Patents

Literature

42results about How to "Reduced specifications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

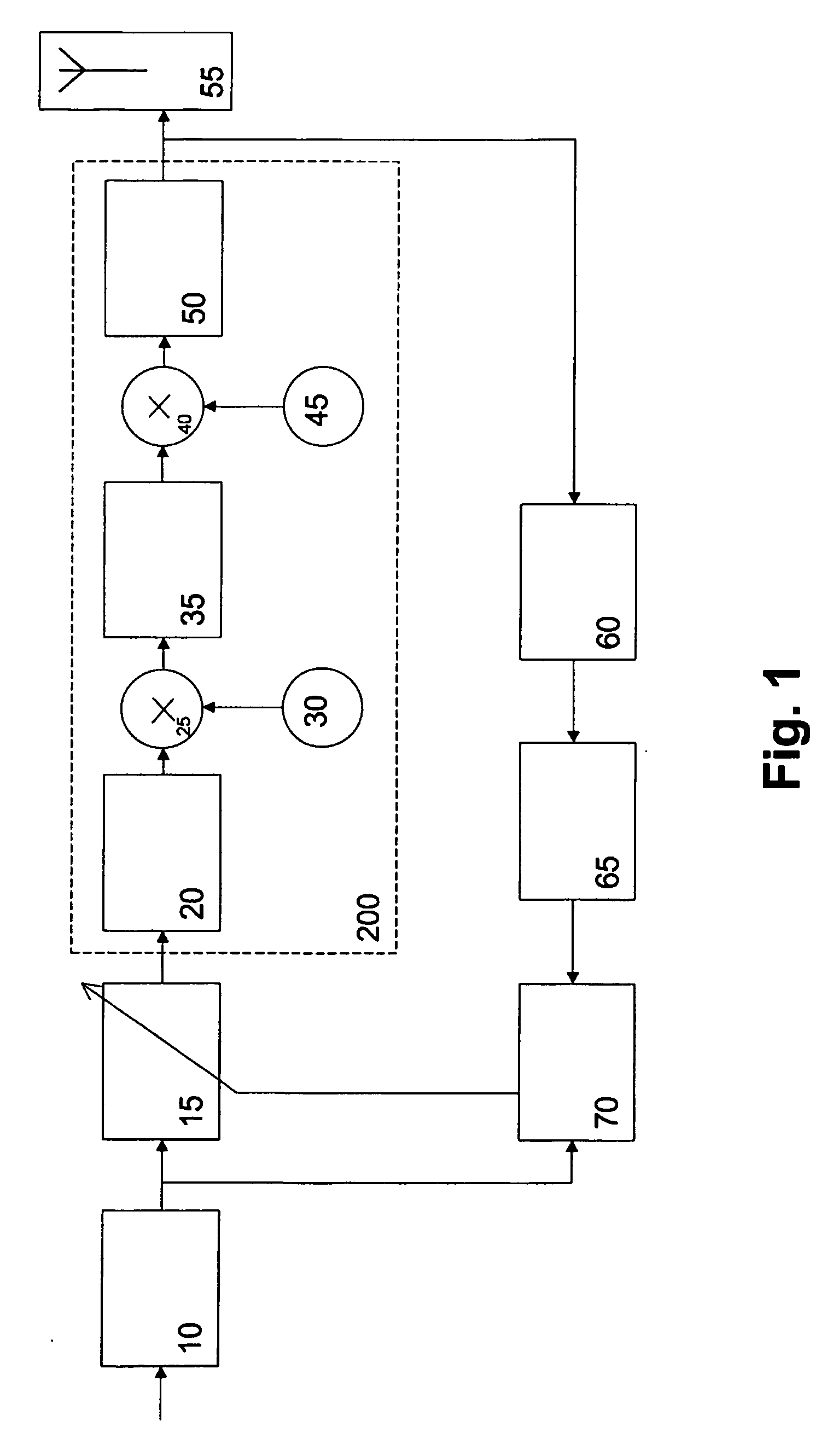

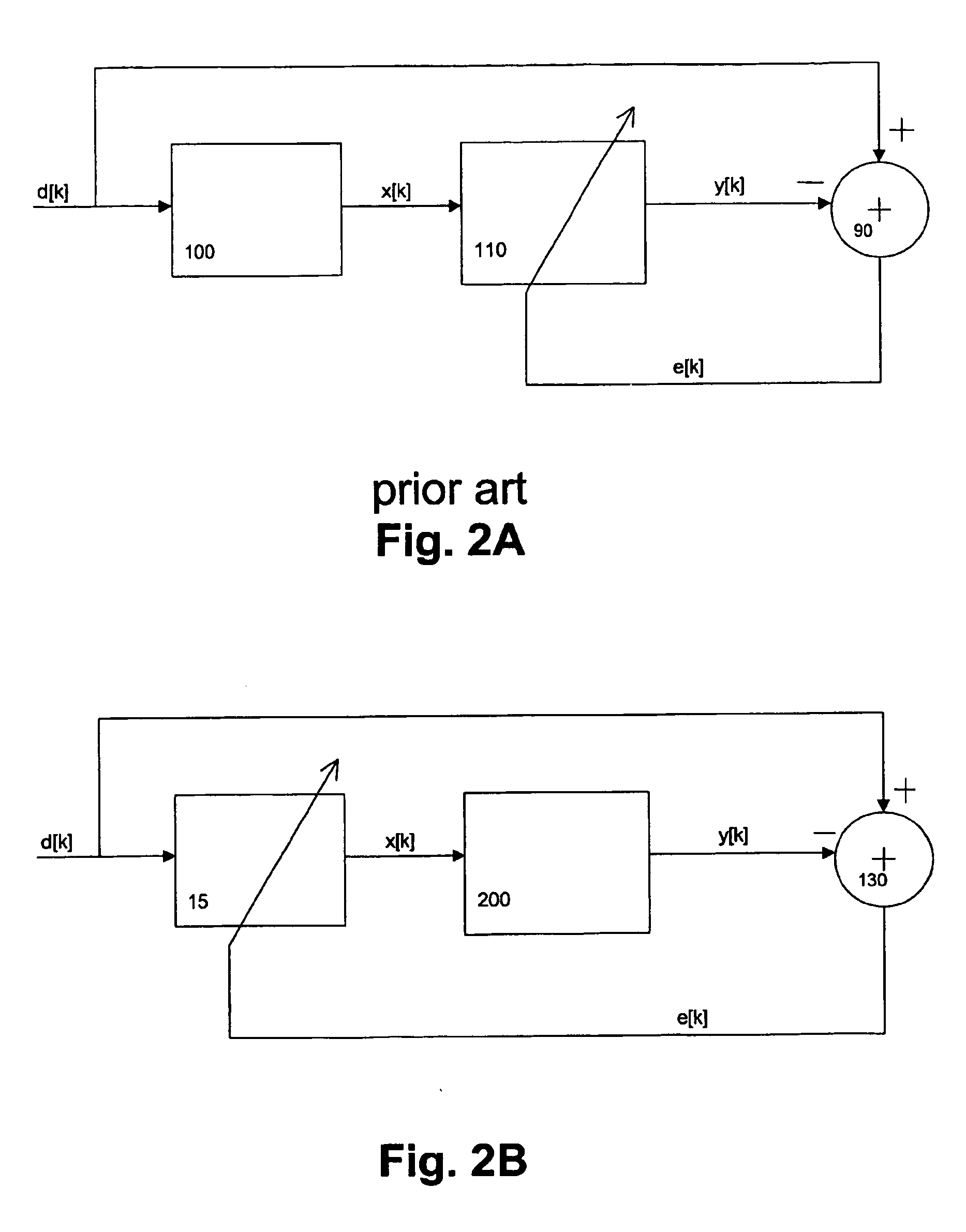

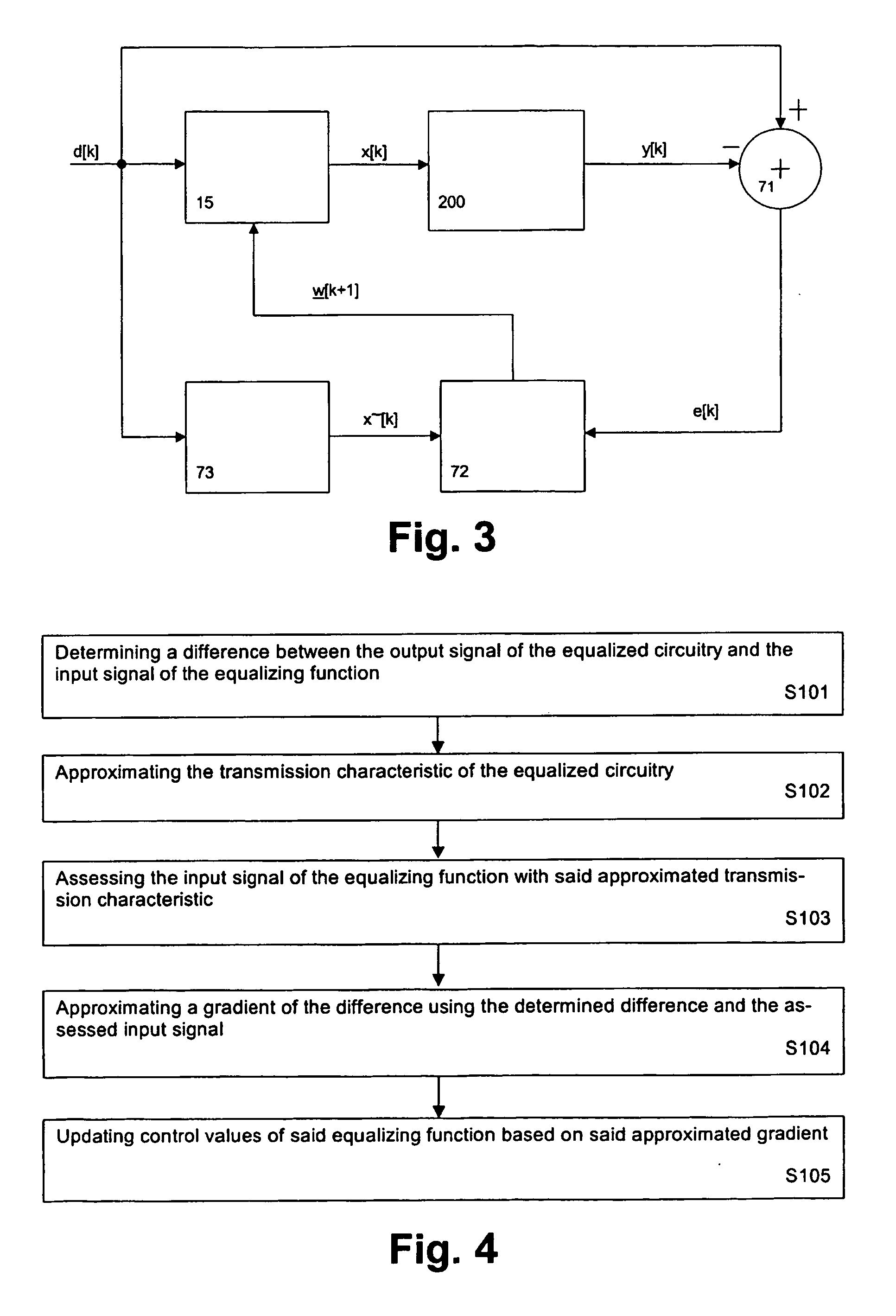

Adaptive pre-equalization method and apparatus

InactiveUS20060056327A1Reduce requirementSignal accuracyAdaptive networkFrequency-division multiplex detailsSelf adaptiveEngineering

An adaptive pre-equalizer is disclosed to compensate amplitude ripples in a low cost transmitter pass-band filter. A filtered-x LMS algorithm is proposed to calculate the equalizer coefficients. To this purpose, the modulated RF signal is demodulated at the transmitter and subtracted from a filtered version of the original base band signal. The impulse response of the low-cost transmit filter is approximated by a delay. The disclosure may be applied to direct conversion or heterodyne transmitters using OFDM.

Owner:NOKIA CORP

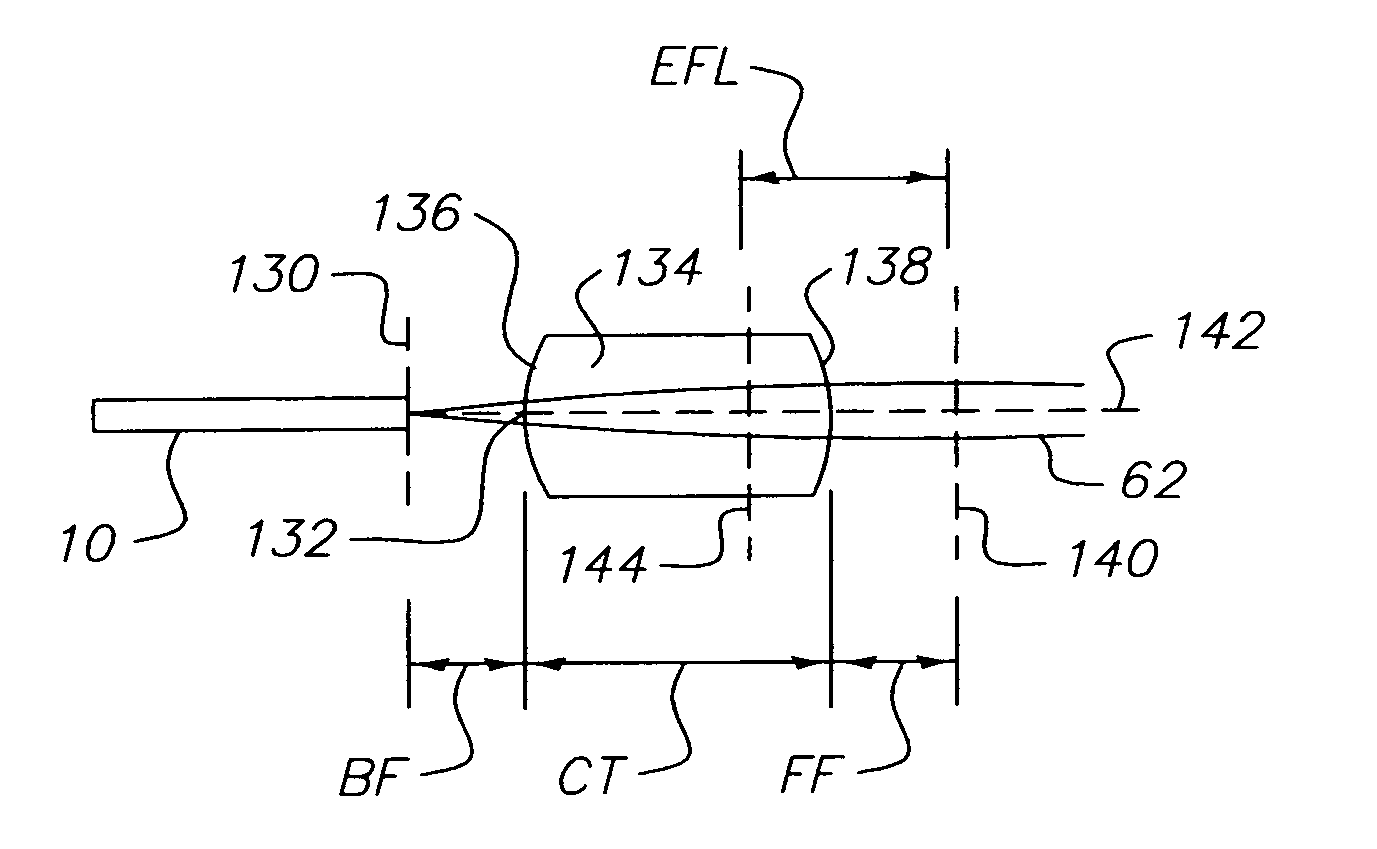

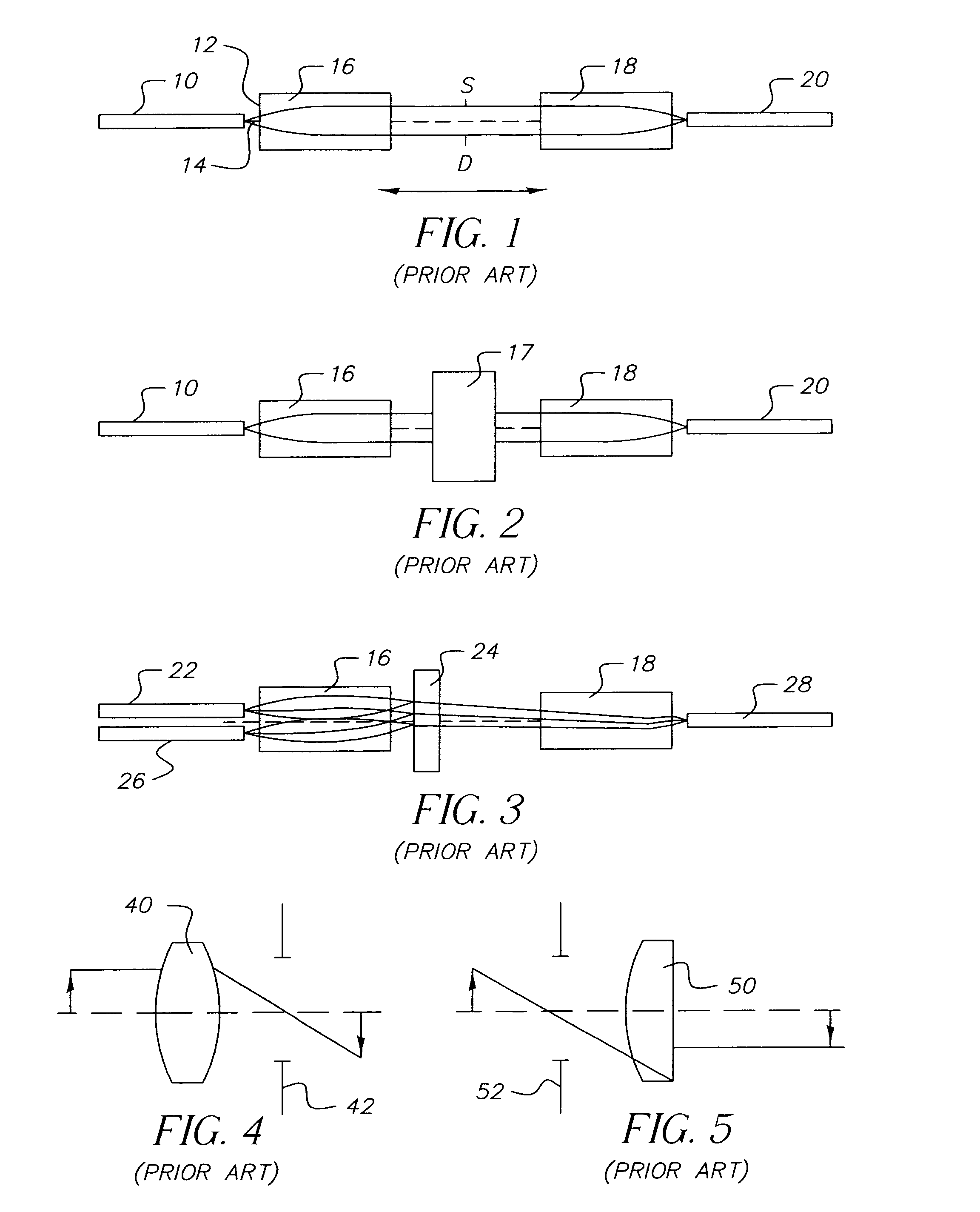

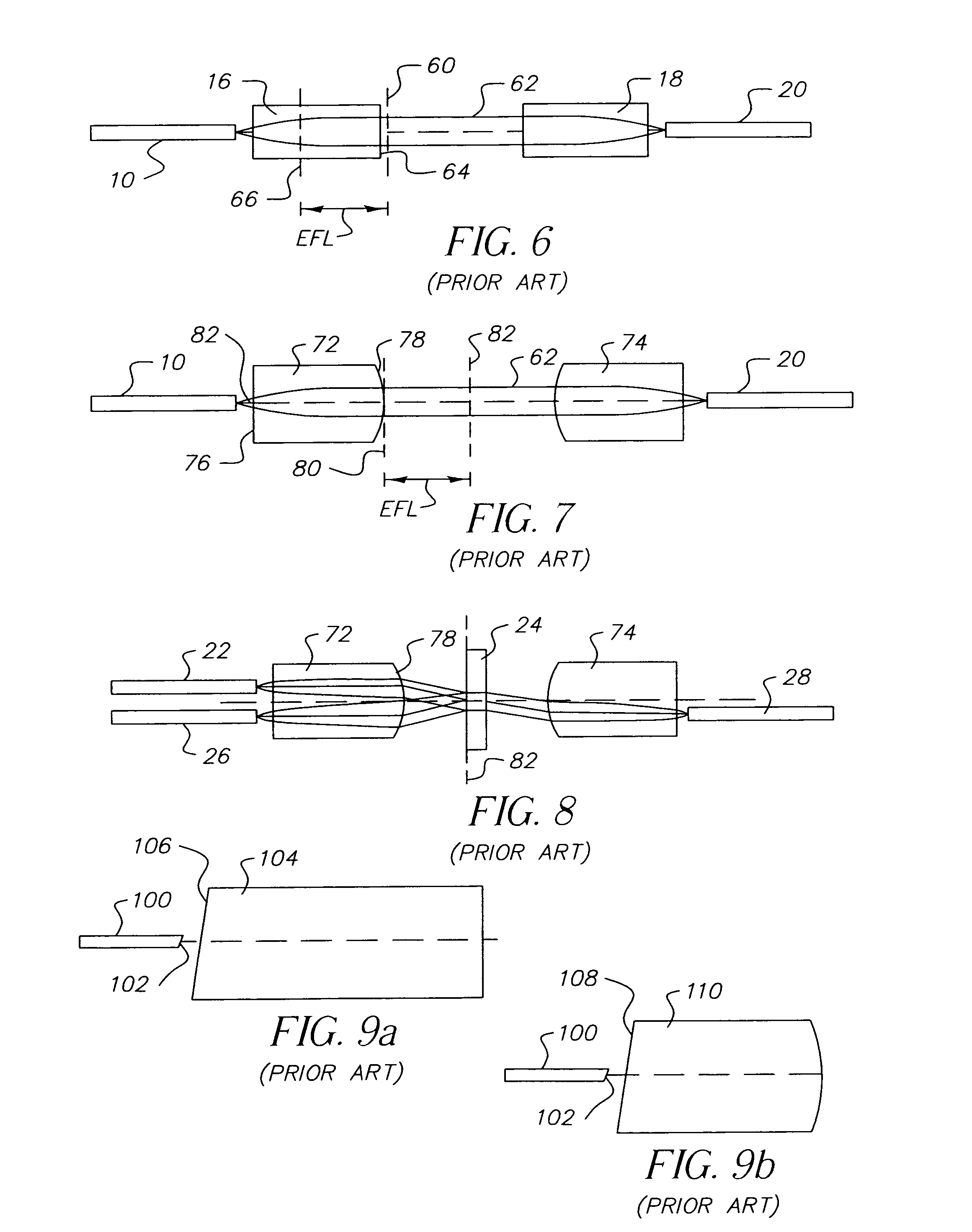

Symmetric, bi-aspheric lens for use in optical fiber collimator assemblies

A fiber optic apparatus comprising a biconvex optical lens having two equivalent aspheric optical surfaces; an optical fiber approximately located at one of a front focal plane and a back focal plane of the optical lens; and a structure positioned relative to the optical lens and the optical fiber, wherein the structure maintains the position of the optical lens relative to the optical fiber.

Owner:EASTMAN KODAK CO

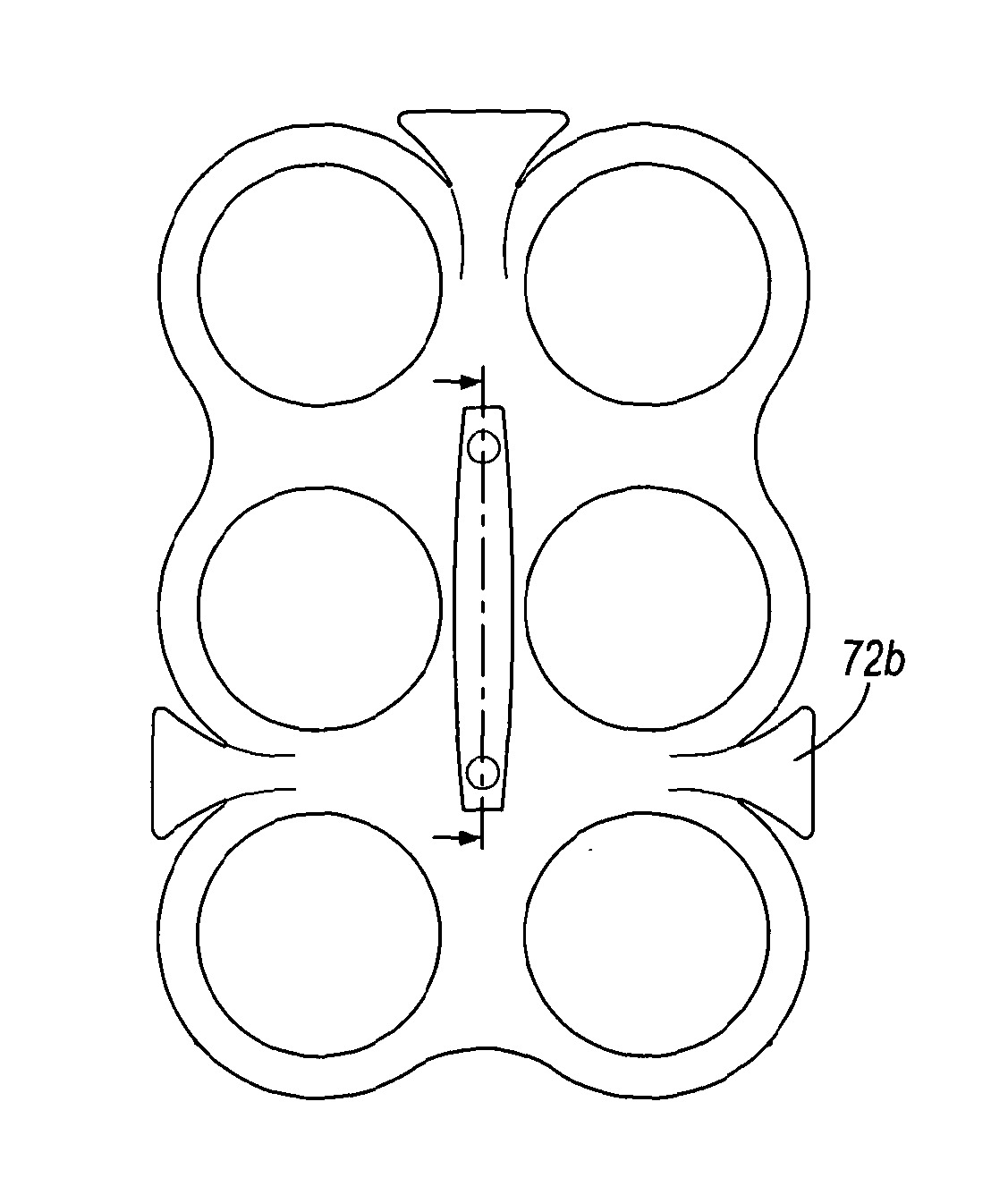

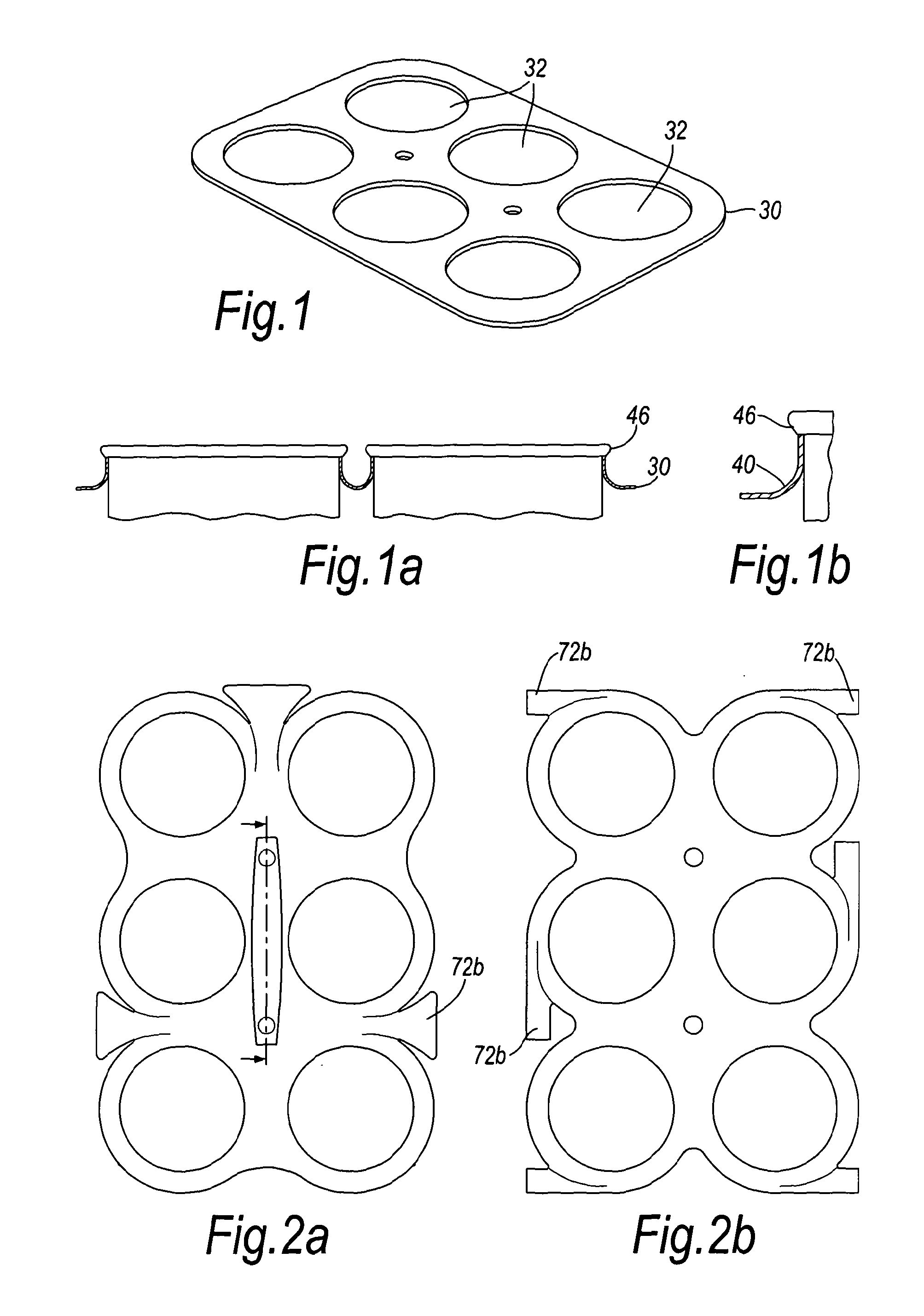

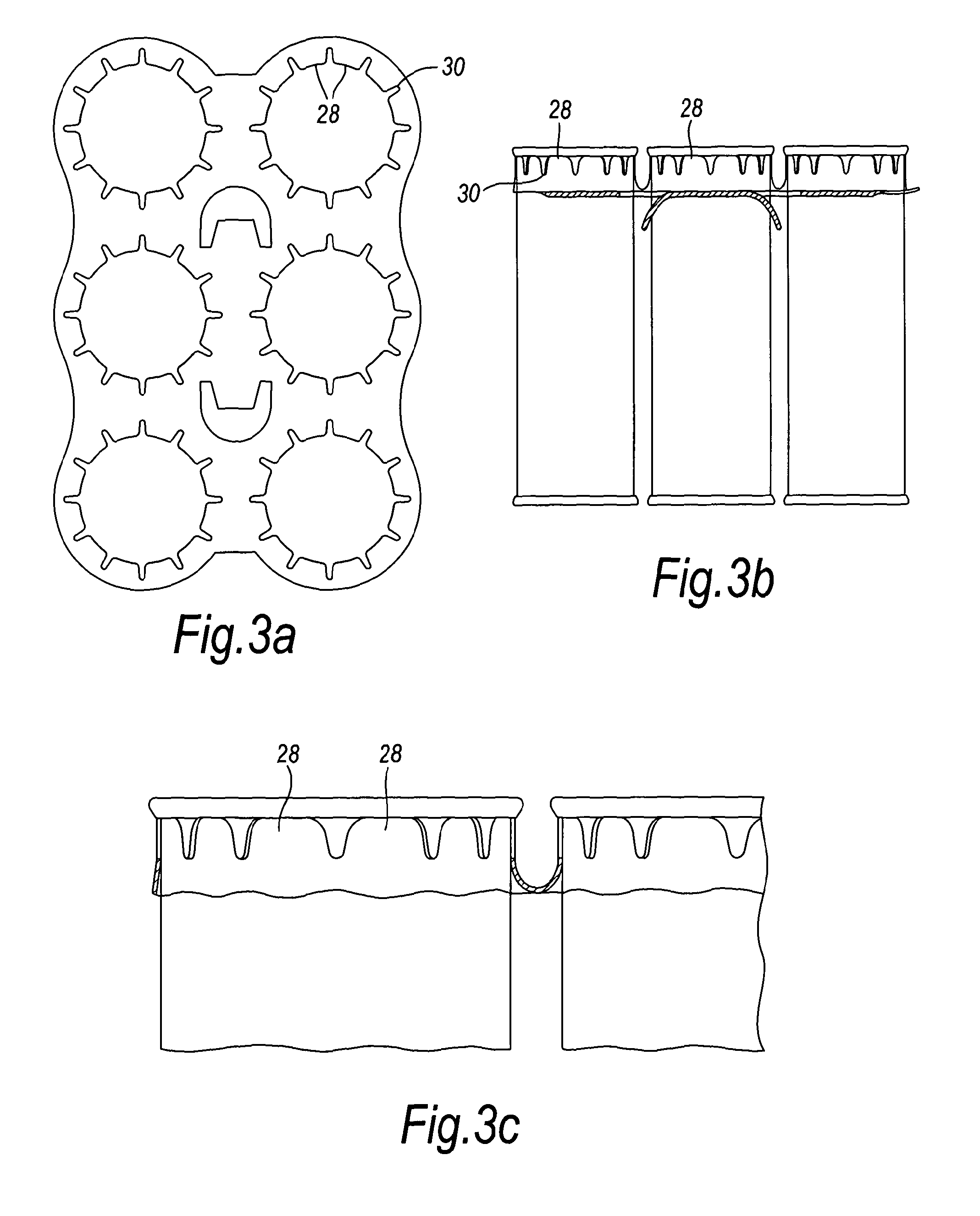

Container carrier

ActiveUS20120227361A1High strengthSecurely holdContainer/bottle contructionPackaging bottlesEngineeringPlastic film

The present invention relates to a container carrier and to packaging systems for containers and using the same. This invention pertains to carrier stock for machine application to substantially identical containers such as beverage cans having annular chimes, cylindrical side walls, and frusto-conical walls between the chimes and the side walls. In particular, the present invention relates to plastic film having apertures to securely retain drinks cans, food cans, bottles and similar containers, a method of applying the film and the resultant combination.

