Intermittent circular iron sheet edge trimmer

An edge trimmer, intermittent technology, used in shearing devices, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as inaccuracy, easy movement of iron sheets, etc., to reduce the possibility of injury, collect buckets The effect of clean interior and standard trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

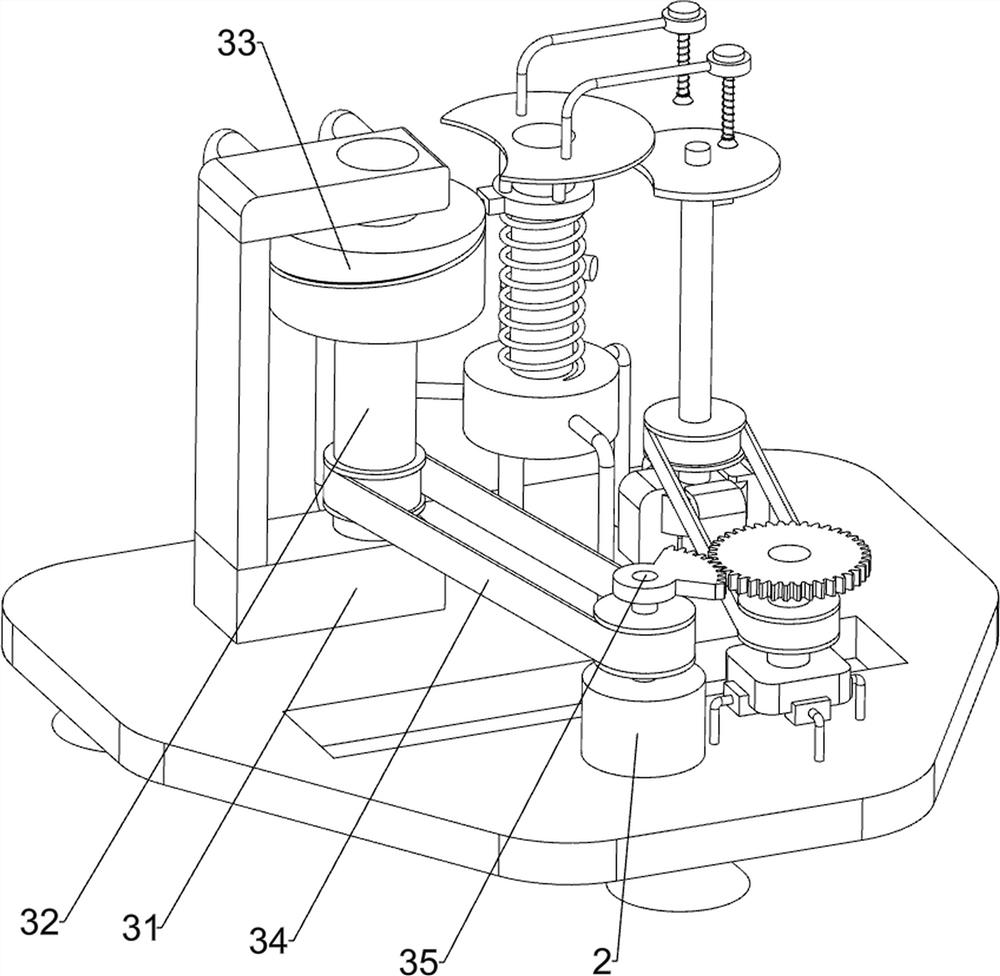

[0027] An intermittent circular iron sheet trimming machine, such as figure 1 Shown, comprise frame 1, motor 2, transmission device 3, press down device 4 and intermittent rotation device 5, motor 2 is installed on the front side on frame 1, and transmission device 3 is provided on the left side on frame 1, machine The right side of the frame 1 is provided with an intermittent rotating device 5, and the center of the frame 1 is provided with a pressing device 4.

[0028] First place the iron sheet that needs to be trimmed on the intermittent rotating device 5, and then turn on the motor 2. The rotation of the output shaft of the motor 2 will drive the operation of the transmission device 3 and the intermittent rotating device 5, thereby driving the operation of the pressing device 4. Realize the edge trimming of the circular iron sheet. After the edge trimming is completed, turn off the motor 2, and the output shaft of the motor 2 will stop the rotation and the transmission de...

