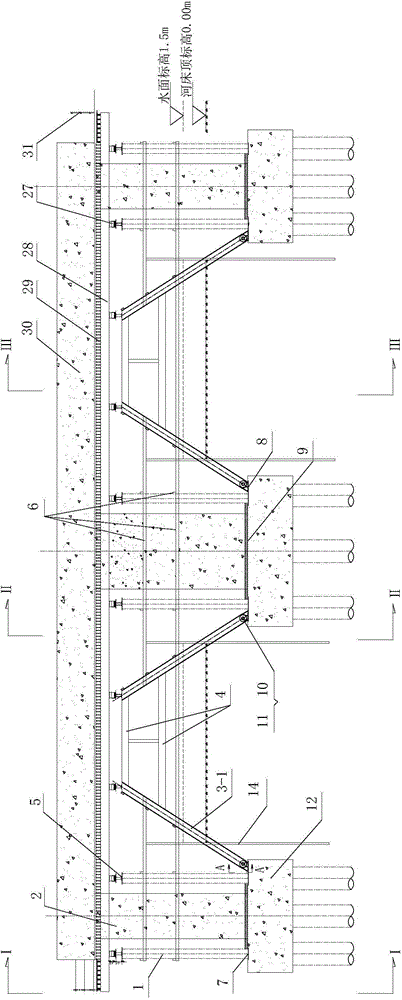

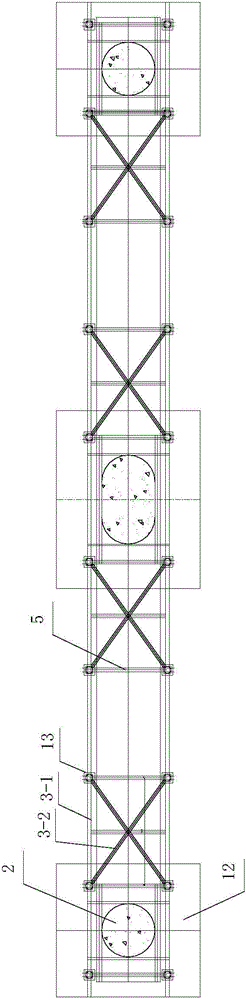

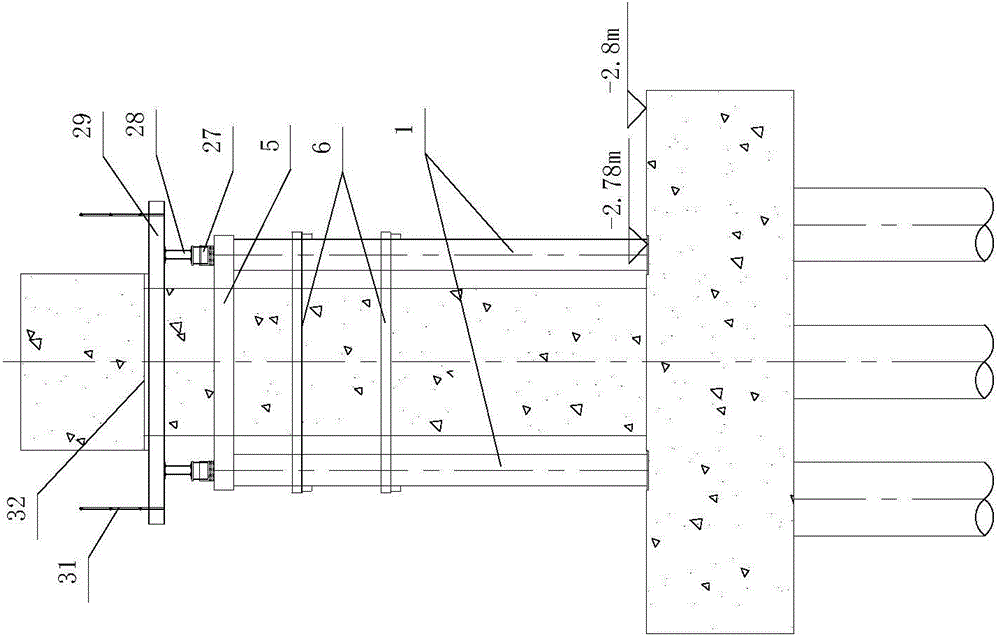

Construction method for whole-roof-truss hoisting of air return narrow lane steel structures

PendingCN109488029AReduce the risk of loose assembly in situReduce the risk of falling from heightsBuilding material handlingSteel columnsMaterials science

