Patents

Literature

66results about How to "High cost of control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

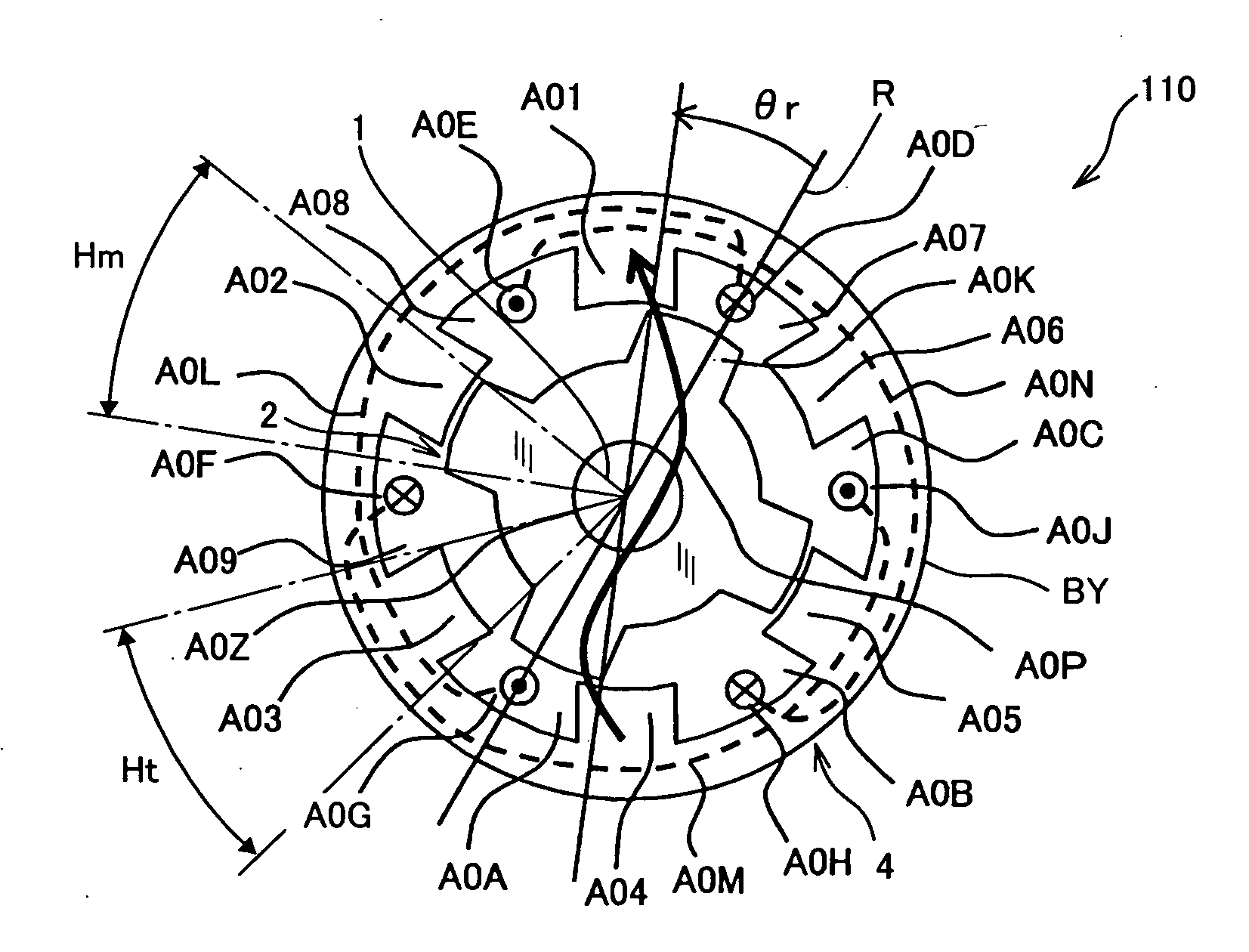

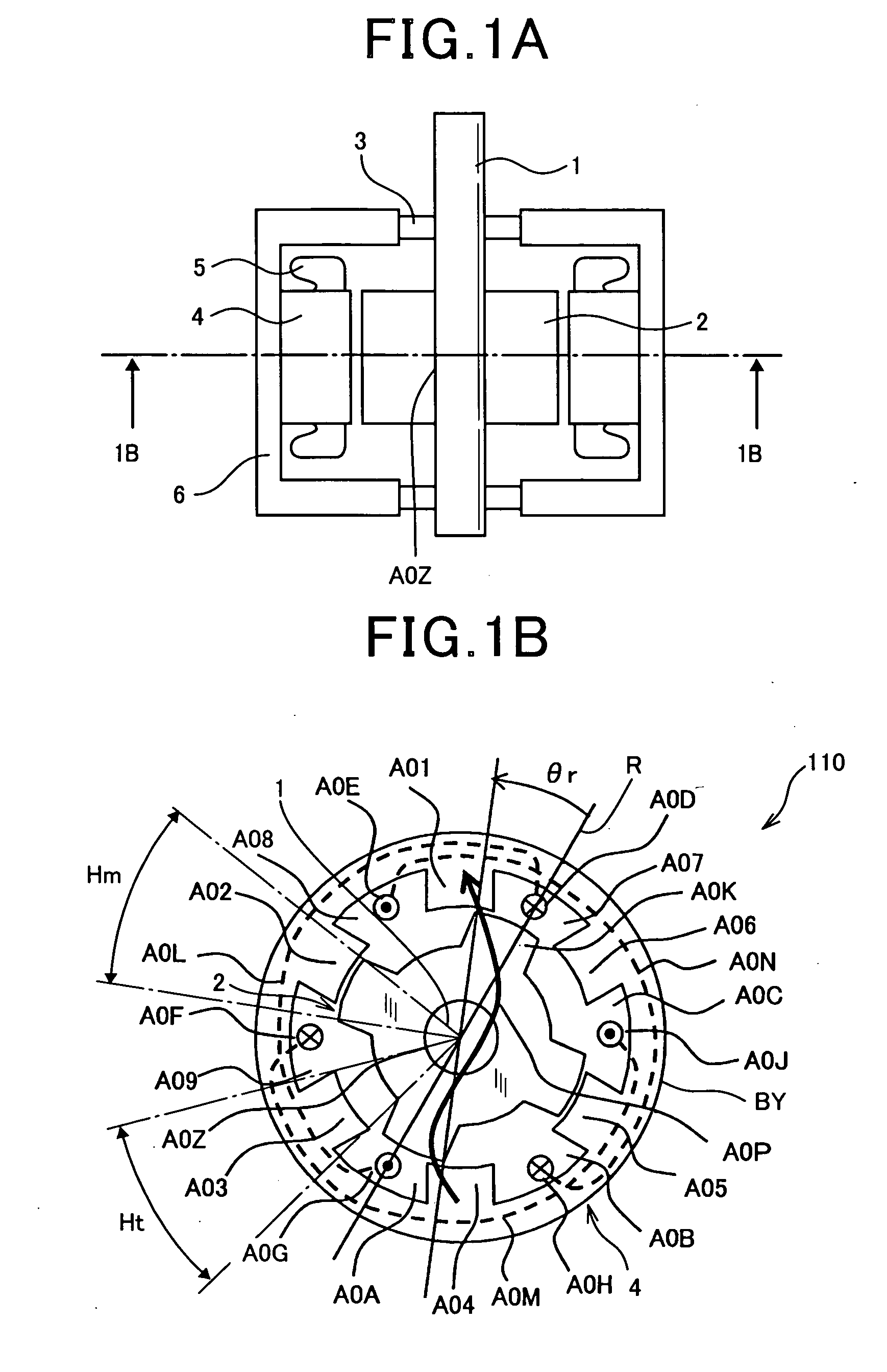

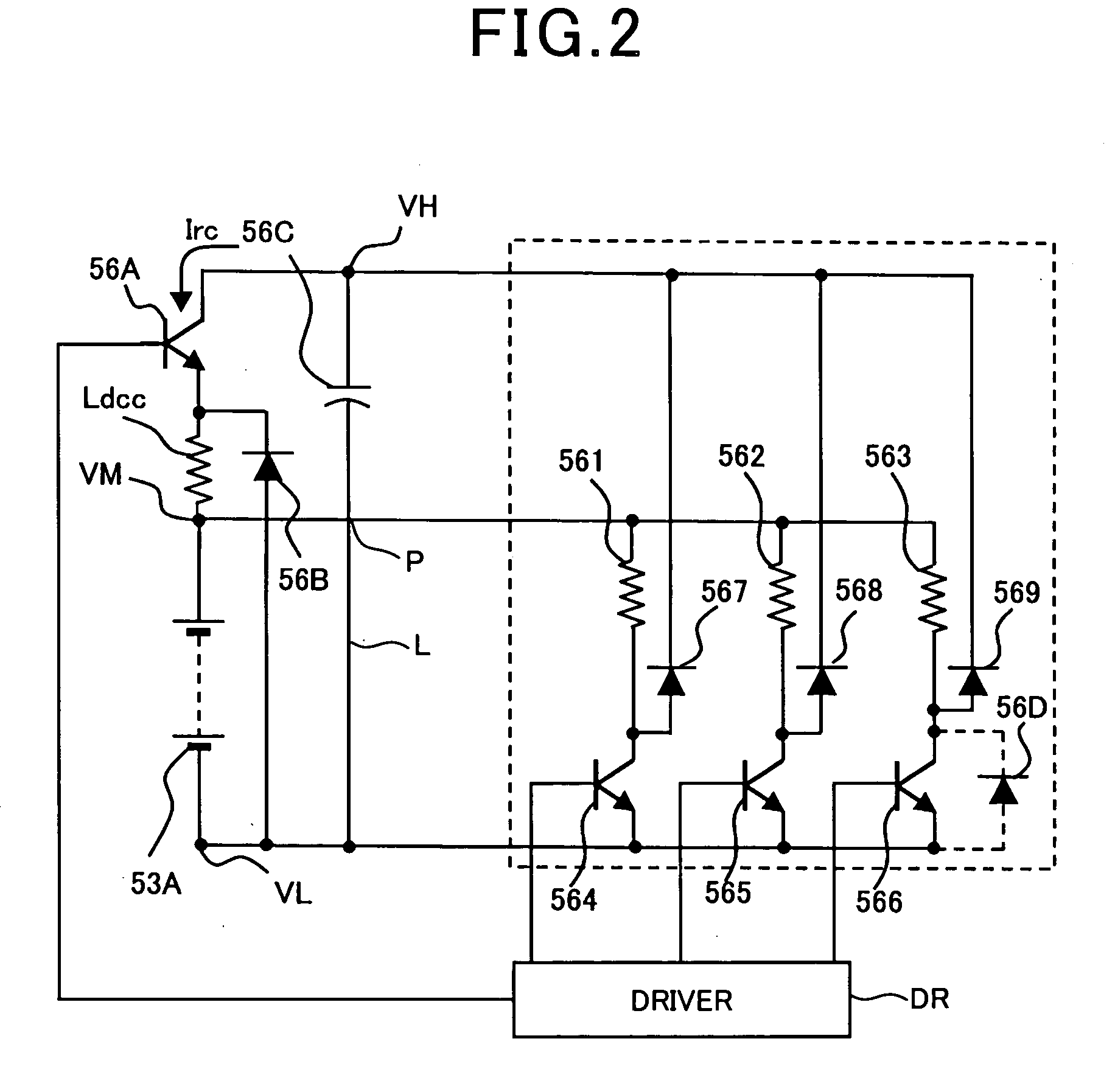

Reluctance motor with improved stator structure

InactiveUS20100123426A1Reduce efficiency of motorHigh cost of controlMotor/generator/converter stoppersAC motor controlReluctance motorEngineering

