Supporting system for construction of super-long water pier prestressed cap beam

A technology of support system and pier in water, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high cost, difficult construction, long construction period, etc., and achieve cost saving, construction difficulty and shorten the installation period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

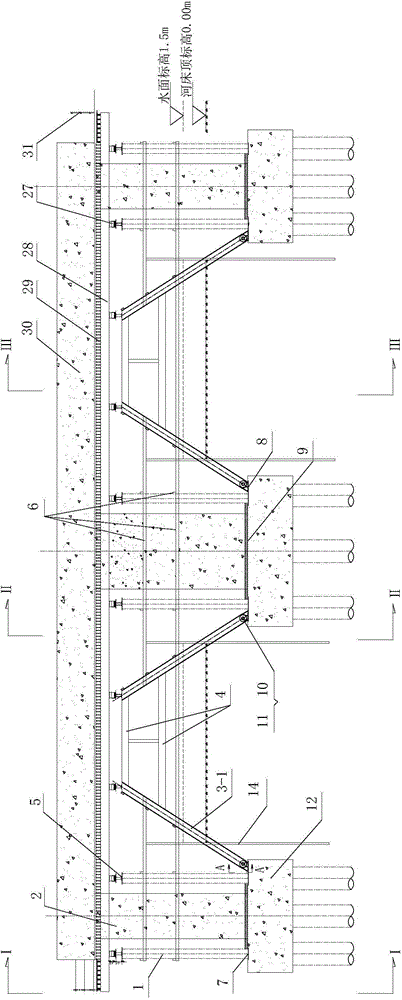

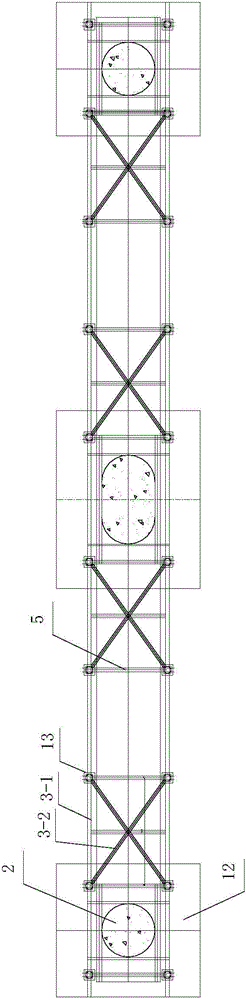

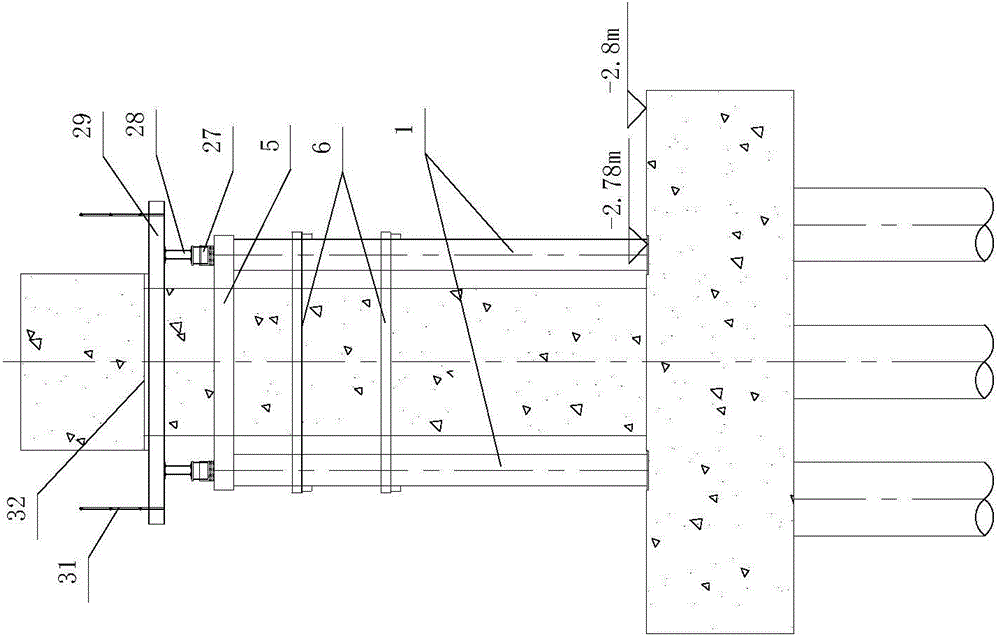

[0035] Please refer to the accompanying drawings, a super-long prestressed cover beam construction support system for submerged pier, at least two submerged pier columns 2 are arranged at the lower part of the cover beam 30, and the support system includes a bracket and its upper supporting structure.

[0036] The support includes two steel diagonal braces arranged in a figure-eight shape between two adjacent water piers 2 and four steel pipe columns 1 arranged around each water piers; corresponding to each of the water piers The bottom ends of the four steel pipe columns 1 of the pier column 2 are fixed to the four corners of the cap 12 of the pier column 2 in the water through the embedded steel plate I7; each of the steel diagonal braces is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com