The invention discloses a construction method for whole-roof-truss of air return narrow lane steel structures. The construction method includes the following steps that steel column bases are mountedon fixing supports; steel members are spliced and welded on the ground to form whole-roof-truss steel structures; after the whole-roof-truss steel structures are welded, the whole-roof-truss steel structures are hoisted in place, and the whole-roof-truss steel structures are subjected to direction control in the hoisting process; the whole-roof-truss steel members are temporarily fixed after beinghoisted in place, position correction is carried out, after position correction is carried out, all the whole-roof-truss steel members are temporarily fixed with the method, and every two adjacent whole-roof-truss steel members are connected. By means of the construction method for whole-roof-truss hoisting of the air return narrow lane steel structures, the amount of aloft work is reduced, meanwhile, the working efficiency is improved, and the construction period is shortened.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

Supporting system for construction of super-long water pier prestressed cap beam

ActiveCN104452597AShorten the installation periodLow costBridge erection/assemblySupporting systemPre stress

The invention discloses a supporting system for construction of a super-long water pier prestressed cap beam. The supporting system comprises a support. The support comprises steel braces and steel tube stand columns, wherein every two steel braces are arranged between the two corresponding adjacent water piers and are arranged in a splayed shape, and every four steel tube stand columns are arranged on the periphery of the corresponding water pier. The bottom end of each brace rod is connected with a pin hinge and a support of the pin hinge. The support of the pin hinge at the bottom end of each steel brace is connected with a bearing platform of the corresponding water pier through an embedded steel plate II. The top end of each brace rod and the top end of each steel tube stand column are each provided with a horizontal supporting cover plate. The horizontal supporting cover plates are fixedly provided with longitudinal supporting beams. The two ends of each longitudinal beam are each provided with a stand box. The stand boxes support transverse bearing beams. Multiple longitudinal distributive beams are fixed to the transverse bearing beams. The longitudinal distributive beams form a systematic horizontal supporting face. The supporting system for construction of the super-long water pier prestressed cap beam is high in bearing capacity, high in stability and suitable for construction of the super-long water pier prestressed cap beam with the length being over 40 m, the installation height being over 8 m and the clear intervals between pier bodies being larger than 18 m.