Owner:DENSO CORP

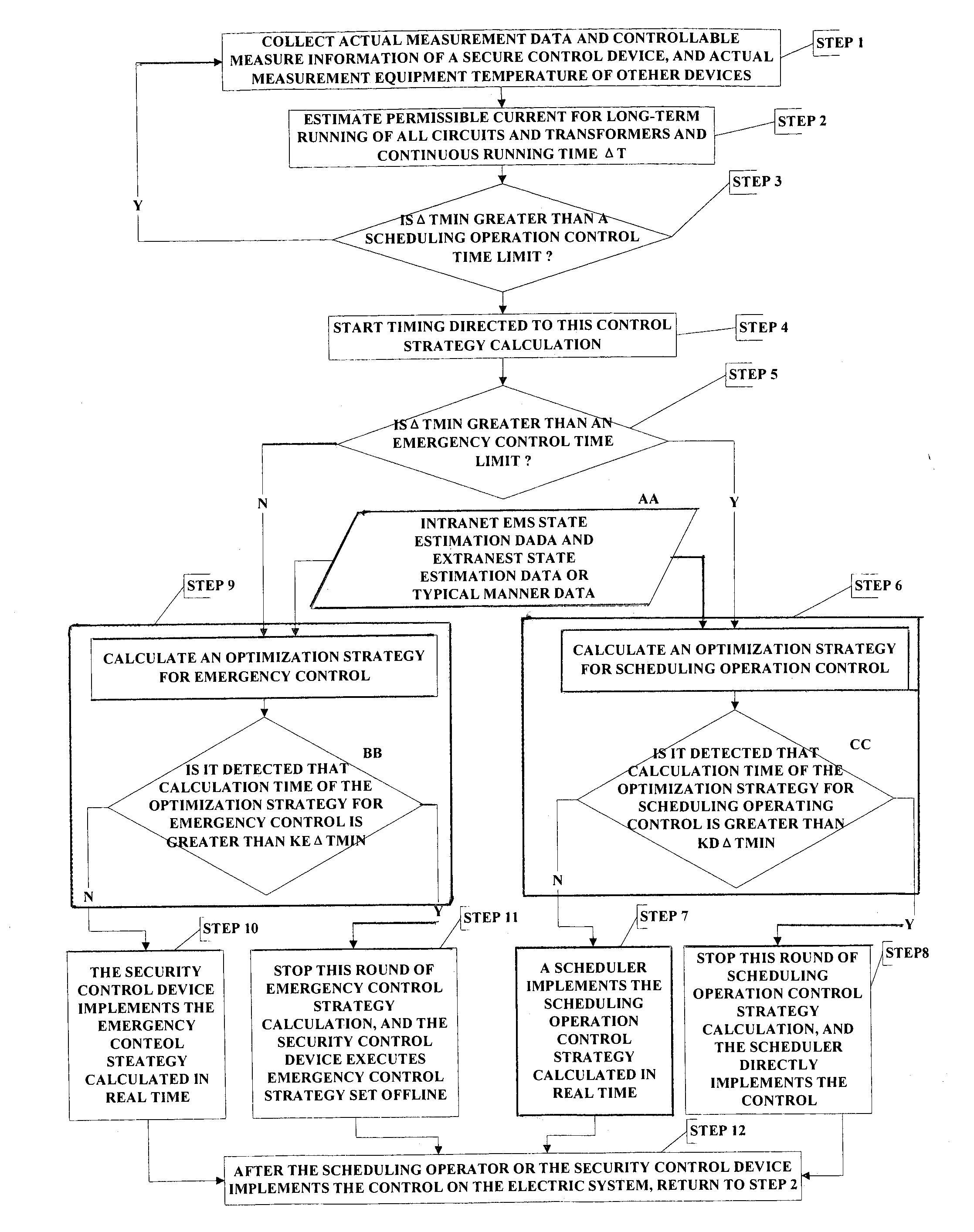

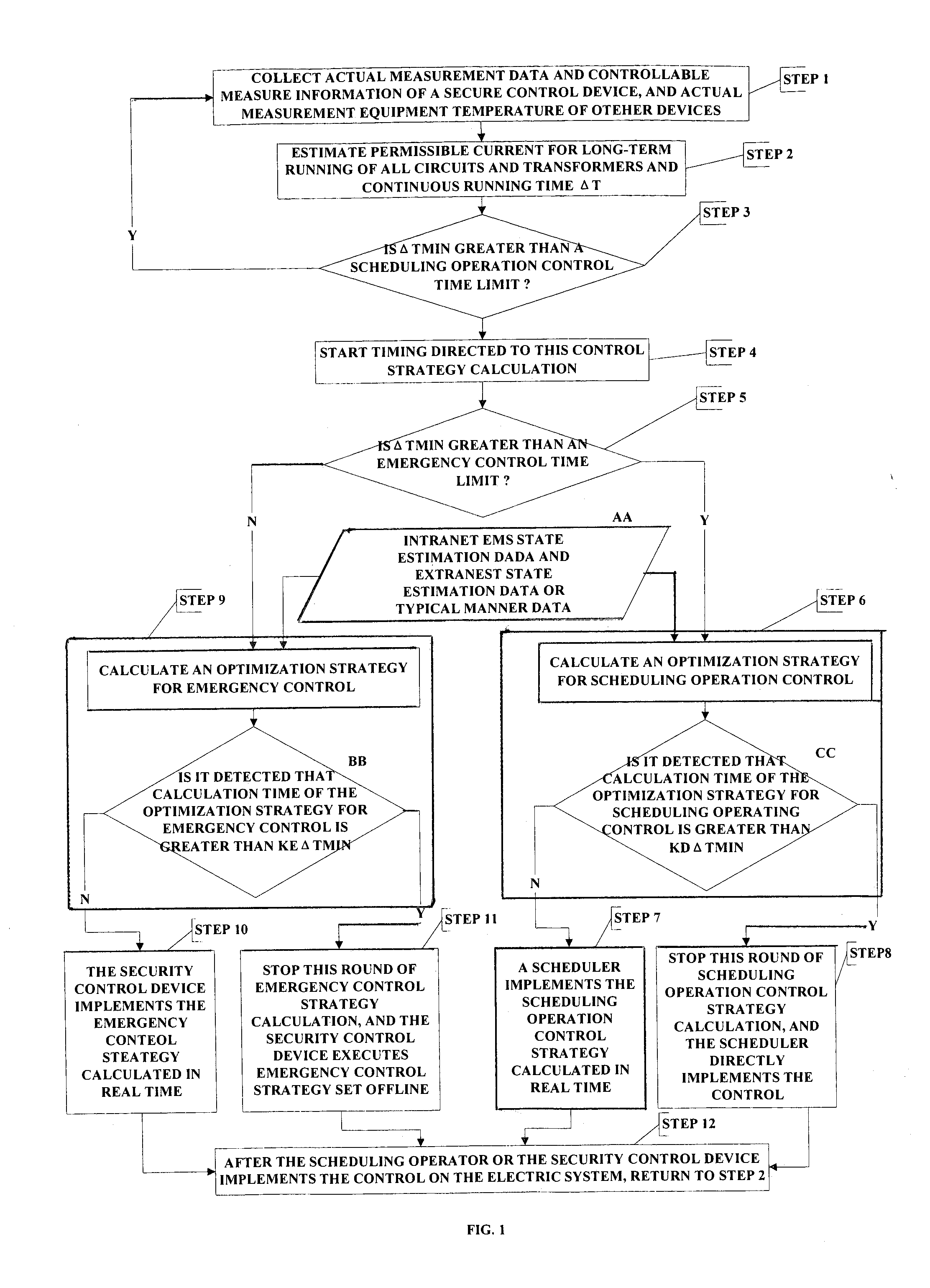

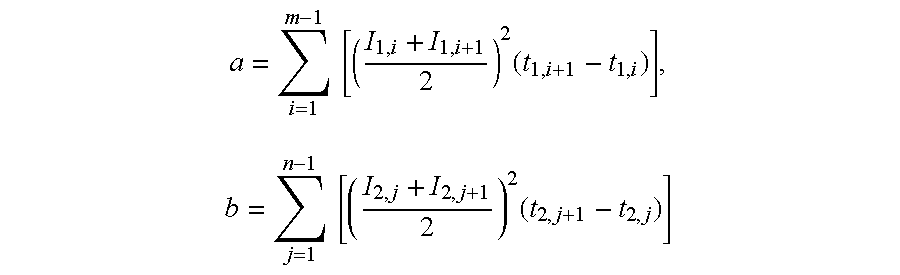

Equipment overload successive approximation adaptive control method based on centralized real-time decision

InactiveUS20150081129A1Low costHigh cost of controlMechanical power/torque controlLevel controlEngineeringMajorization minimization

An equipment overload successive approximation adaptive control method based on centralized real-time decisions is provided. The method estimates in real time permissible current for long-term running of equipment and continuous running time according to current and temperature actual measurement information of the equipment. Control modes are decided according to the continuous running time of the equipment instead of current. On the basis of mixed integer nonlinear programming algorithm, a target function which aims to control the total cost and minimize comprehensive indexes of proportions of load control quantities of different regions is adopted, discreteness and cost of a control measure are taken into consideration, flow restraint of an electric system is measured, a centralized optimization decision and successive approximation control strategy are adopted, coordination to real-time scheduling operation control and emergency control for overload of equipment of the electric system is realized.