Owner:BRITISH POLYTHENE

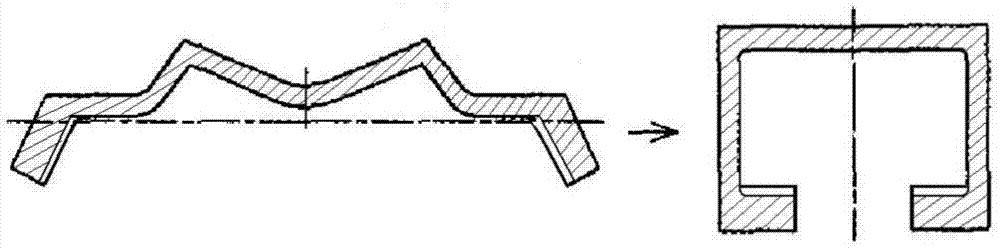

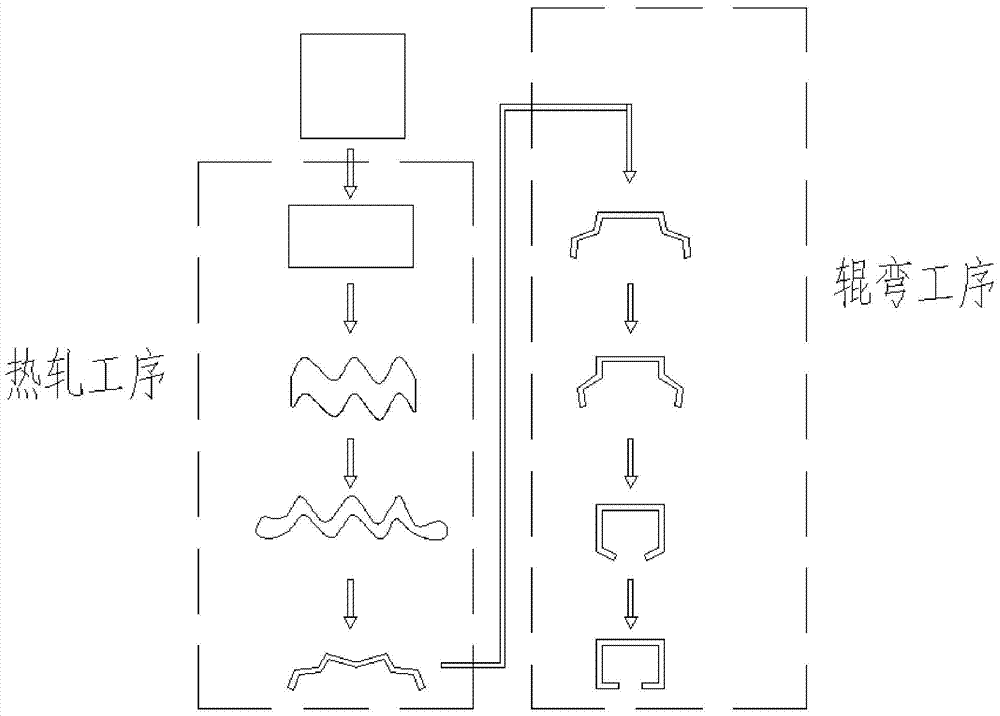

Channel section steel production system and production method thereof

ActiveCN104759892ASimple production processSimplified pass rolling passesOther manufacturing equipments/toolsProduction lineMethods of production

The invention provides a channel section steel production system and a production method thereof. The channel section steel production system comprises a feeding device, a heating device, a hot-rolling unit, a roll-bending unit and a fixed-length cutting device which are sequentially arranged. Flat steel blank raw materials are selected, heated through an electric induction heating device and then are fed into rolling mills of two machine frames to be subjected to rolling deformation, a first pass is used for thickness decrease, a second pass is used for plate shape forming of cross sections of rolled pieces before hot bending, and the two machine frames conducts deformation rolling on the raw materials simultaneously in a continuous-rolling state. By the adoption of simplified two-pass hot rolling, the thickness and plate shapes all cross section of flattened and spread channel section steel are rolled, waste heat is utilized to conduct hot bending forming on the continuous roll-bending unit, and fixed-length sawing, cooling and finishing are performed to obtain channel section steel products. The production method is simplified, hole type rolling pass is simplified, production difficulty is reduced, and the production success rate and finished material rate are improved. The number of the rolling mills is decreased, a production line is shortened, short-process production is achieved, and investment and follow-up maintenance cost are reduced.

Owner:CISDI ENG CO LTD +1

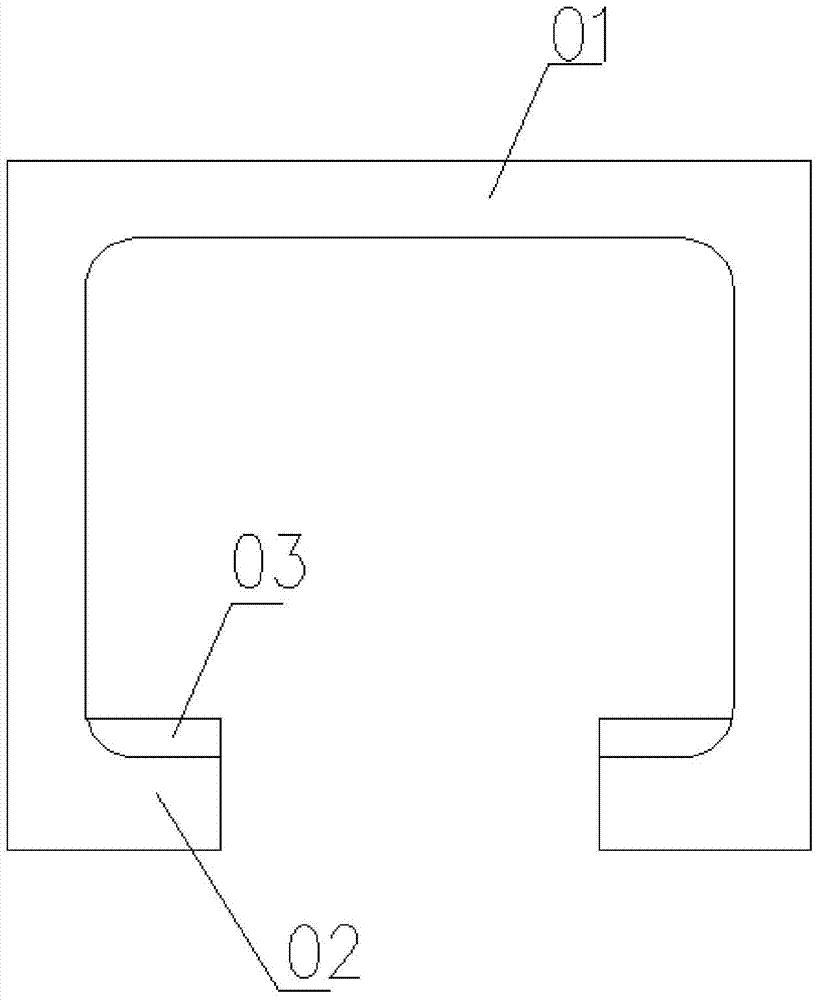

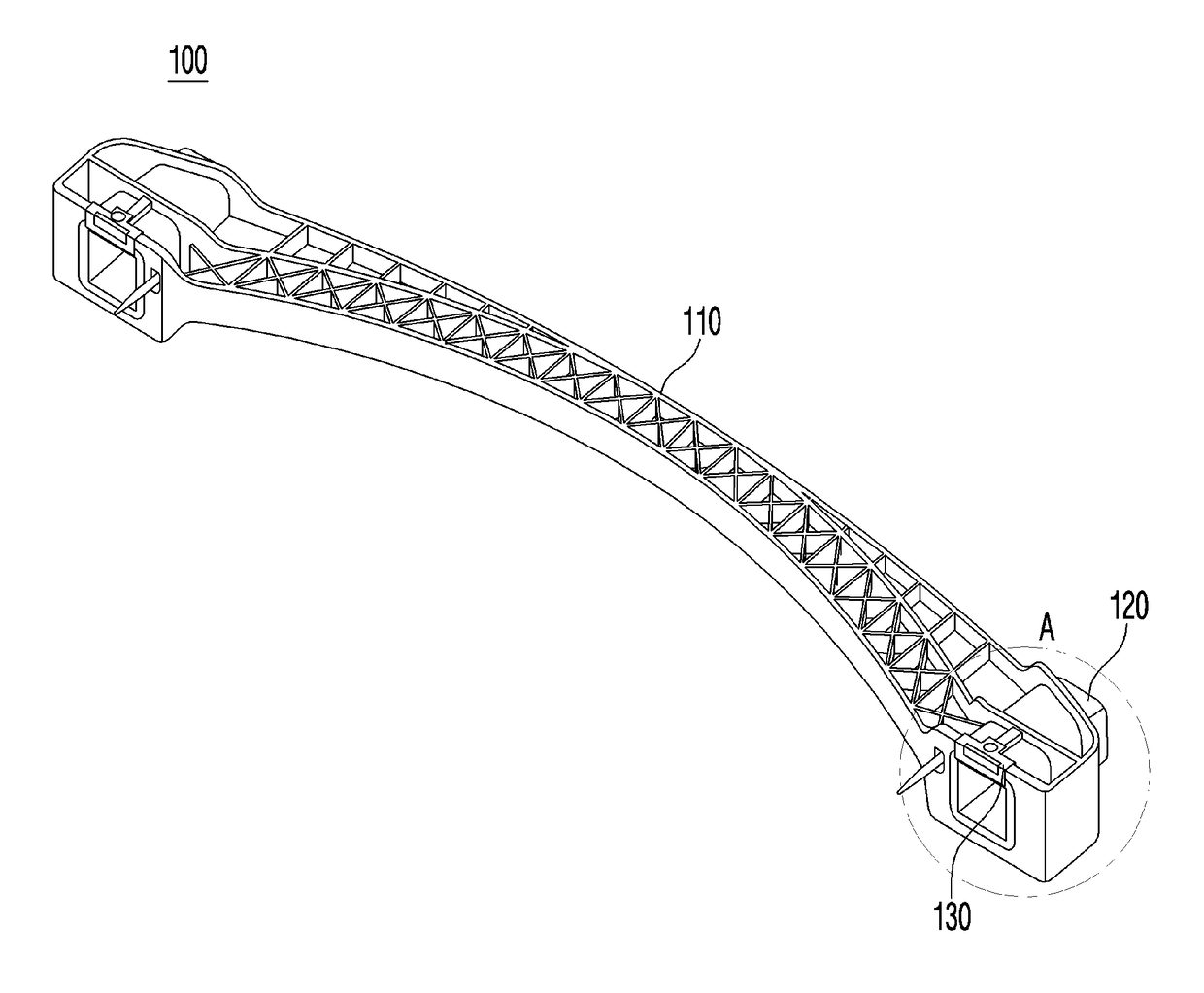

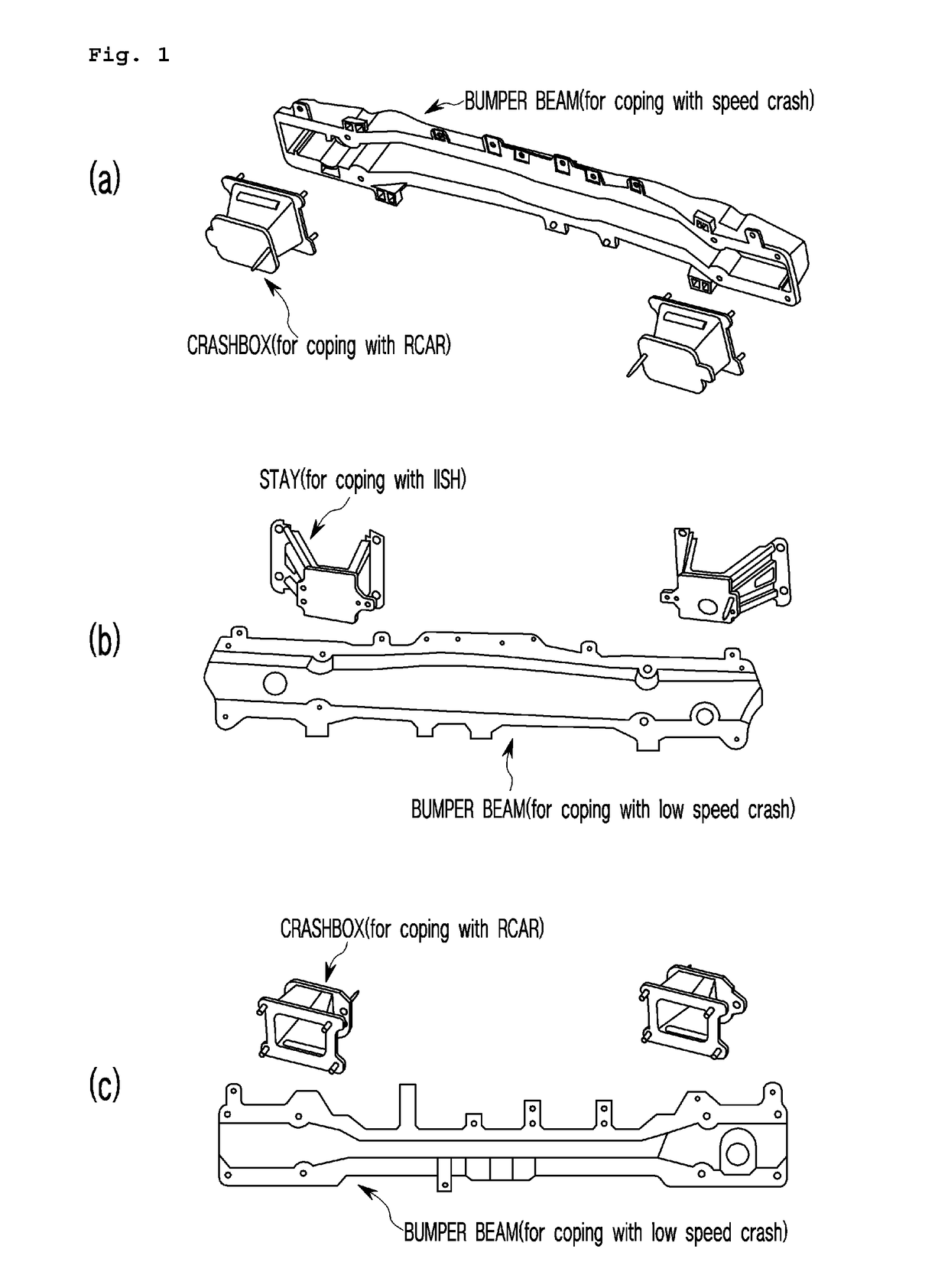

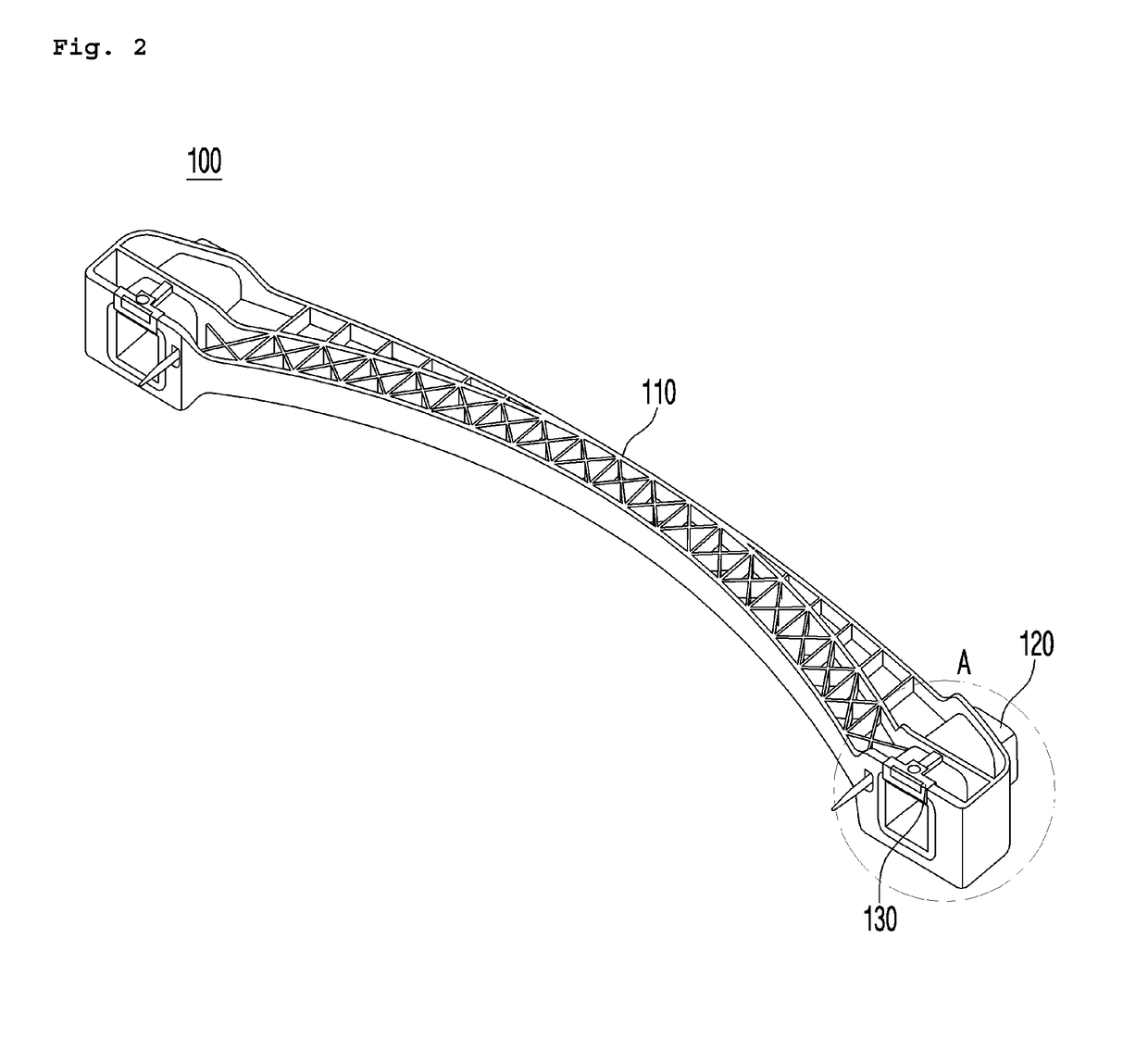

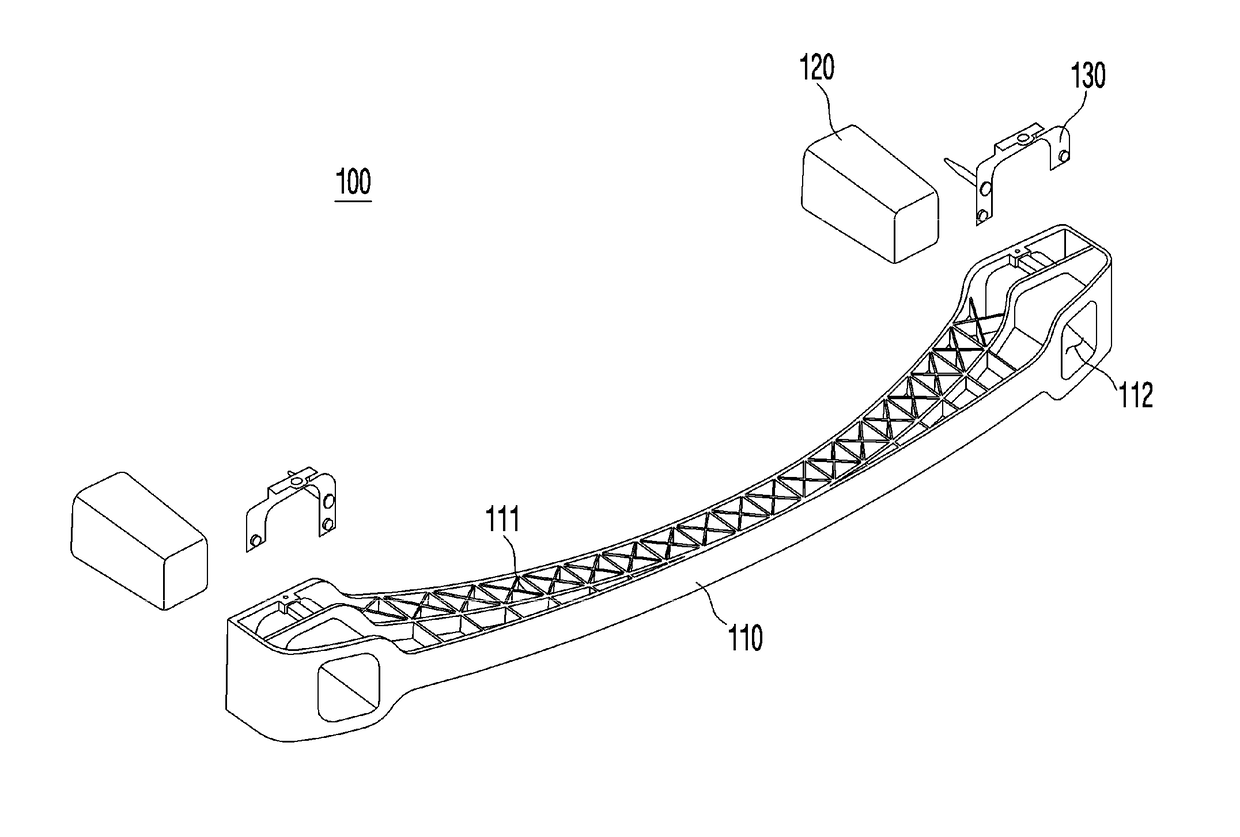

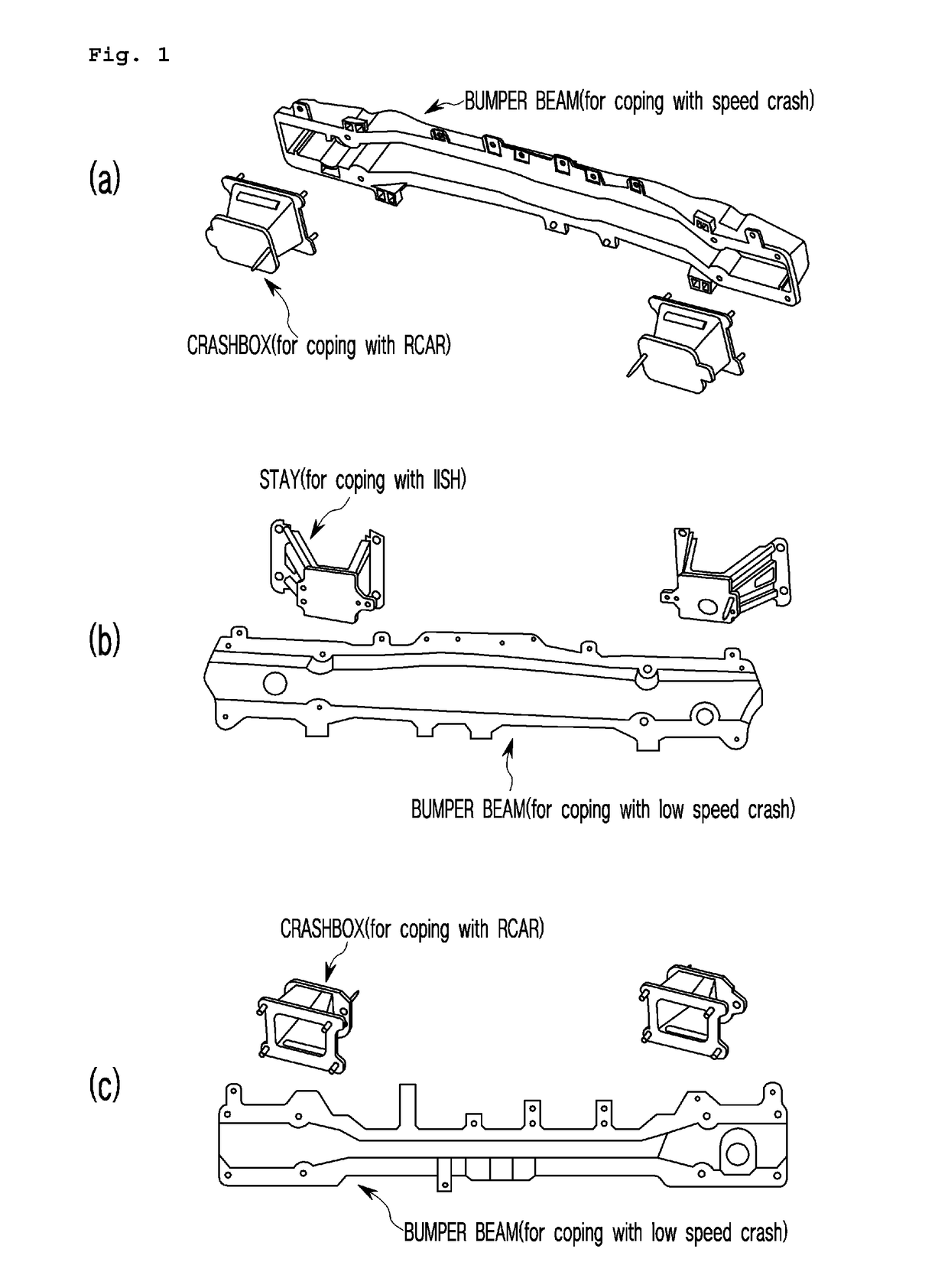

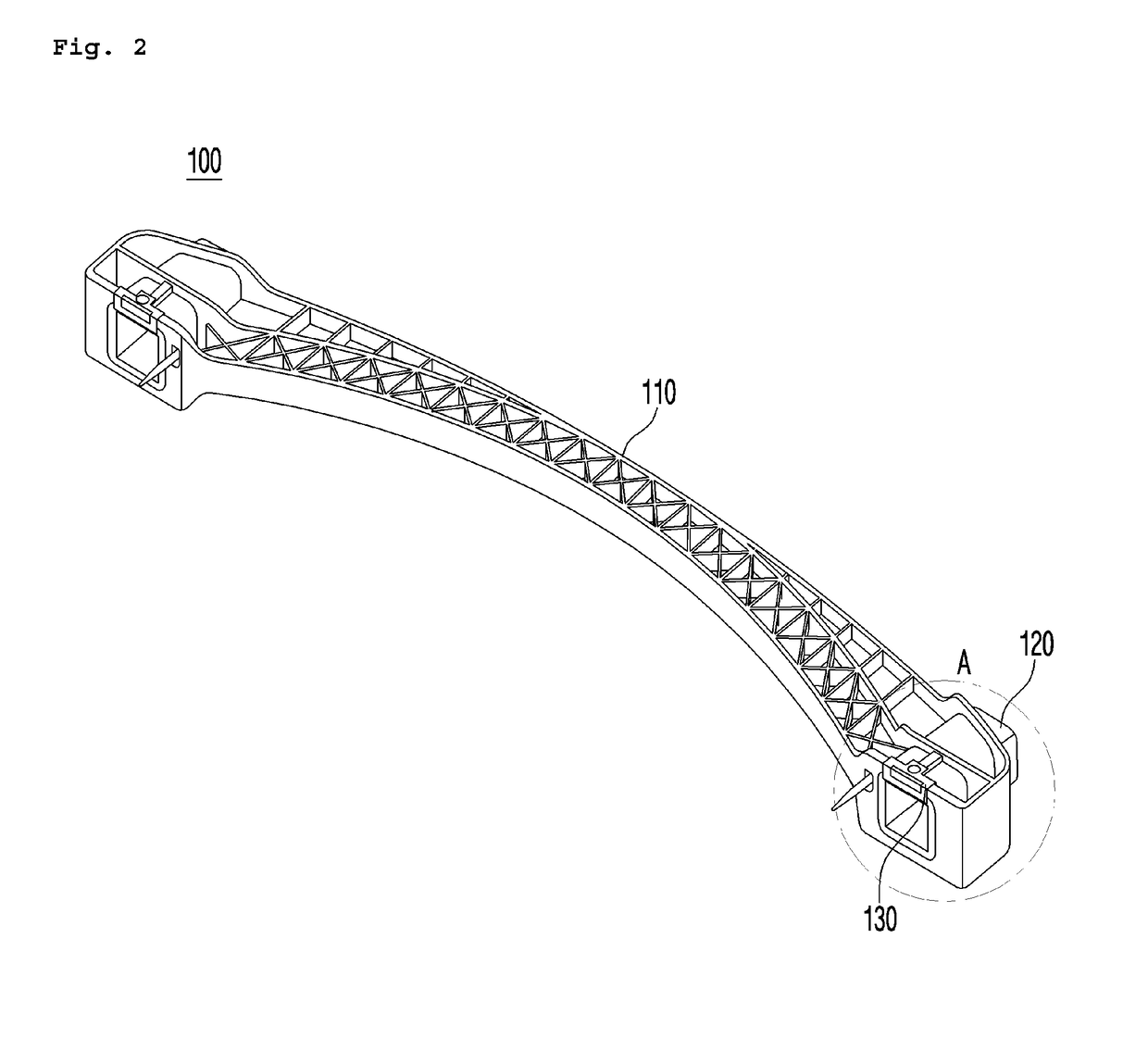

Bumper system for vehicle

ActiveUS20170327065A1Cost be requireCost reductionPedestrian/occupant safety arrangementElastic dampersMechanical engineeringEngineering

The present invention relates to a bumper system for a vehicle, and provides a bumper system for a vehicle, the system comprising: a bumper beam which has a fastening hole formed through each end thereof in the forward and backward direction; a crash box which is inserted into the fastening hole of the bumper beam; and a bracket which is fastened to the bumper beam so as to be able to prevent the crash box from being separated. Thereby, the system can meet both low speed crash regulations and RCAR performance.