Owner:中建六局第一建设有限公司 +1

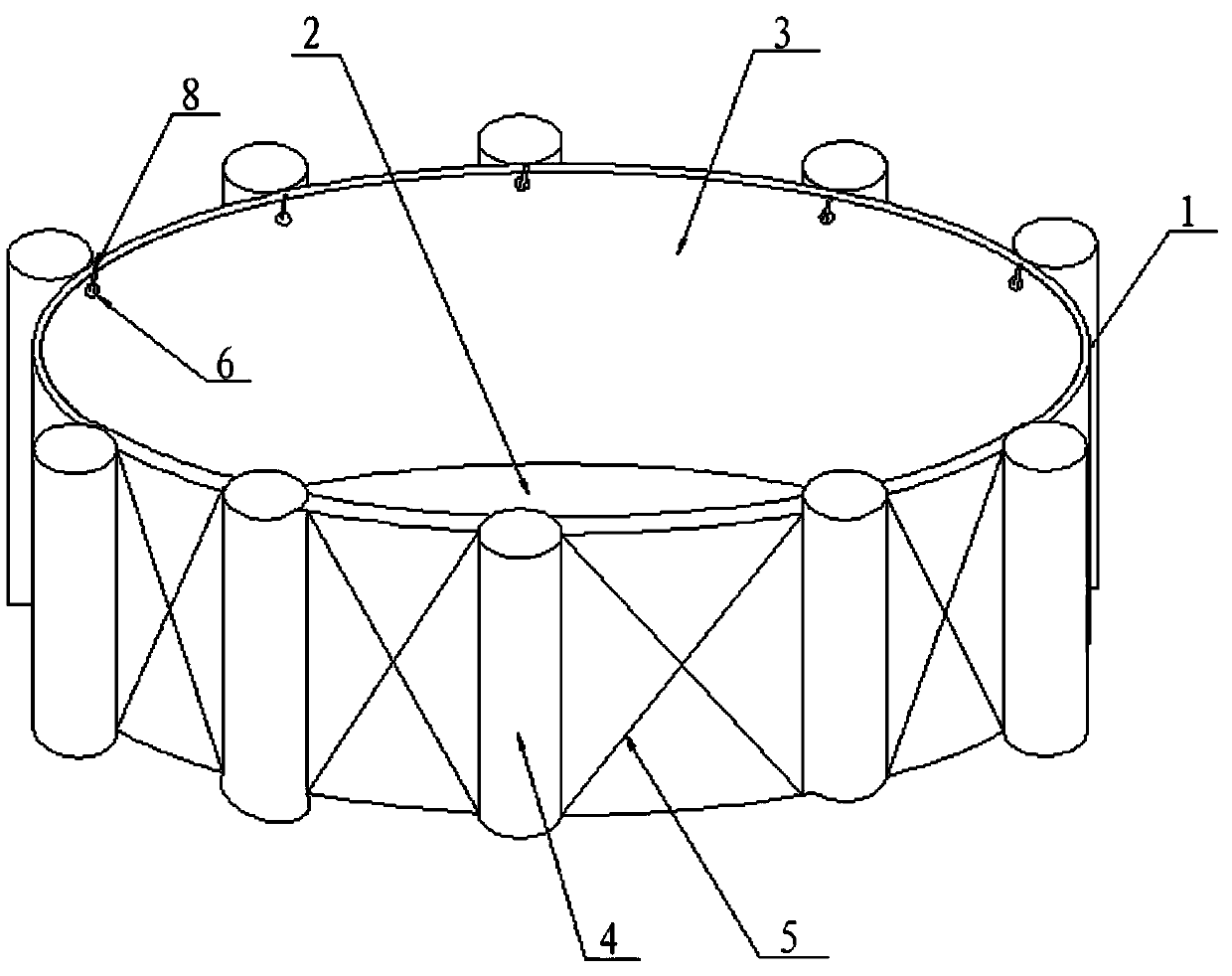

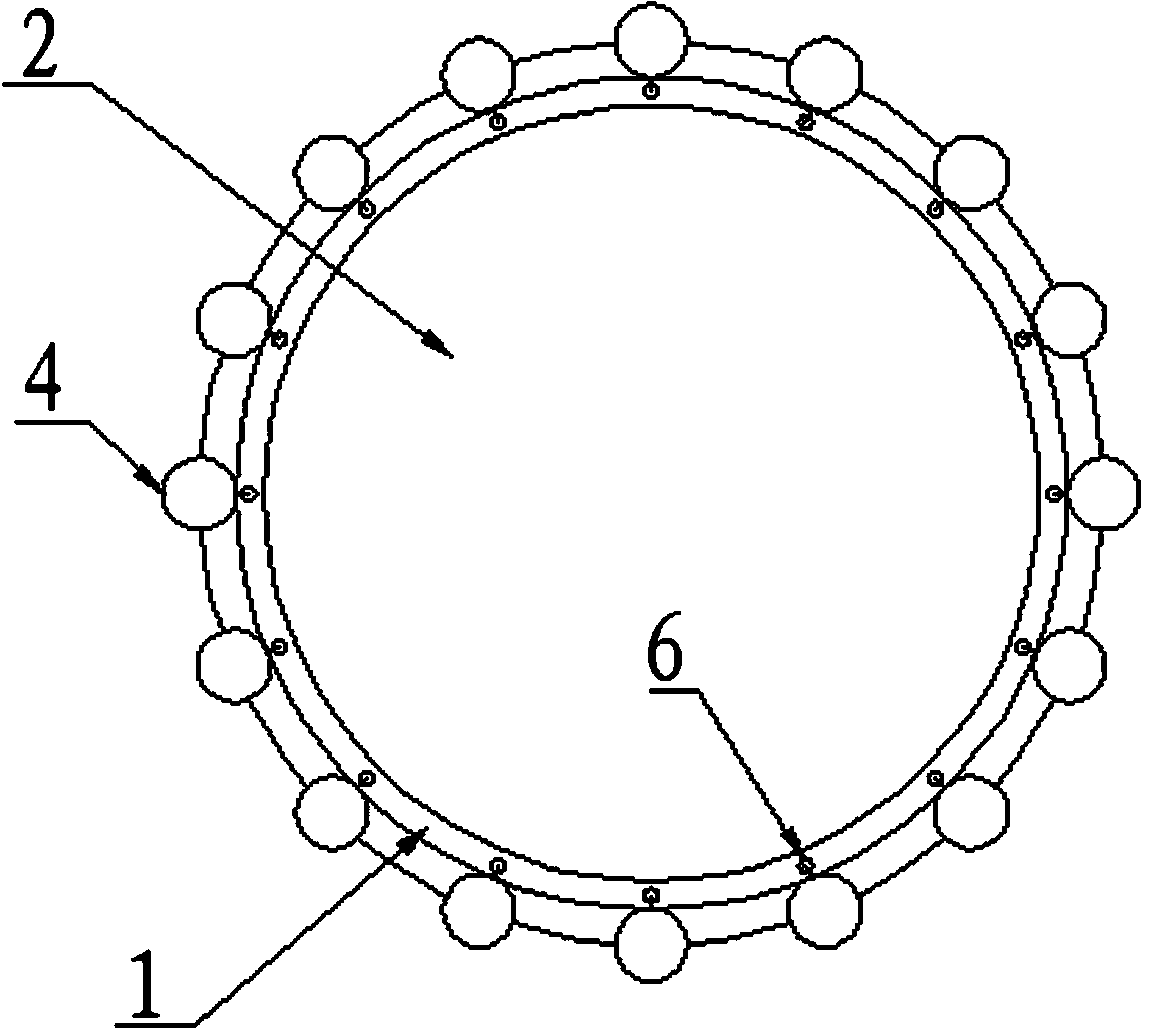

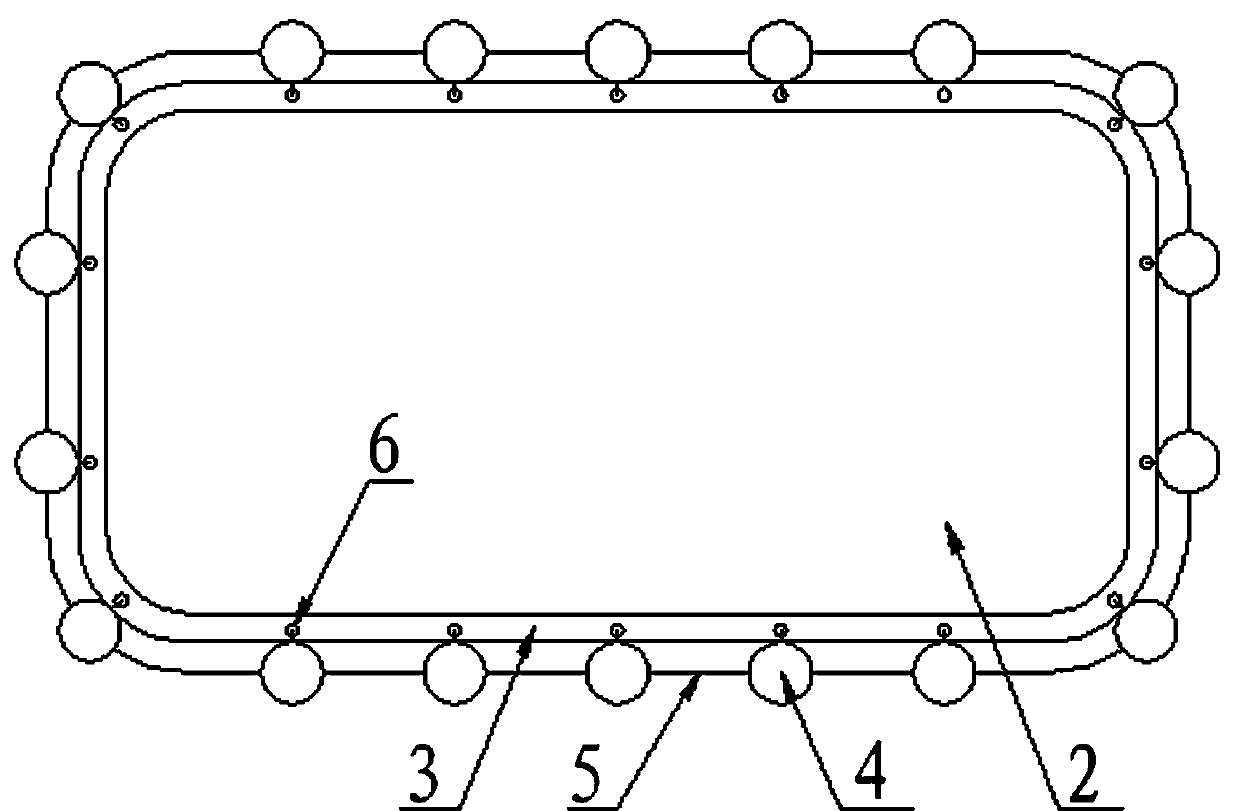

Large-scale emergency rapid waterproof cloth water storage tank

ActiveCN103422567AQuick releaseSave moneySewerage structuresWater storage tankMechanical engineering

The invention provides a large-scale emergency rapid waterproof cloth water storage tank which comprises a water tank body, and the water tank body comprises a tank bottom and side walls. A plurality of supporting pillars are arranged on the peripheries of the side walls. The large-scale emergency rapid waterproof cloth water storage tank has the advantages of being simple in structure, convenient to use, capable of being mounted and dismounted at any time according to needs, low in manufacturing cost and good in using effect.