Owner:STATE GRID ELECTRIC POWER RES INST +2

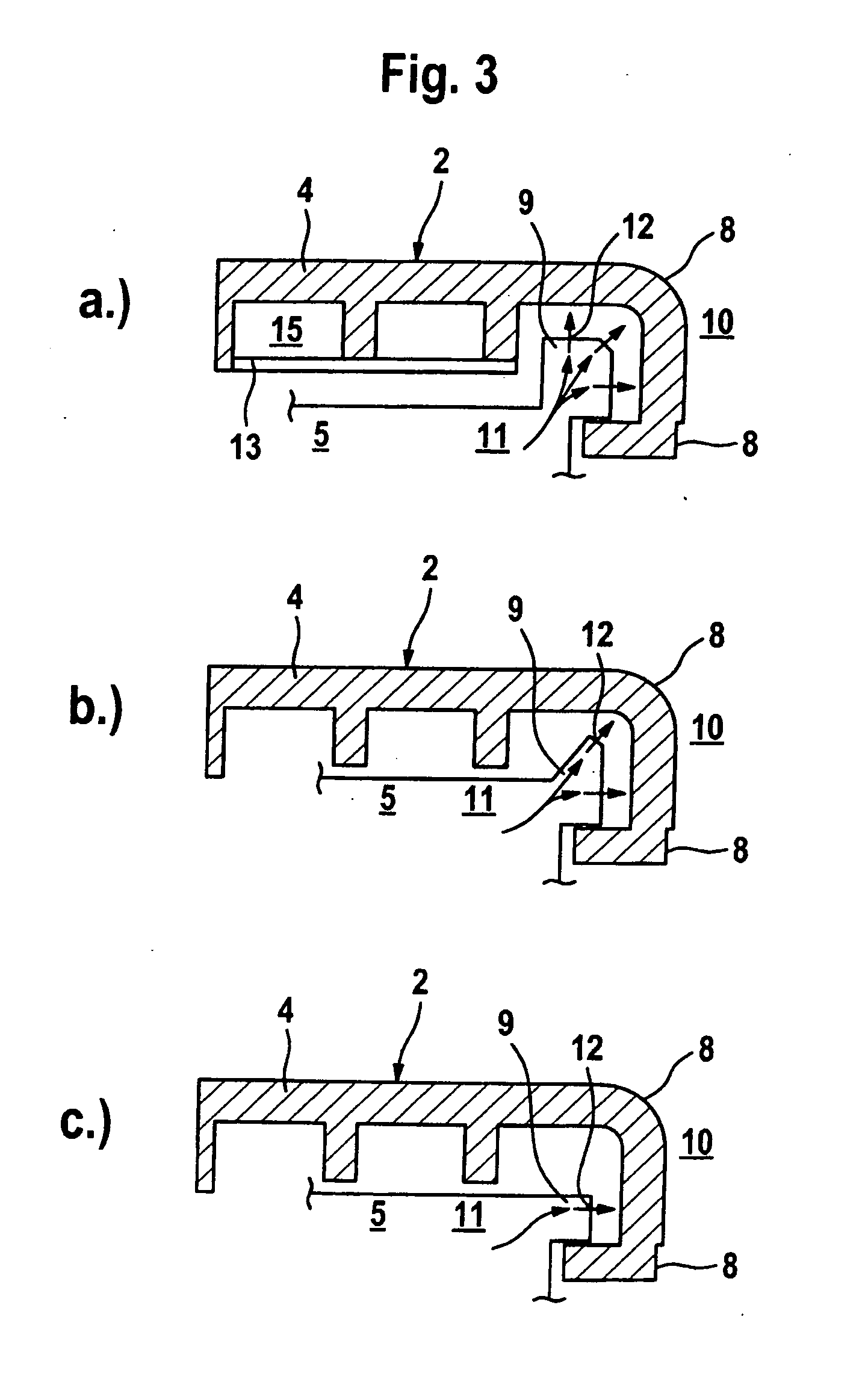

Combustion chamber of a combustion system

InactiveUS20090202956A1Reduce operating costsAvoid damageBurnersContinuous combustion chamberCombustion systemCombustion chamber

A combustion chamber of a combustion system has a combustion space, a support structure, a support element, and a heat shield. The heat shield has at least two segments, and each segment includes a liner element facing the combustion space and has an edge region, a gap communicating with the combustion space being formed between edge regions of adjacent segments, and a retaining device. The retaining device fixes the respective liner element on the support structure via the support element and forms a flange region that fits over the edge region of the respective liner element. The retaining device forms a first cooling passage with the support element and has at least one through-opening in the flange region. A cooling gas flows through the through.opening from the first cooling passage to the edge region.

