Profile steel framework structure concrete floor slab suspension mould pouring construction method

A technology of frame structure and construction method, which is applied in the direction of construction, building structure, and construction material processing, and can solve the problems of high labor intensity for operators, slow construction progress, and high cost of construction, so as to relieve vertical transportation pressure and reduce hanging loads. Second, the effect of reducing rental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

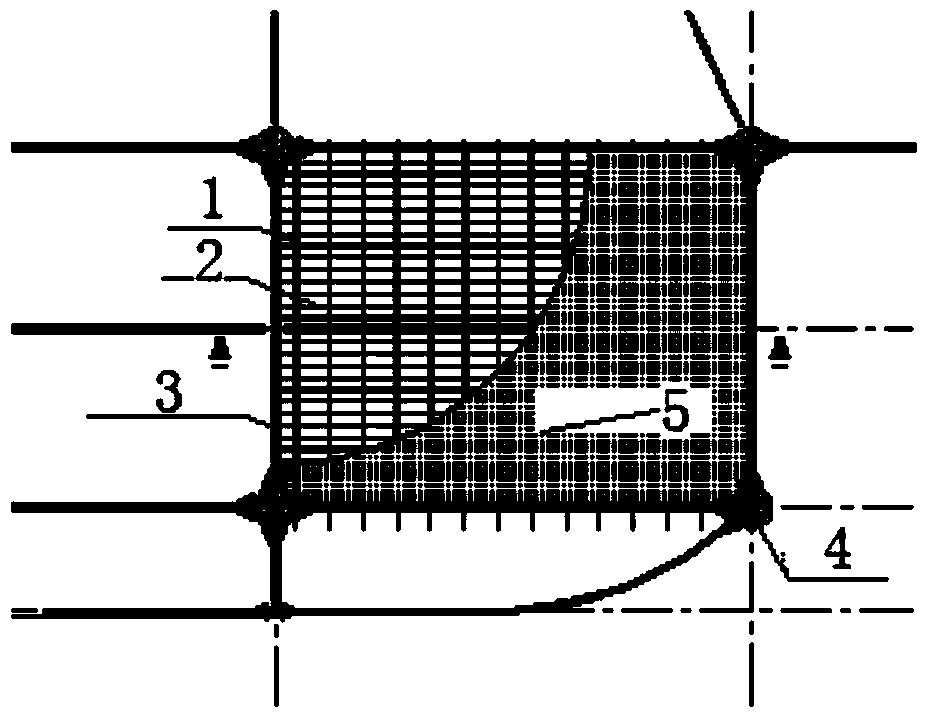

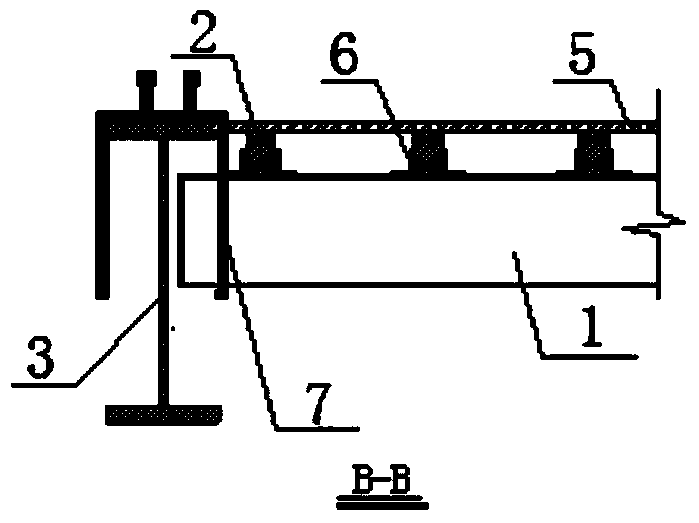

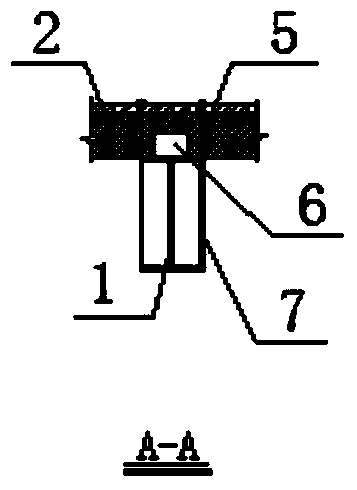

[0053] Below in conjunction with the accompanying drawings, the construction method of the concrete floor slab with steel frame structure will be concretely explained. Among them, in the accompanying drawings, it is marked as main flute 1, secondary flute 2, structural steel beam 3, structural column 4, formwork panel 5, U-shaped fastener 6, and hanger support 7.

[0054] This construction method is suitable for the construction of concrete floor slabs of steel structure concrete floors of high-rise buildings, and the optimal economic and technical spacing of structural steel beams is 2.5m to 5.0m.

[0055] The process principle is to analyze the force of the structural steel beam 3, make full use of the structural steel beam 3 as a supporting system, and use hanging bars to suspend the formwork system on the structural steel beam 3. The formwork system is mainly composed of high-frequency welded I-beams. It consists of corrugated 1 plus wooden side corrugated 2 plus formwork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com