Owner:LOTTE CHEM CORP

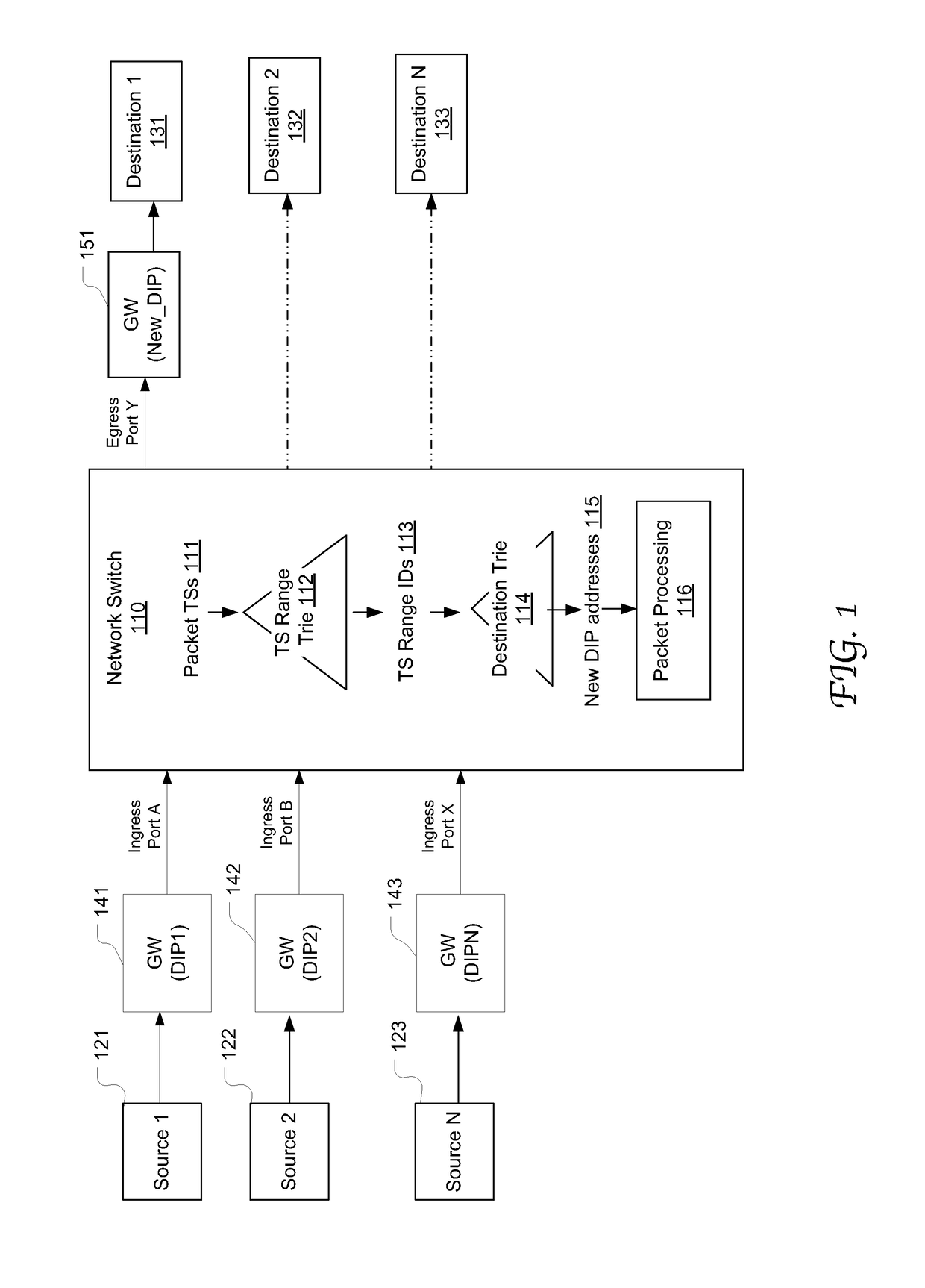

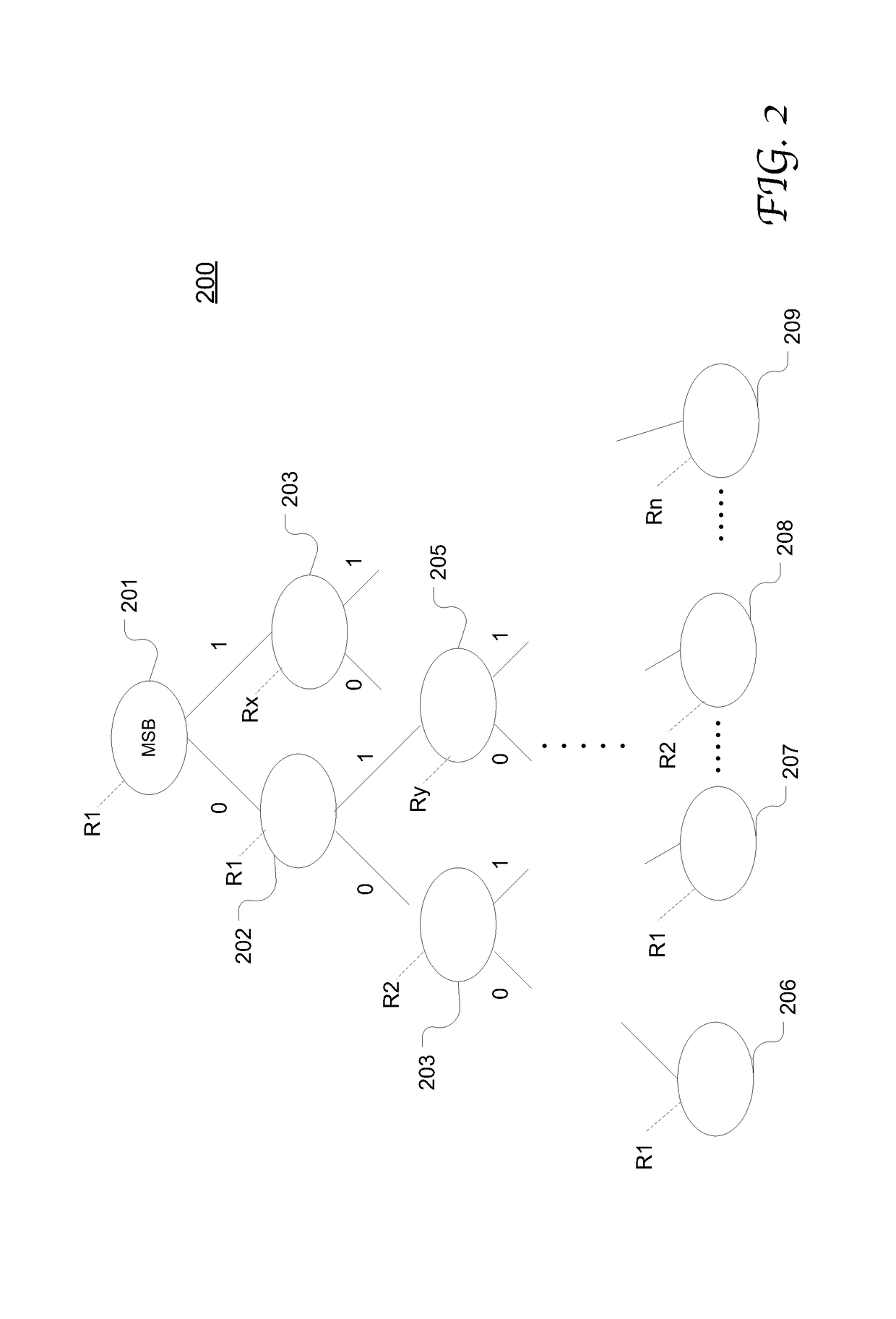

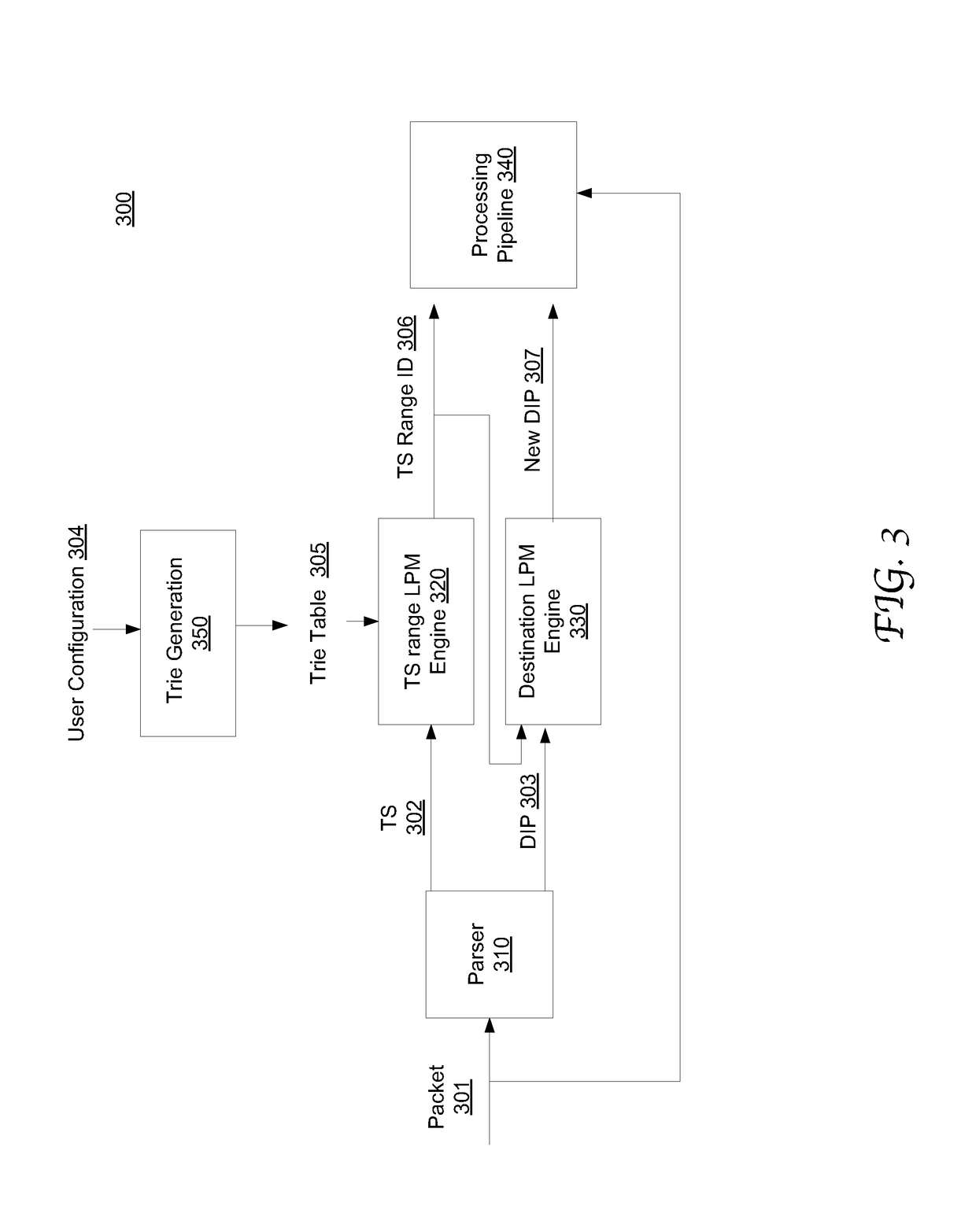

Timestamp-based packet switching using a trie data structure

ActiveUS20180359195A1Improve efficiencyImprove scalabilityData switching networksTime rangeTimestamp

System and method of network packet switching using a table representation of a trie data structure to identify a timestamp (TS) range (or time range) for a received packet based on the packet timestamp (TS). The trie data structure is programmed with a plurality of predetermined time ranges. Each node in the trie data structure corresponds to a TS prefix and is associated with a corresponding predetermined time range. A search engine in the network switch can use the packet TS as a key to traverse the trie data structure and thereby matching the packet TS to a predetermined time range according to a Longest Prefix Match (LPM) process. Provided with the TS ranges of the incoming packets, various applications and logic engines in the network switch can accordingly process the packets, such as determining a new destination IP address and performing channel switch accordingly.

Owner:MARVELL ASIA PTE LTD

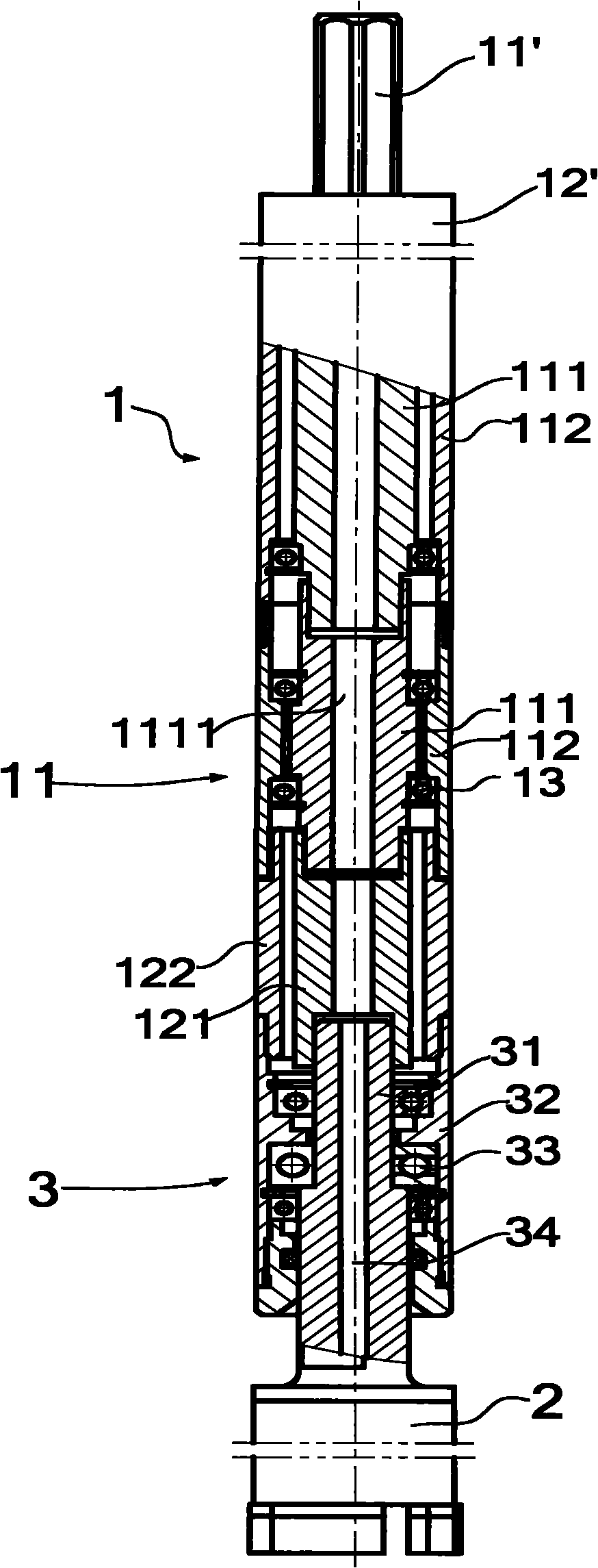

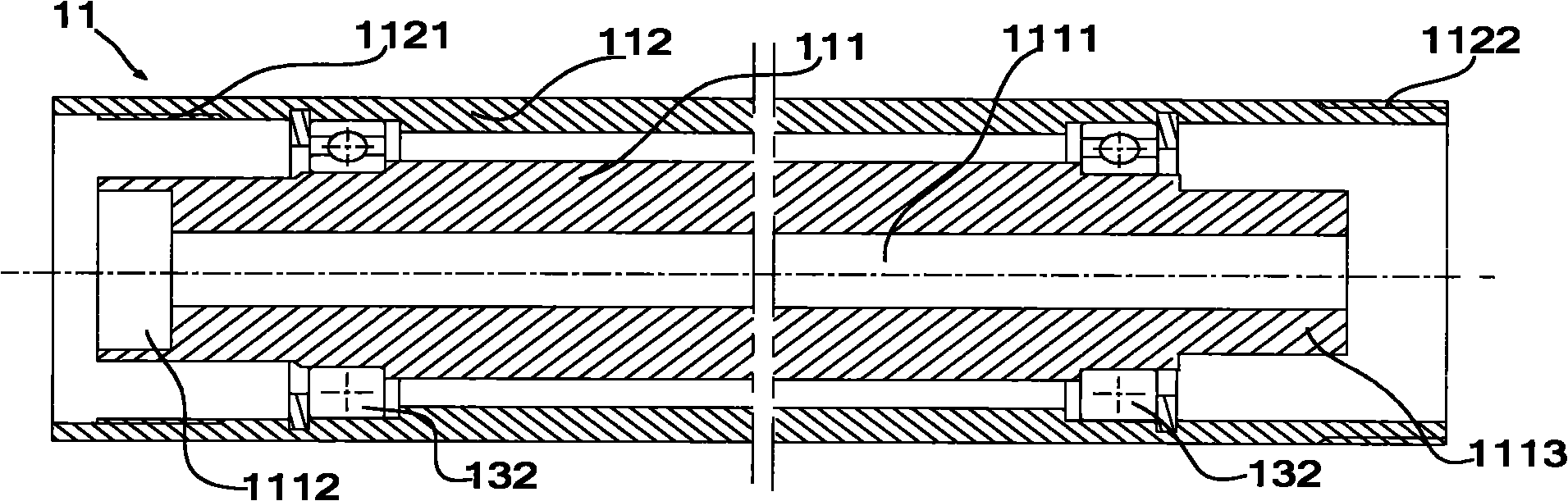

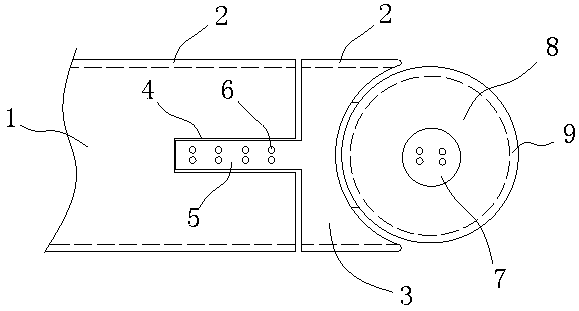

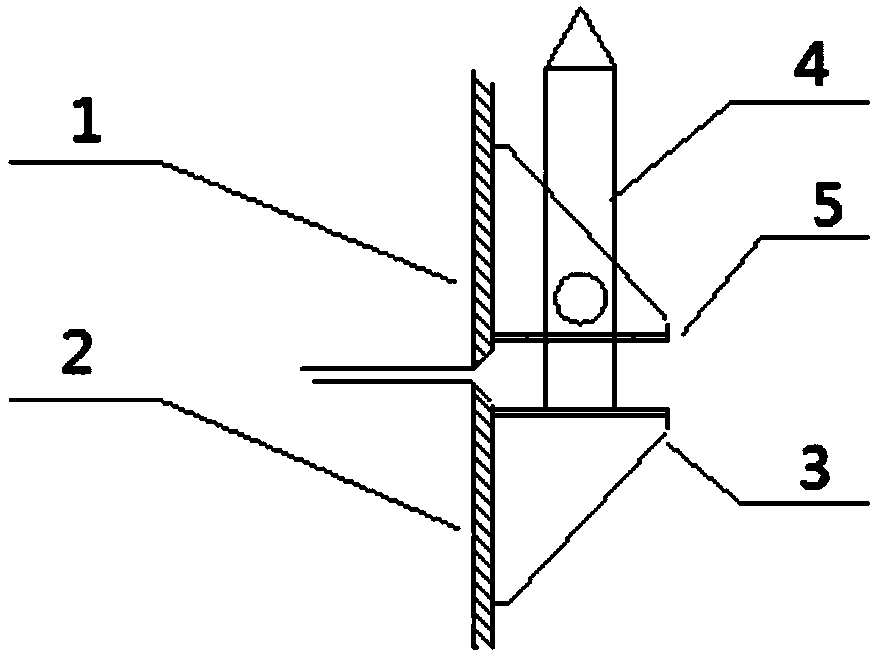

Combined drilling tool

InactiveCN101975029AReduced specificationsEasy to drillDrilling rodsDrilling casingsDrill bitDrill pipe

The invention provides a combined drilling tool, which comprises a drill stem, a drill bit and a drill bit joint. The drill bit is connected with the drill stem through the drill bit joint; the drill stem is connected by drill stem sections; each drill stem section comprises an inner stem section and a hollow outer stem section; the inner stem section can be rotatably fixed in the outer stem section; the inner stem sections of the drill stem sections are connected to form an inner stem of the drill stem; the outer stem sections are connected to form an outer stem of the drill stem; the inner stem is connected with an output shaft of power machinery; and the outer stem is fixedly connected with a shell of the power machinery. For the provided combined drilling tool, the length of the drillstem can be optionally adjusted to meet the demands of different drilling depths; the outer stem is fixedly connected with the shell of the power machinery immovably; and the inner stem is connected with the output shaft of the power machinery and can rotate inside the outer stem at a high speed but does not have friction with the hole wall. Therefore, the drill bit rotates at a high speed on thepremise of no rotary friction between the drill stem and the hole wall, and the drilling speed and efficiency are greatly improved.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