Owner:ANSALDO ENERGIA IP UK LTD

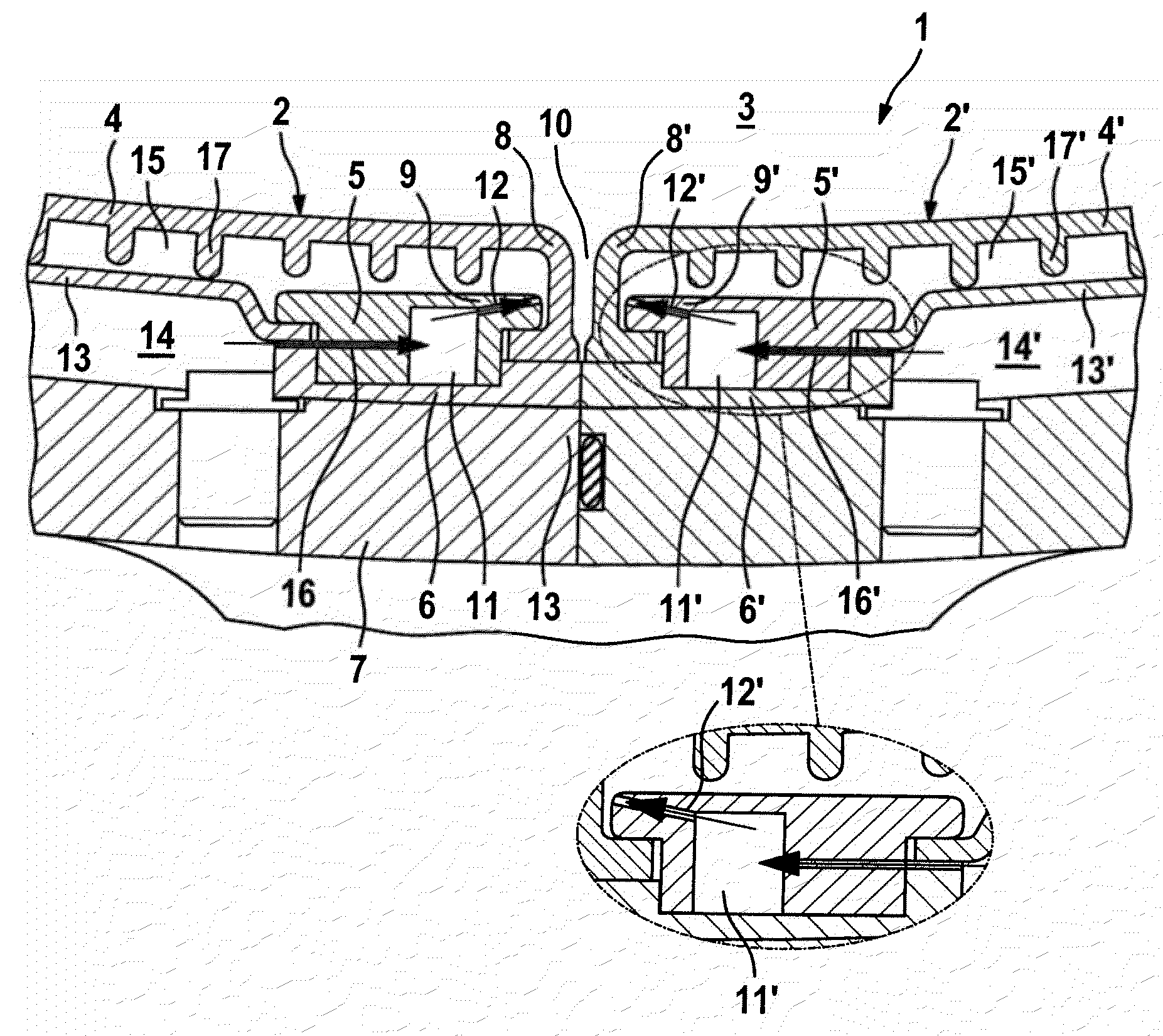

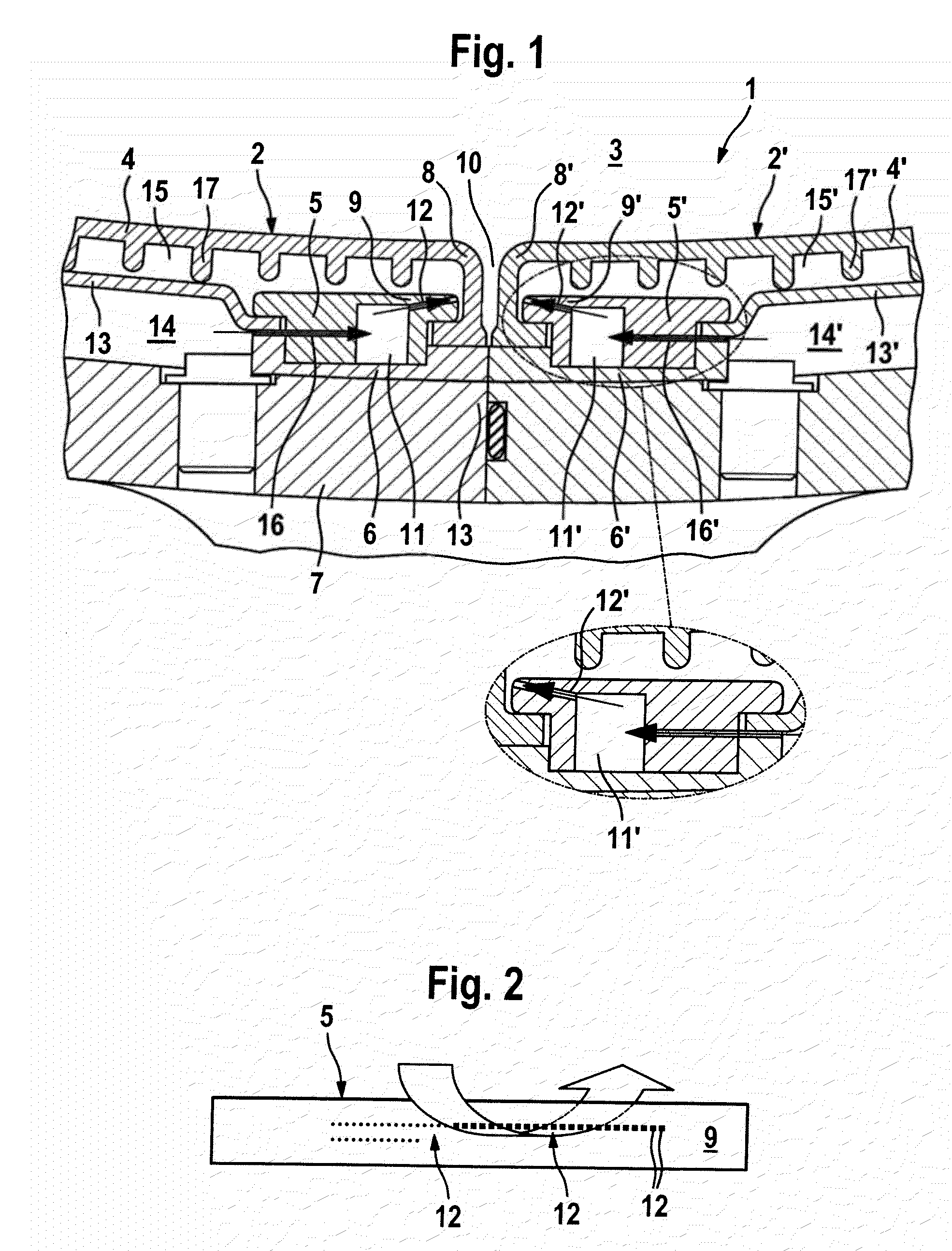

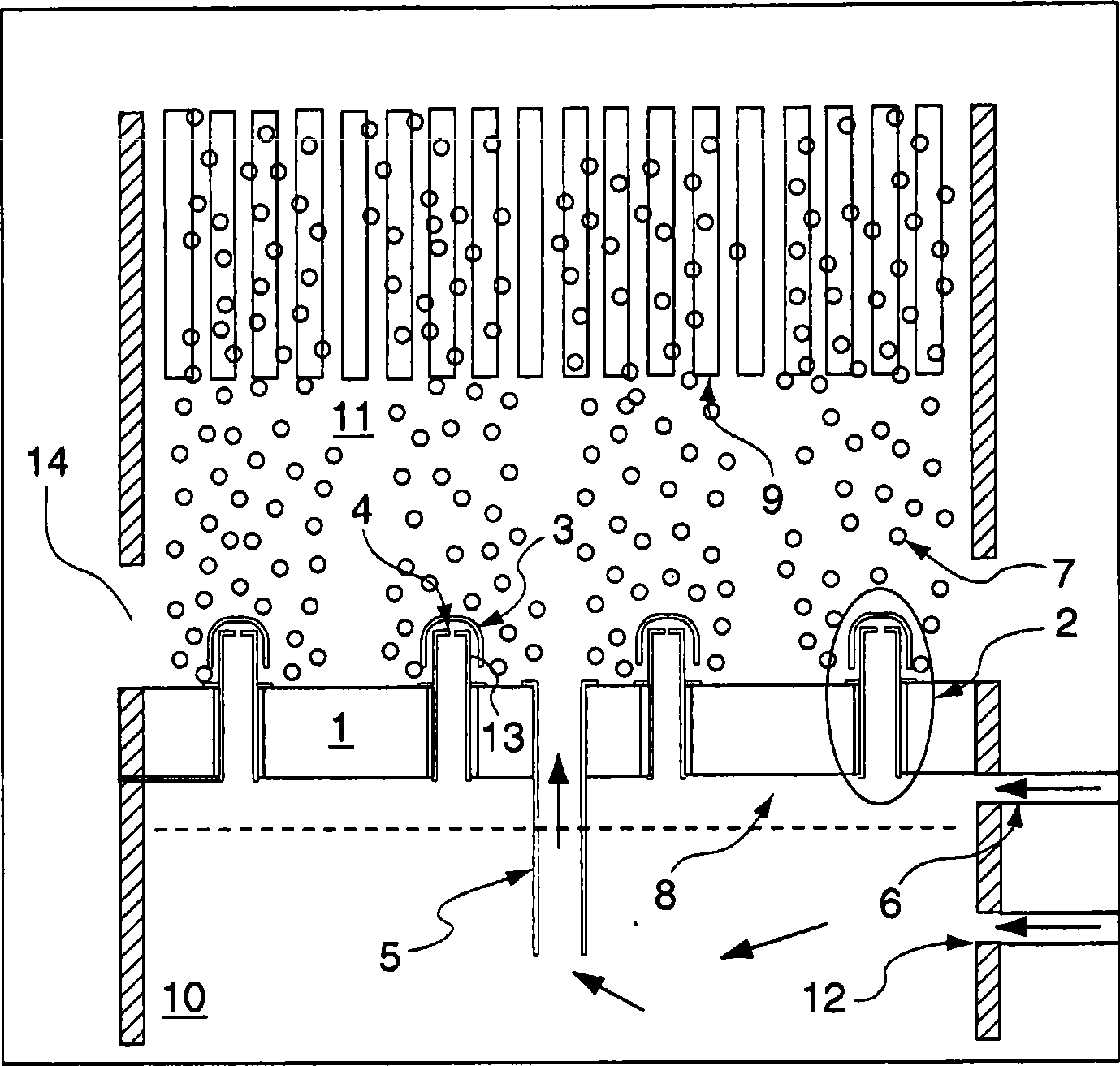

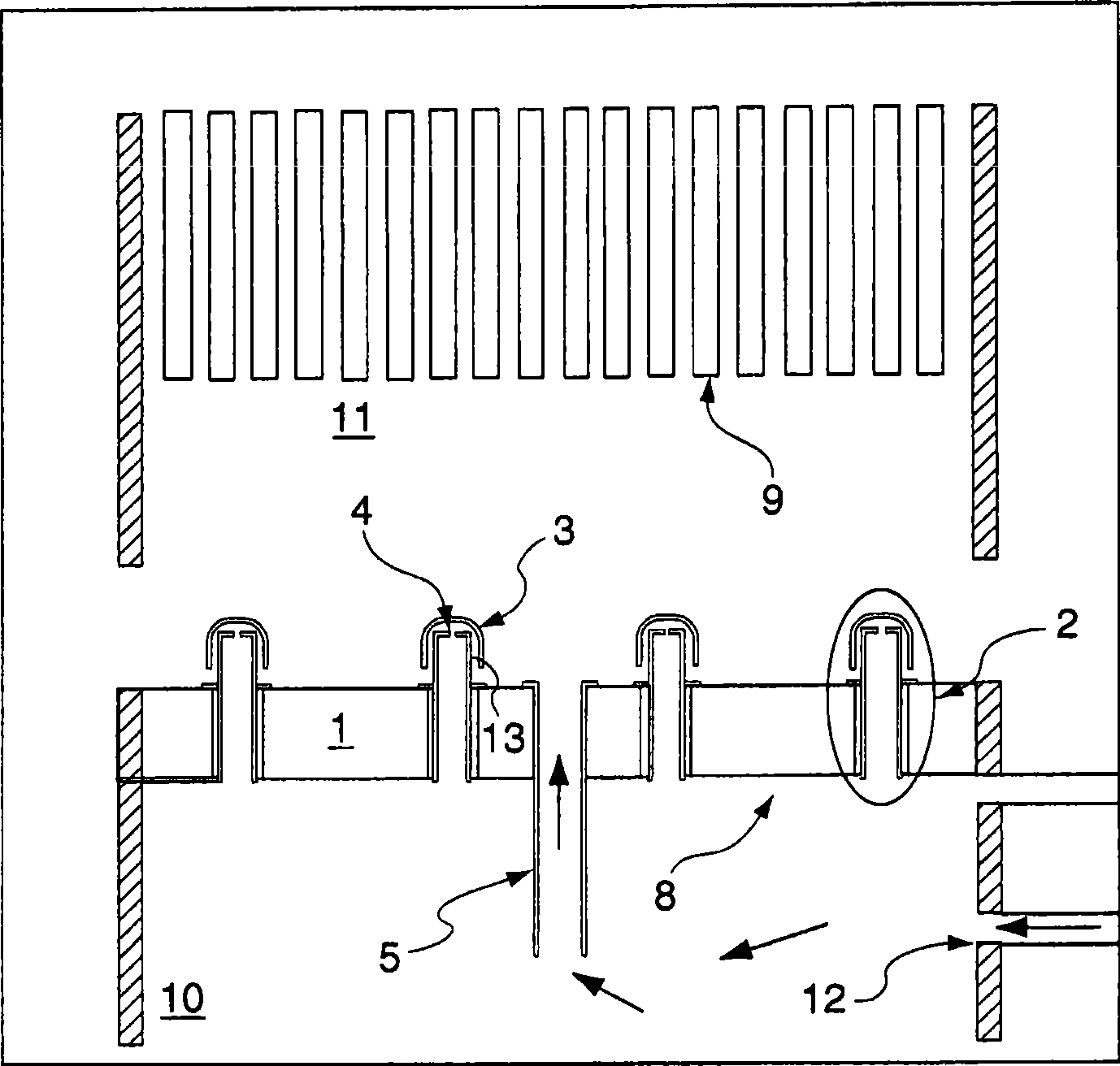

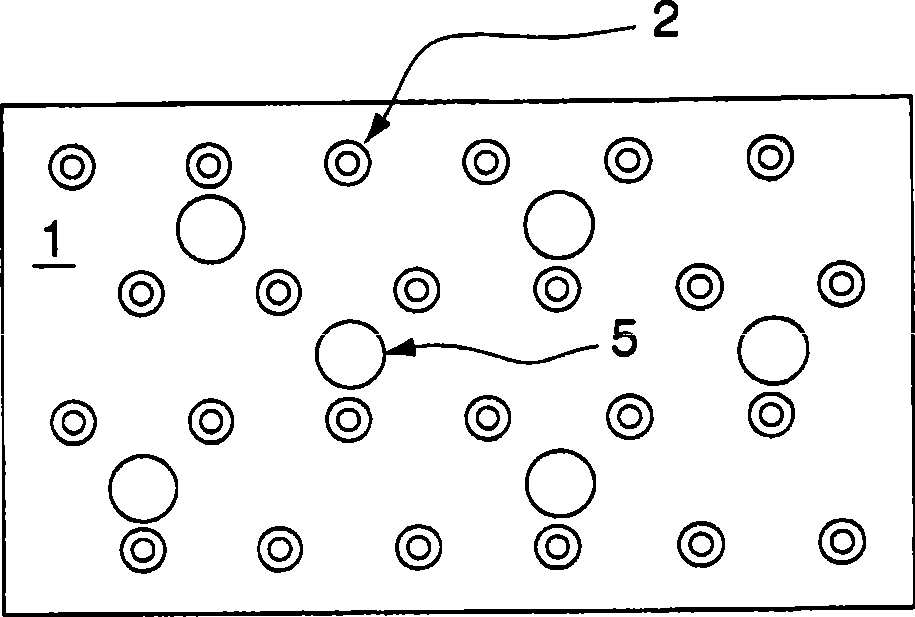

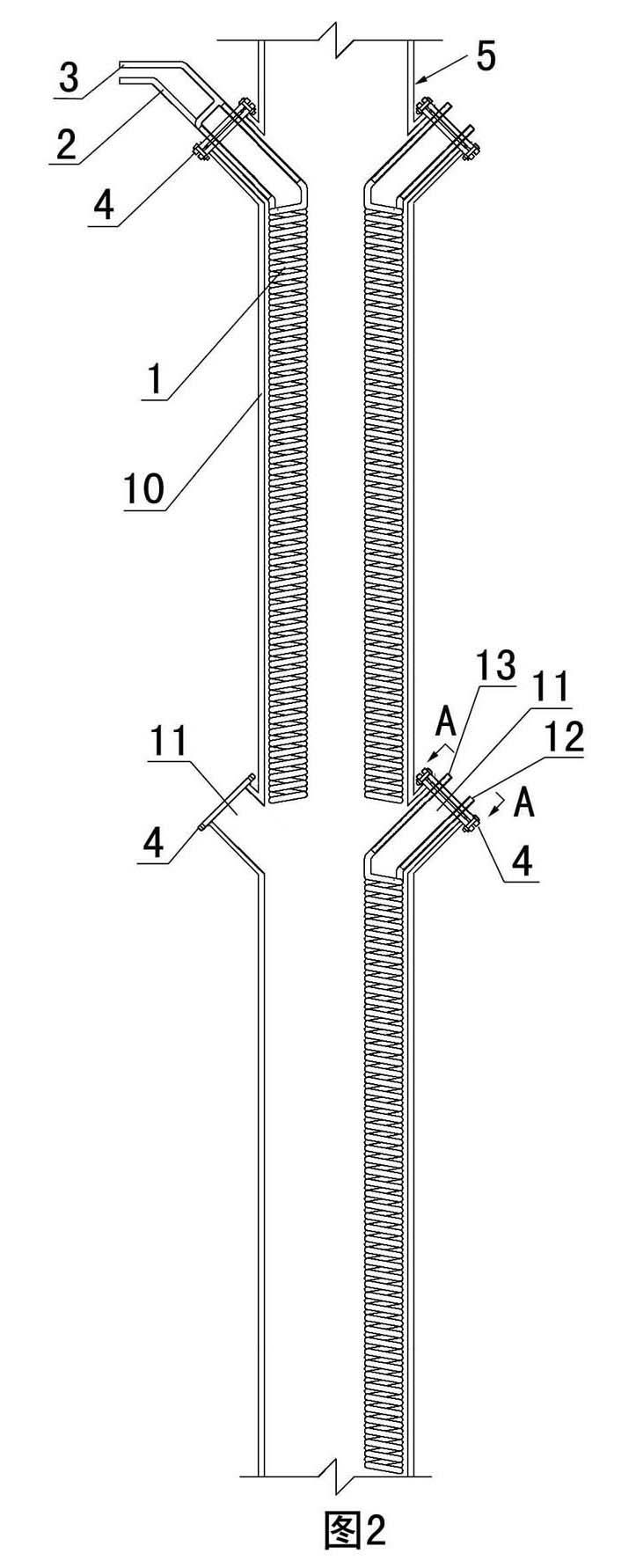

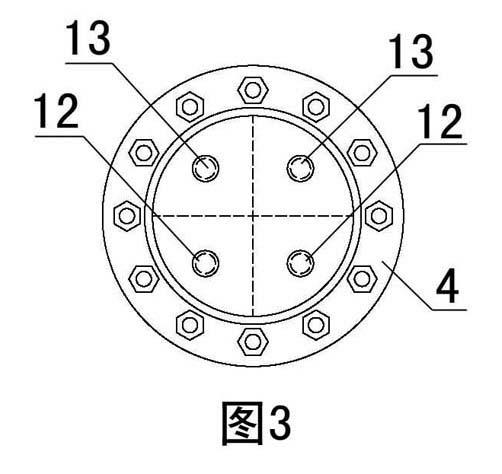

Aerating device for a water filtering system with immersed membranes, including a floor provided with means for injecting a gas and at least one pressure balancing system

InactiveCN101448562ALow running costImprove distributionTreatment using aerobic processesUltrafiltrationProduct gasEngineering

The invention concerns an aerating device for a water filtering system with immersed membranes (9) designed to be installed substantially beneath said membranes (9). The invention is characterized in that it comprises a floor (1) separating an upper chamber wherein said membranes are immersed and a lower chamber comprising means for feeding a liquid to be treated and means for feeding an aerating gas, said floor being provided with plural strainers (2) and with at least one system (5) for balancing pressures between said upper and lower chambers, and in that each strainer (2) includes a substantially tubular element (13) passing through said floor and having in its upper part at least one orifice (4), and an air chamber forming element (3) mounted atop said upper part.

