Manufacturing process of cloth patch

A production process and cloth sticker technology, which is applied in the field of cloth sticker production technology, can solve problems such as affecting the aesthetics of cloth stickers, difficulty in installing cloth stickers, and poor pattern standardization, so as to improve installation efficiency and quality, and facilitate installation , The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

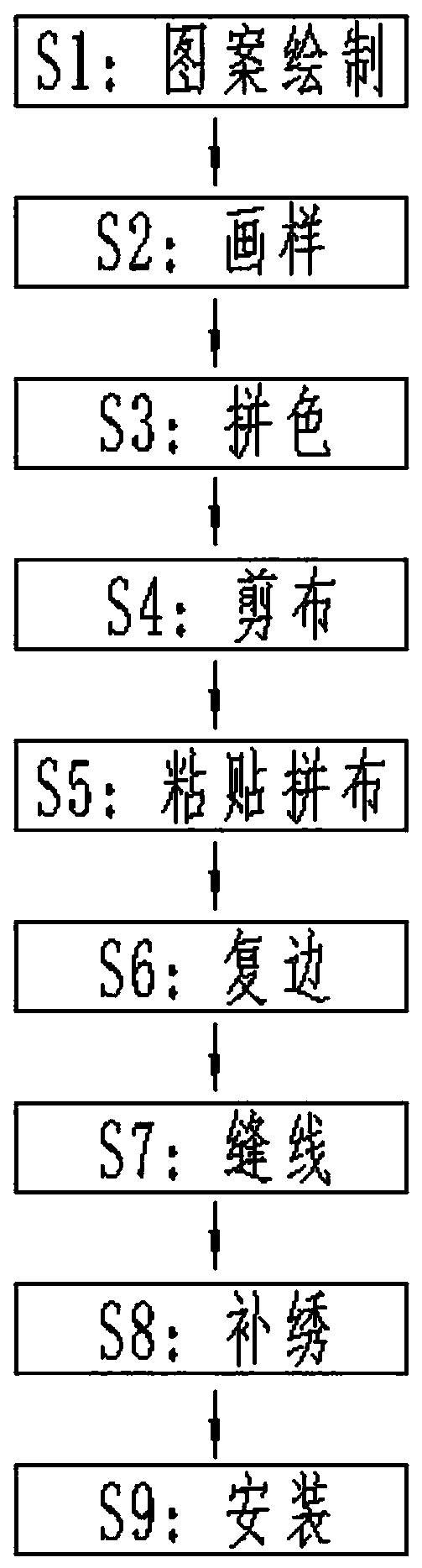

[0025] Please refer to figure 1 ,in, figure 1 It is a process flow chart of a preferred embodiment of the fabric patch manufacturing process provided by the present invention. The production process of cloth stickers includes:

[0026] S1: Pattern drawing, according to the elements of daily life, use the computer to design the pattern, and print out the pattern, and the pattern forms the constituent elements of the cloth sticker;

[0027] S2: drawing samples, place a transparent thin plastic sheet on the pattern, and draw all the outlines of the pattern on the thin plastic sheet one by one, and then print the outline drawn on the thin plastic sheet On a white cardboard, a plurality of independent pattern outlines are formed on the white cardboard, and the pattern outlines form a "lining" of a plurality of independent figures;

[0028] S3: color matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com