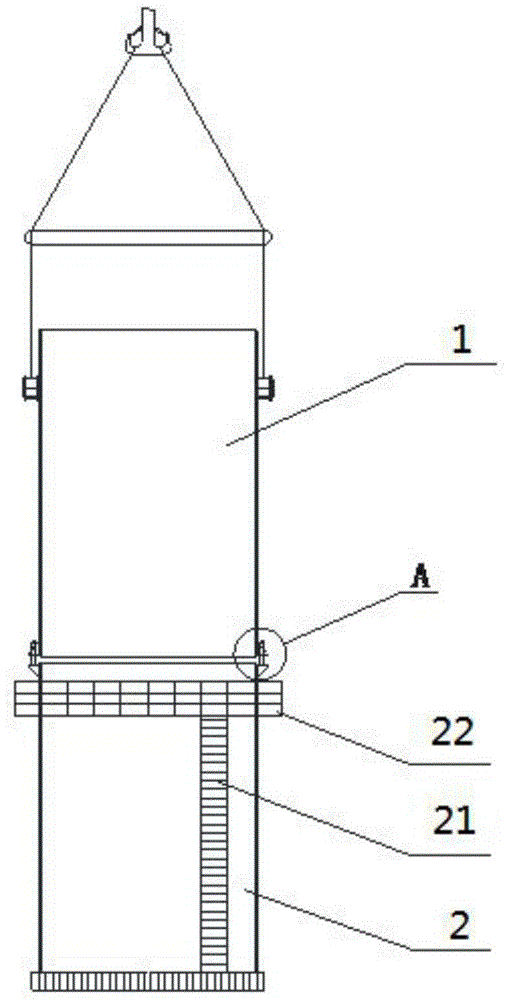

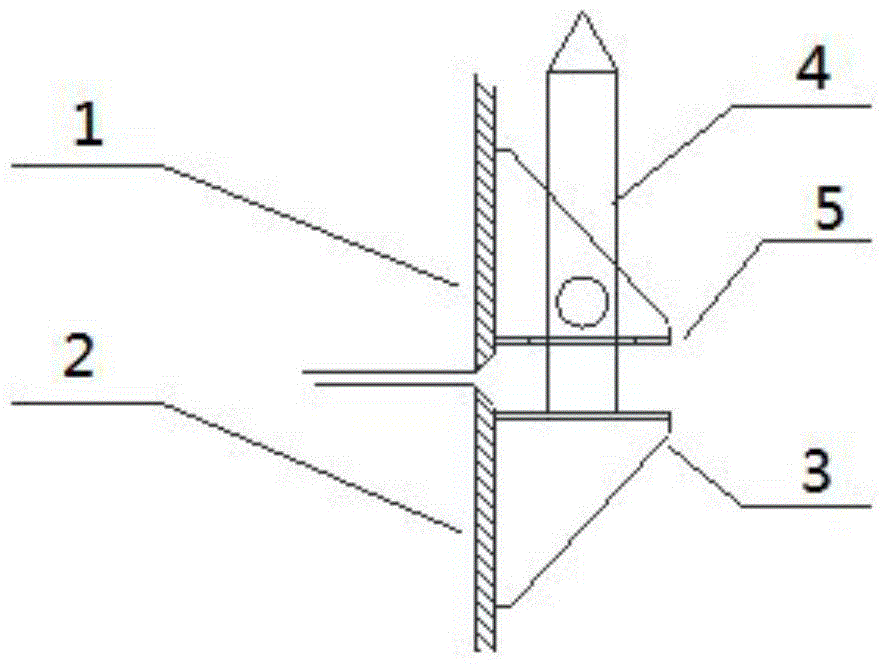

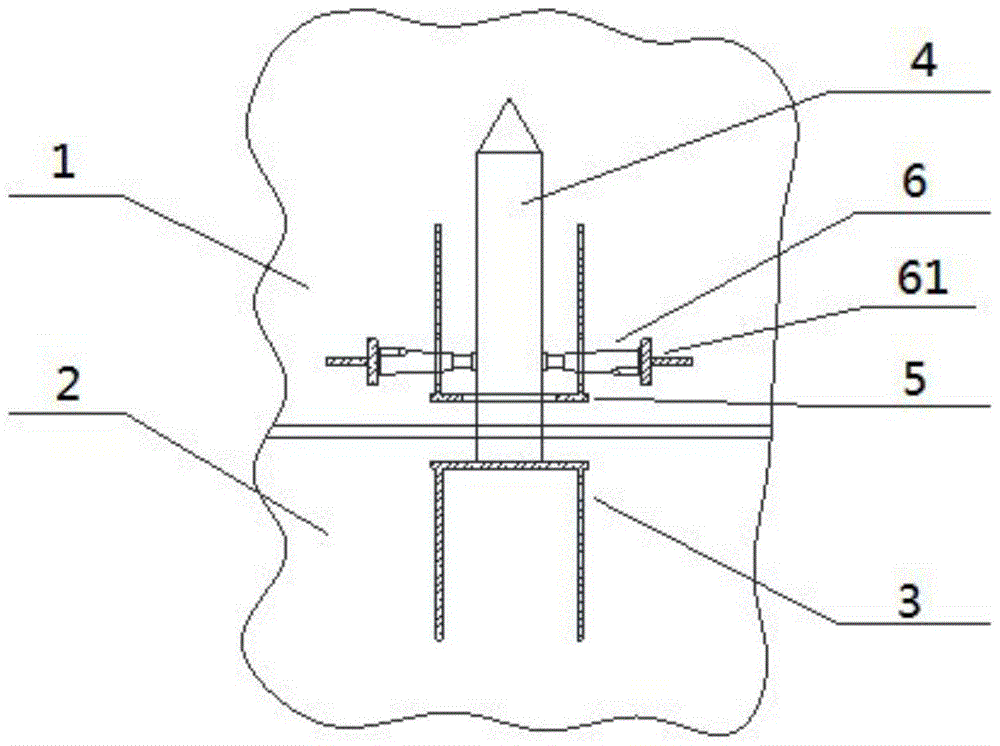

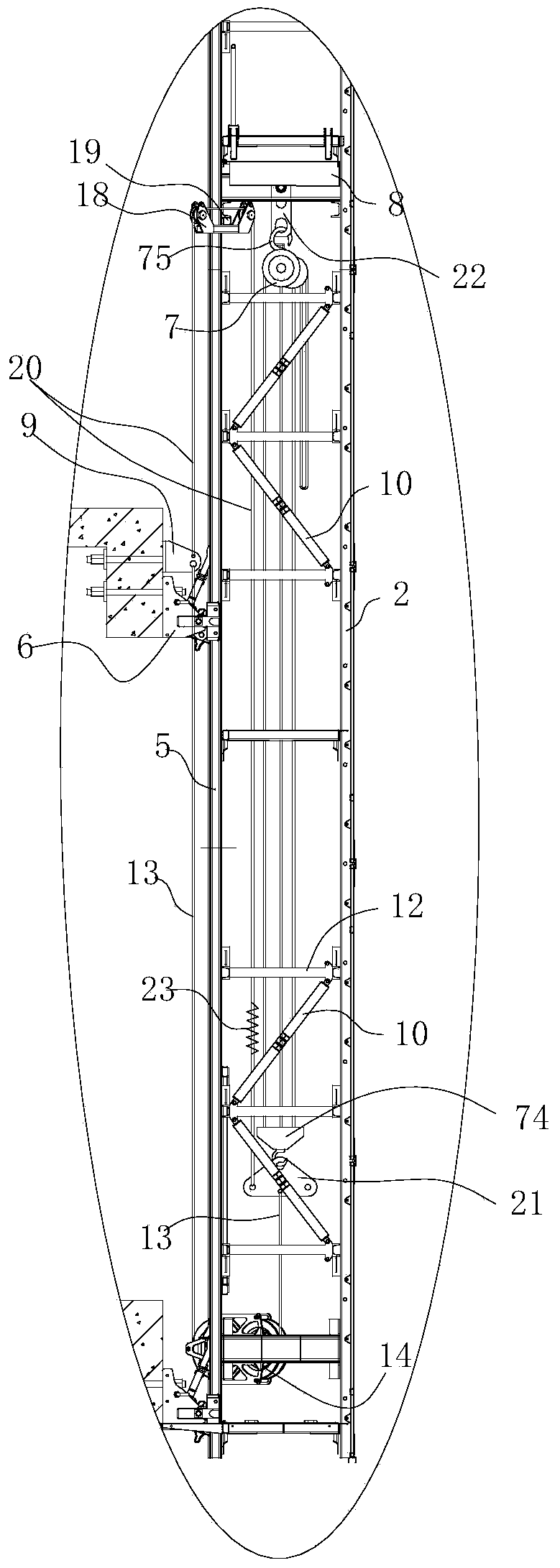

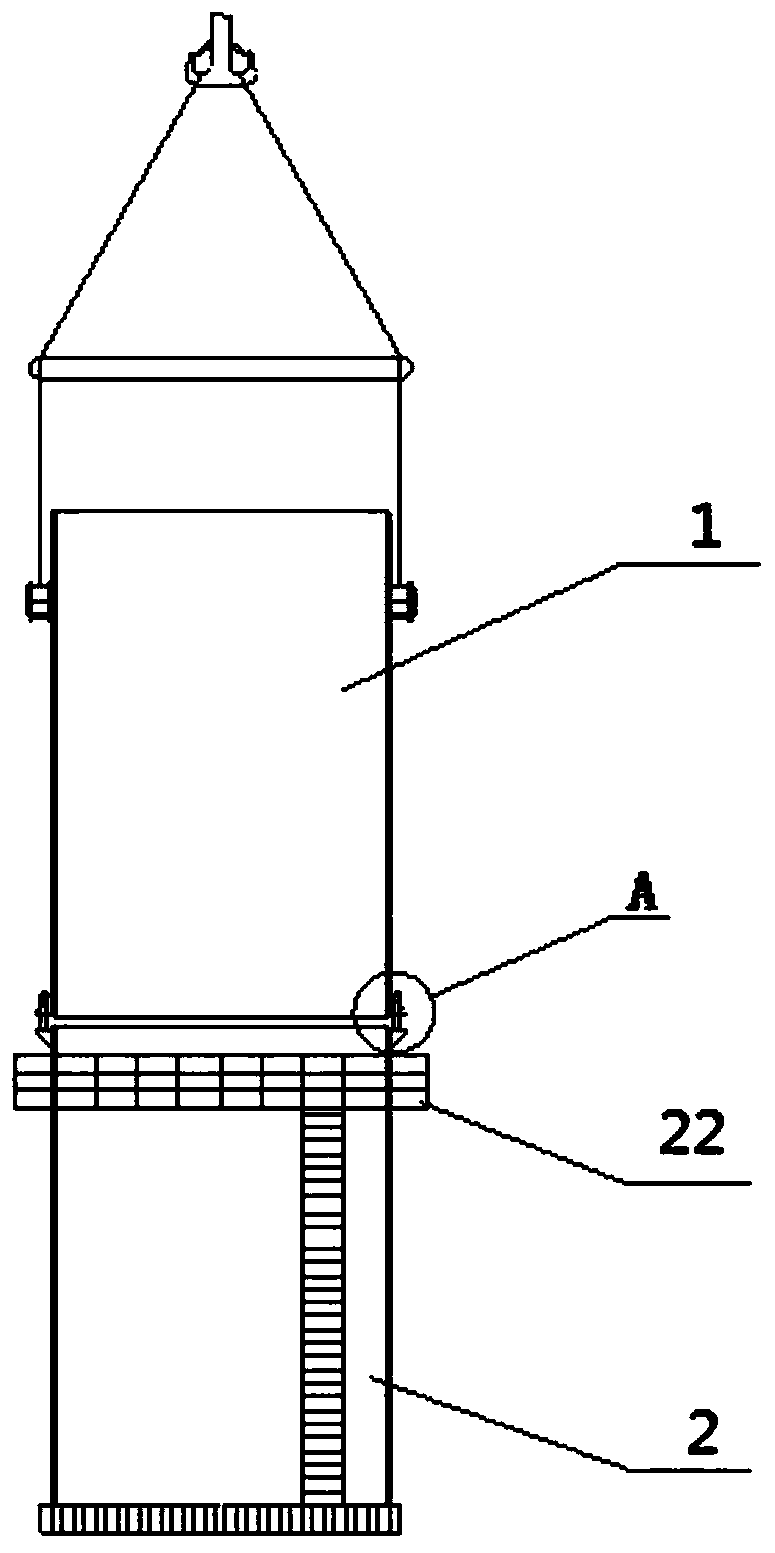

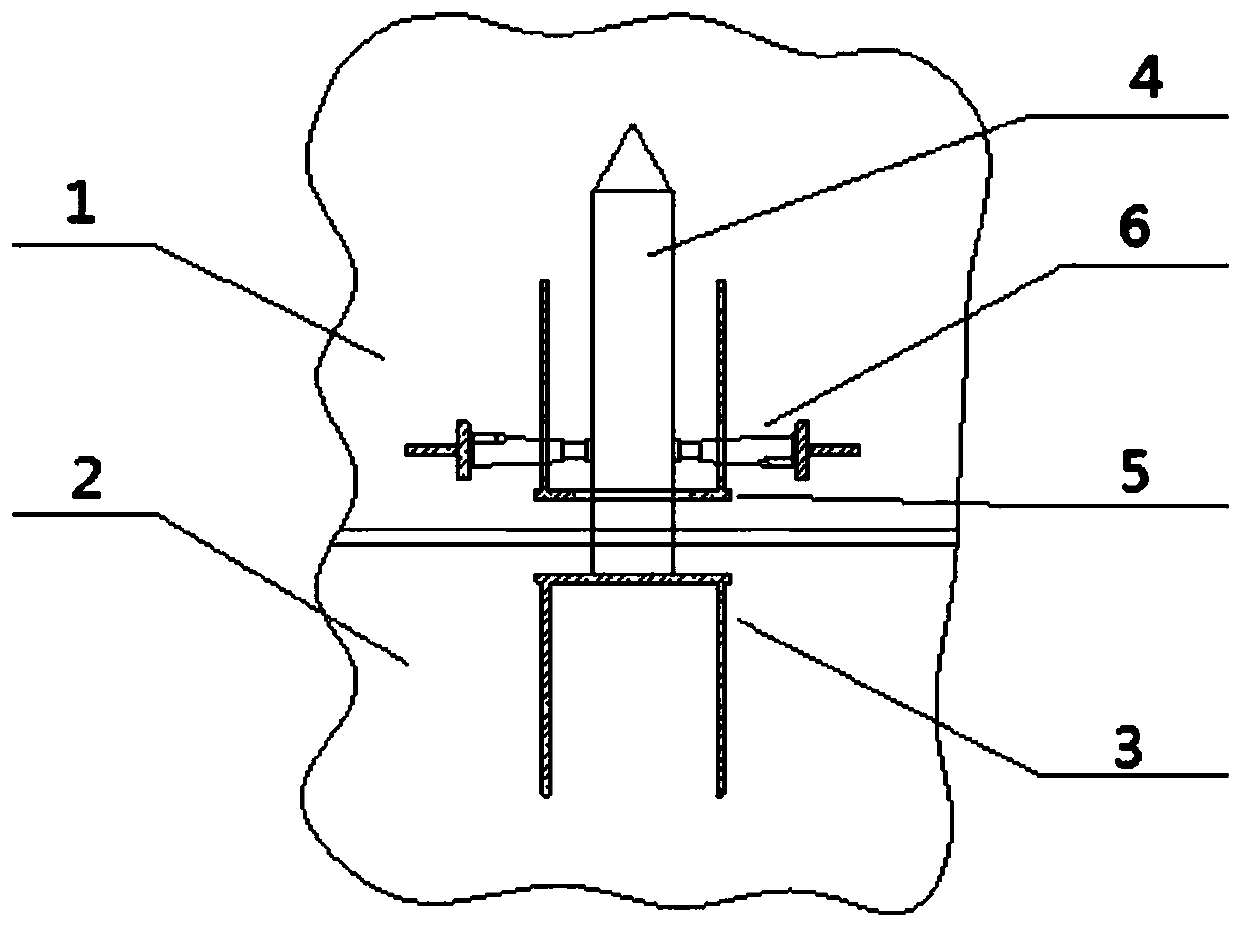

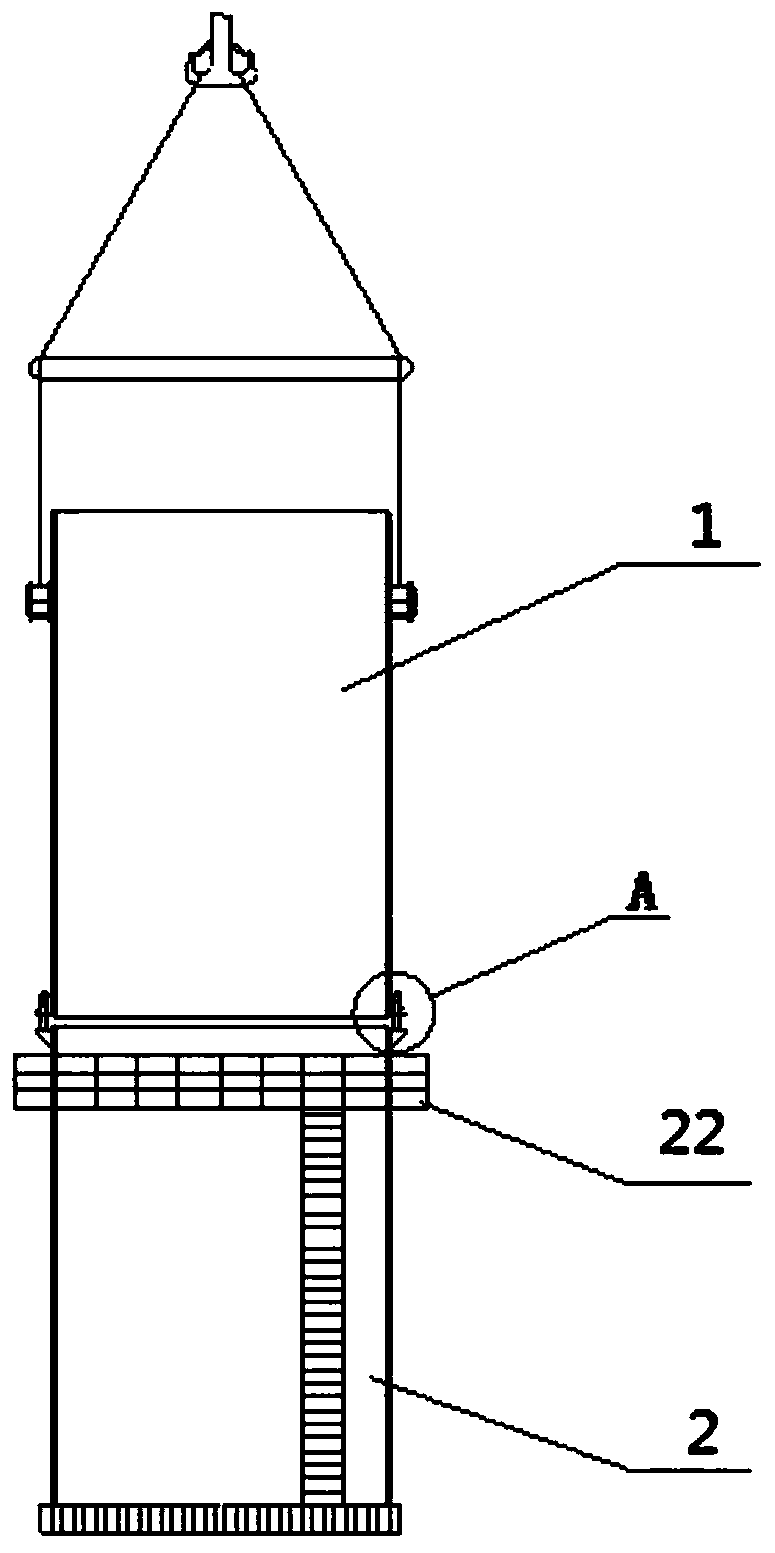

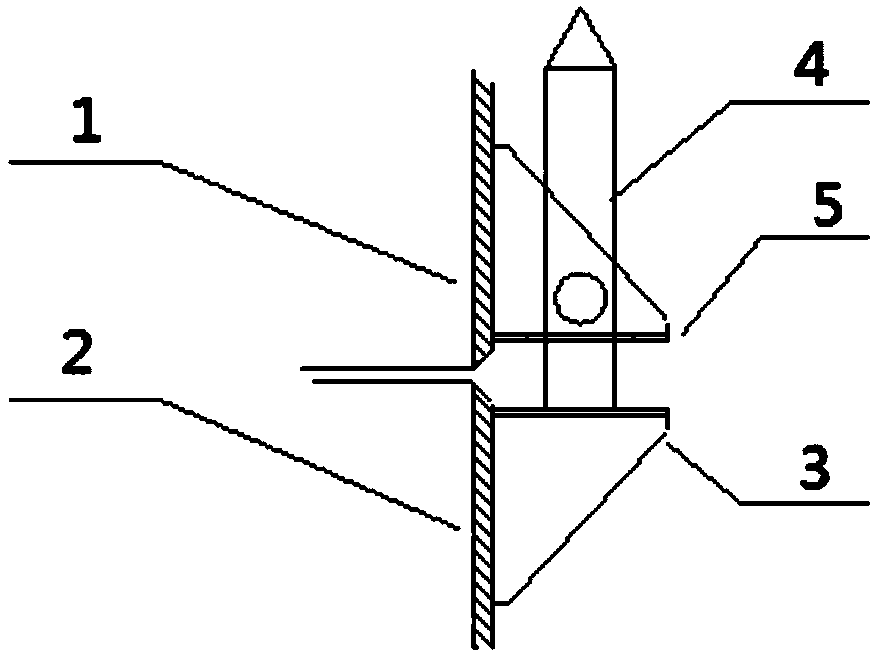

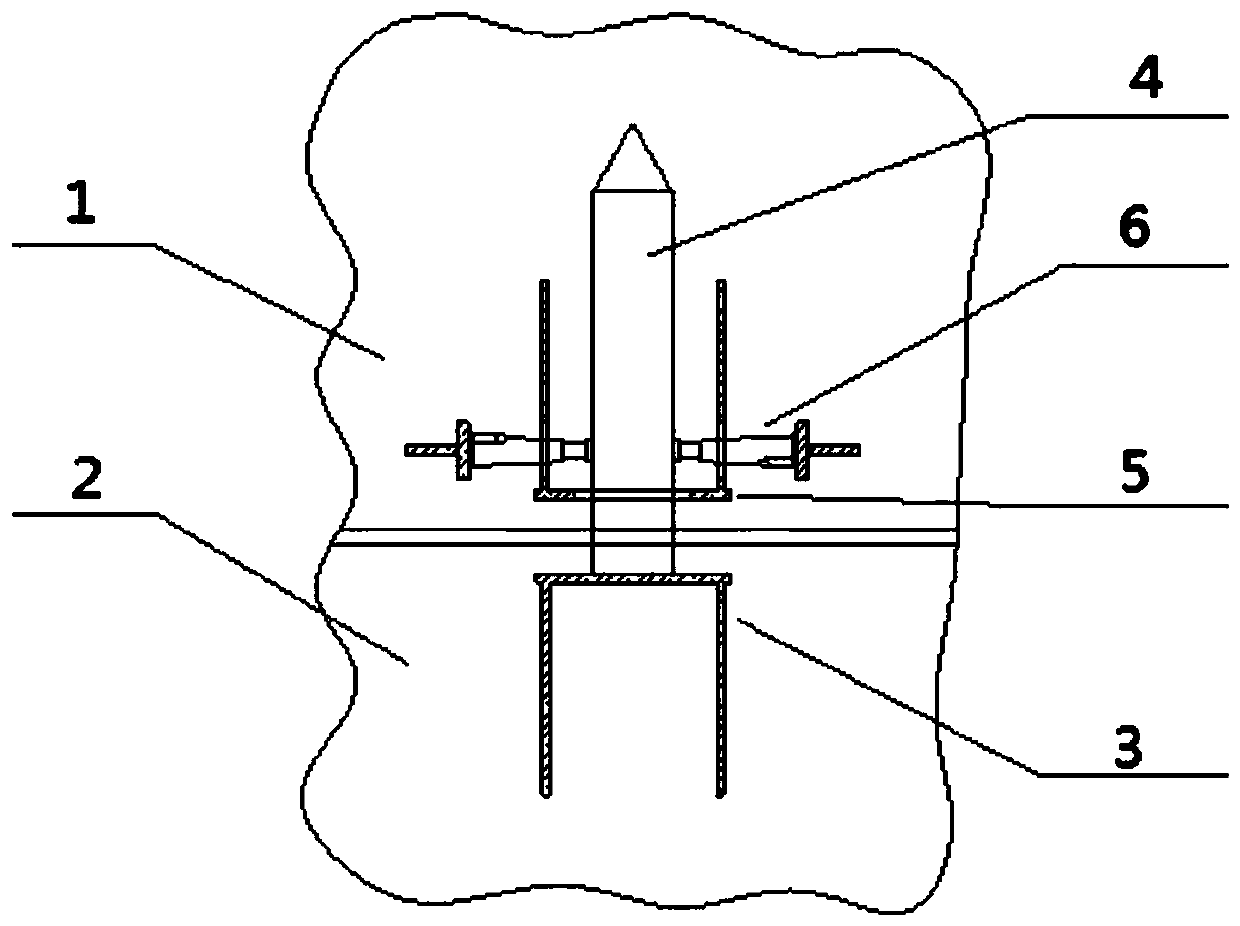

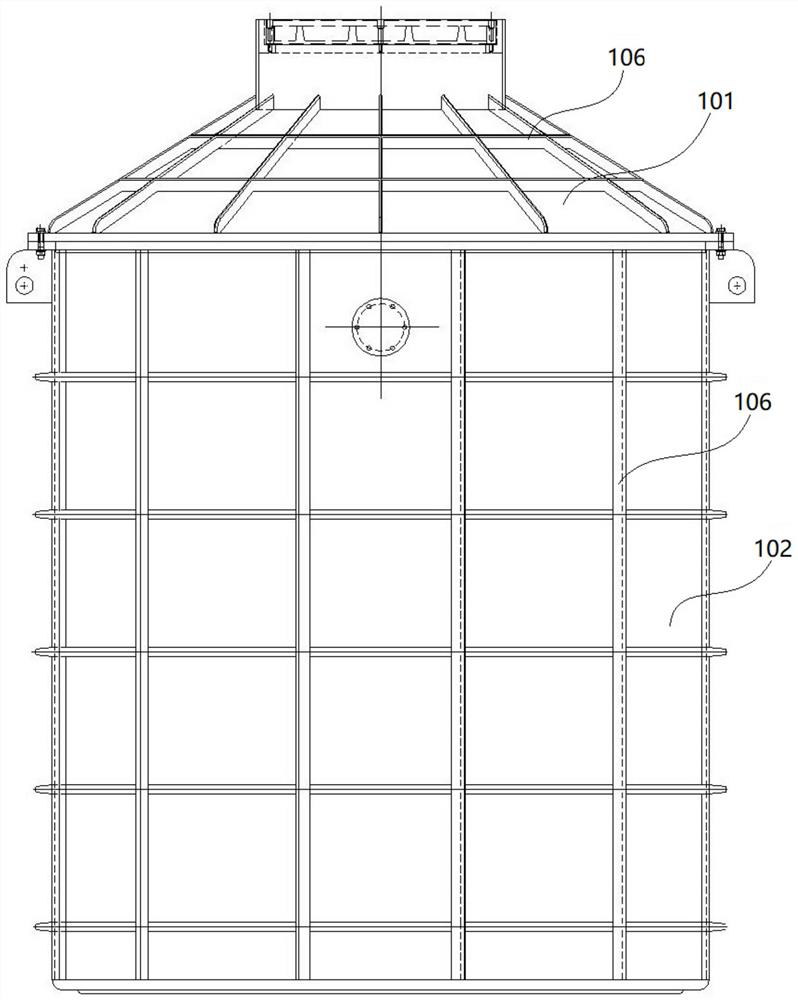

In-place guiding device for segmented hoisting and air pairing of heavy tower equipment

The invention discloses an in-place guiding device for segmented hoisting and air pairing of heavy tower equipment and belongs to the technical field of equipment manufacturing and installation. According to the in-place guiding device, supporting tools are installed on the peripheral wall of the portion, close to a paired welding position, of a lower section of a tower, and guide columns are welded to the tools; guiding rings are installed on the portion, located above a paired weld joint, of the tower section to be hoisted; the guiding rings are uniformly distributed on the peripheral wall of the portion, close to the welding position, of an upper section of the tower and correspond to the guiding columns of the lower section of the tower; and the upper section of the tower is hoisted to the position above the lower section of the tower, the position of the upper section of the tower is adjusted and controlled by drawing hemp ropes tied in advance, the guiding columns installed on the upper portion of the lower section of the tower are sleeved with the guiding rings installed on the lower portion of the upper section of the tower by descending hoisting rings, and the upper section and the lower section of the tower are guided to be aligned rapidly and accurately. A brand-new method for segmented hoisting and vertical pairing of the heavy tower equipment is designed. By the adoption of the technical scheme, pairing of the upper section and the lower section of the equipment can be completed more safely, rapidly and accurately.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