Owner:WEIFANG XINSHAN ENVIRONMENTAL PROTECTION HEAVY IND TECH

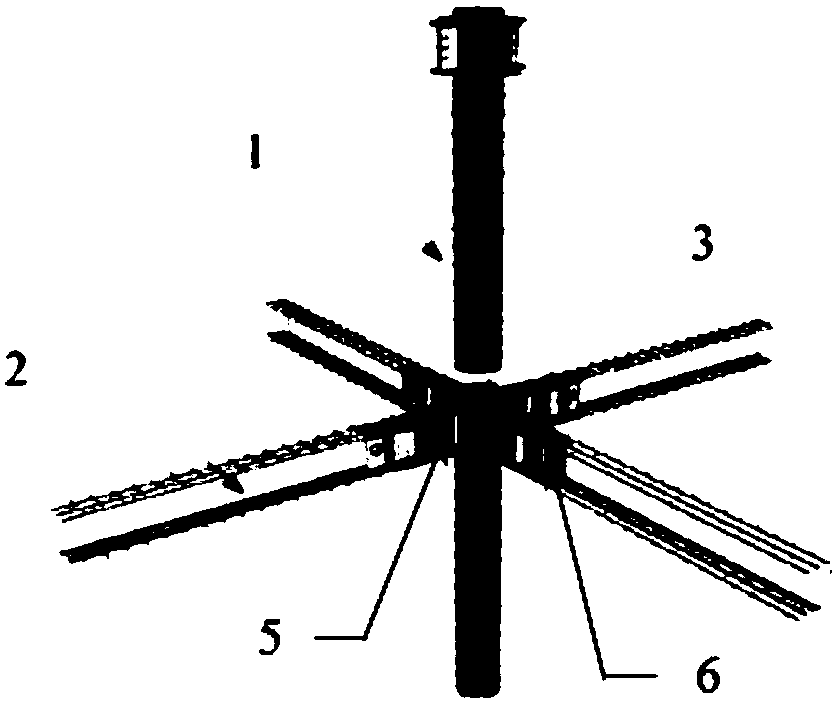

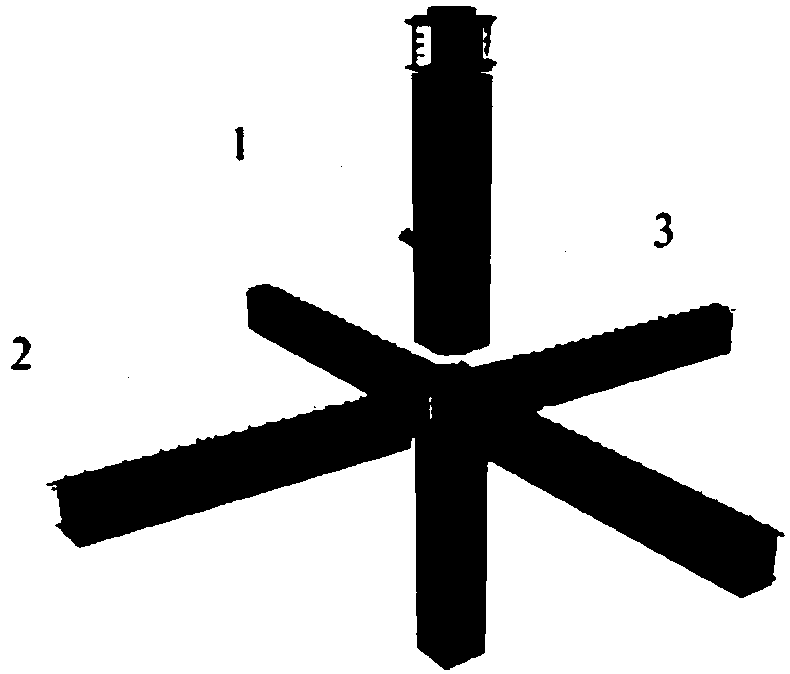

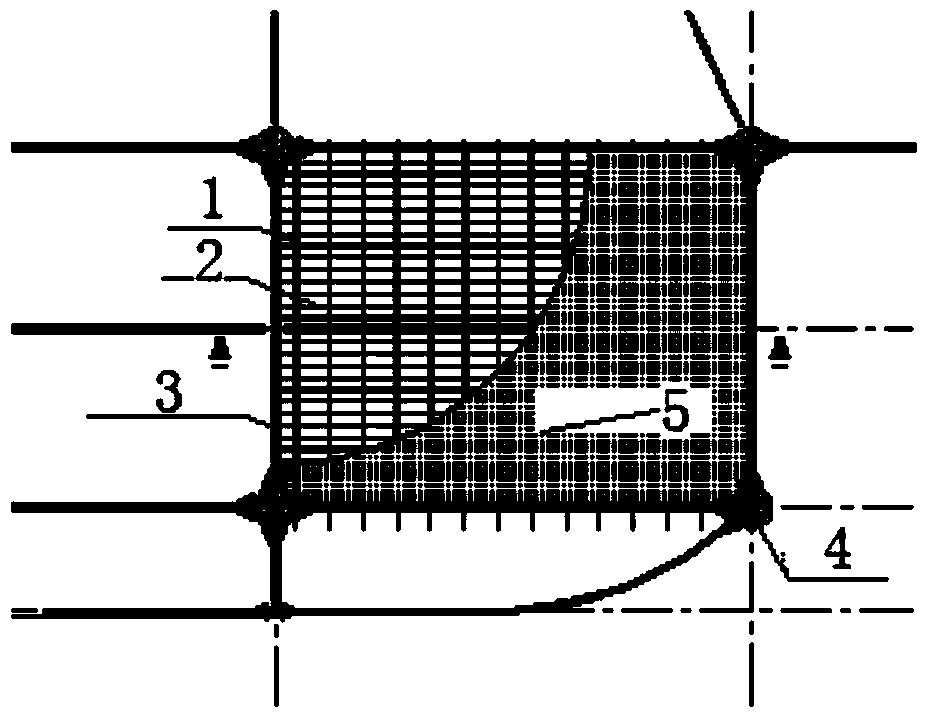

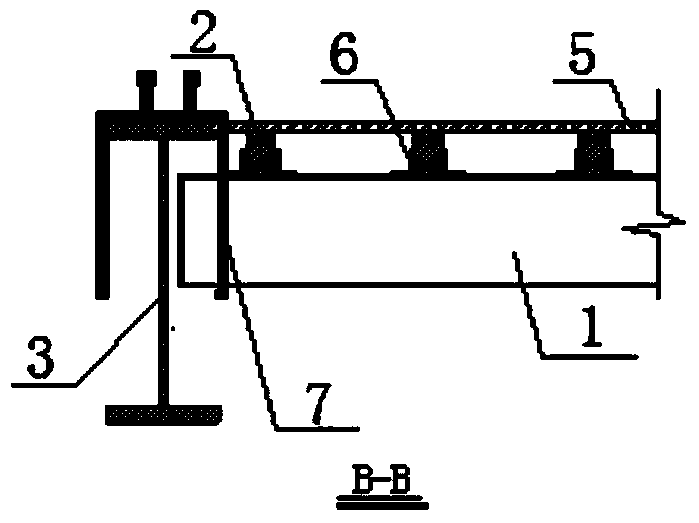

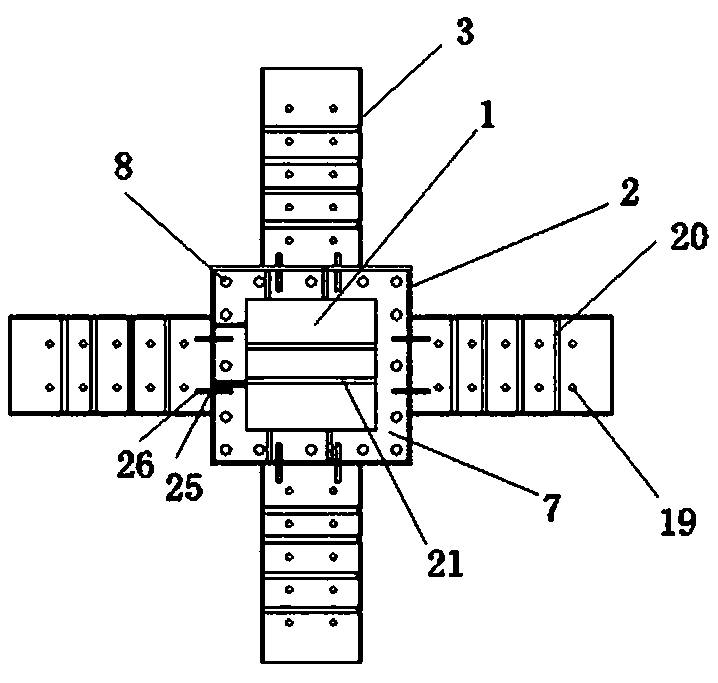

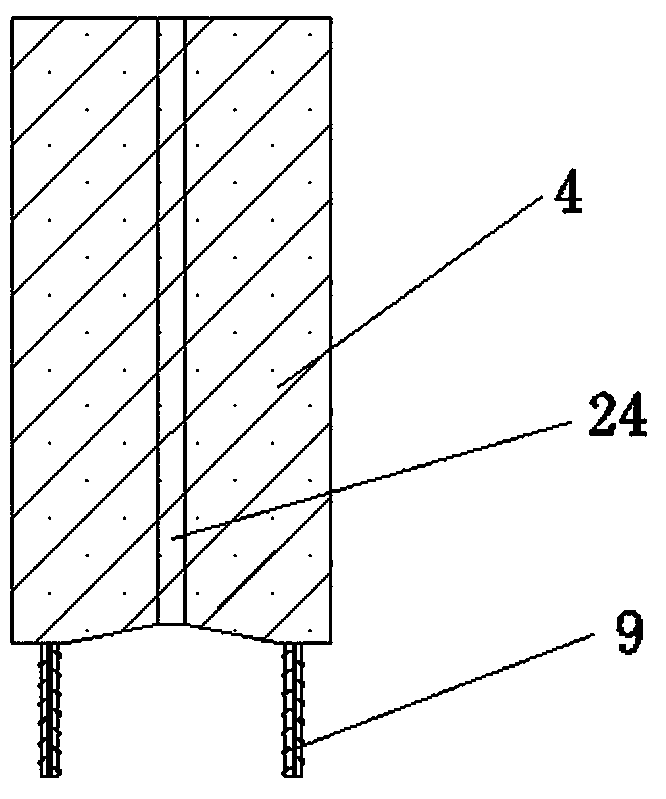

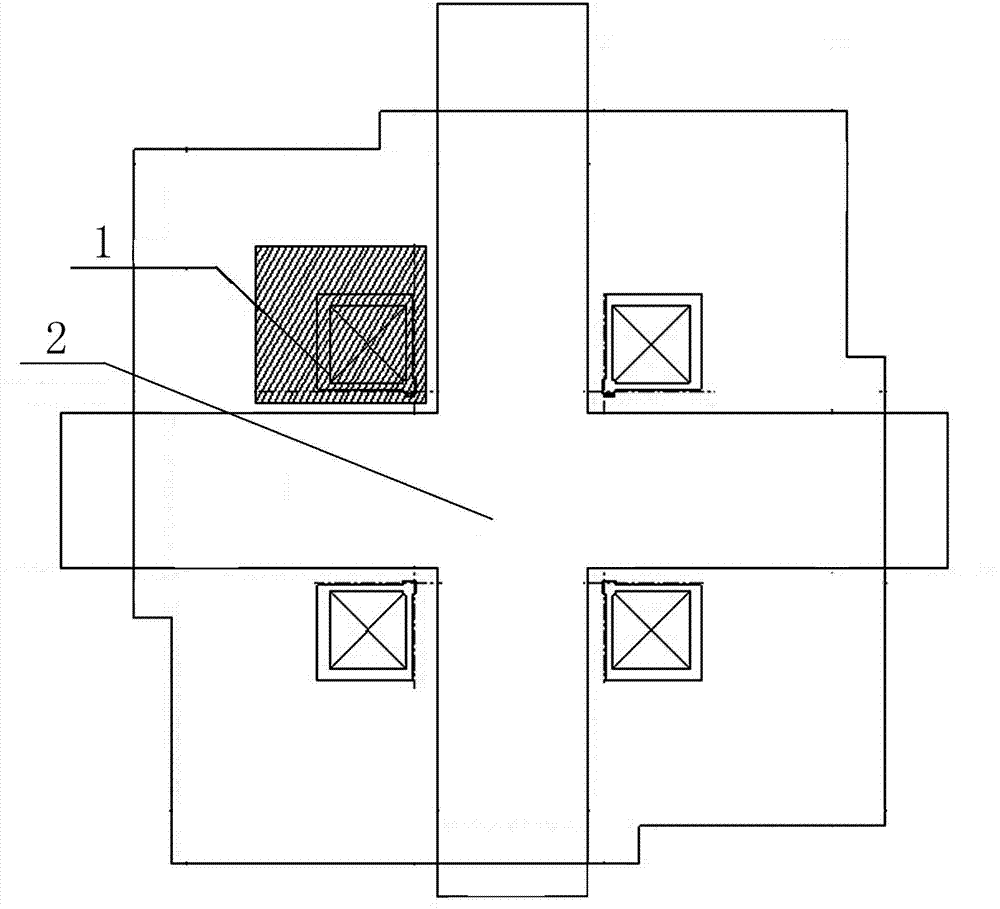

Fabricated type concrete frame beam column connecting construction of steel tube with U-shaped steel brackets

PendingCN109707040AFast installationSuperior seismic performance of structural nodesProtective buildings/sheltersBuilding material handlingRebarSteel tube

The invention provides a fabricated type concrete frame beam column connecting construction of a steel tube with U-shaped steel brackets. The fabricated type concrete frame beam column connecting