Owner:ODISHA TV

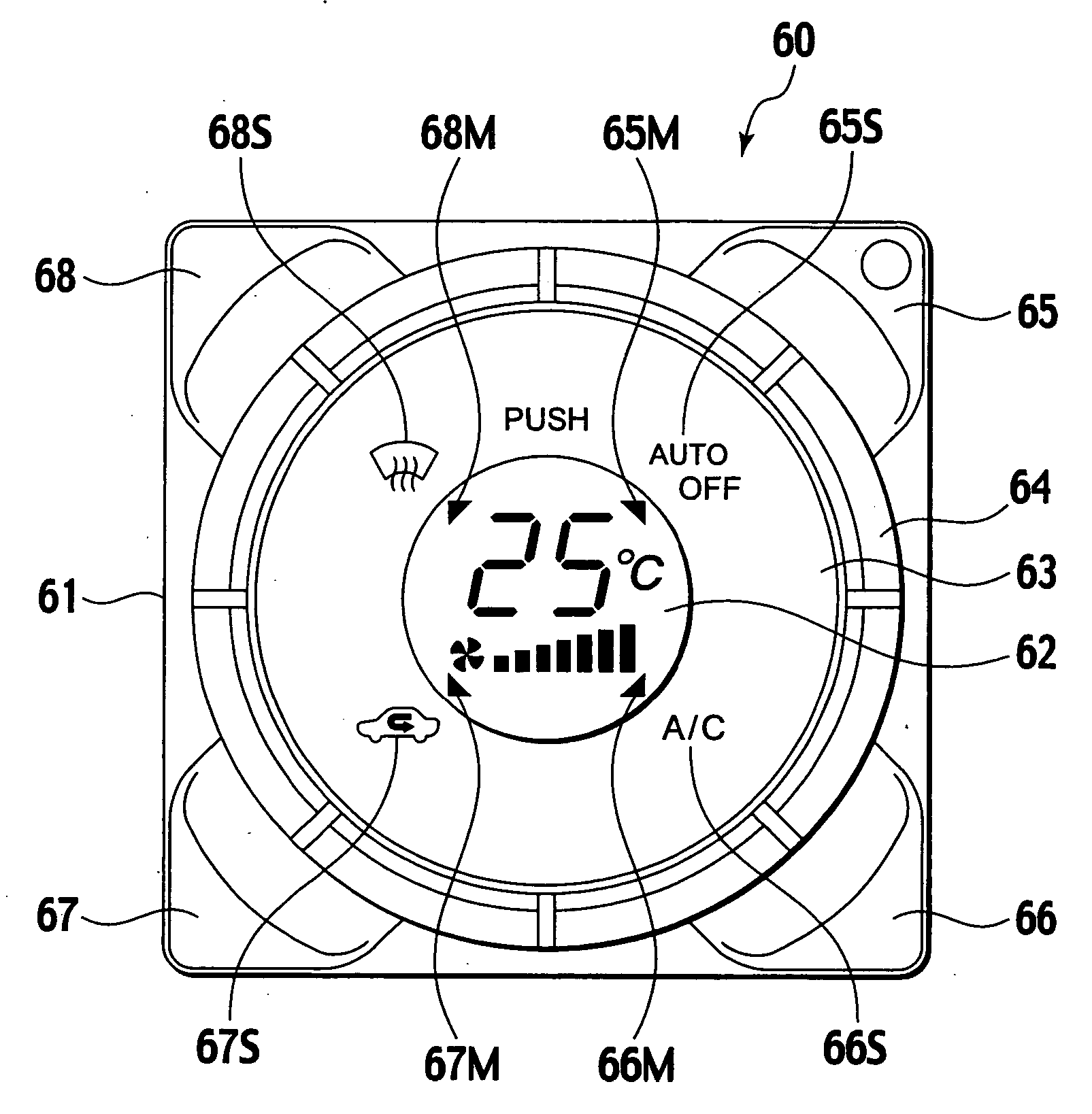

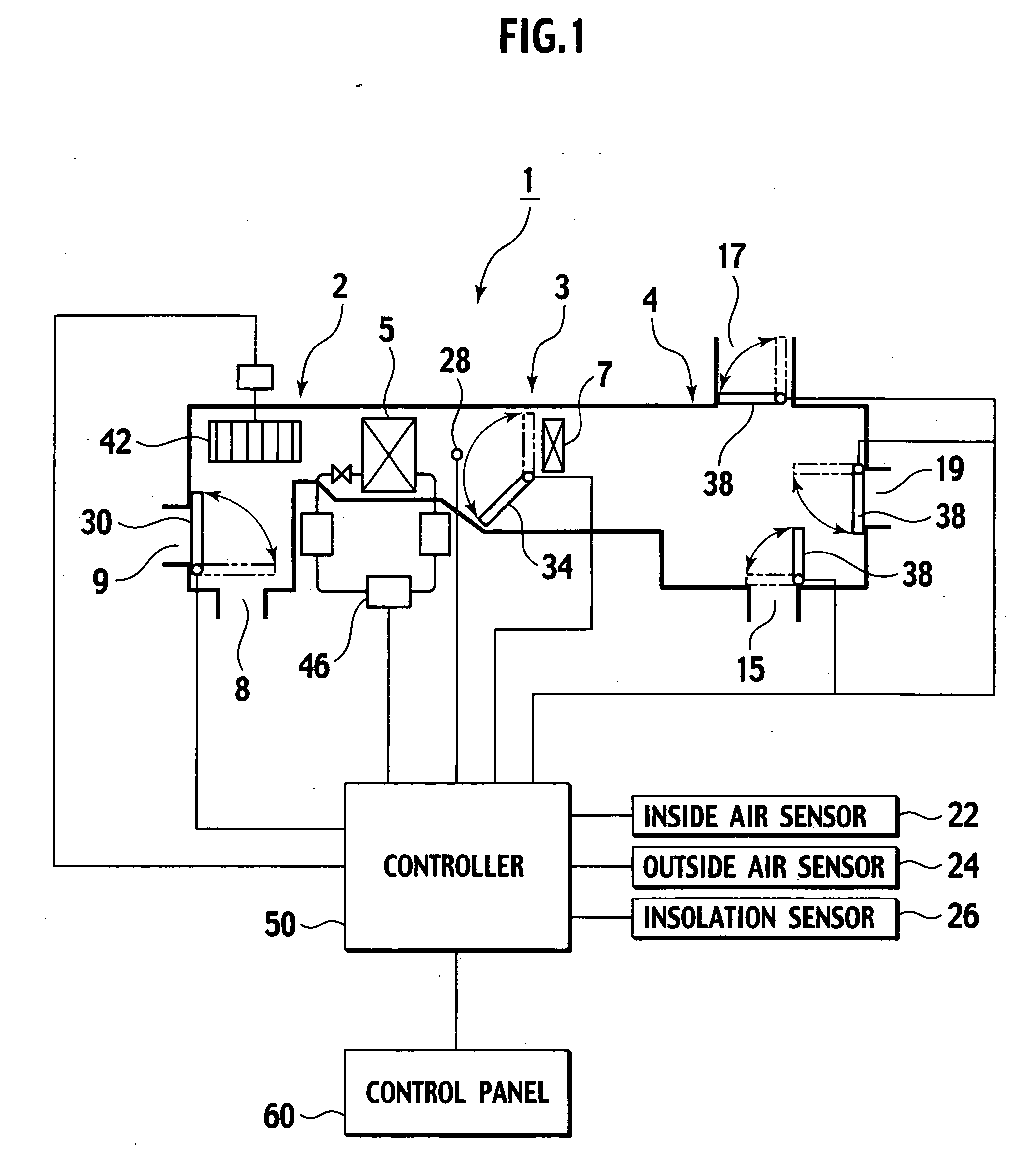