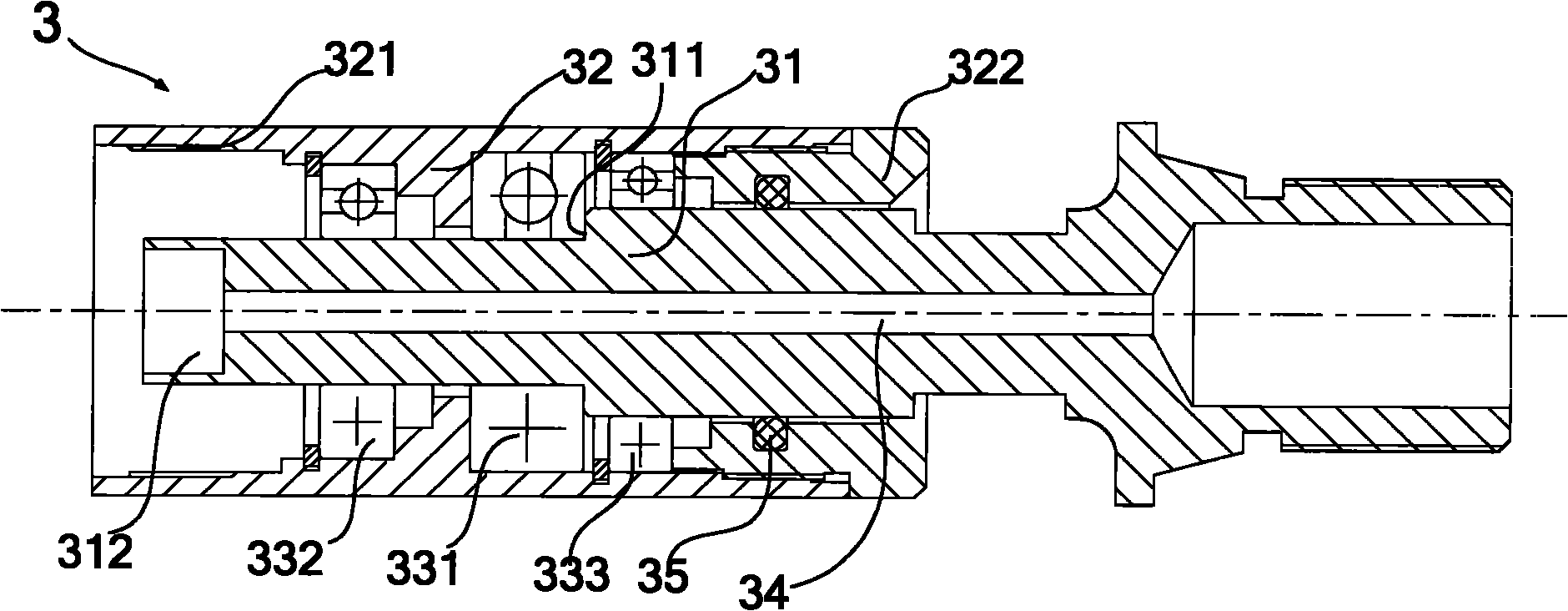

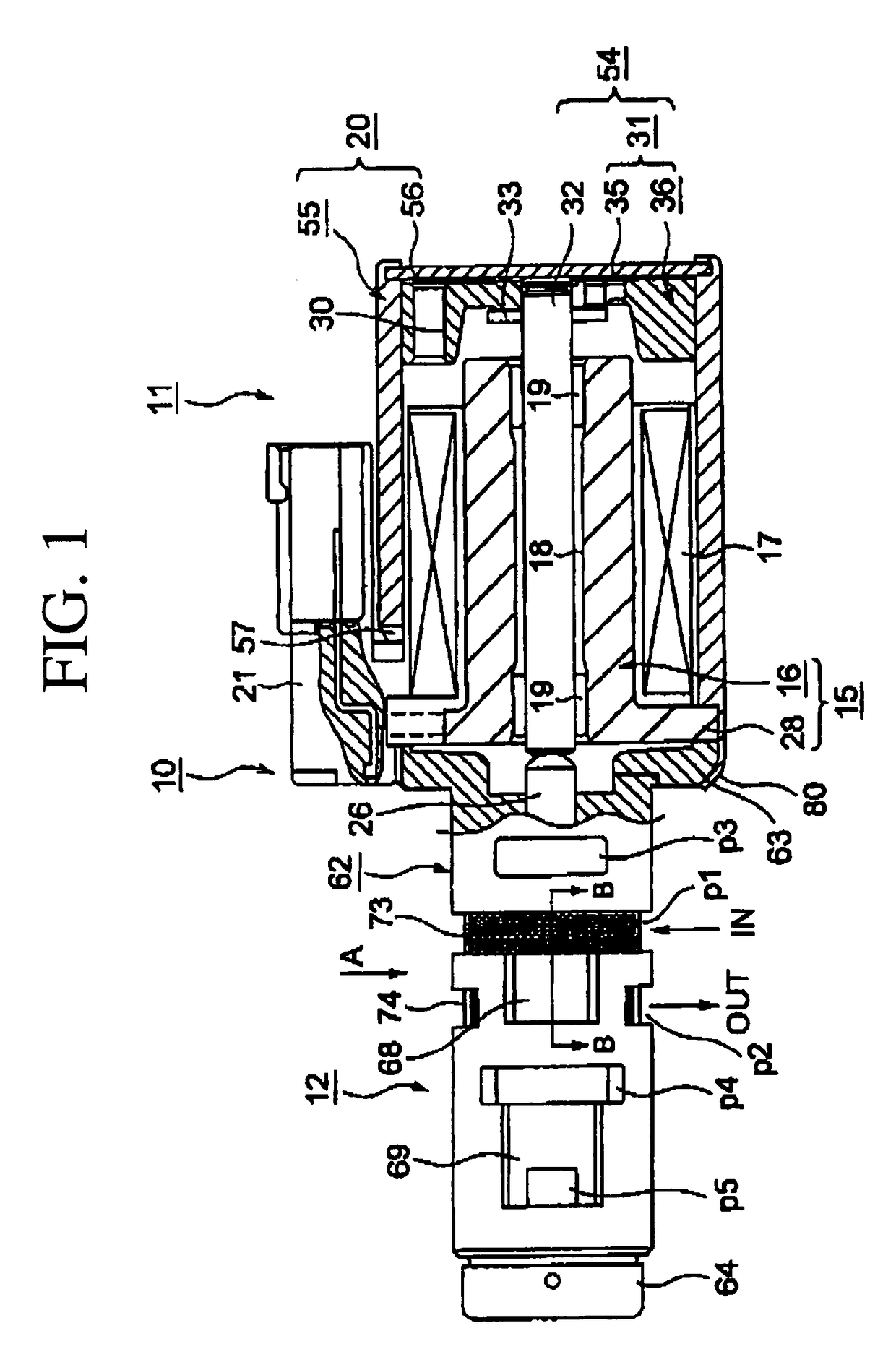

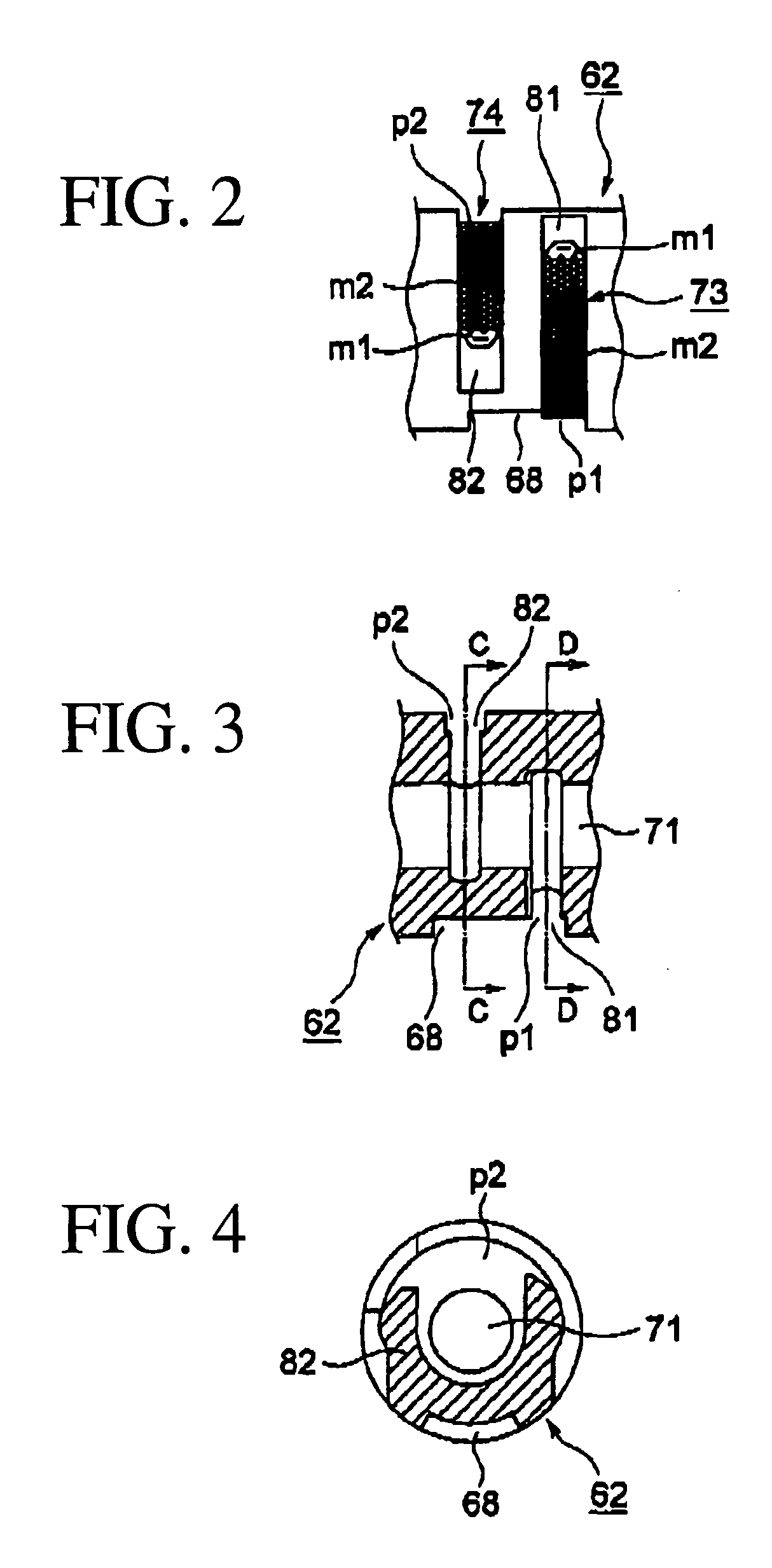

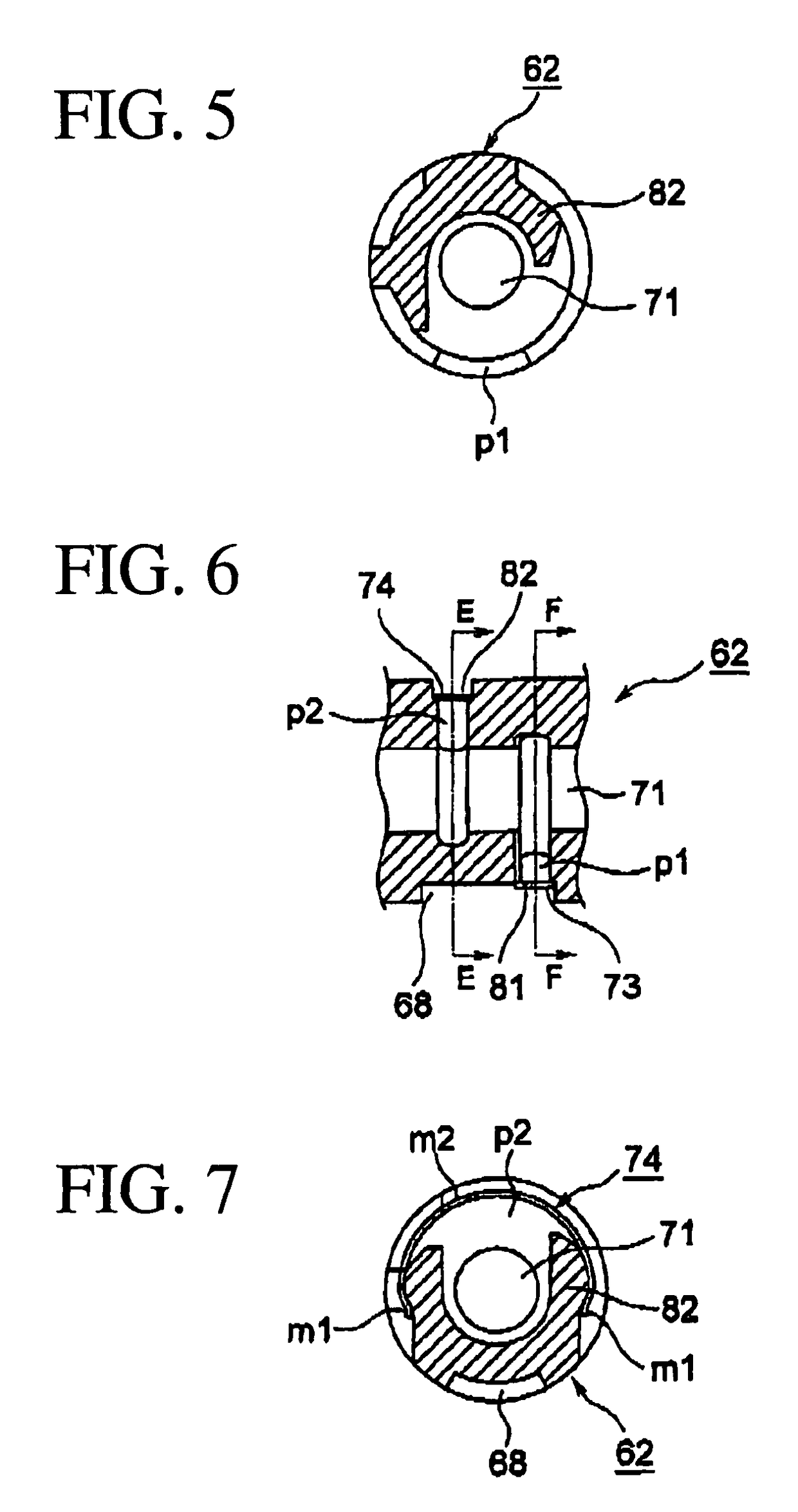

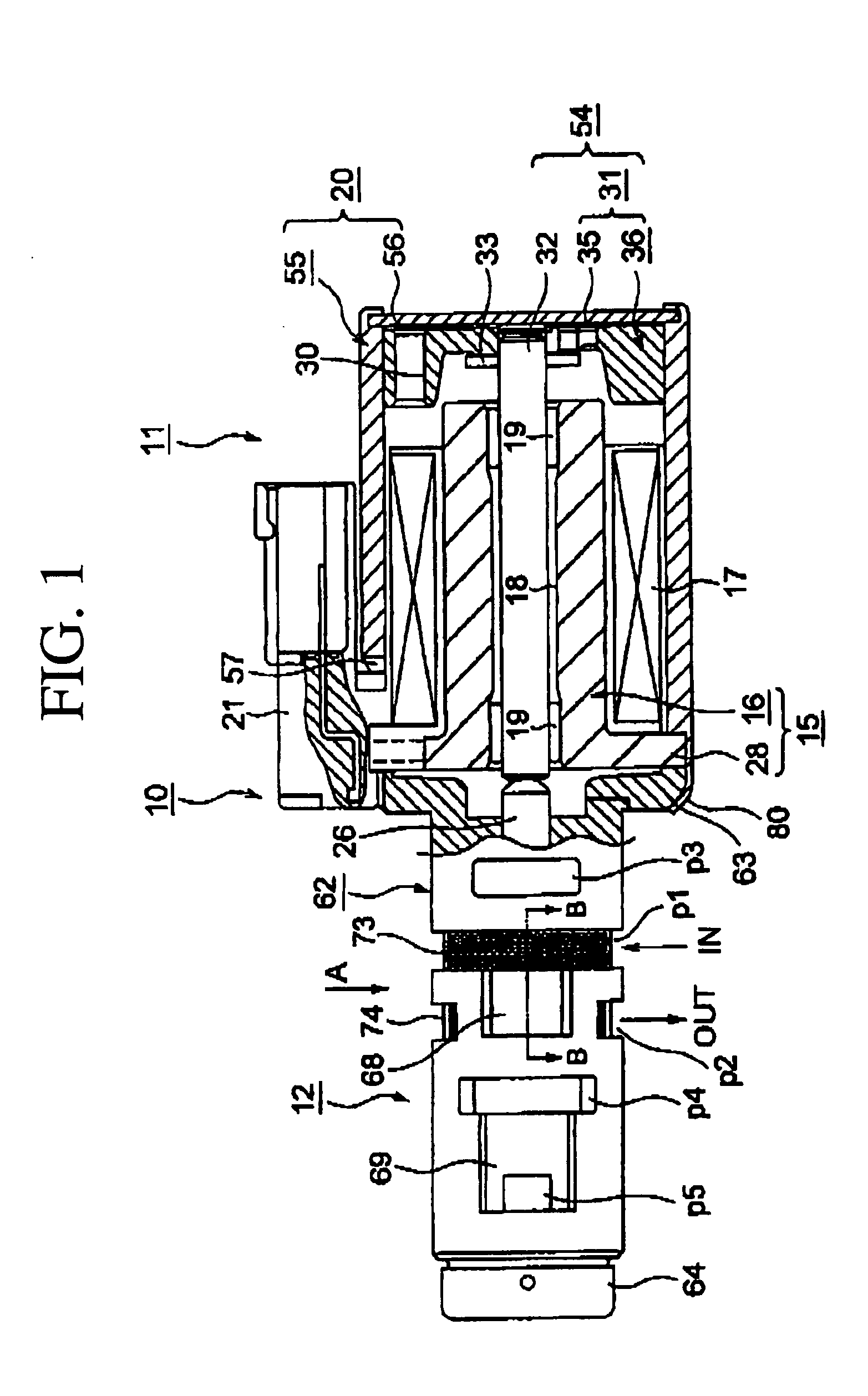

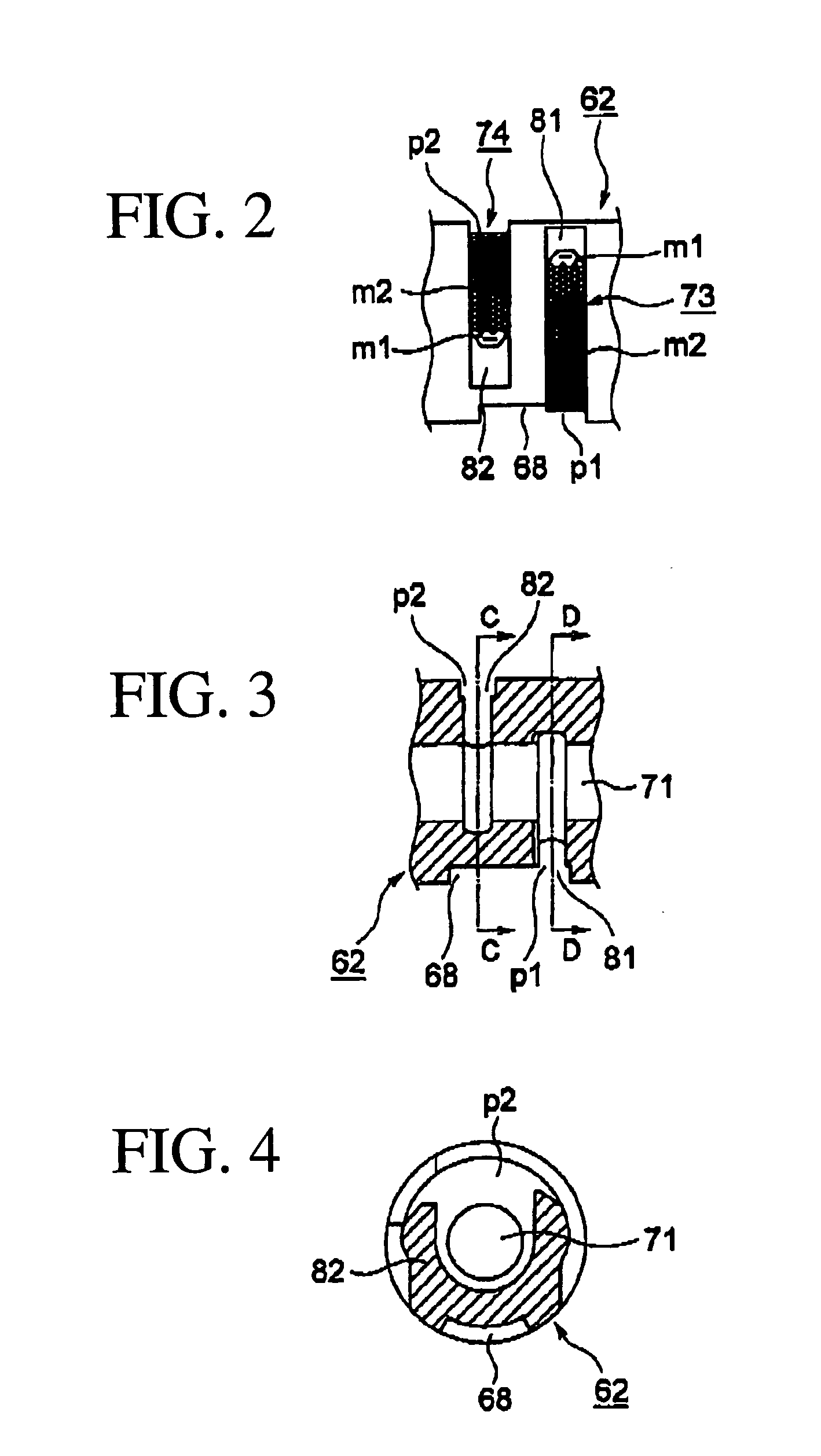

Strainer and control valve

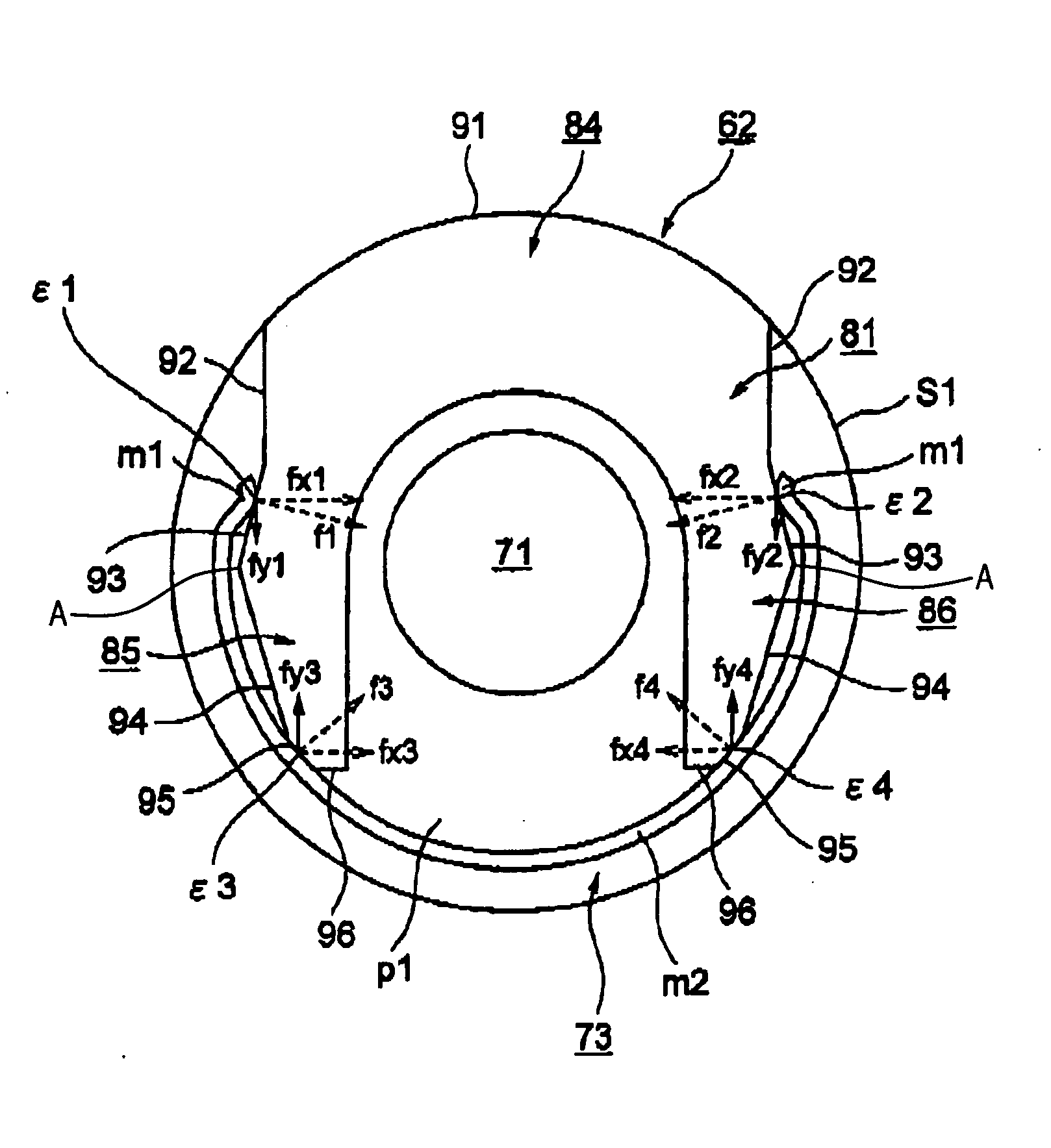

InactiveUS7905248B2Improve sealingReduced specificationsOperating means/releasing devices for valvesSettling tanks feed/dischargeForeign matterControl valves

The present invention prevents foreign matter from infiltrating into a control valve and enables reduction in the cost of the valve. A strainer is mounted on an attachment portion of a valve sleeve, and a valve spool is disposed in the sleeve so as to be free to slidably advance and retreat. The strainer includes engagement portions m1 contacting first contact sites ε1 and ε2 formed on the attachment portion and a contact portion contacting second contact sites ε3 and ε4 formed on the attachment portion. Since the strainer includes the engagement portions m1 in contact with the first contact sites ε1 and ε2 and the contact portion in contact with the second contact sites ε3 and ε4, the sleeve has sufficient sealing contact with the strainer 73 at the first and second contact sites ε1 to ε4.

Owner:AISIN AW CO LTD

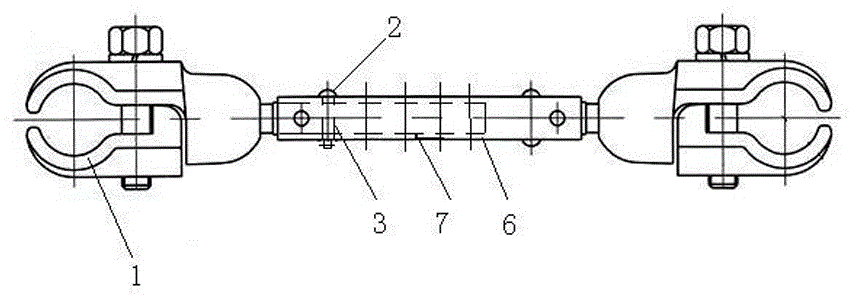

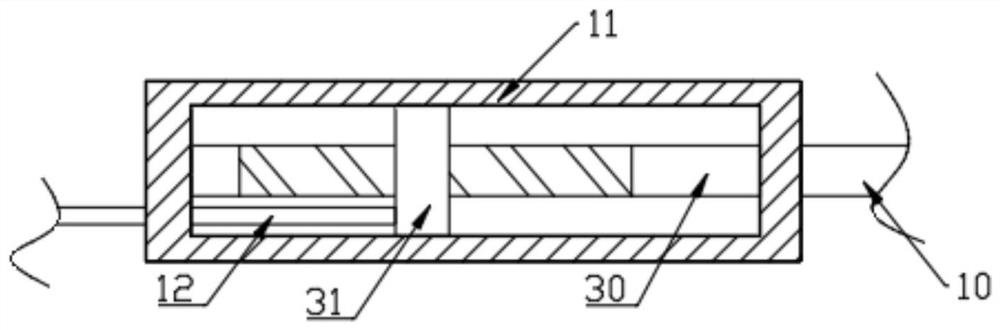

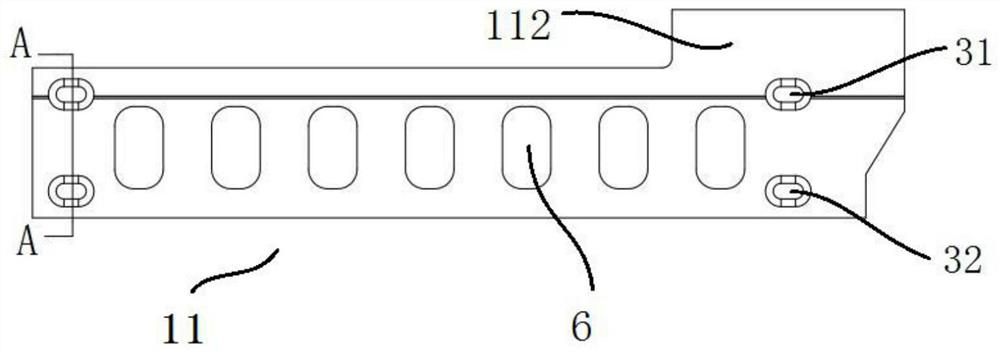

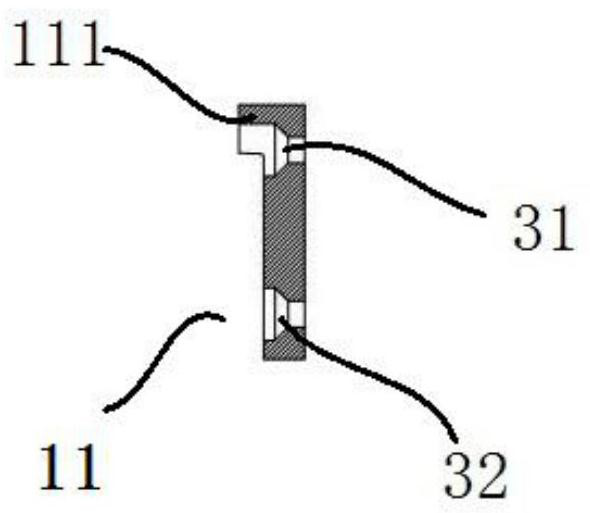

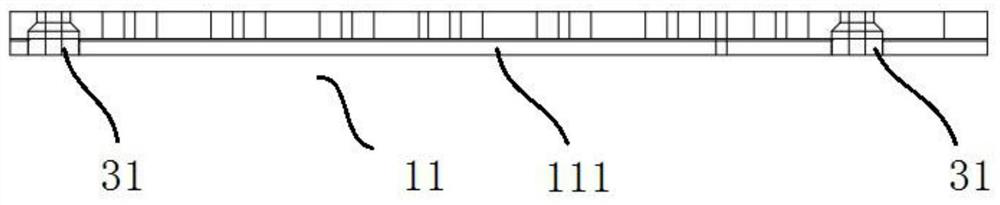

Telescopic spacer

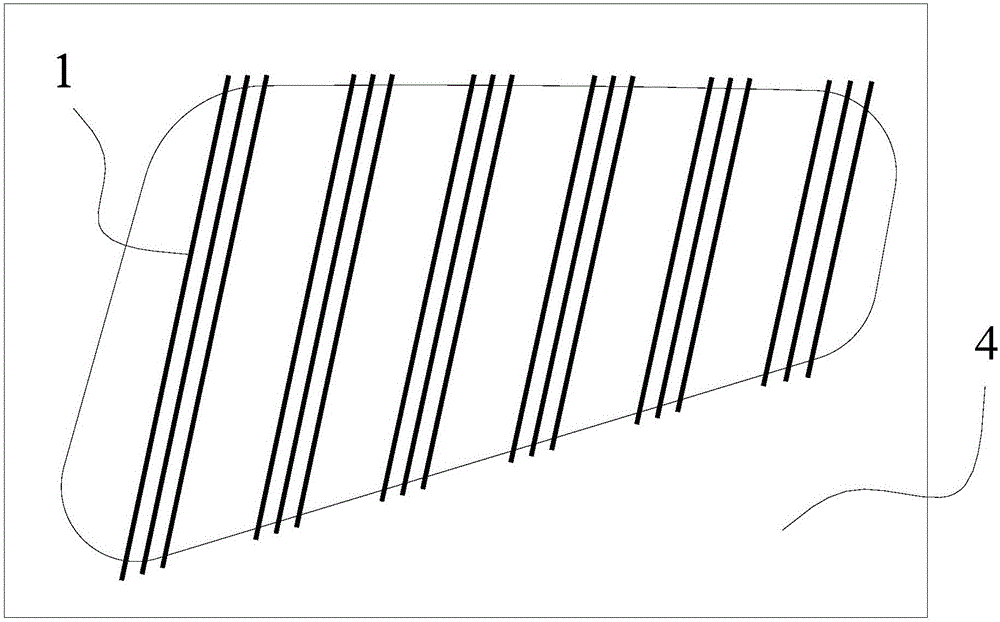

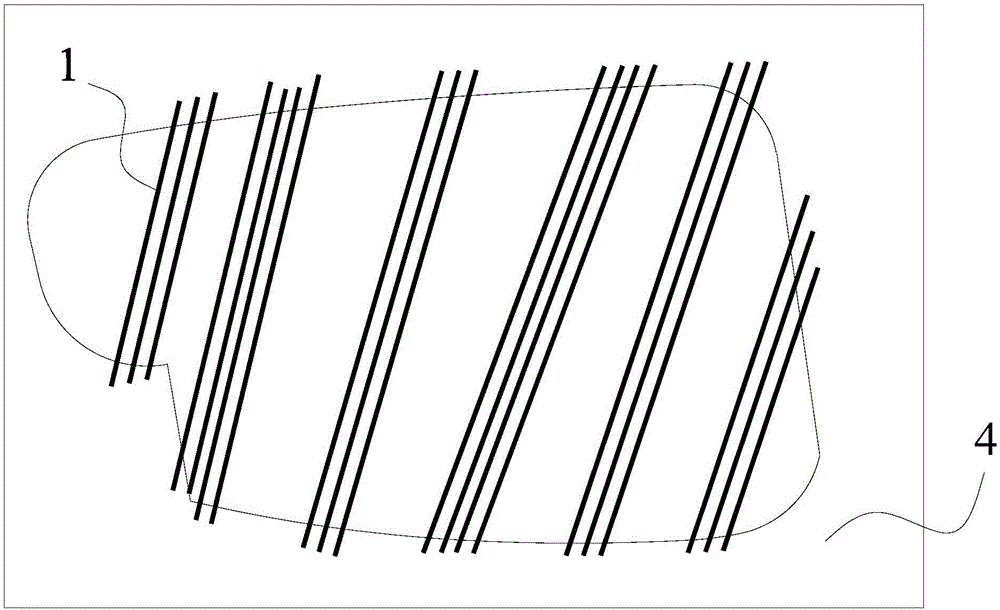

InactiveCN105655954AEasy to installEasy to useMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsTransfer linePhysics

The invention relates to a component of a power transmission line system, especially to an anti-oscillation anti-binding anti-whipping telescopic spacer for a high-voltage transmission line. The spacer comprises an intermediate connecting rod and wire-capturing clamp heads arranged at the two ends of the intermediate connecting rod. The intermediate connecting rod has a telescopic structure; and a plurality of positioning pin holes for insertion of pins or bolts are formed in the telescopic rod at intervals. The intermediate connecting rod of the spacer is a telescopic rod whose length can not be adjusted and positioning is realized by the pins or bolts, so that adaptation to distances between different leads can be realized, the specification types can be reduced, and the cost can be lowered. Besides, the spacer can be installed and used conveniently.

Owner:STATE GRID CORP OF CHINA +1

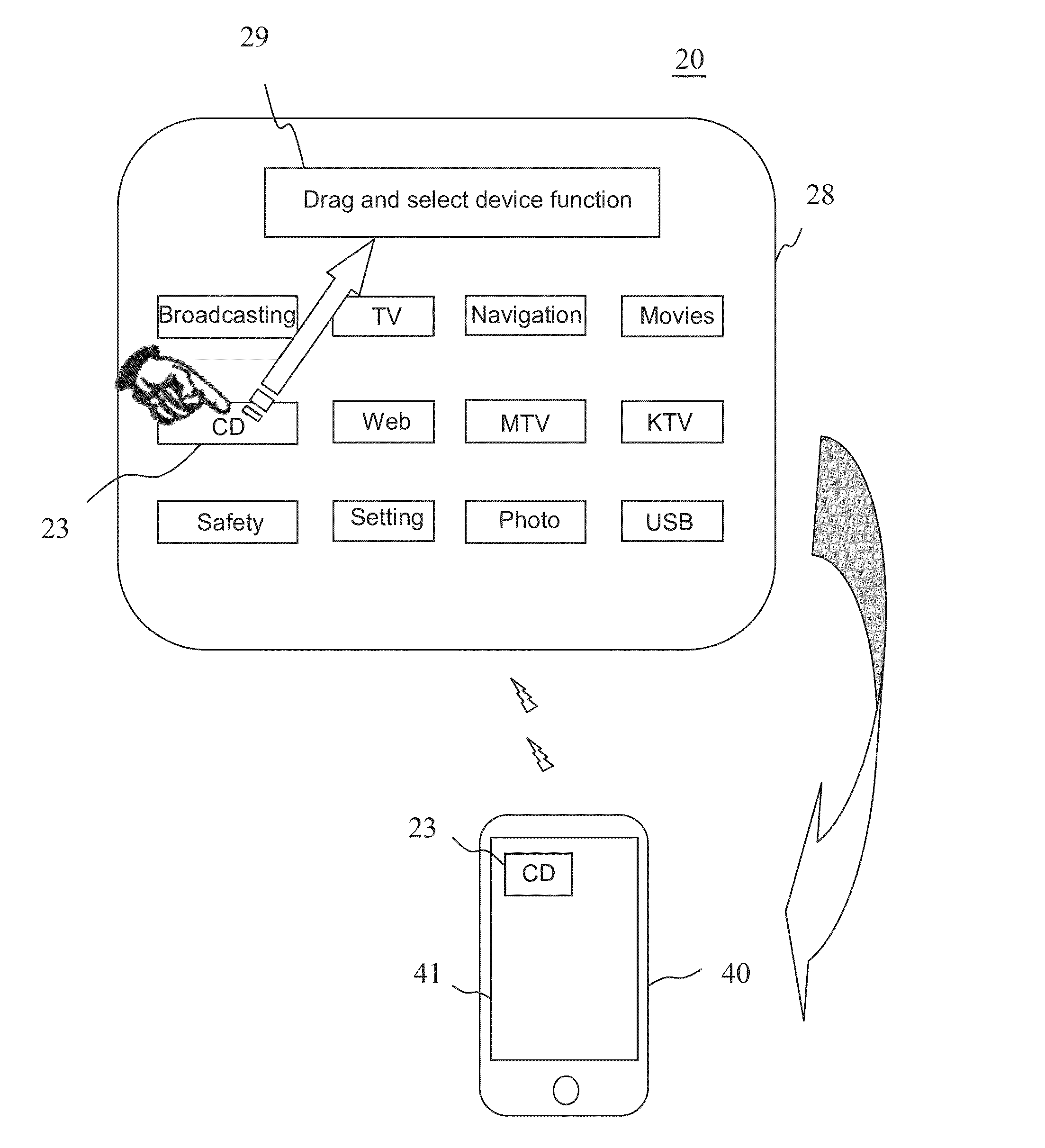

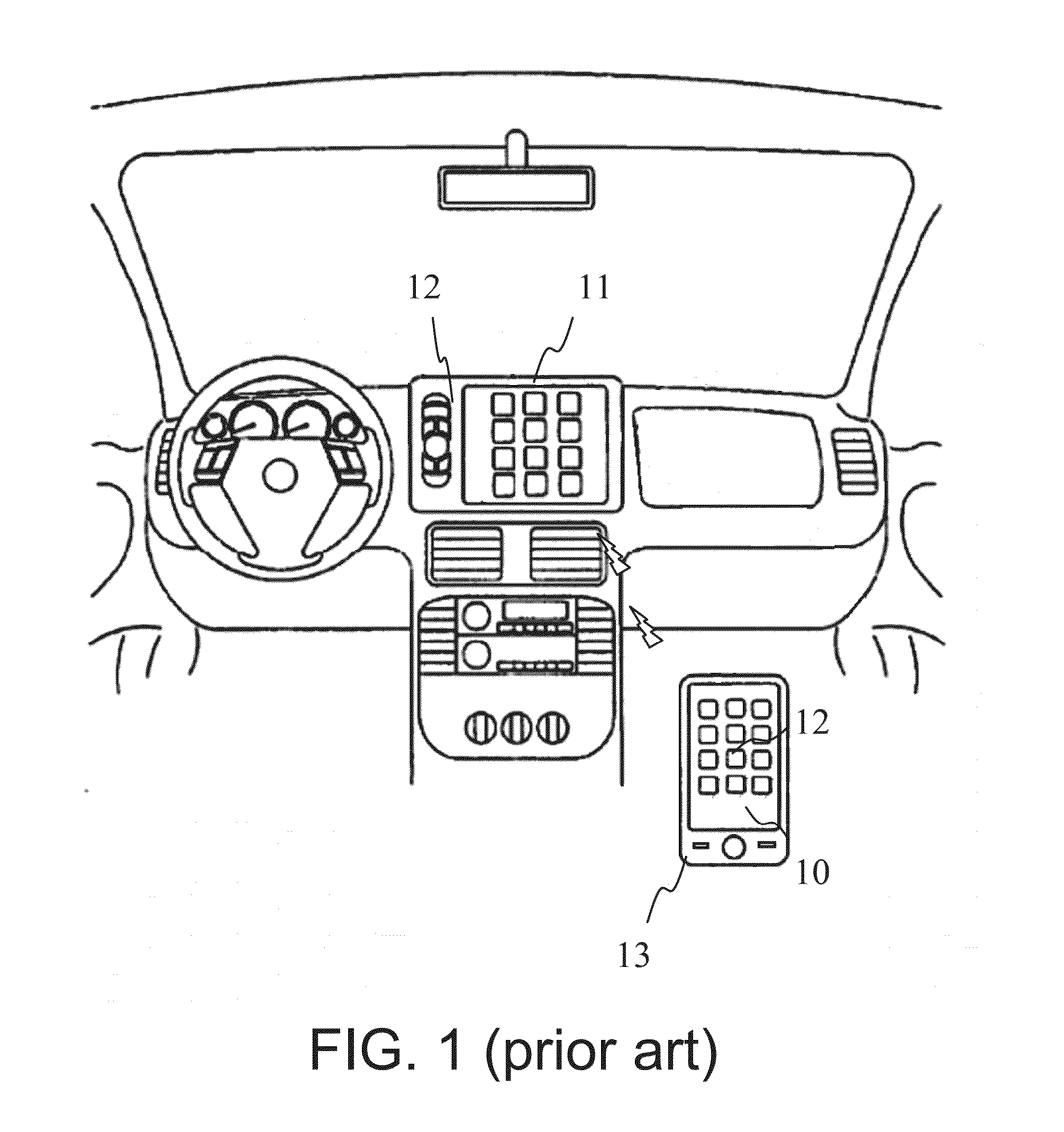

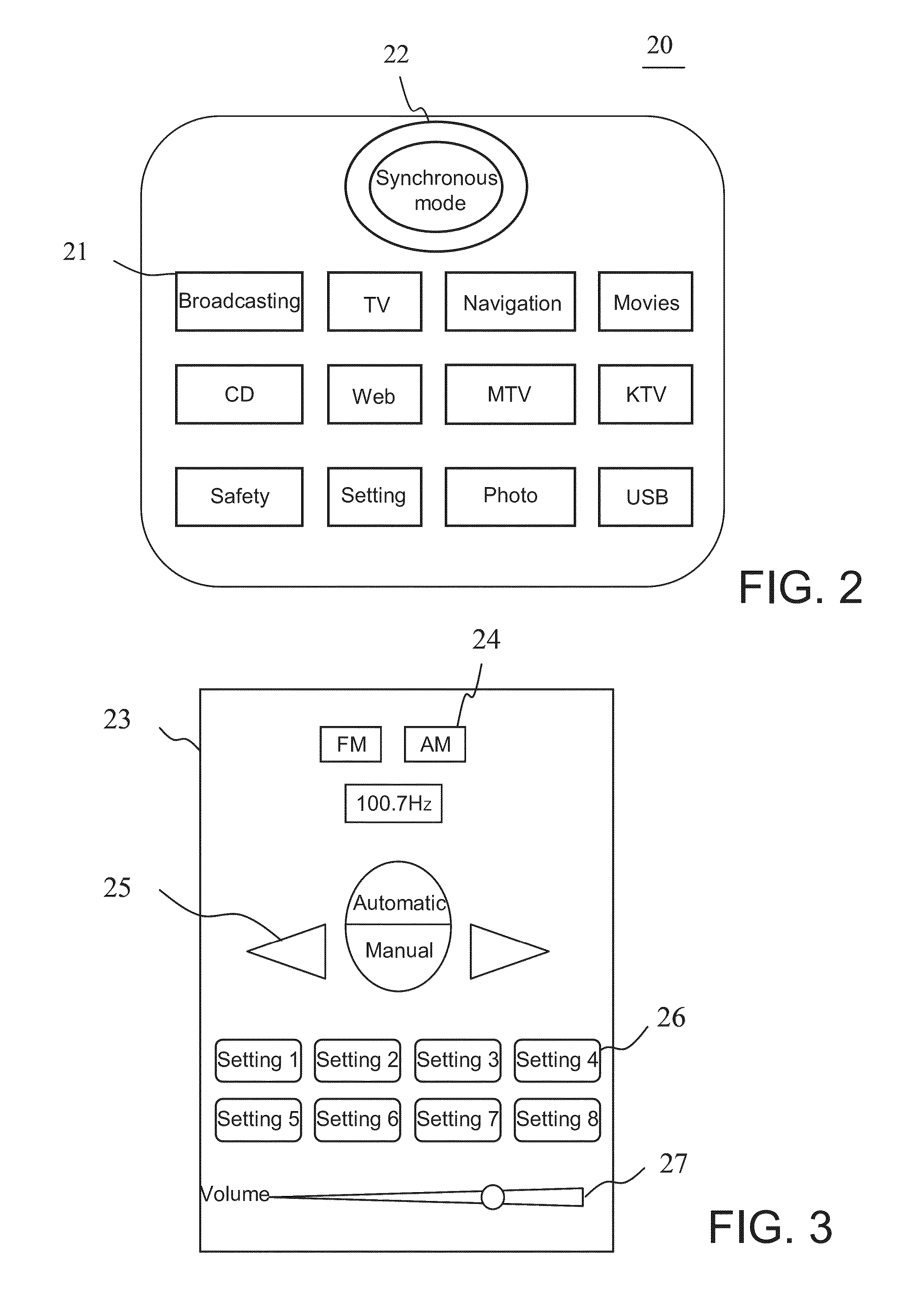

Method for controlling vehicle-mounted device by portable terminal

InactiveUS20140114501A1Broaden applicationReduce capacityDigital data processing detailsNavigation instrumentsComputer terminalOperation mode