construction of the steel tube with the U-shaped steel brackets comprises a steel joint, a prefabricated lower cutted column, a prefabricated upper cutted column and 2-6 prefabricated superposed beams. The steel joint comprises an annular steel tube and the 2-6 U-shaped steel brackets. More than two annular flanges are arranged on the inner wall of the annular steel tube, the annular flange at the bottommost end is parallel and level with the bottom of the annular steel tube, and a plurality of steel bar positioning holes are formed in the annular flanges. A plurality of upper reserved longitudinal ribs are arranged on the prefabricated upper cutted column, a plurality of lower reserved longitudinal ribs are arranged on the prefabricated lower cutted column, external threads are arranged on the end parts of the lower reserved longitudinal ribs, and the lower reserved longitudinal ribs penetrate through the steel bar positioning holes and are connected with the upper reserved longitudinal ribs through semi-grouting type steel bar joints. The bottom surfaces of the semi-grouting type steel bar joints abut against the annular flange at the most upper end. The prefabricated superposed beams are inserted into the U-shaped steel brackets. According to the fabricated type concrete frame beam column connecting construction of the steel tube with the U-shaped steel brackets, a template andsupport are not required on the outer side of the joint, the joints are not required in connection of the prefabricated superposed beams, the mounting speed is greatly improved, and the anti-seismic performance of the structural joint is more excellent.

