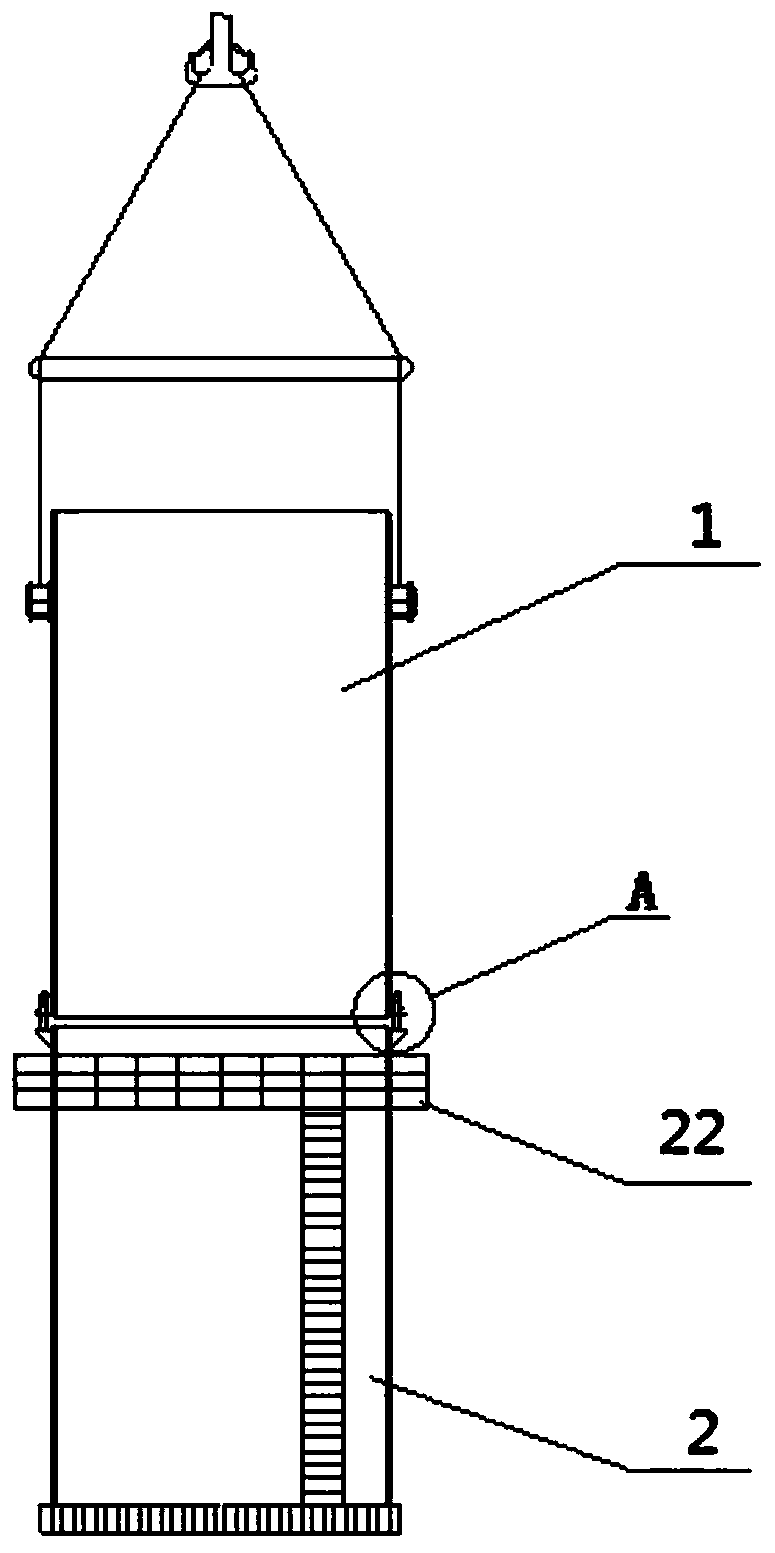

A method for segmental hoisting and aerial assembly of heavy-duty tower equipment

A segmented hoisting and aerial assembly technology, which is applied to welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of difficult assembly accuracy, high labor intensity, and many construction workers, so as to achieve fewer operators, The effect of low labor intensity and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

