Ultra-precise efficient polishing device and method suitable for large-size KDP crystals

A polishing device and ultra-precise technology, applied in grinding drive devices, grinding/polishing equipment, machine tools for surface polishing, etc., can solve the problem of difficult to achieve high-quality processing of large-sized KDP crystals, easy residual oily polishing liquid, and polishing liquid. Concentration imbalance and other problems, to achieve the effect of being conducive to gravity balance, avoiding gravity aggregation, and avoiding displacement interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

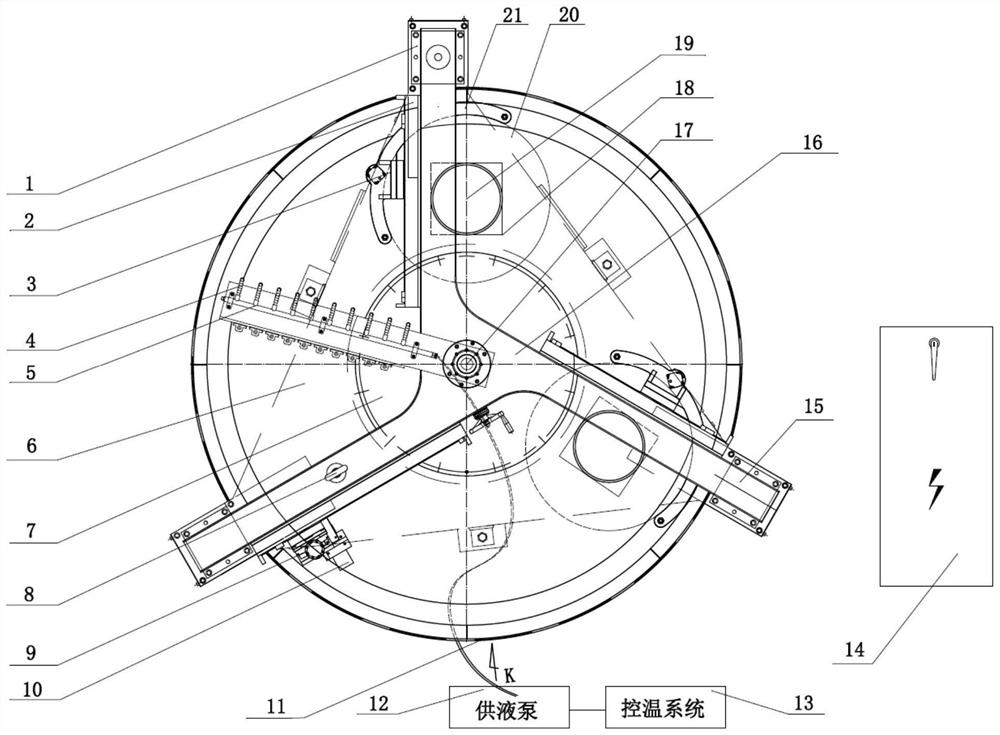

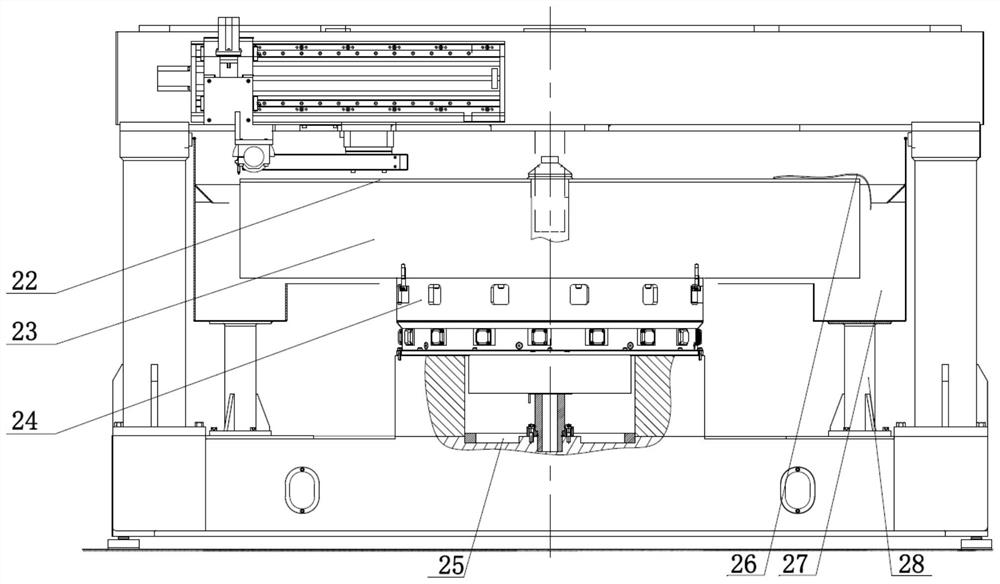

[0053] The specific implementation manners of the present invention will be described in detail below in combination with technical solutions and accompanying drawings. Such as figure 1 As