A method for controlling a vehicle-mounted device by a portable terminal is provided. The method comprises the following steps. The vehicle-mounted device is turned on. A synchronous mode is started. Connection to the portable terminal is confirmed. The vehicle-mounted device is switched to the synchronous mode. An operation module is selected. A stored pattern of operation modes of the operation module is transmitted to the portable terminal. An operation module on the portable terminal is started for enabling the vehicle-mounted device to playback the function mode corresponding to the operation module and controlling the vehicle-mounted device by operating the operation mode on the portable terminal.

Owner:QUANTA STORAGE INC

Strainer and Control Valve

InactiveUS20080223778A1Improve sealingHigh cost of controlOperating means/releasing devices for valvesSettling tanks feed/dischargeForeign matterControl valves

The present invention prevents foreign matter from infiltrating into a control valve and enables reduction in the cost of the valve. A strainer is mounted on an attachment portion of a valve sleeve, and a valve spool is disposed in the sleeve so as to be free to slidably advance and retreat. The strainer includes engagement portions m1 contacting first contact sites ε1 and ε2 formed on the attachment portion and a contact portion contacting second contact sites ε3 and ε4 formed on the attachment portion. Since the strainer includes the engagement portions m1 in contact with the first contact sites ε1 and ε2 and the contact portion in contact with the second contact sites ε3 and ε4, the sleeve has sufficient sealing contact with the strainer 73 at the first and second contact sites ε1 to ε4.

Owner:AISIN AW CO LTD

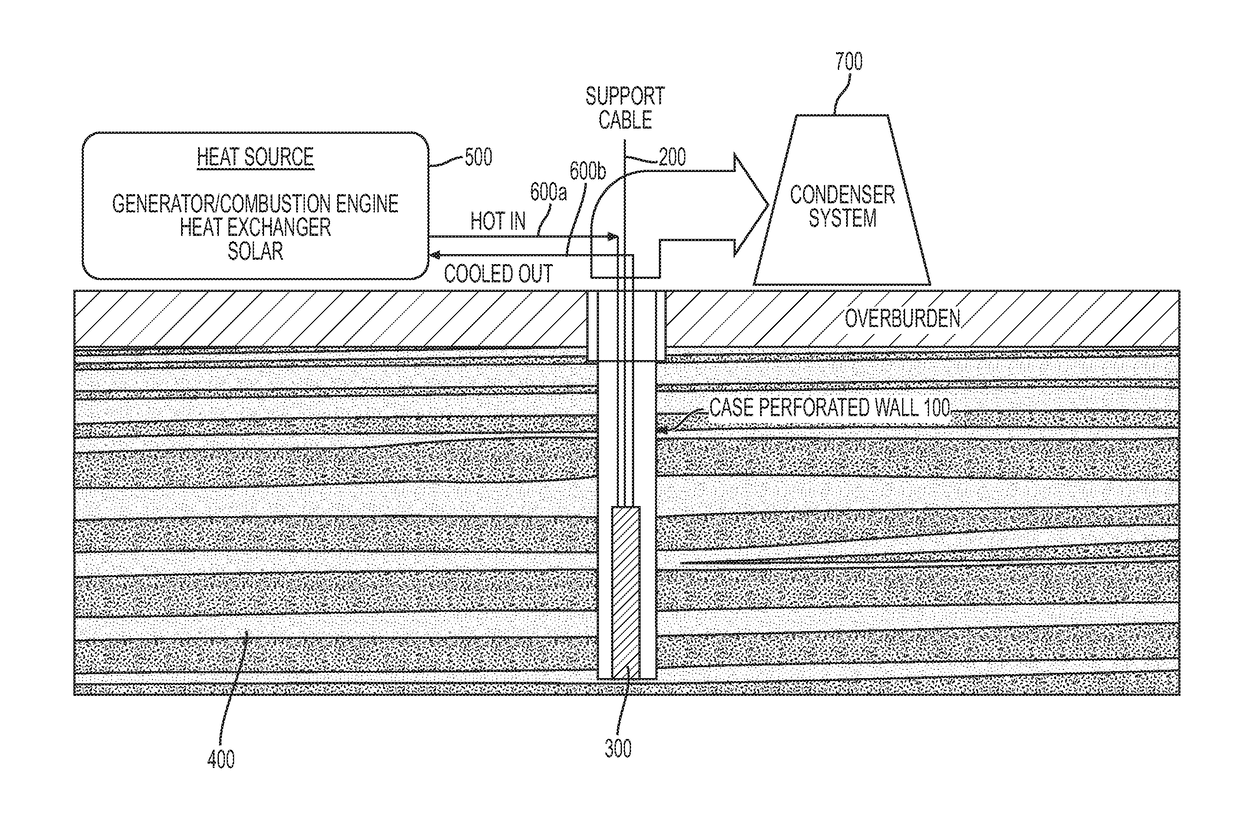

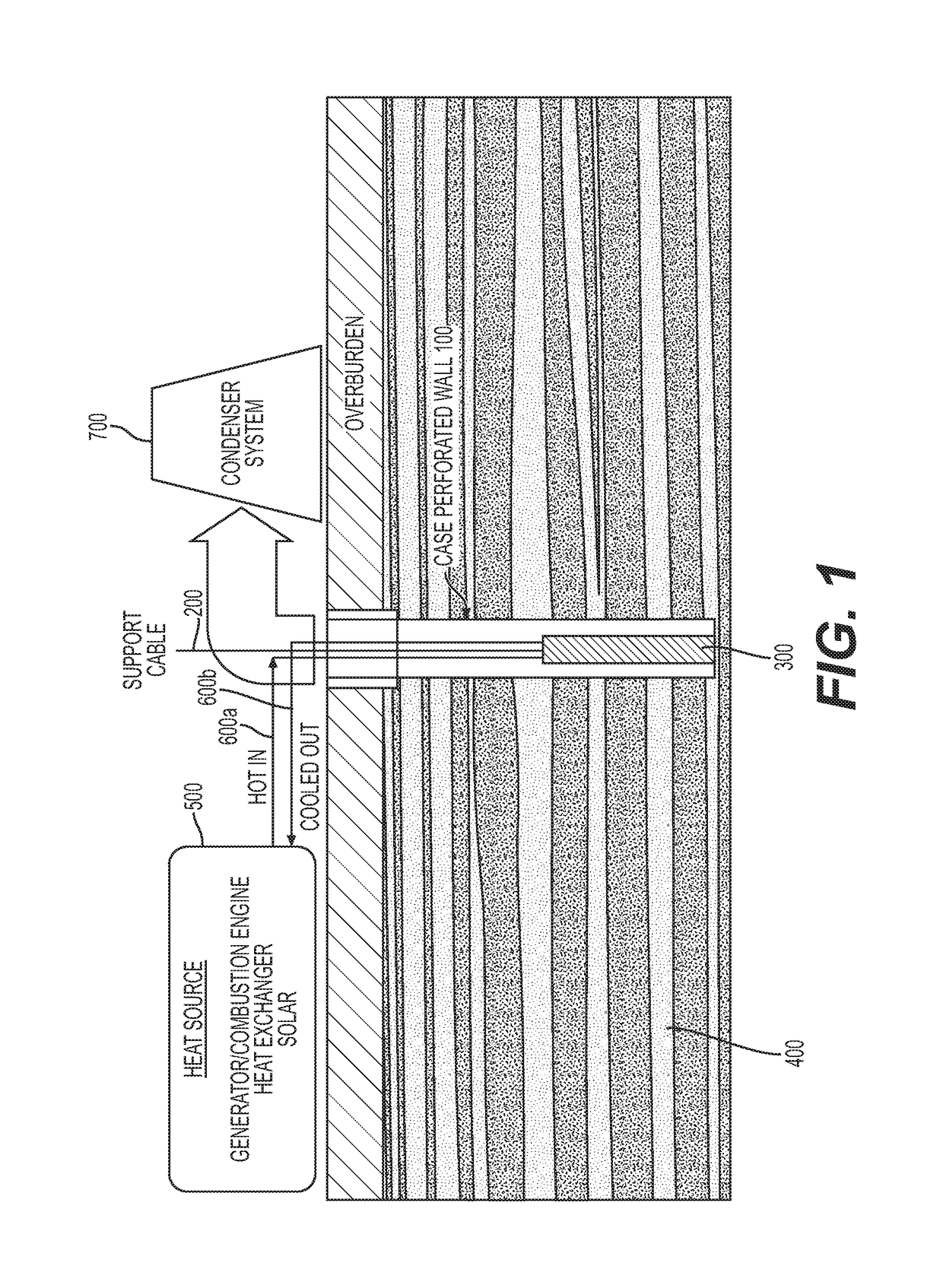

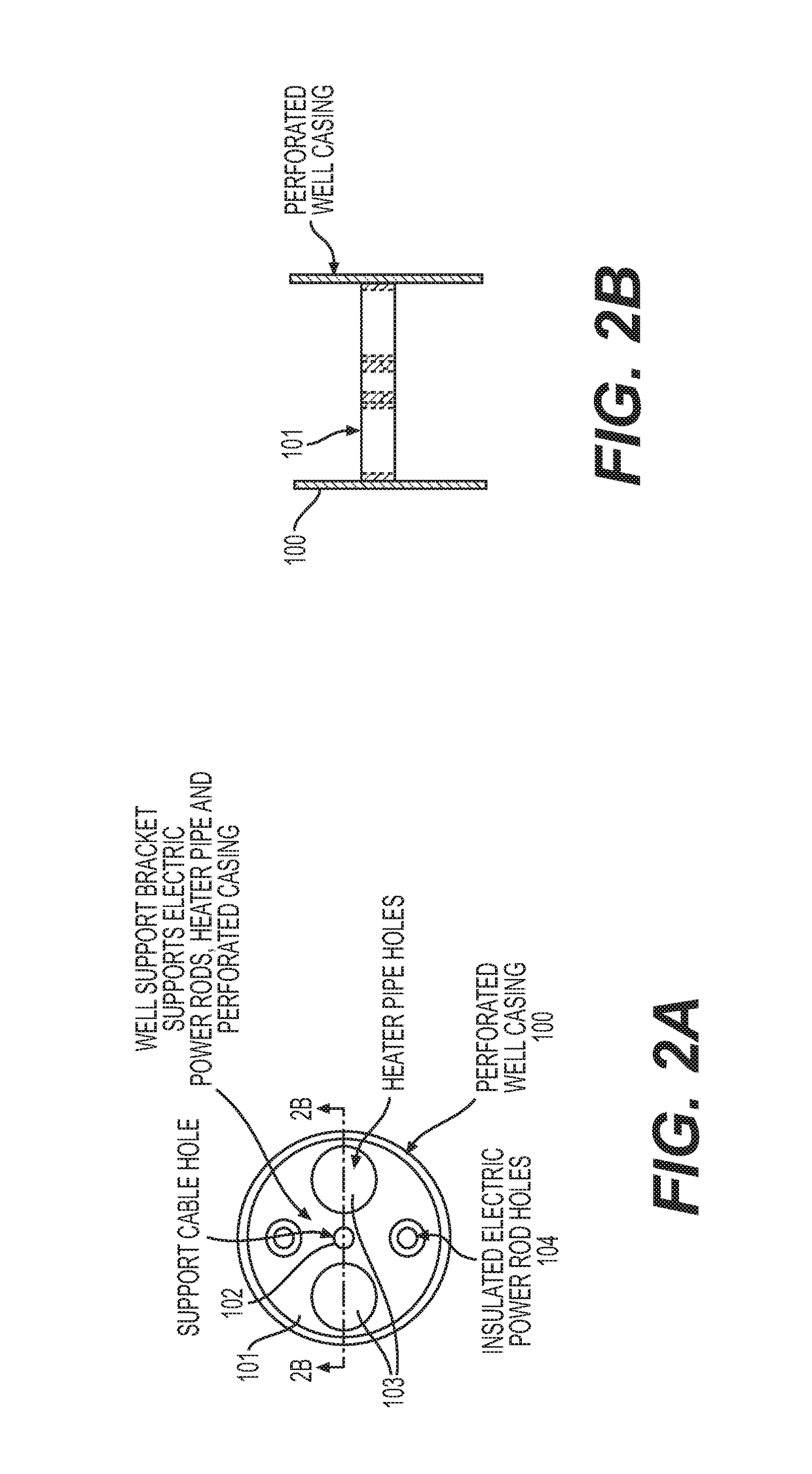

Systems and methods for the in situ recovery of hydrocarbonaceous products from oil shale and/or oil sands

InactiveUS10125587B1Avoid disadvantagesMinimize expansion/contraction issueDrilling rodsConstructionsKerogenClosed loop

Systems and methods are described for the in situ recovery of hydrocarbonaceous products from nonrubilized oil shale and / or oil sands. The inventive system comprises a closed loop, in-ground radiator that is suspended from a support cable (or rod) along with support bracket(s) and perforated outer casing sections into a borehole, in order to target and heat kerogen and / or bitumen within oil shale and / or oil sand deposits, and to collect the resultant hydrocarbonaceous product gases from the borehole without the need for separating processing gases and / or liquids. The inventive system avoids the drawbacks associated with “open” systems including the mixing of processing and product gases, and the problems historically associated with control and management of prior art in situ recovery systems.

