Externally attached built-in tower crane fixing structure

A tower crane and fixed structure technology, which is applied in building construction, building material processing, construction and other directions, can solve problems such as reducing construction costs, achieve good practicability and save internal climbing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below with reference to accompanying drawing, the present invention is further described

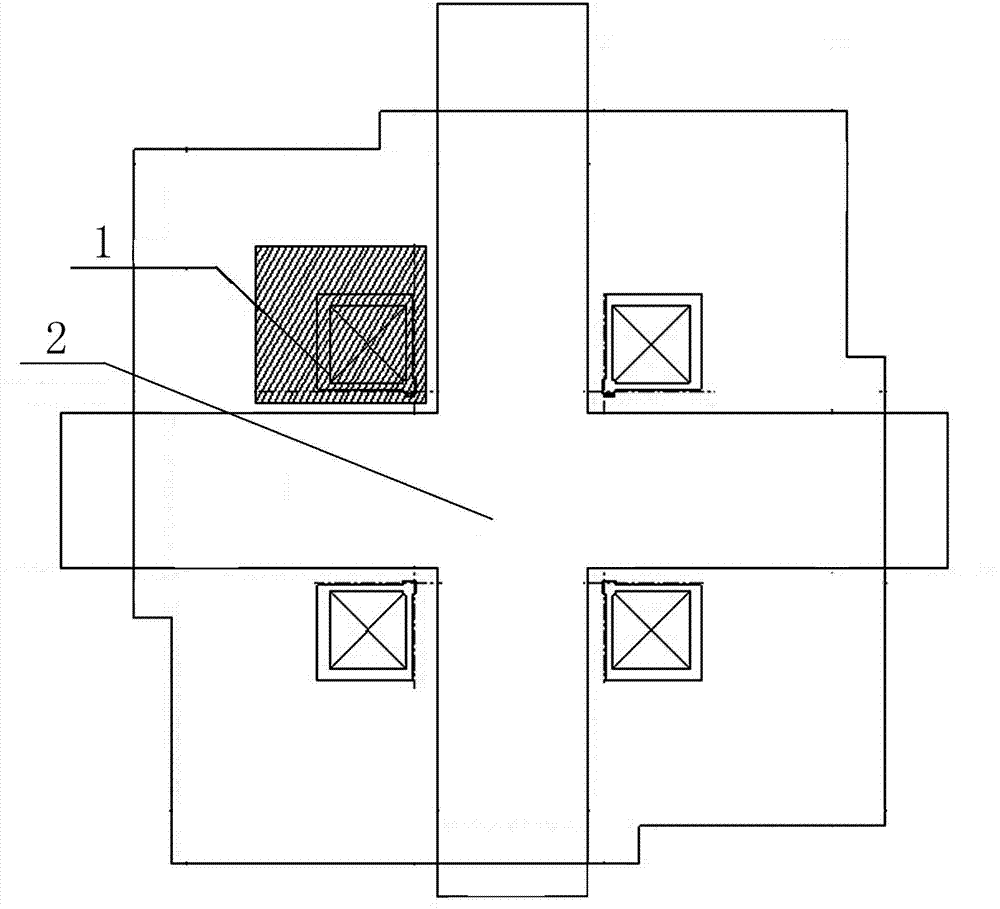

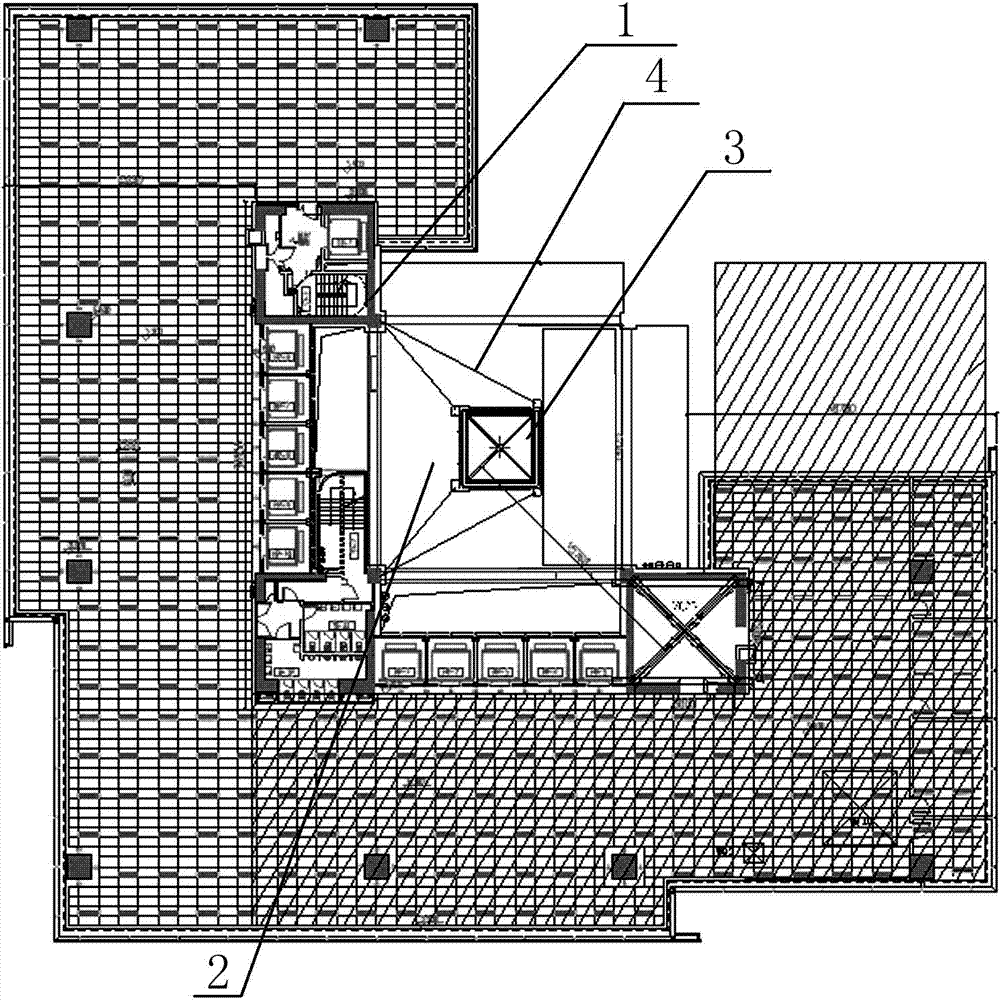

[0010] The present invention is a tower crane fixed structure with external attachment and internal installation, which mainly includes four building core tubes 1, and is characterized in that: a patio 2 is formed in the center of the four building core tubes 1, and a patio 2 is provided inside the patio 2 The tower crane 3, the tower crane 3 is fixedly connected with the building core tube 1 through the wall-attached rod 4, this design scheme can change the original boom crane into a flat boom crane, which reduces the rental cost and saves the tower crane Climbing costs.

[0011] In actual implementation, installing a 1,100-ton-meter flat-arm tower crane in the patio can fully realize the hoisting requirements proposed in the project. The tower crane attached to the wall is just like the external tower crane, just attached to the pillars of the two core tubes.

[0012] The above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com