Transporting technology of large-span structural sheet

A structural piece and large-span technology, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of inability to realize large-span structural piece transportation operations and shorten the construction period, so as to improve logistics efficiency and shorten the construction period , The effect of saving axis resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention adopts following steps:

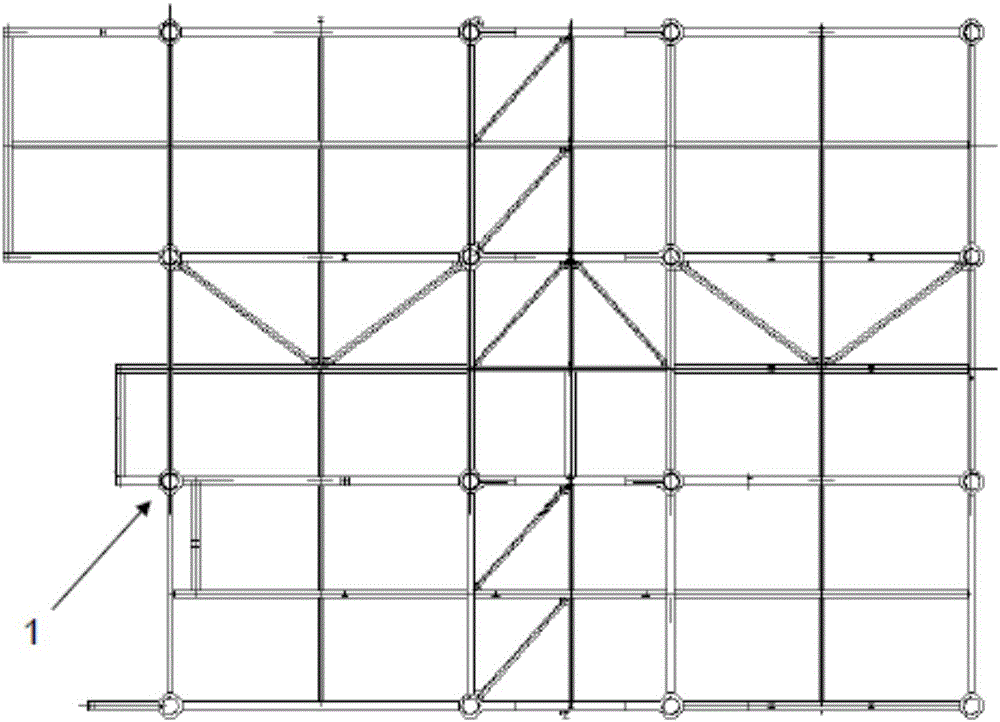

[0030] The first step: if figure 1 As shown, prefabricate the large-scale structural piece 1 in the prefabrication workshop, and pay attention to the orientation of the large-scale structural piece 1, so that it is advisable to facilitate the entry and exit of transport vehicles;

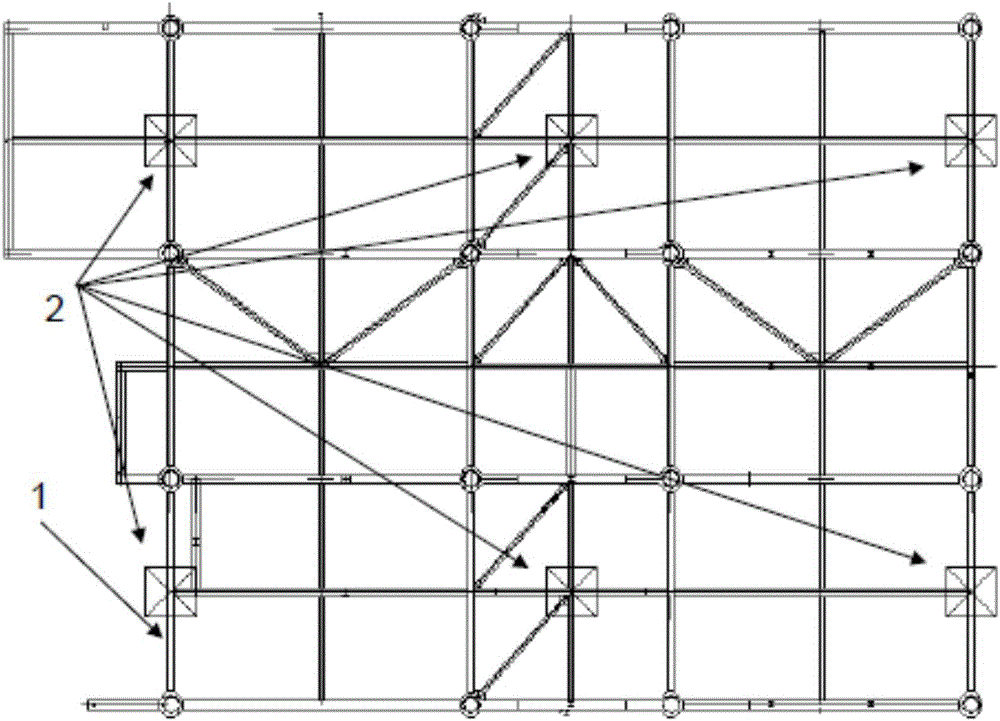

[0031] The second step: if figure 2 , image 3 As shown, according to the size and weight of the large structural piece 1, after checking the jacking strength, arrange several hydraulic jacking devices 2 at the designated jacking point under the large structural piece 1 to carry out the jacking operation;

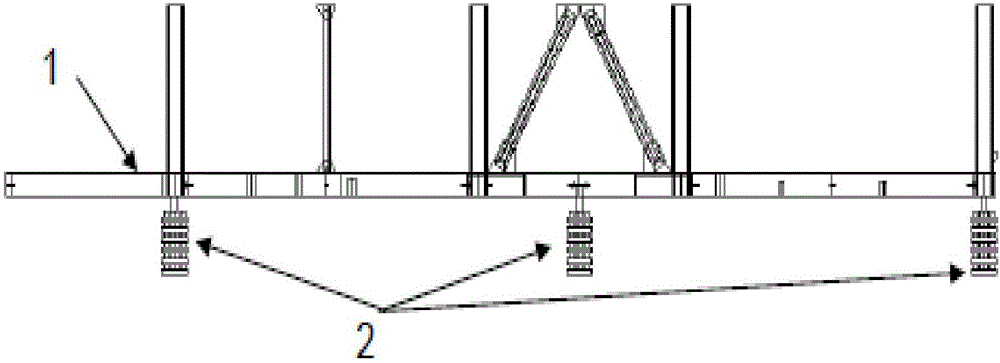

[0032] Step 3: If Figure 4 , Figure 5 As shown, after the large structural piece 1 is lifted to a specified height by the hydraulic jacking device 2, a temporary support 3 is installed at a designated position under the large structural piece 1 by welding to support and fix the large structural piece 1. Then, withdraw from the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com