Embodiment 2

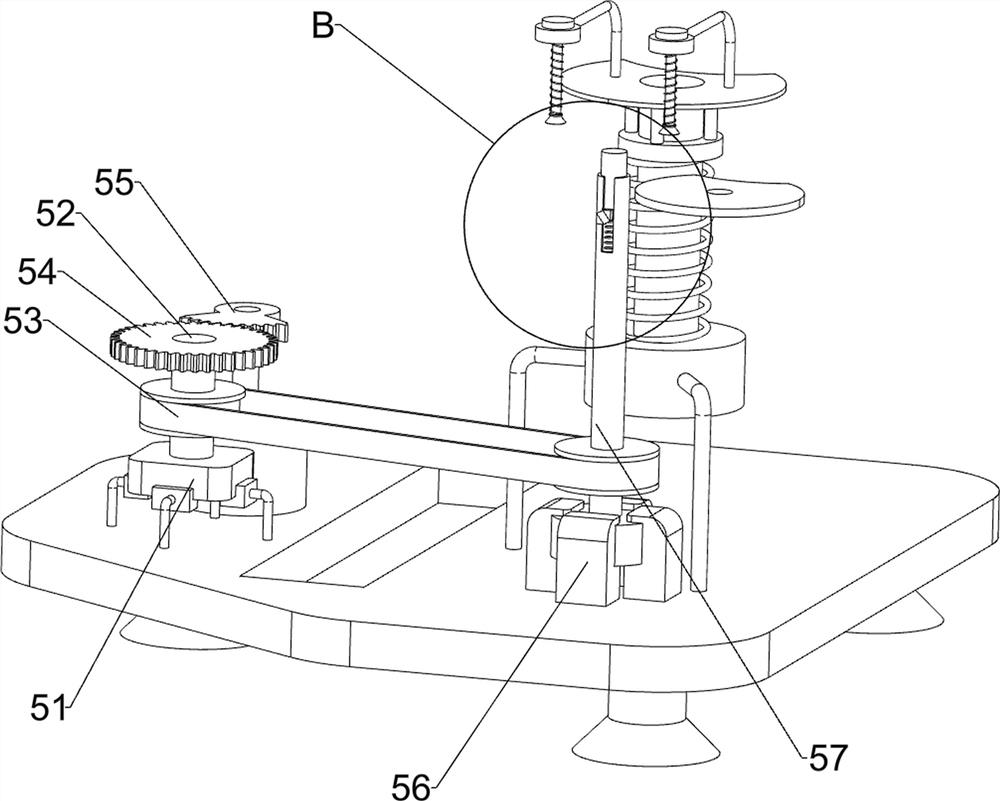

[0030] On the basis of Example 1, such as Figure 2 to Figure 6 As shown, the transmission device 3 includes a first support frame 31, a first rotating shaft 32, a sheave 33, a first belt 34 and a second rotating shaft 35, and the output shaft of the motor 2 is provided with the second rotating shaft 35, and on the frame 1 The rear side of the left part is provided with a first support frame 31, on which the first support frame 31 is rotatably provided with a first rotating shaft 32, and a first belt 34 is wound between the first rotating shaft 32 and the second rotating shaft 35, on the first rotating shaft 32 A sheave 33 is provided.

[0031] When the output shaft of the motor 2 rotates, it will drive the rotation of the second rotating shaft 35, and then the first belt 34 will drive the rotation of the first rotating shaft 32, thereby driving the rotation of the sheave 33. Reciprocating in this way can drive the pressing device 4 The repeated movement of the pressing devic...

Embodiment 3

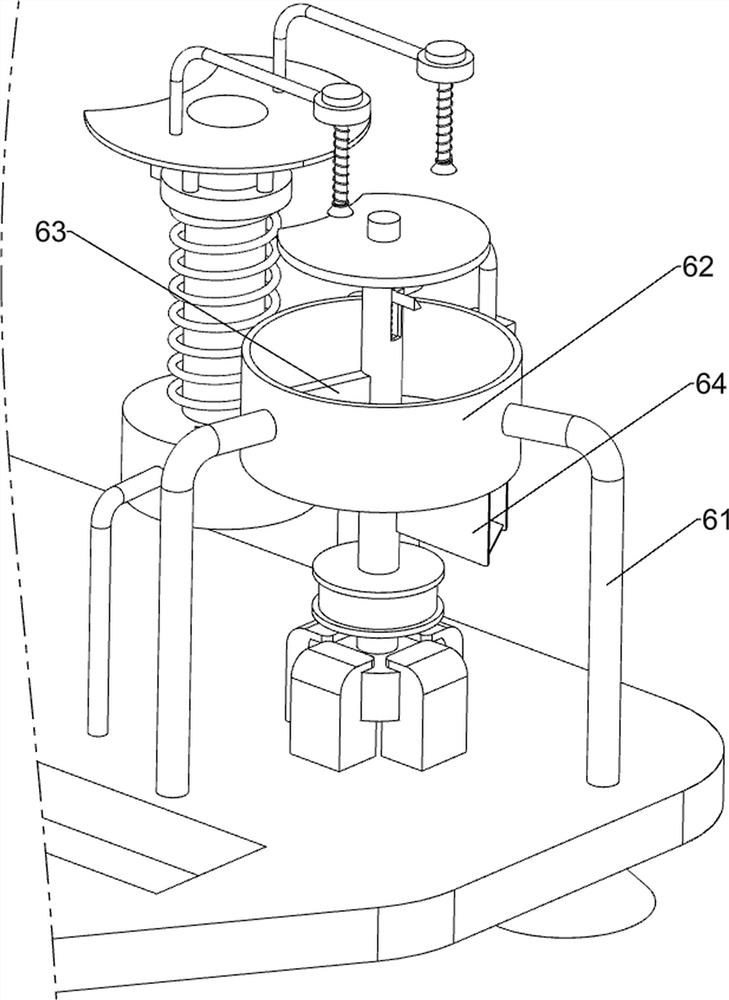

[0037] On the basis of Example 2, such as figure 1 , Figure 7 , Figure 8 As shown, a waste collection device 6 is also included. The right side of the upper rear portion of the frame 1 is provided with a waste collection device 6. The waste collection device 6 includes a second connecting rod 61, a collection bucket 62, a cleaning plate 63, a fixed block 65, The third connecting rod 66 and the wedge block 67, three second connecting rods 61 are arranged on the right side of the upper rear part of the frame 1, and a collection bucket 62 is arranged between the second connecting rod 61 tops, and a cleaning plate is provided on the fourth rotating shaft 57 63, the cleaning plate 63 is in sliding contact with the collection barrel 62, the bottom of the collection barrel 62 is provided with a chute 64, the rear side of the collection barrel 62 is provided with a fixed block 65, the fixed block 65 is provided with a third connecting rod 66, and the third connecting rod 66 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com