shown, in order to achieve the above object, the technical solution adopted by the present invention is: a kind of ultra-precision high-efficiency polishing device suitable for large-size KDP crystals, including a support unit 1, a precision horizontal motion slide table 2, a workpiece polishing clamping unit 3, multiple Point concentration continuously adjustable polishing liquid supply unit 5, base 6, precision rotary table 7, polishing pad dressing unit 9, on-line measurement unit 10, continuous polishing residual liquid absorption and recovery unit 11 and equipment control system unit 14;

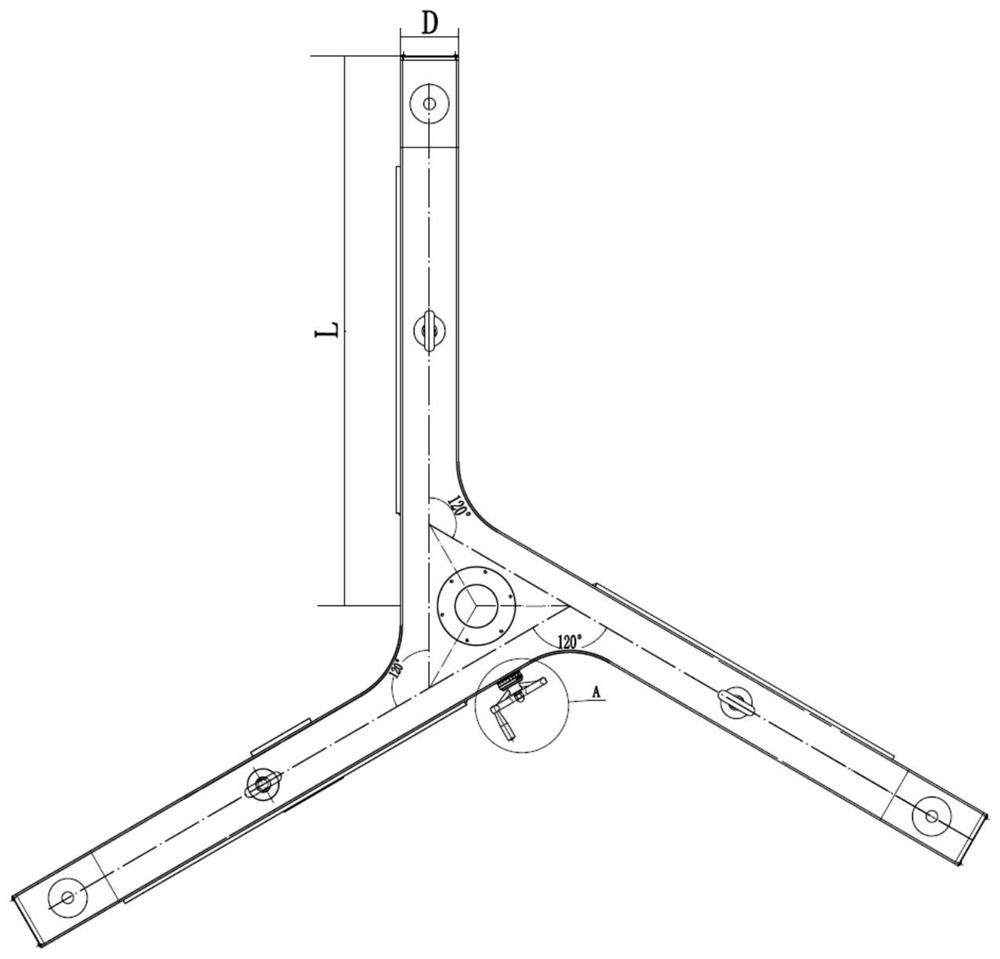

[0054] The support unit 1 includes three column supports 15, a Y-shaped beam 16 and a central auxiliary support 17. The lower ends of the three column supports 15 are respectively connected to the bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com