Owner:RIVA LABS LLC

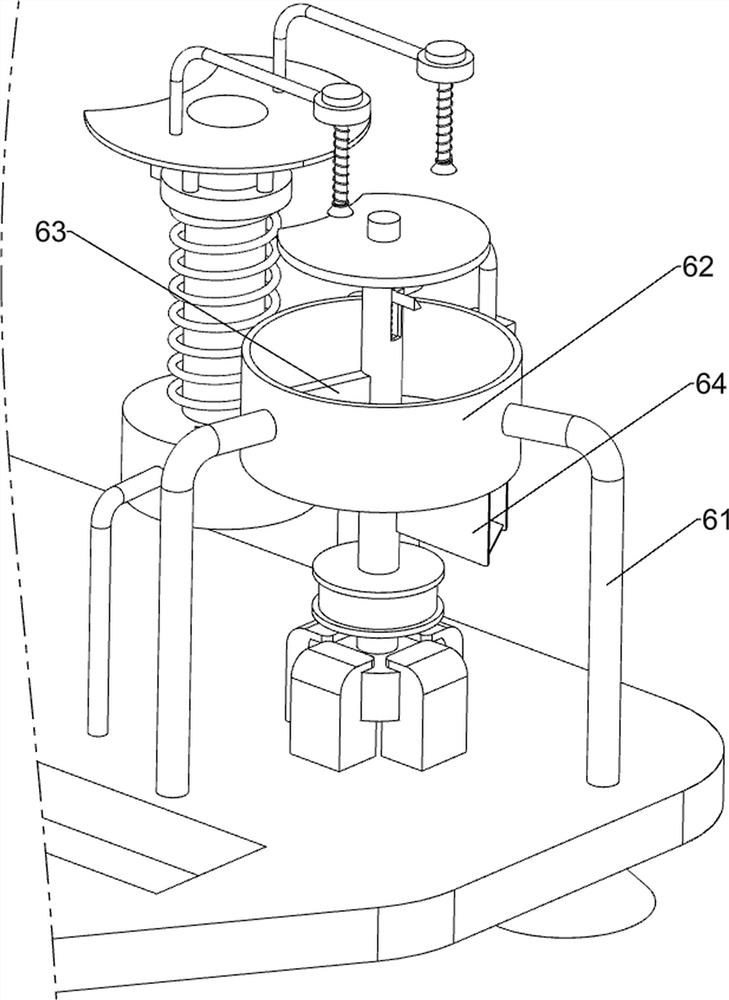

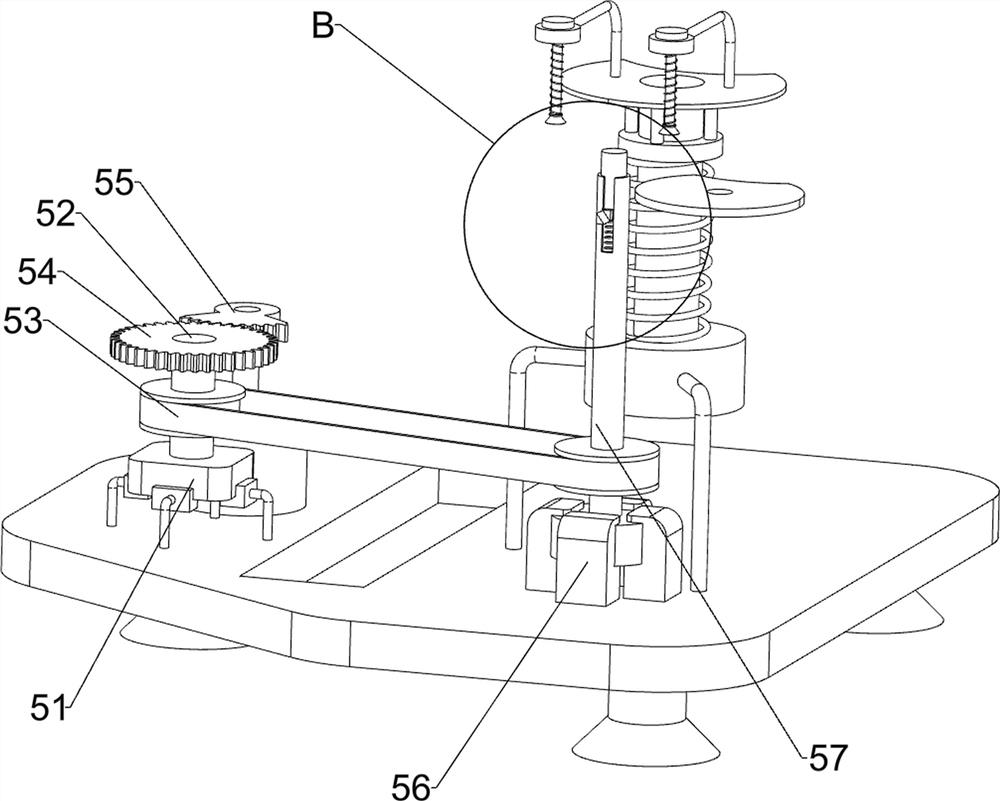

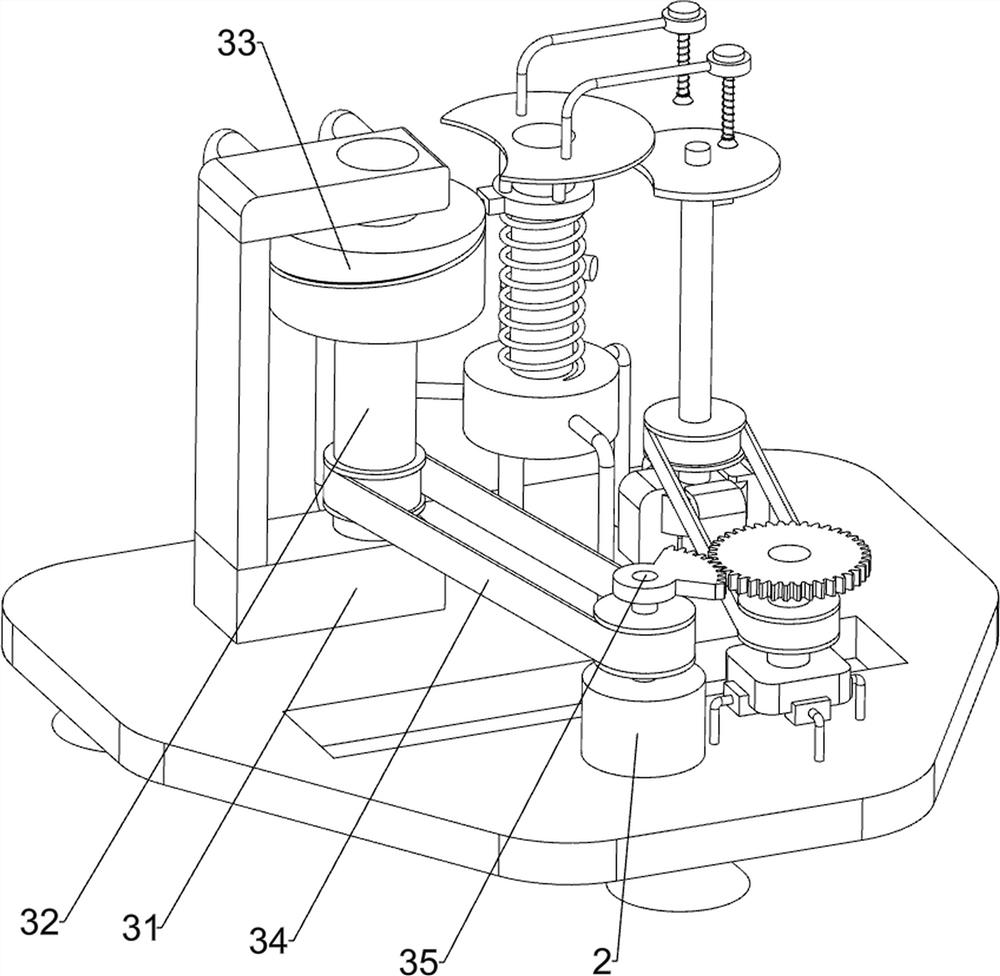

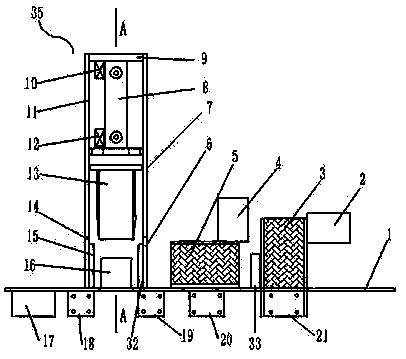

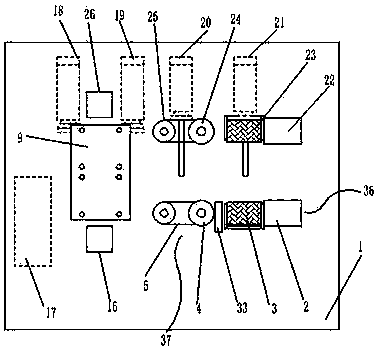

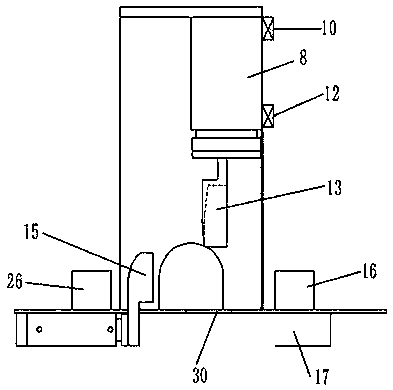

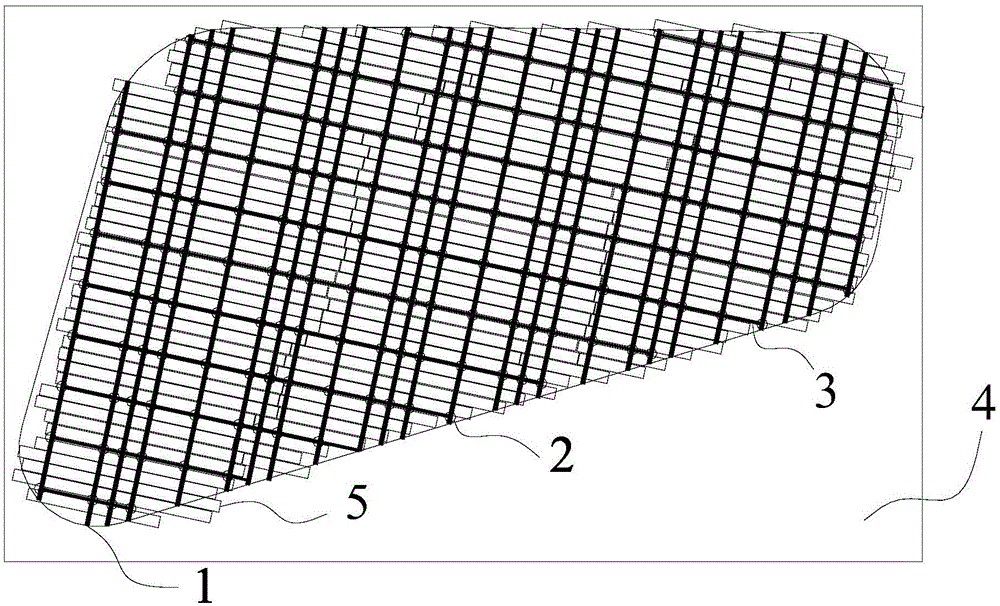

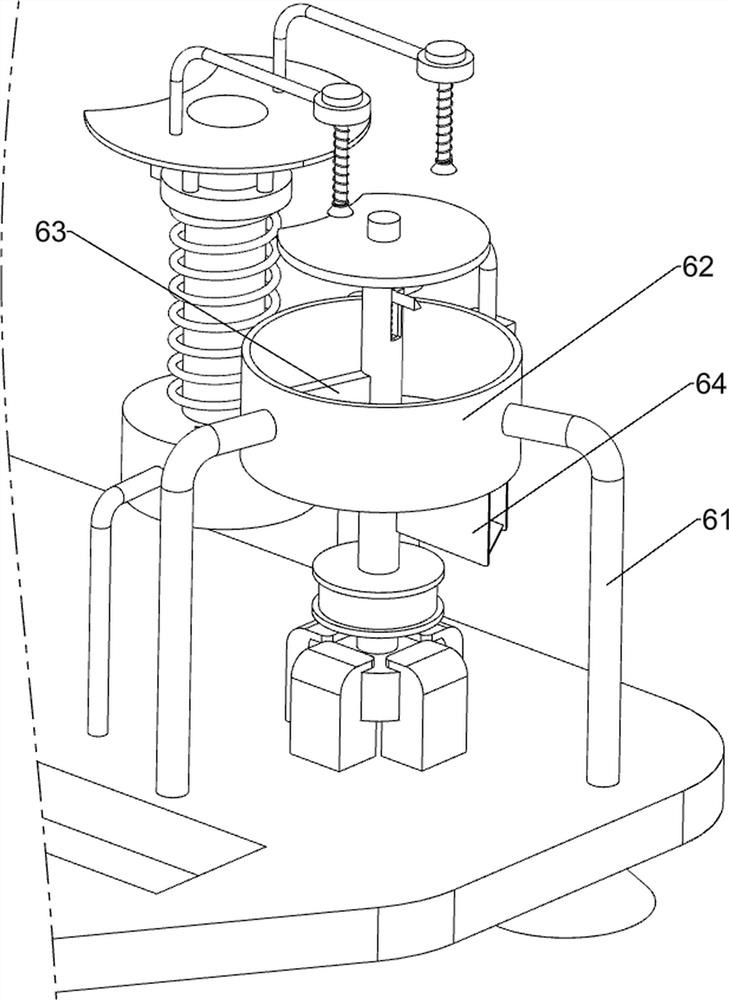

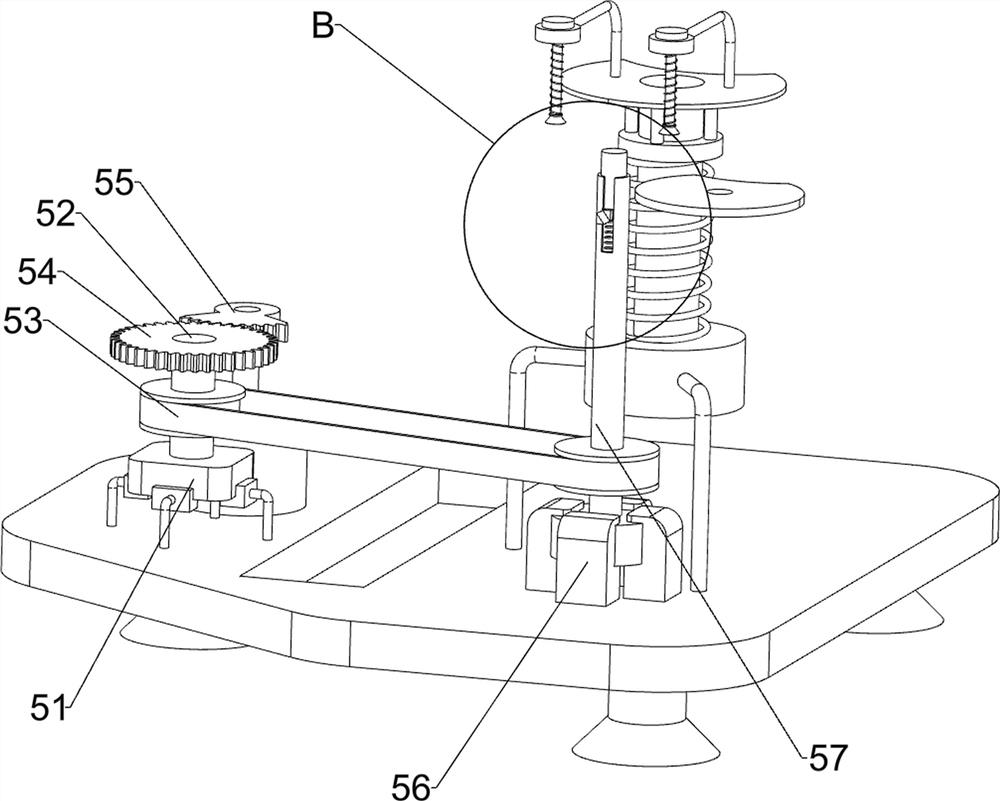

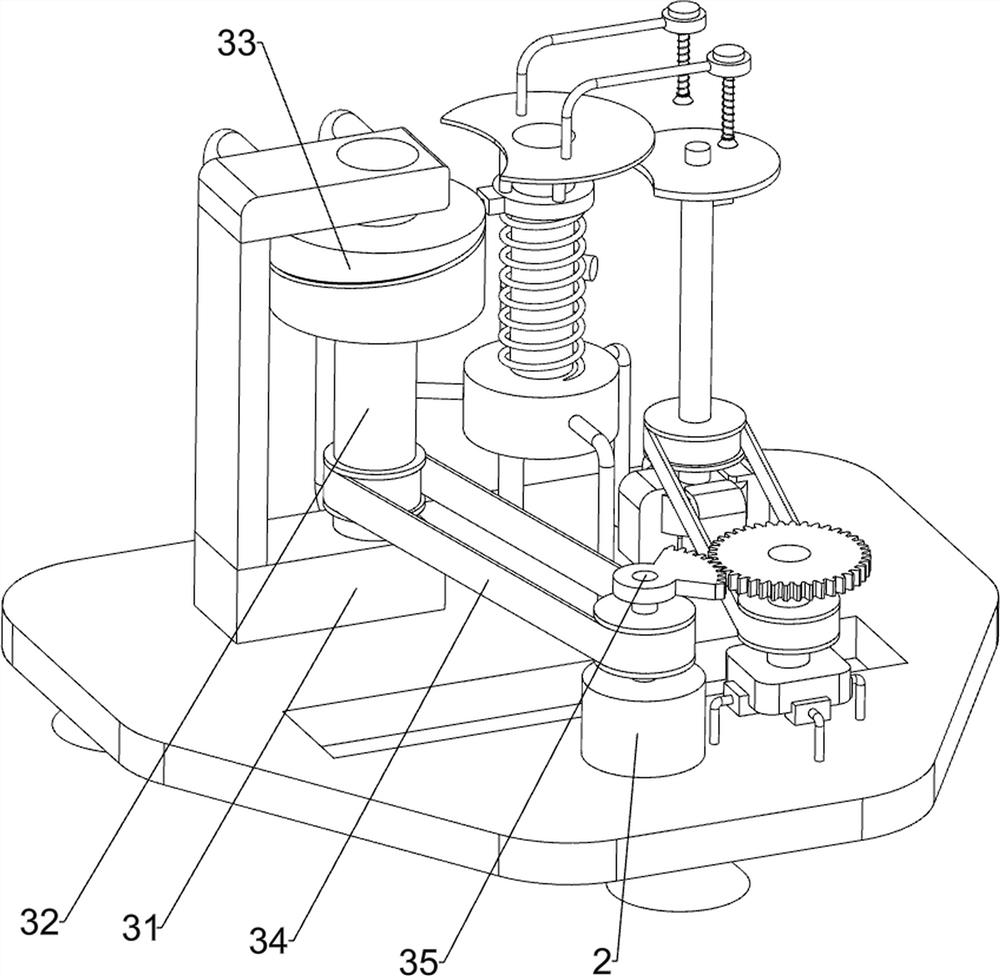

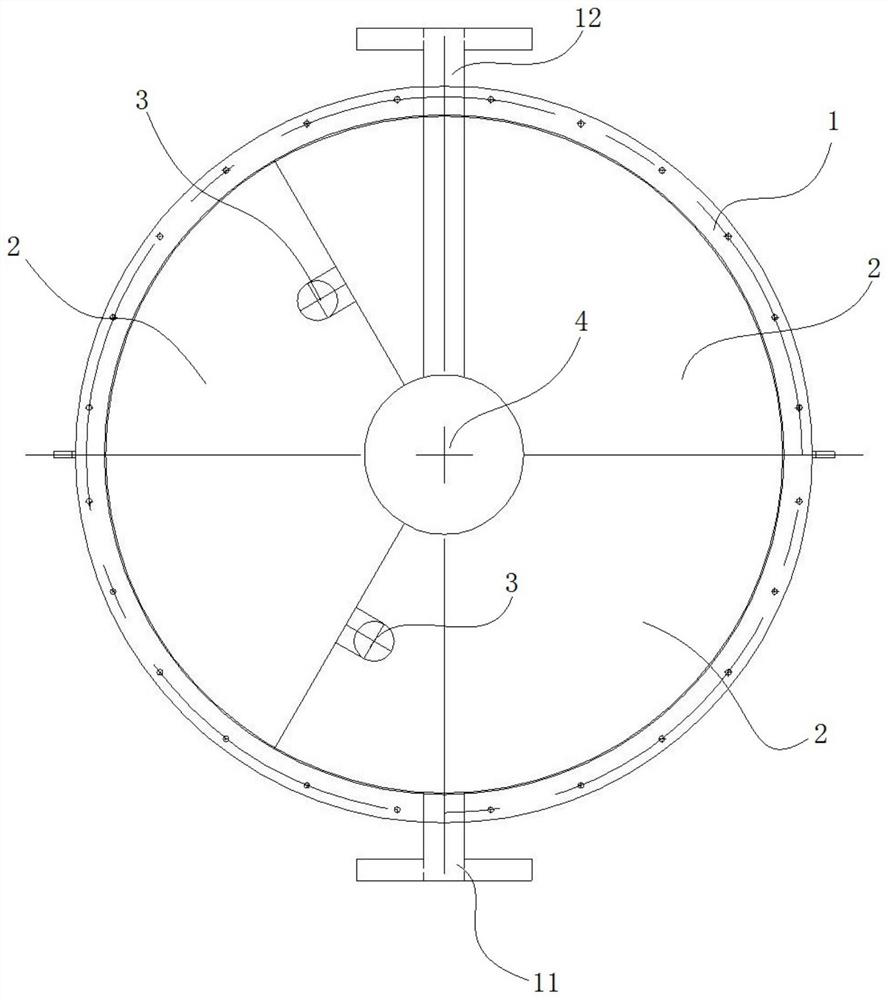

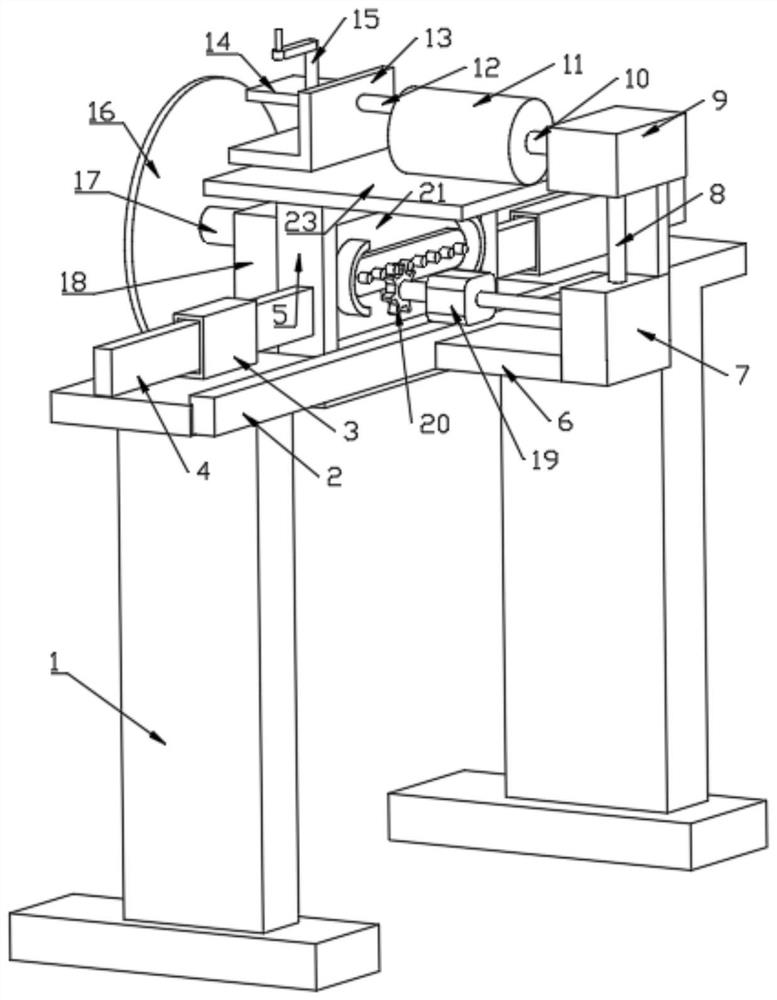

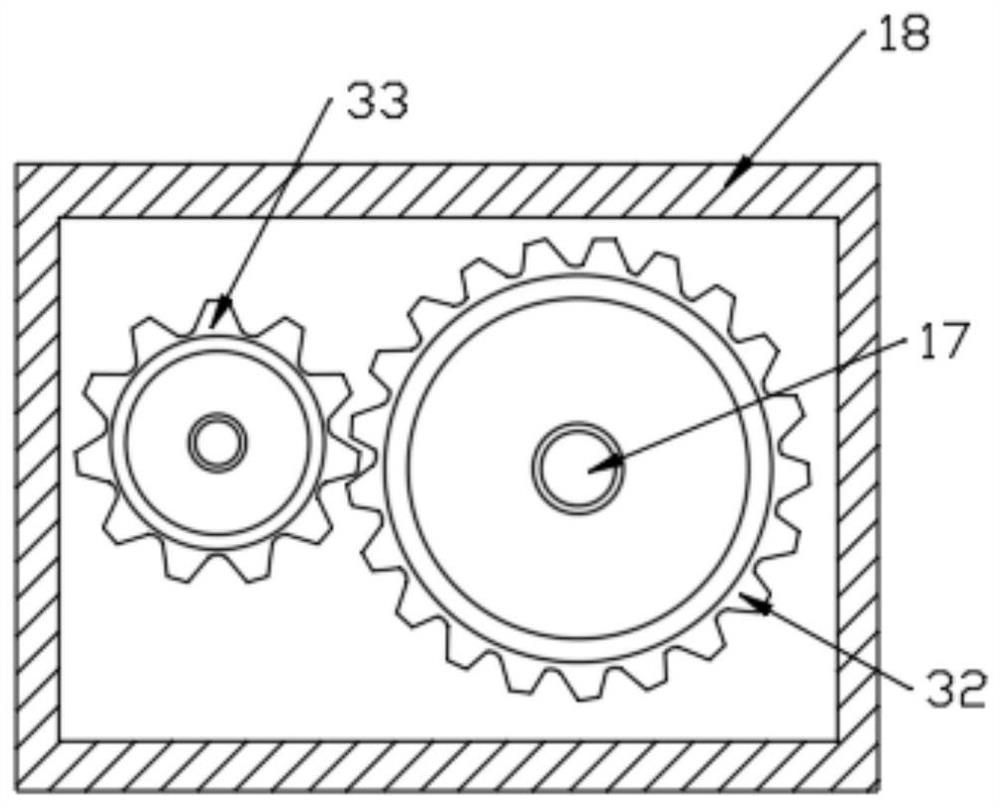

Intermittent circular iron sheet edge trimmer

ActiveCN112247249ARealize trimmingCutting specificationShearing machinesFeeding apparatusElectric machineStructural engineering

The invention relates to an edge trimmer, and particularly relates to an intermittent circular iron sheet edge trimmer. The invention provides the intermittent circular iron sheet edge trimmer, and the intermittent circular iron sheet edge trimmer can fix iron sheet and intermittently rotate the iron sheet while automatically cutting the iron sheet. The intermittent circular iron sheet edge trimmer comprises a rack, a motor, a transmission device, an intermittent rotating device and a downward pressing device, wherein the motor is installed on the rack; the transmission device is arranged on one side of the rack; the intermittent rotating device is arranged on the side, close to the motor, of the rack; and the downward pressing device is arranged in the middle of the rack. According to theintermittent circular iron sheet edge trimmer, through the design of the transmission device, the downward pressing device can be driven to move repeatedly, and the transmission device is matched with the downward pressing device, edge trimming of the circular iron sheet is achieved, the downward pressing edge trimming time is fixed, and edge trimming is more standard; and through the design of awaste collecting device, the waste obtained after edge trimming of the circular iron sheet in a collecting barrel is moved out of the collecting barrel through a sliding groove, and the interior of the collecting barrel can be cleaned, so that the interior of the collecting barrel is tidier.

Owner:杭州戴乐搪瓷有限公司

Full-automatic sugarcane seed bud cutting machine

InactiveCN110583143ALabor-saving processingImprove efficiencyMetal working apparatusPotato seed cluttersEngineeringBud

The invention discloses a full-automatic sugarcane seed bud cutting machine. The machine comprises a bottom plate, a cutting mechanism, a reverse rotation mechanism and a material conveying mechanismare installed on the bottom plate, the cutting mechanism is provided with a cutting air cylinder, the cutting cylinder is provided with a magnetic switch A and a magnet switch B, a cutter is installedat the front end of a pushing rod of the cutting air cylinder, and cutting is conducted downward perpendicularly; a front camera and a back camera are installed on the bottom plate and used for detecting the positions of sugarcane buds or segments; the reverse rotation mechanism is provided with a motor A, a conveying belt A, a motor C and a conveying belt C, and the conveying belt C is installedat the front end of a compression air cylinder C; the material conveying mechanism is provided with a conveying belt B driven by a motor B and a conveying belt C driven by a motor D and installed atthe front end of the compression air cylinder C. The cutting machine is of a mechanical and electrical integration structure, so that the efficiency of sugarcane seed bud processing is higher, the more standard purpose is achieved, the waste is reduced, and the earnings of sugarcane growers are improved.

Owner:广西四季沣禾农业科技有限公司

Template support system and construction method

InactiveCN106193592AReduce the erection heightLow costForms/shuttering/falseworksSupporting systemArchitectural engineering

The invention discloses a template support system and a construction method. The template support system comprises a plurality of pieces of profile steel and formwork supports. The two ends of each piece of profile steel are connected with floors where hole areas are located correspondingly. The profile steel is connected into a whole through a plurality of steel pipes. The formwork supports are connected to all the profile steel. According to the construction method, beam centerlines of to-be-poured beams are led out in the hole areas, the profile steel is laid on the beam centerlines corresponding to the hole areas and in the positions of outer combining plates on the two sides, the steel pipes are arranged continuously and ledger boards are full laid in the span direction of the profile steel, reinforcing devices are arranged, and the formwork supports are erected. According to the template support system, stress is more stable, the security coefficient is increased, the construction cost is reduced, and the construction progress is quickened. Through the construction method, the erected height of the formwork supports can be decreased, thus the safety is improved, the bearing capacity of the profile steel is improved, so that the support system is more stable, the construction progress is quickened, the construction intensity is relieved, the project cost is reduced, and demolition and material turnover are convenient.

Owner:CHENGDU NO 4 CONSTR ENG

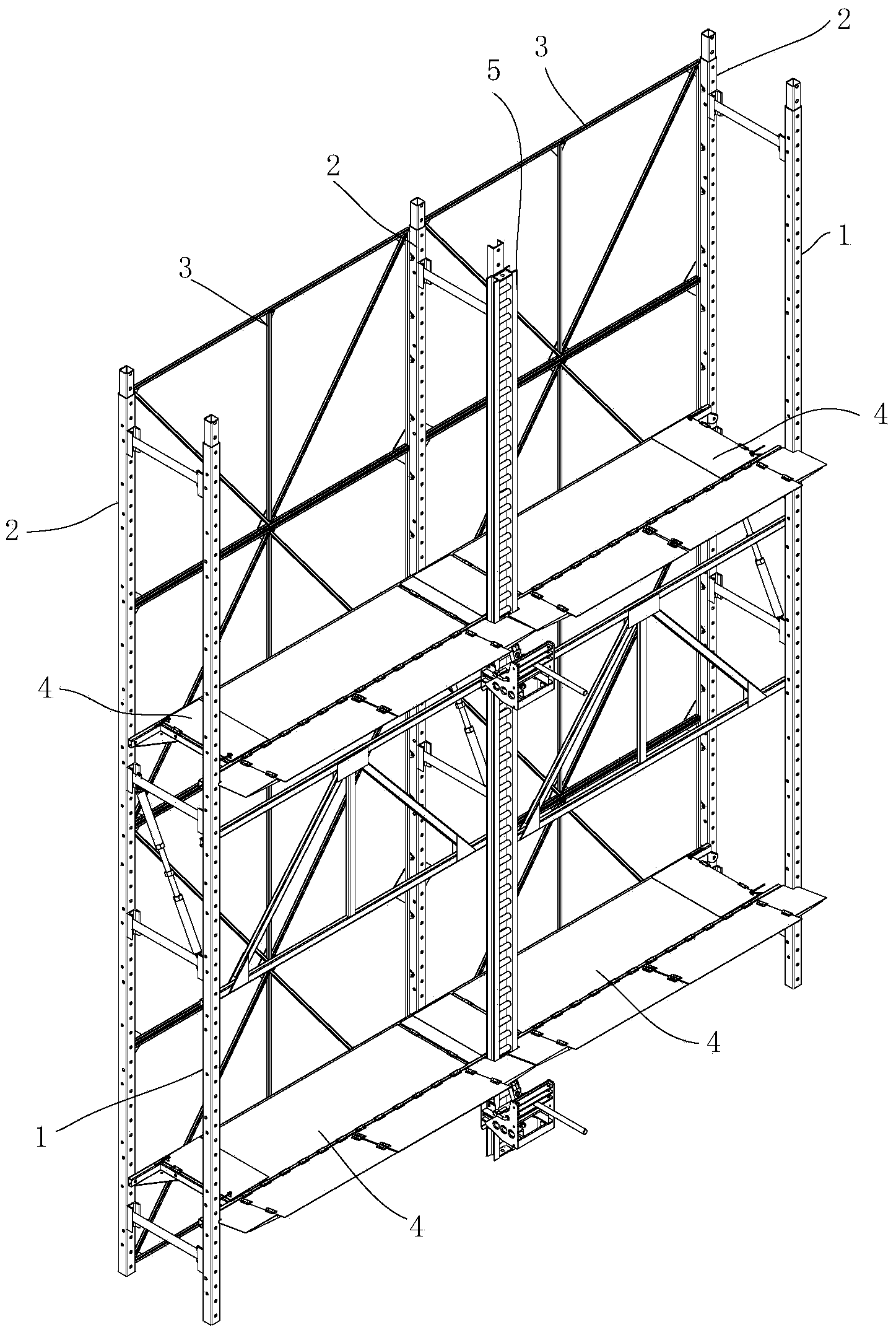

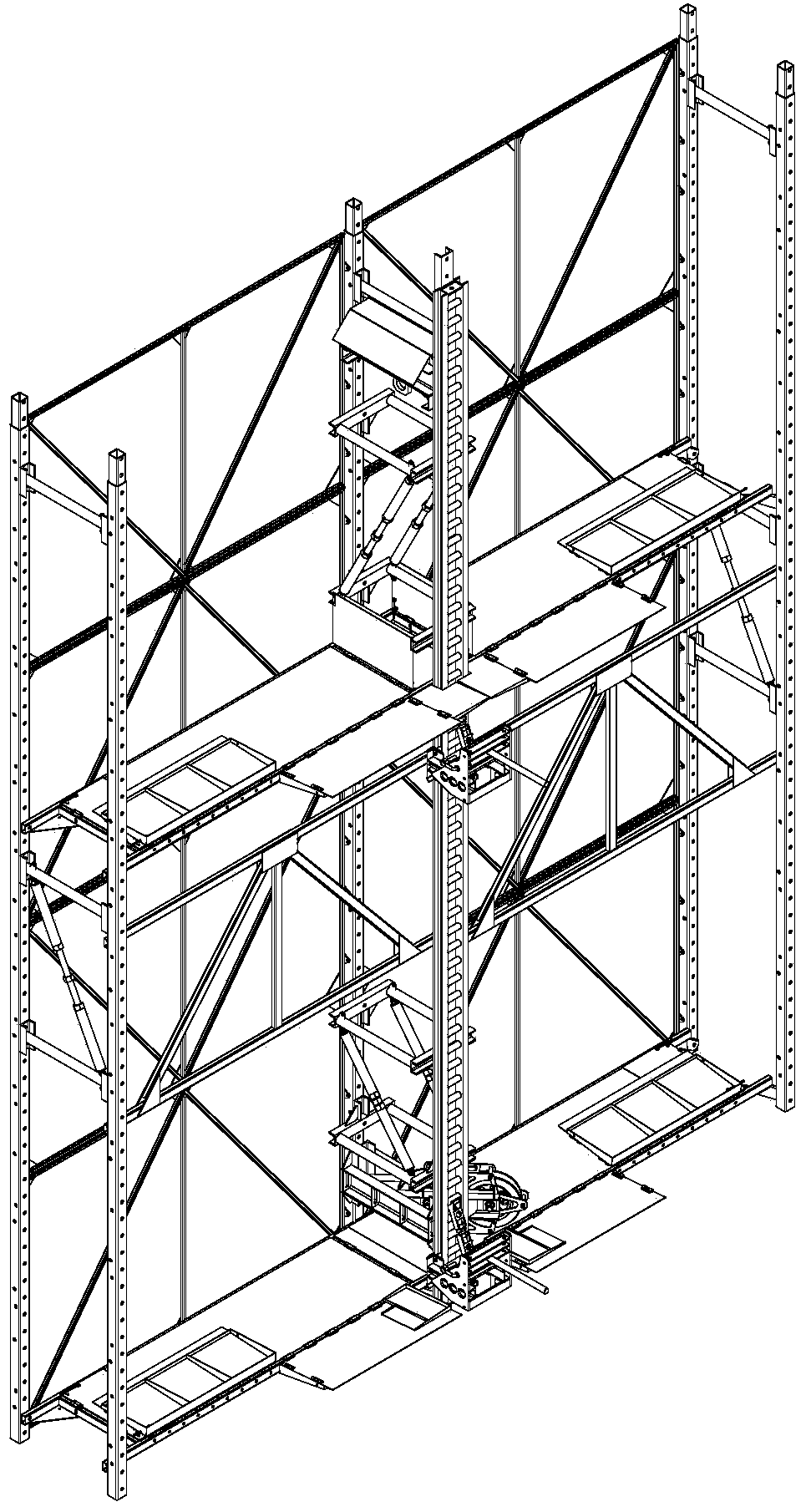

Construction platform module unit and construction platform thereof

ActiveCN103821339AFlexible assemblyEasy to disassembleScaffold accessoriesBuilding support scaffoldsModularityComputer module

The invention discloses a construction platform module unit and a construction platform thereof. The construction platform module unit comprises a module unit A, wherein the module unit A comprises inner row uprights, outer row uprights and a guide rail, wherein three outer row uprights are vertically arranged side by side at intervals; two inner row uprights and one guide rail are arranged, the guide rail is arranged between the two inner row uprights, and the inner row uprights and the guide rail are vertically arranged side by side at intervals; the two inner row uprights, the three outer row uprights and the guide rail form a square frame body; a platform bottom plate is arranged on the square frame body. According to the construction platform module unit and the construction platform thereof, the modularization degree is high, the assembly between modules is flexible, the detachment is convenient, the interchangeability is strong, the specifications and models of parts are fewer, and the processing is easy; the parts can be temporarily increased, reduced or adjusted and replaced according to needs, the interference among the parts is little, and the independence is strong.

Owner:JUSTREACH SCI & TECH CO LTD CHENGDU

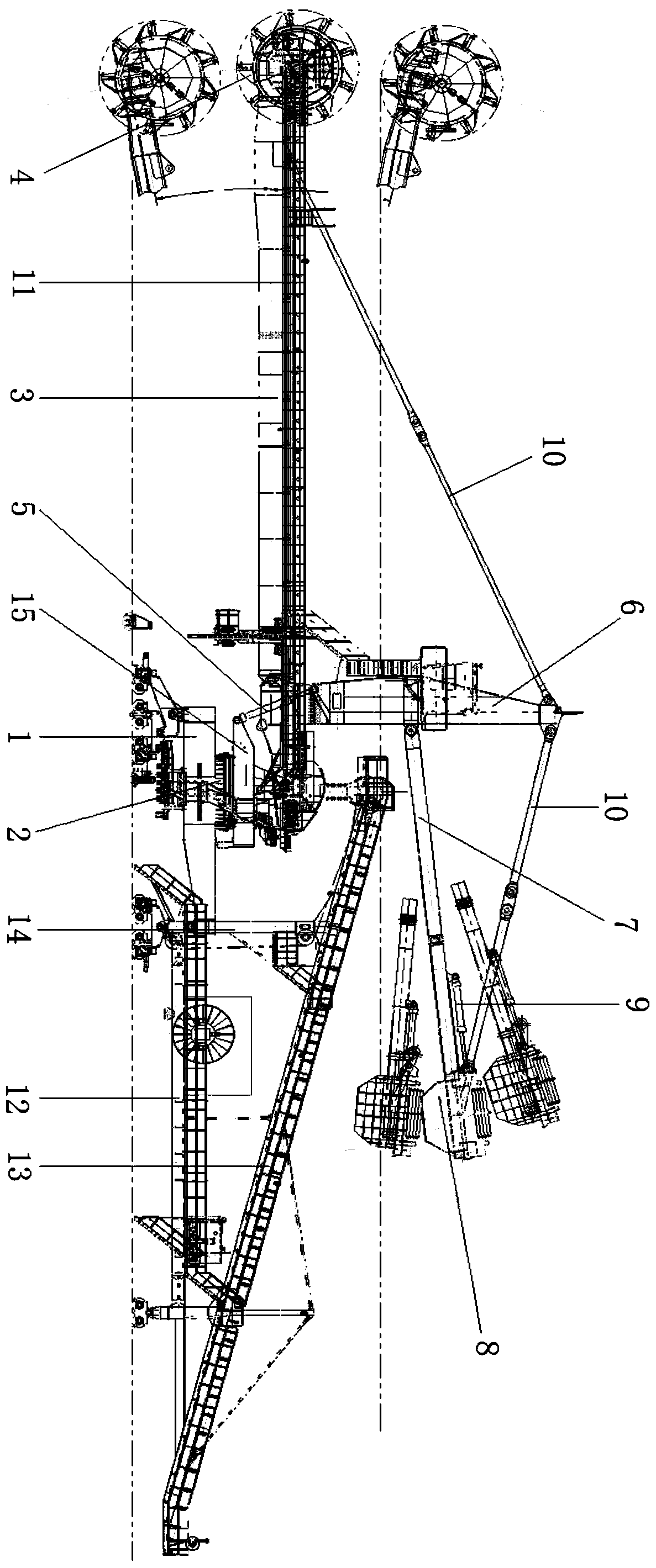

Stacker-reclaimer

The invention discloses a stacker-reclaimer. The stacker-reclaimer comprises a portal base, a slewing bearing, a rotary plate, an arm frame, a bucket wheel, a pitching oil cylinder and a portal column, and further comprises a counterweight frame, a counterweight block and a counterweight oil cylinder. The rotary plate is arranged on the portal seat, and the slewing bearing is connected with the rotary plate and the portal base to enable the rotary plate to rotate around a rotation center. One end of the arm frame is hinged to the rotary plate, the other end of the arm frame is connected with the bucket wheel, and the portal column is vertically connected to one end, close to the rotary plate, of the arm frame. One end of the pitching oil cylinder is hinged to the rotary plate, and the other end of the pitching oil cylinder is hinged to the portal column. One end of the counterweight frame is connected with the portal column. The counterweight oil cylinder and the counterweight block are arranged on the counterweight frame, and the counterweight block slides on the counterweight frame under the driving of the counterweight oil cylinder. According to the stacker-reclaimer, differentcounterweight moments can be obtained by changing a moment arm of the counterweight block, the gravity center of the upper structure can be controlled within a very small range near a hinge point of the arm frame according to balance requirements at different pitching angles, the load of the pitching oil cylinder and the slewing bearing can be reduced, and the safety performance can be improved.