Owner:江苏金砼预制装配建筑发展有限公司

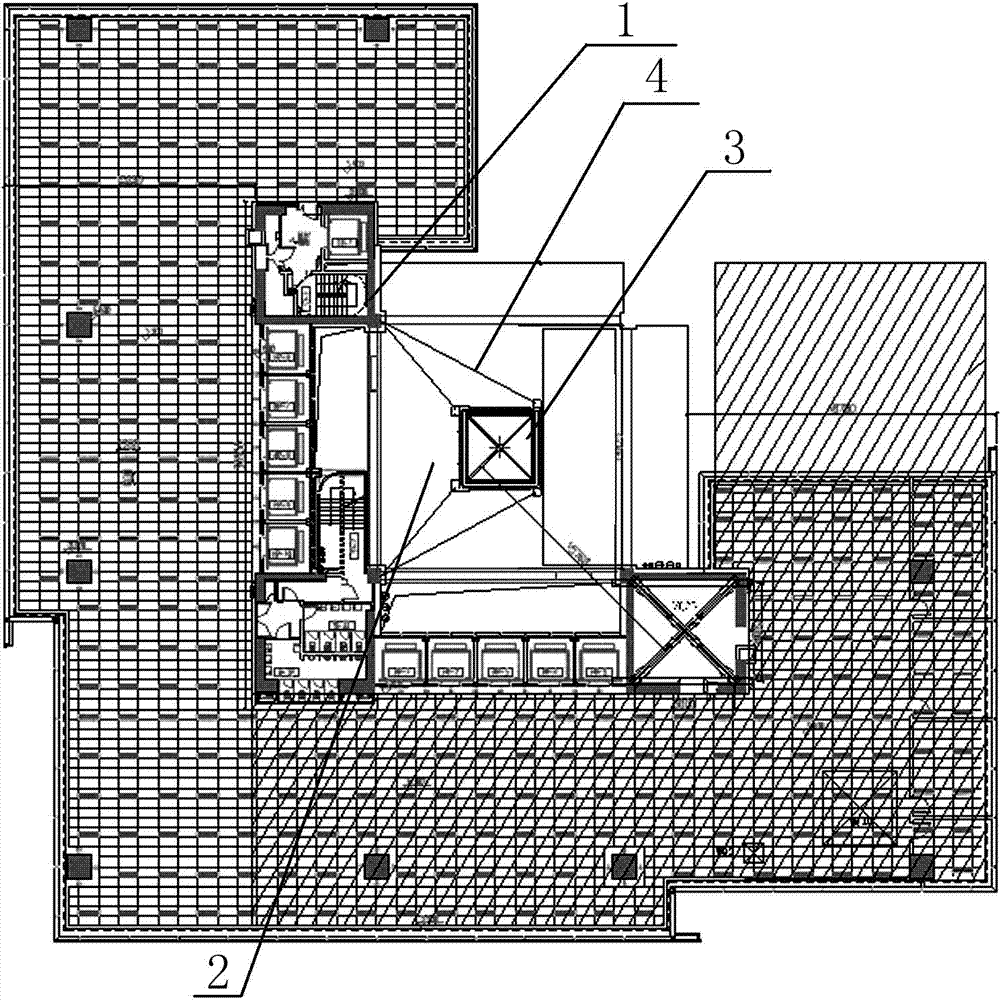

Externally attached built-in tower crane fixing structure

The invention discloses an attached built-in tower crane fixing structure. The attached built-in tower crane fixing structure is characterized in that centers of four building core tubes form a courtyard; a tower crane is arranged inside the courtyard; the tower crane is fixedly connected with the building core tubes through a wall attaching rod. In practical use, a tower hoist is saved for a general contracting unit, a crane is used at the same time, and the rental price of the crane is 70-80% of that of a jib crane. By changing the scheme, over 60% of cost can be saved for the project on the rental price of the tower; meanwhile, the internally climbing cost is also saved, and the tower crane fixing structure has good practicability.

Owner:SHANGHAI PANGYUAN CONSTR MACHINERY RENTAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com