Chain saw guide plate and chain saw with same

A technology of chain saw guide plate and guide plate, which is applied in the direction of chain saws, sawing components, manufacturing tools, etc., which can solve the problems of increased difficulty and complicated production management, and achieve the effects of reducing specifications and models, facilitating production, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] This embodiment proposes a chainsaw guide plate with good versatility and applicable to chains with different pitches and a chainsaw with the chainsaw guide plate.

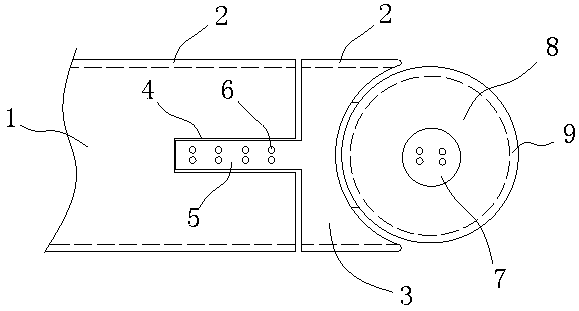

[0015] Such as figure 1 As shown, the chainsaw guide plate of this embodiment includes a plate-shaped body 1 and a connecting plate 3, both sides of the body 1 and the connecting plate 3 are provided with guide plate grooves 2, and the body 1 and the connecting plate 3 are composed of two panels and A middle board is superimposed, wherein the two panels of the body 1 are provided with a positioning groove 4 at the head end of the board body, and the two panels of the connecting board 3 are provided at the tail end of the connecting board 3 to be inserted into the The protruding part 5 at the positioning groove 4, the middle plate of the body 1 is provided with a through hole at the position corresponding to the positioning groove 4, and the protruding part 5 of the connecting plate 3 is provided with a numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com