Owner:TAIZHONG TIANJIN BINHAI HEAVY MACHINERY

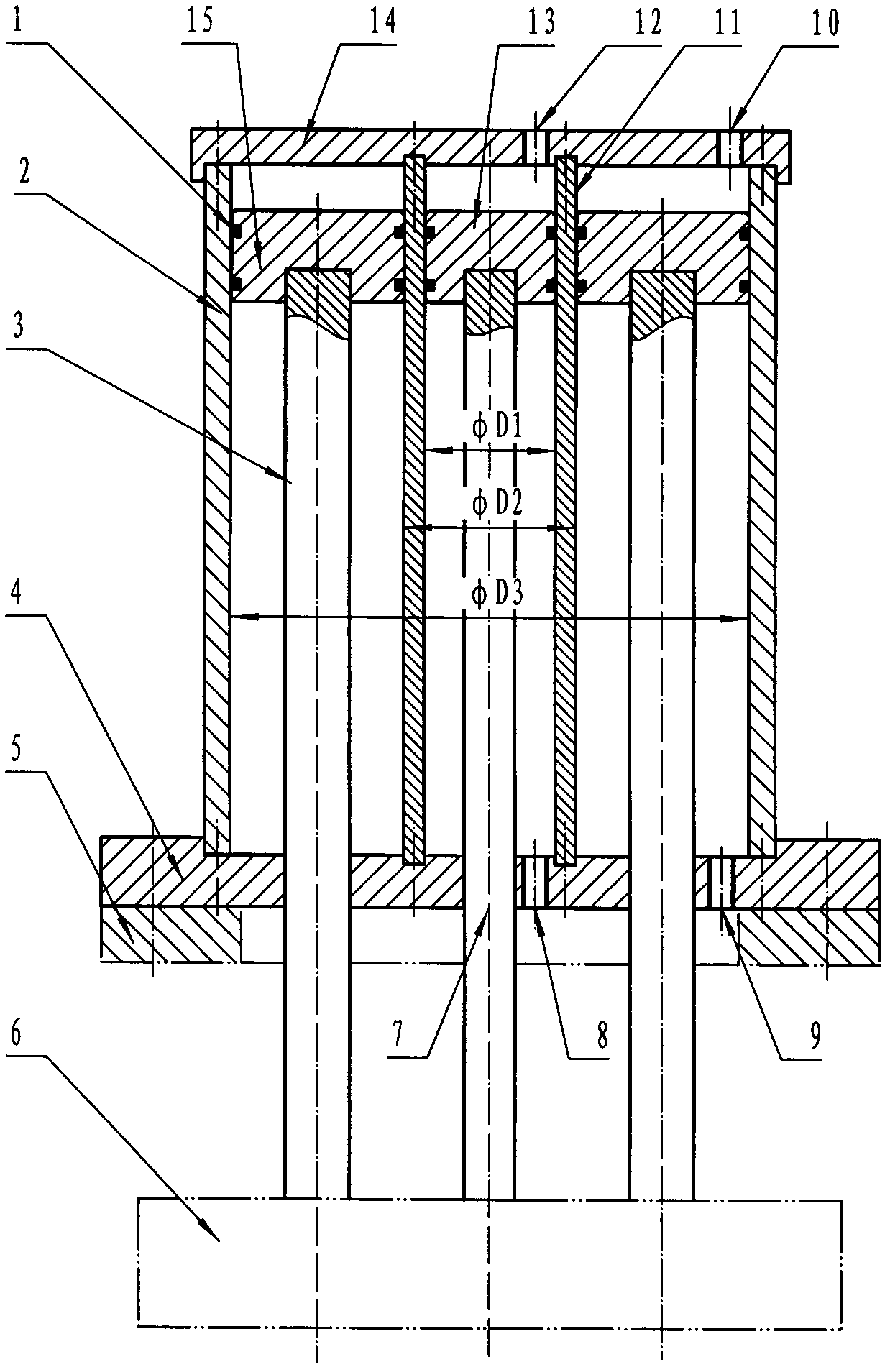

Combined energy-saving oil cylinder

The invention relates to a combined energy-saving oil cylinder. Two oil cylinders with different cylinder diameter and identical strokemm are combined into a whole to drive plastic molding mechanical moulds to realize mold clamping. In a rapid mold clamping stage, a hydraulic system only supplies pressure oil to a small oil cylinder, a big oil cylinder absorbs static oil without pressure from an auxiliary oil tank to fill liquid, and he big oil cylinder and the small oil cylinder act synchronously. In a high pressure mold closing stage, the hydraulic system supplies the pressure oil to the big oil cylinder and the small oil cylinder simultaneously through the switch of an electromagnetic reversing valve. Therefore, the combined energy-saving oil cylinder can increase mold clamping speed and provide an extremely large mold closing force only by a small hydraulic system. The oil cylinder motor power and an oil pump flow are reduced greatly; a hydraulic circuit board, hydraulic valves, oil cylinders, oil coolers and size of piplines are decreased at the same time; and the combined energy-saving oil cylinder is low in cost and energy conservation.

Owner:ZHANGJIAGANG BEIER MACHINERY

Bumper system for vehicle

ActiveUS10106112B2Low costReduced specificationsPedestrian/occupant safety arrangementElastic dampersLow speedMechanical engineering

The present invention relates to a bumper system for a vehicle, and provides a bumper system for a vehicle, the system comprising: a bumper beam which has a fastening hole formed through each end thereof in the forward and backward direction; a crash box which is inserted into the fastening hole of the bumper beam; and a bracket which is fastened to the bumper beam so as to be able to prevent the crash box from being separated. Thereby, the system can meet both low speed crash regulations and RCAR performance.

Owner:LOTTE CHEM CORP

Chain saw guide plate and chain saw with same

InactiveCN110712246AReduce wearReduced specificationsWorking accessoriesChain sawsMaterials preparationGear wheel

The invention aims to provide a chain saw guide plate which is good in universality and applicable to chains with different pitches and a chain saw with the chain saw guide plate. The chain saw guideplate comprises a plate-shaped body, wherein guide plate grooves are formed in two sides of the body. The chain saw guide plate is characterized in that a guide wheel is mounted at the head end of thebody through a rotating shaft, and a guide groove is formed in the outer edge of the guide wheel. According to the chain saw guide plate, the guide wheel with the guide groove is used for replacing atraditional guide chain wheel, a saw chain can be directly clamped in the guide groove of the guide wheel, and the guide wheel can be driven to rotate synchronously when the saw chain rotates, so that abrasion of the saw chain is reduced. More importantly, the guide wheel and the saw chain are matched through a sliding groove instead of a gear and a chain, so that the guide wheel can be matched with saw chains with different specifications, chain saws with different models can use the same chain saw guide plate, the specifications and the models of the chain saw guide plate can be reduced, and production and material preparation management are facilitated.

Owner:GUANGZHOU CRYSTAL TECH

A method for segmental hoisting and aerial assembly of heavy-duty tower equipment

ActiveCN106395628BReduced specificationsSave on rental costsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTower

The invention discloses a hoisting and overhead-assembling method for sections of heavy tower equipment, and belongs to the technical field of equipment manufacturing and mounting. The hoisting and over-head assembling method comprises the following steps of: mounting supporting tools on the peripheral wall, close to an assembling and welding position, of a lower section of a tower, and welding guide posts on each tool; mounting guide rings on positions, above an assembling welding seam, of a to-be-hoisted tower section, uniformly distributing the guide rings on the peripheral wall, close to the assembling and welding position, of the lower section of the tower so as to correspond to the guide posts on the lower section of the tower, hoisting the upper section of the tower to the upper part of the lower section of the tower, pulling, regulating and controlling the direction of the upper section of the tower through a hemp rope which is tied and suspended in advance, dropping a lifting hook, nesting guide rings mounted on the lower part of the upper section of the tower into the guide posts mounted on the upper part of the lower section of the tower, and guiding the upper tower section and the lower tower section to quickly and precisely align. The invention designs a brand-new hoisting and perpendicularly assembling method for sections of heavy tower equipment. With the adoption of the technical scheme, assembling for the upper section and the lower section can be completed more safely, quickly and precisely.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

An intermittent round iron sheet trimming machine

ActiveCN112247249BRealize trimmingReduced specificationsShearing machinesFeeding apparatusElectric machineStructural engineering

Owner:杭州戴乐搪瓷有限公司

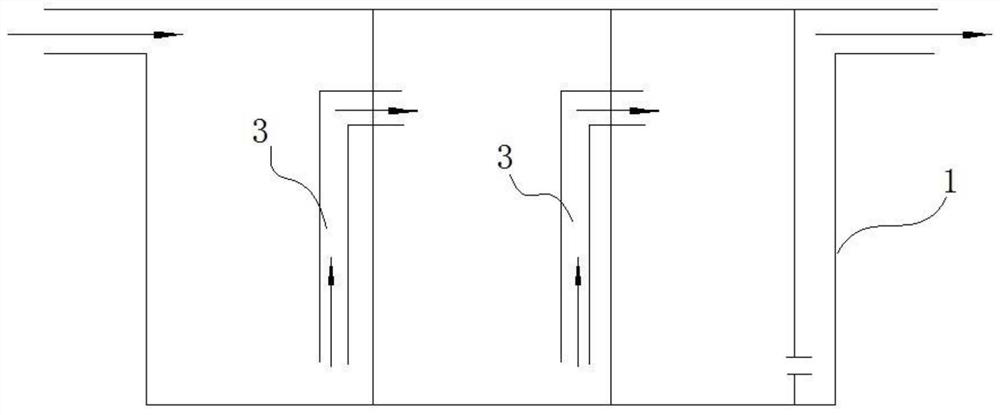

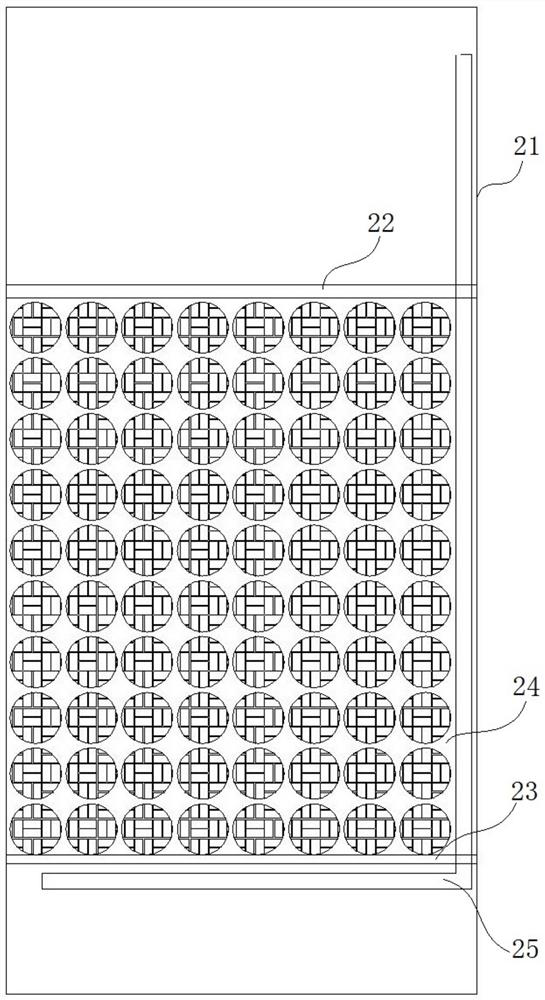

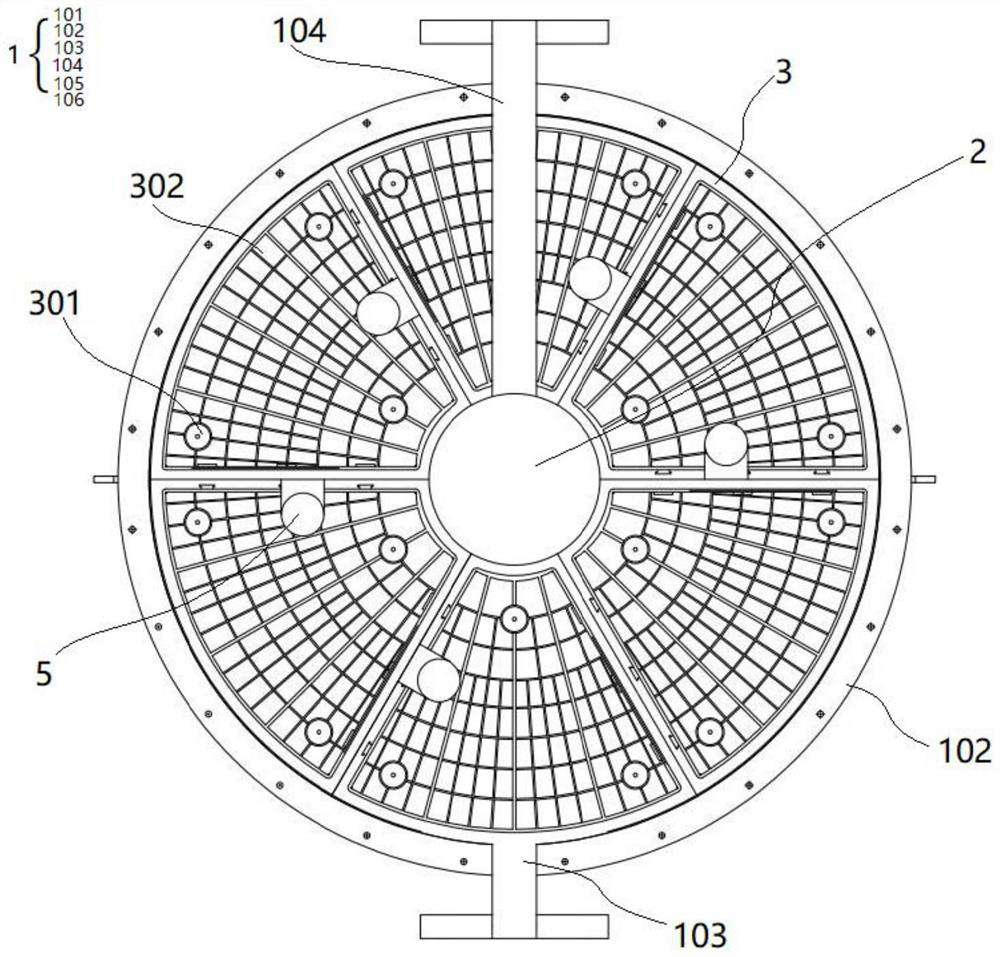

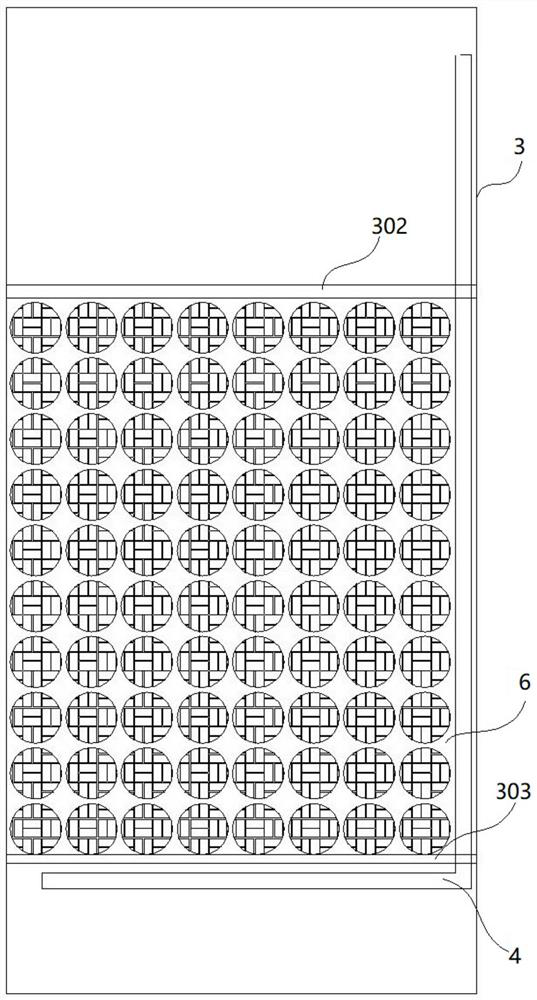

Sewage treatment device

PendingCN112759202AEasy to handleReduce processWater treatment parameter controlWater contaminantsMicroorganismFood chain

The invention relates to the technical field of sewage treatment, and discloses a sewage treatment device, which comprises a tank body and a plurality of division barrels arranged in the tank body, wherein a water inlet and a water outlet are formed in the upper part of the tank body; each grid barrel comprises a barrel body, an upper fixed grid and a lower fixed grid, the upper fixed grid and the lower fixed grid are vertically arranged in the barrel body at an interval, a filler layer is arranged between the upper fixed grid and the lower fixed grid, and an aeration pipe is arranged below the lower fixed grid; and the plurality of division barrels are sequentially communicated through a water guide pipe, the first end of the water guide pipe is located at the bottom of one division barrel, and the second end of the water guide pipe is located at the top of the adjacent division barrel. According to the sewage treatment device disclosed by the embodiment of the invention, the sewage is treated in sequence by arranging the plurality of lattice buckets in the tank body, and microorganisms in the sewage can be trained to form a hierarchical food chain relationship, so that the sewage can be discharged up to the standard without staying for maintenance and operation and unattended operation.

Owner:GUANGZHOU RESOURCE ENVIRONMENTAL PROTECTION TECH CO LTD +1

An in-place guide device for segmental hoisting and aerial assembly of heavy-duty tower equipment

The invention discloses an in-place guiding device for segmented hoisting and air pairing of heavy tower equipment and belongs to the technical field of equipment manufacturing and installation. According to the in-place guiding device, supporting tools are installed on the peripheral wall of the portion, close to a paired welding position, of a lower section of a tower, and guide columns are welded to the tools; guiding rings are installed on the portion, located above a paired weld joint, of the tower section to be hoisted; the guiding rings are uniformly distributed on the peripheral wall of the portion, close to the welding position, of an upper section of the tower and correspond to the guiding columns of the lower section of the tower; and the upper section of the tower is hoisted to the position above the lower section of the tower, the position of the upper section of the tower is adjusted and controlled by drawing hemp ropes tied in advance, the guiding columns installed on the upper portion of the lower section of the tower are sleeved with the guiding rings installed on the lower portion of the upper section of the tower by descending hoisting rings, and the upper section and the lower section of the tower are guided to be aligned rapidly and accurately. A brand-new method for segmented hoisting and vertical pairing of the heavy tower equipment is designed. By the adoption of the technical scheme, pairing of the upper section and the lower section of the equipment can be completed more safely, rapidly and accurately.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

Distributed sewage equipment assembling method

InactiveCN112919621AEmission complianceReduce processBiological treatment apparatusSustainable biological treatmentSewageSewage treatment

The invention relates to the technical field of sewage treatment, and particularly discloses a distributed sewage equipment assembling method, and distributed sewage equipment comprises a tank body, a water outlet cylinder and grid cylinders; the water outlet cylinder is arranged in the middle of the tank body; the plurality ofgrid cylinders are spliced and mounted between the water outlet cylinder and the tank body; thegrid cylinder comprises supporting legs, an upper grid, a lower grid and a cylinder body, the supporting legs are installed in the cylinder body, and the upper grid and the lower grid are installed on the supporting legs in parallel at intervals; a packing layer, an aeration pipe and a water guide pipe are respectively arranged on each grid cylinder; the packing layer is arranged between the upper grid and the lower grid; one end of the aeration pipe is arranged at the bottom of the grid cylinder; and one end of the water guide pipe is arranged at the bottom of the latticed cylinder, and the other end of the water guide pipe is arranged at the top of the adjacent latticed cylinder. The modular assembly mode is adopted, various requirements can be met, the production efficiency can be improved, and meanwhile follow-up replacement and maintenance are facilitated.

Owner:GUANGZHOU RESOURCE ENVIRONMENTAL PROTECTION TECH CO LTD +1

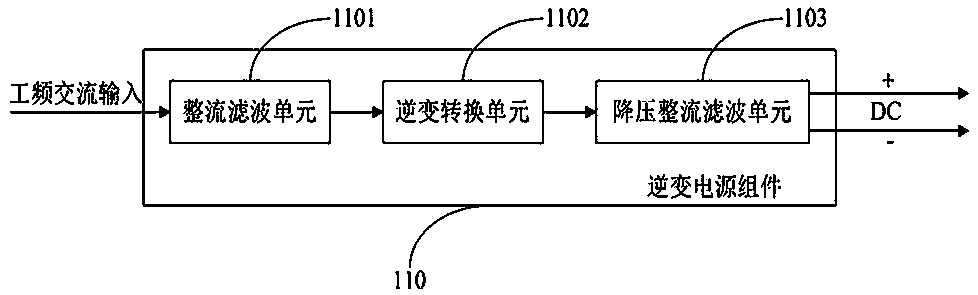

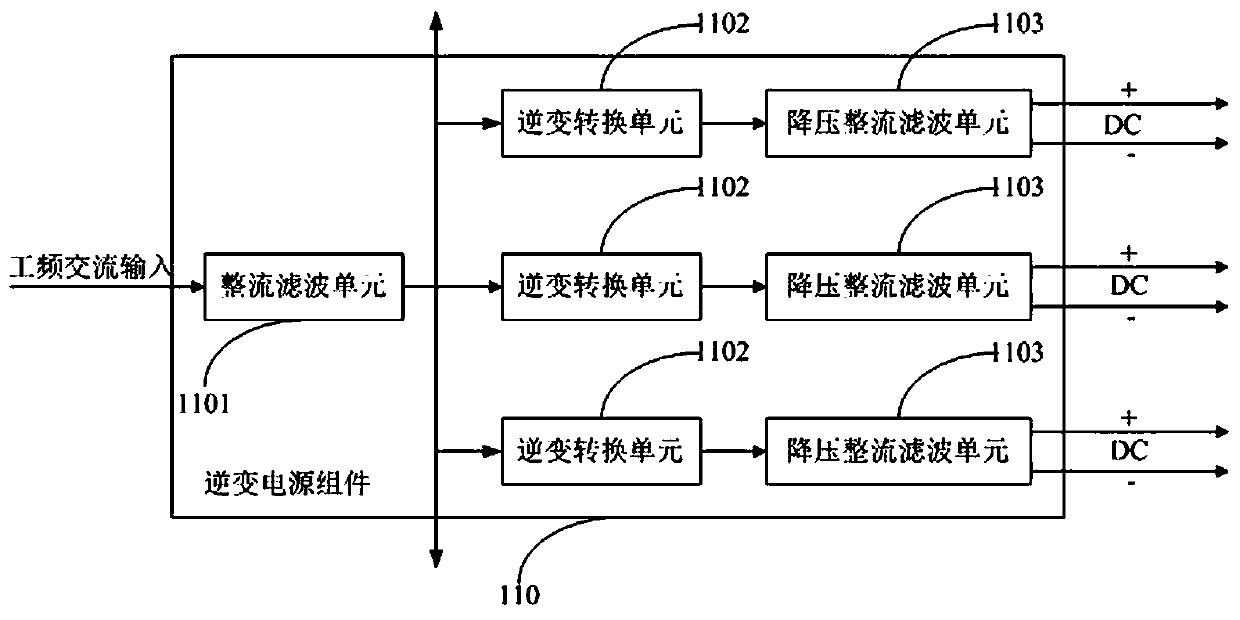

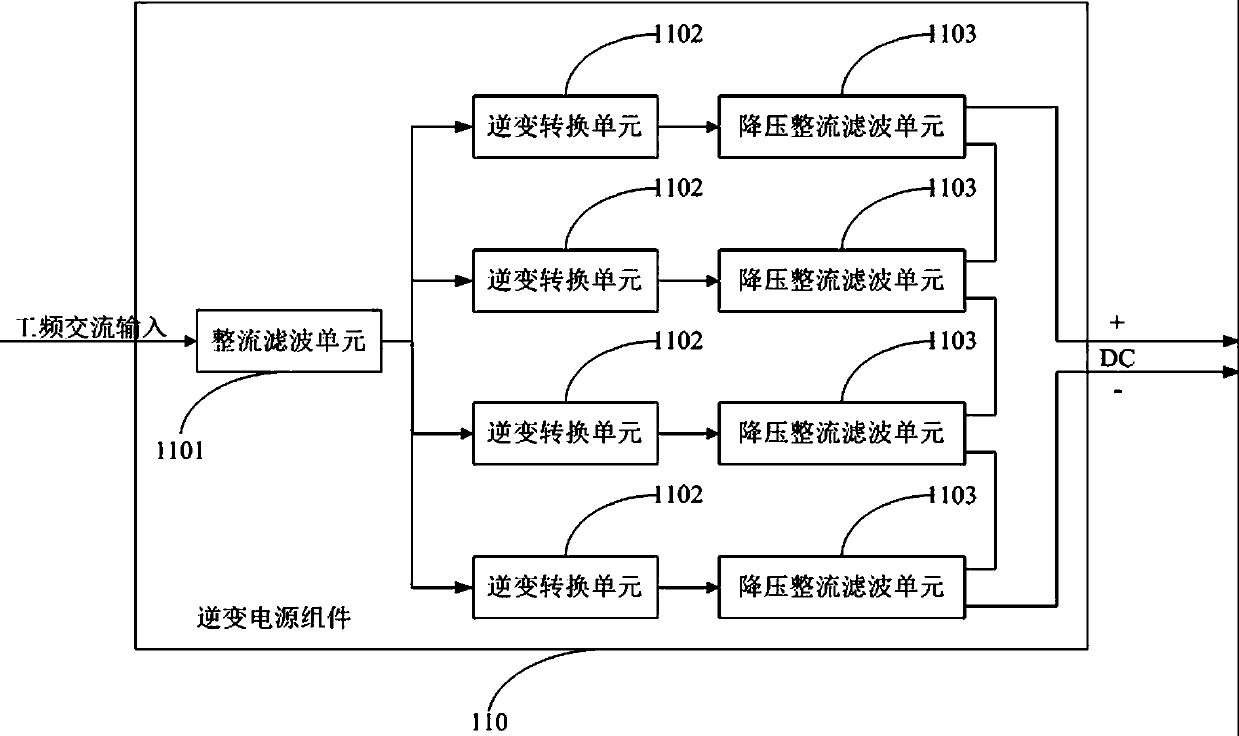

Inverter power supply assembly, welding and cutting power output device and welding and cutting equipment

PendingCN110401358AReduce manufacturing costImprove product qualityAc-dc conversion without reversalConversion with intermediate conversion to dcAC powerUtilization rate

The invention discloses an inverter power supply assembly, a welding and cutting power output device and welding and cutting equipment. The inverter power supply assembly comprises a rectifying and filtering unit for performing rectifying and filtering on inputted power frequency AC power, at least one inverter conversion unit for performing inverter conversion on the power completing rectifying and filtering, at least one step-down rectifying and filtering unit for performing step-down rectifying and filtering on the power completing inverter conversion and a DC power output unit for outputting the DC power completing step-down rectifying and filtering, wherein the DC power output unit comprises a forward DC power output end and a negative DC power output end. Combined online operation can be carried out, the versatility of the equipment is enhanced, and the utilization rate of the equipment is improved.

Owner:马春辉

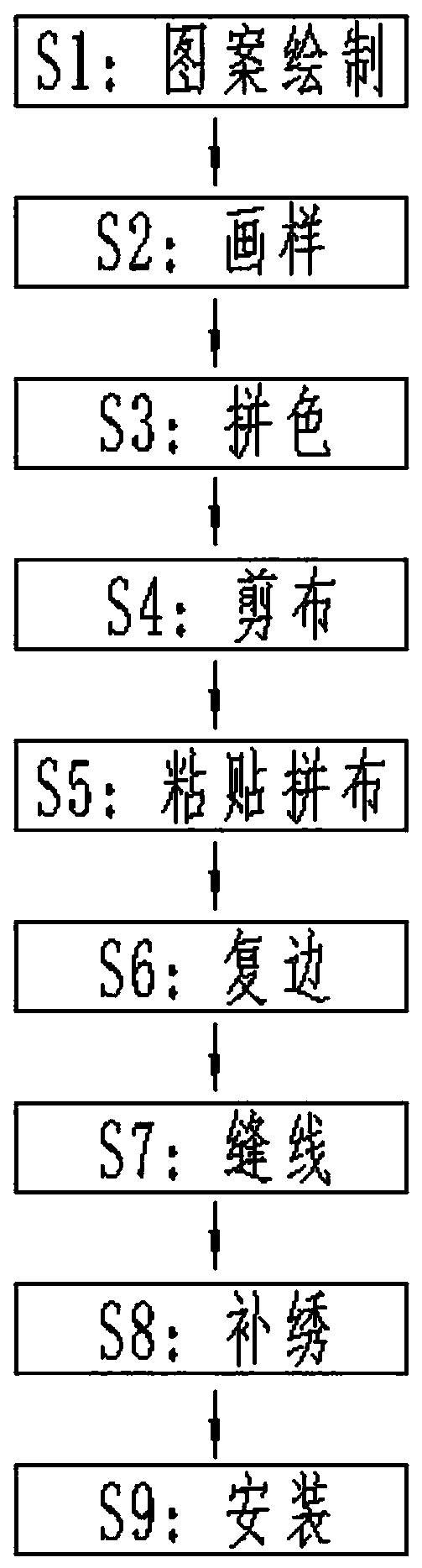

Manufacturing process of cloth patch

InactiveCN110158249AEasy to installImprove installation efficiencyEmbroidering machines apparatusCardboardEngineering

The invention provides a manufacturing process of a cloth patch. The manufacturing process includes the steps of S1, pattern drawing, to be specific, using a computer to design a pattern which is thecomponent of the cloth patches, and printing the pattern; S2, sample drawing, to be specific, placing a transparent thin plastic sheet on the pattern, drawing all the contours of the pattern on the plastic sheet one by one, and printing the contours drawn on the thin plastic sheet onto a white paper board to form a plurality of independent pattern contours, namely 'liners', on the white paper board; S3, color adhering, to be specific, adhering cloth of different colors to the 'liners'; S4, cutting, to be specific, cutting off the cloth adhered to the 'liners' along the pattern contours of the'liners' to form a plurality of cloth patch components; S5, adhering the cloth patch components together on single-color base cloth according to the pattern in S1; S6, internally folding the edges ofthe cloth on the cloth patch components; S7, sewing the folded edges; S8, performing supplementary embroidery; S9, directly mounting the manufactured cloth patch into a mounting frame or onto a scrollor adhering the cloth patch to garments. The manufacturing process is good in cloth patch production and processing quality, and the manufactured cloth patch is convenient to mount.

Owner:湖北鸿运工艺品股份有限公司

Efficient plate cutting machine for construction site

PendingCN112719400AEfficient cuttingImprove cutting efficiencyShearing machinesShearing machine accessoriesBraced frameElectric machinery

The invention provides an efficient plate cutting machine for a construction site. The efficient plate cutting machine for the construction site comprises two supporting platforms of the cutting machine, a supporting rod is fixedly connected between the two supporting platforms, a double-shaft motor is fixedly connected to the upper end of the supporting rod, and guide sleeves are fixedly connected to the upper ends of the two supporting platforms correspondingly, a supporting frame is arranged between the two supporting platforms, guide rods penetrating through the two guide sleeves are fixedly connected to the two sides of the supporting frame correspondingly, a reciprocating mechanism capable of enabling the supporting frame to move in a reciprocating mode is arranged in the supporting frame in a matched mode, a differential box is arranged on one side of the supporting frame, a cutting shaft is rotationally connected to the side wall of the differential box, a cutting disc is fixedly connected to the tail end of the cutting shaft, and a cutting mechanism capable of enabling the cutting disc to conduct efficient cutting is arranged in the differential box. The efficient plate cutting machine for the construction site has the advantages that semi-automatic rapid and effective cutting can be conducted on plates, and the cutting efficiency is greatly improved.

Owner:郑婵和

Heat-resistant structures for kiln cars in tunnel kilns

The invention discloses a heat-resistant structure for a tunnel kiln car, and relates to a kiln car heat-resistant structure. The heat-resistant structure comprises a convex coaming plate, a concave coaming plate, side coaming plates, front coaming plates and back coaming plates; the convex coaming plate and the side coaming plates are connected through coaming plate channel steel, the concave coaming plate and the side coaming plates are connected through coaming plate channel steel, and the coaming plate channel steel is fixed to a frame of the kiln car; a convex coaming plate convex plate is arranged at the upper end of the face, far away from the kiln car, of the convex coaming plate, and a concave coaming plate convex plate is arranged at the upper end of the face, close to the kiln car, of the concave coaming plate; side coaming plate convex plates are arranged at the upper ends of the faces, far away from the kiln car, of the side coaming plate; front coaming plate convex platesare arranged at the upper ends of the faces, far away from the kiln car, of the front coaming plates, and back coaming plate convex plates are arranged at the lower ends of the faces, far away from the kiln car, of the back coaming plates; and heat-resistant cotton, earth and red bricks are sequentially laid on the upper surface of the kiln car from bottom to top. According to the heat-resistantstructure for the tunnel kiln car, the service life of the kiln car is significantly prolonged, the manufacture cost and the maintenance cost of the kiln car are significantly reduced, refractory bricks are replaced with the earth and the red bricks, and almost no maintenance cost is generated.

Owner:武汉四海大通自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com