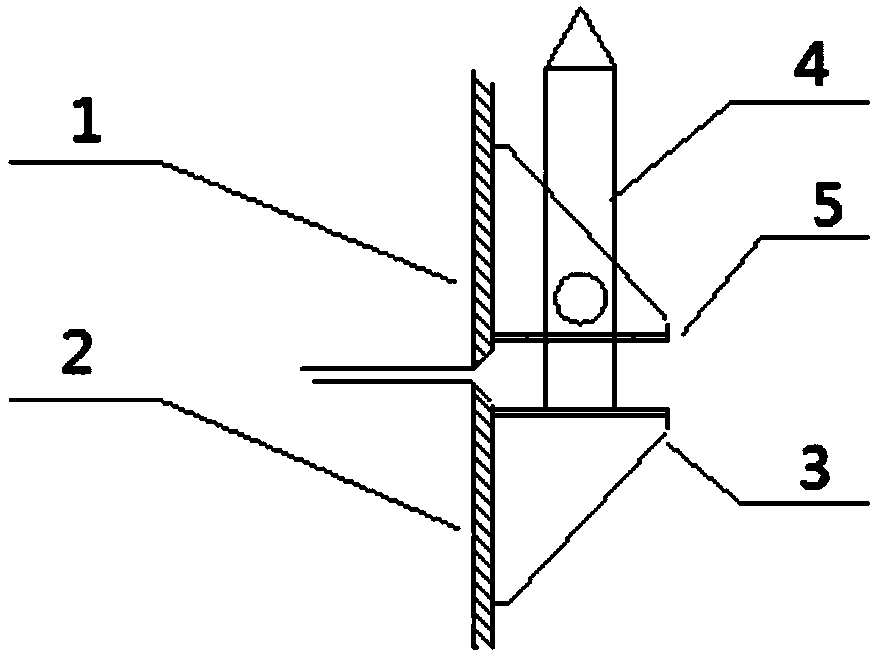

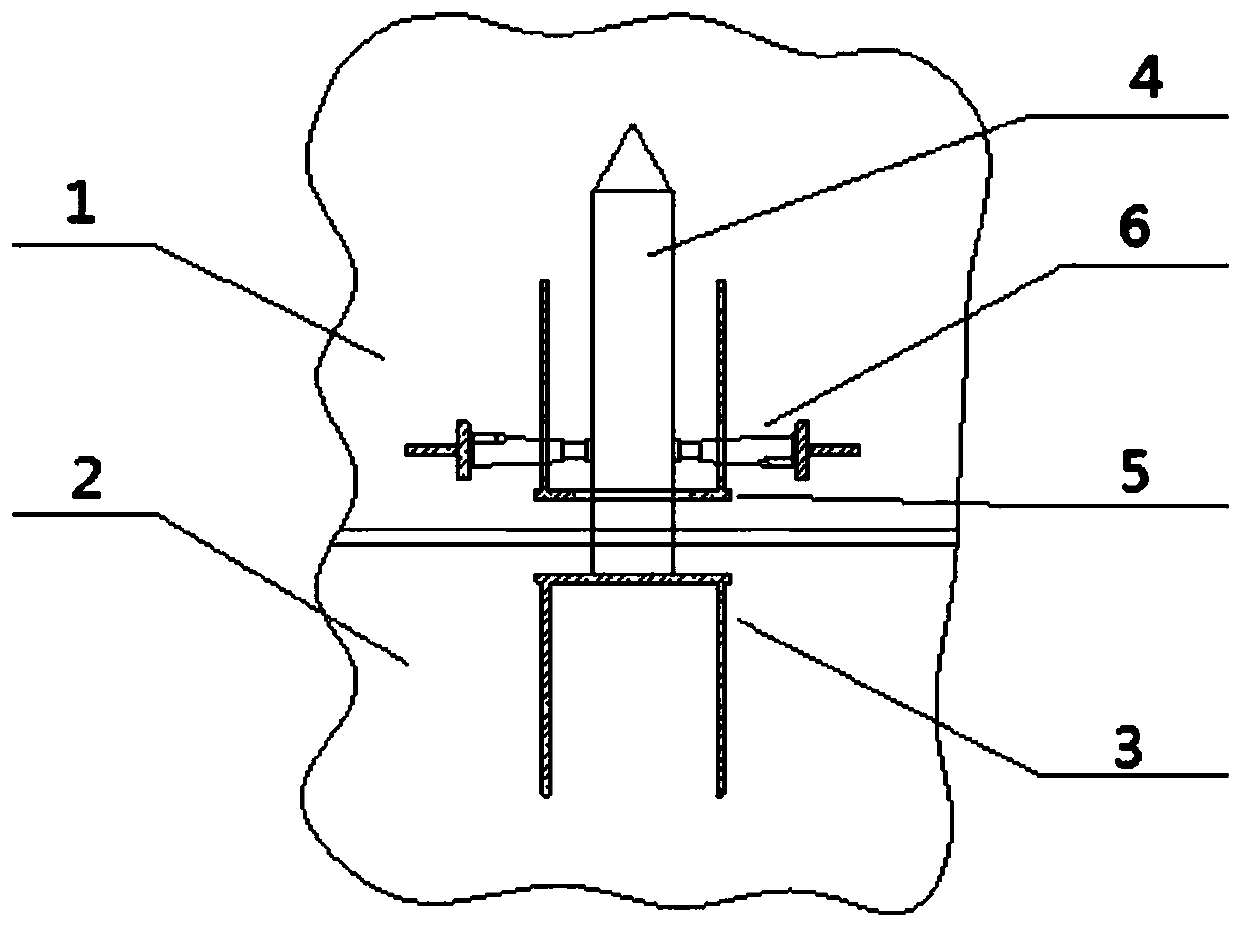

Method used

Image

Examples

Embodiment 1

[0043] The propylene propane separation tower in a propane dehydrogenation project undertaken by our company has a diameter of 9.7 meters, a height of 108 meters, and a shell weight of 960 tons. This technical scheme is adopted on site. The equipment is transported into the site in four sections, and the aerial assembly is hoisted in sections For welding, complete the installation of this heavy equipment safely and with high quality.

[0044] Technical scheme of the present invention, its concrete construction steps are:

[0045] 1) Construction road construction, foundation hardening treatment at the crane station, main crane 1250t crawler crane and auxiliary crane 400t crawler crane to

[0046] field, and assembled according to the working conditions required by the hoisting scheme.

[0047] 2) The first segment with the longest segment length and the heaviest weight is transported into the site horizontally.

[0048] 3) Lift and unload the truck jointly by the main and au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com