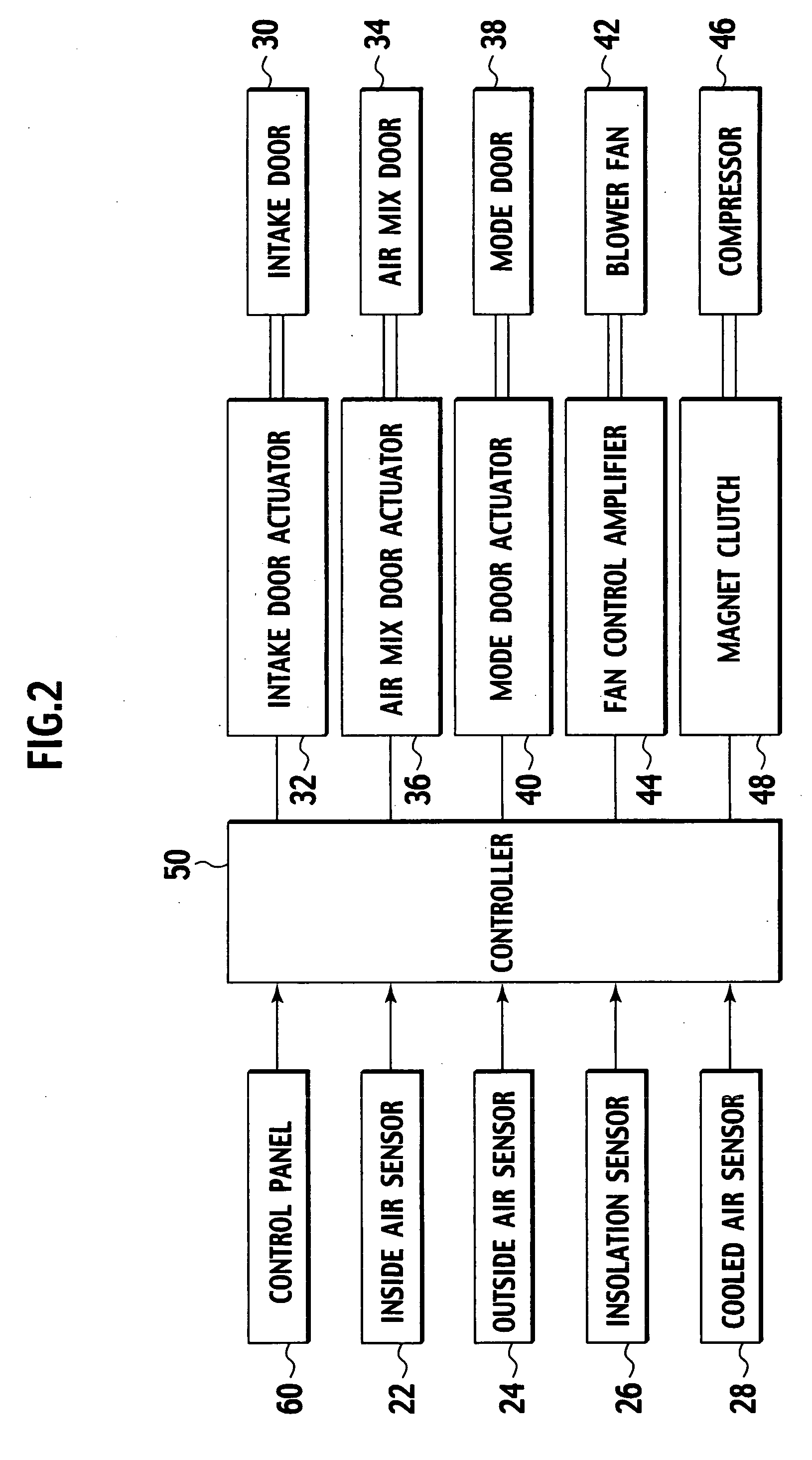

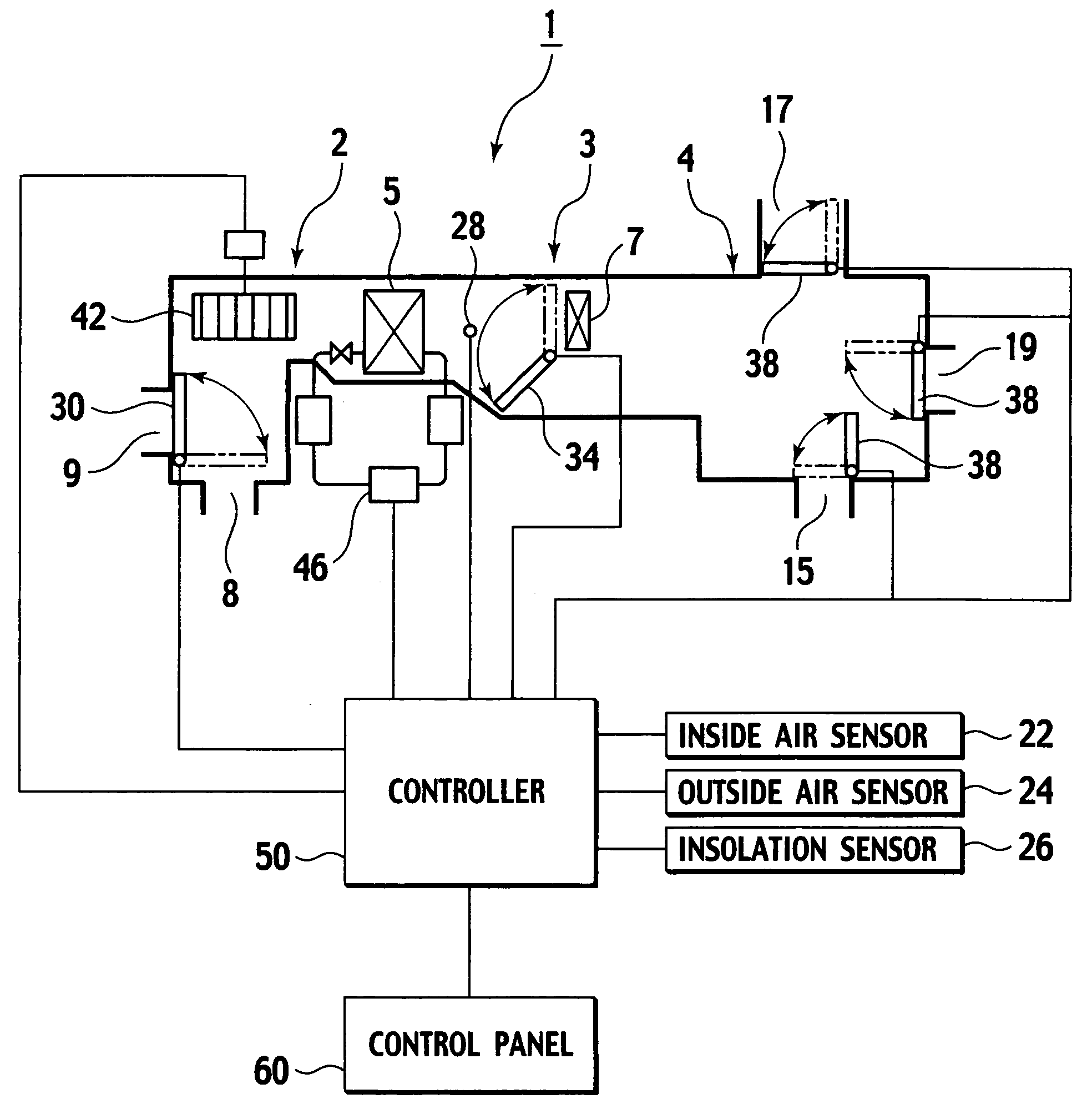

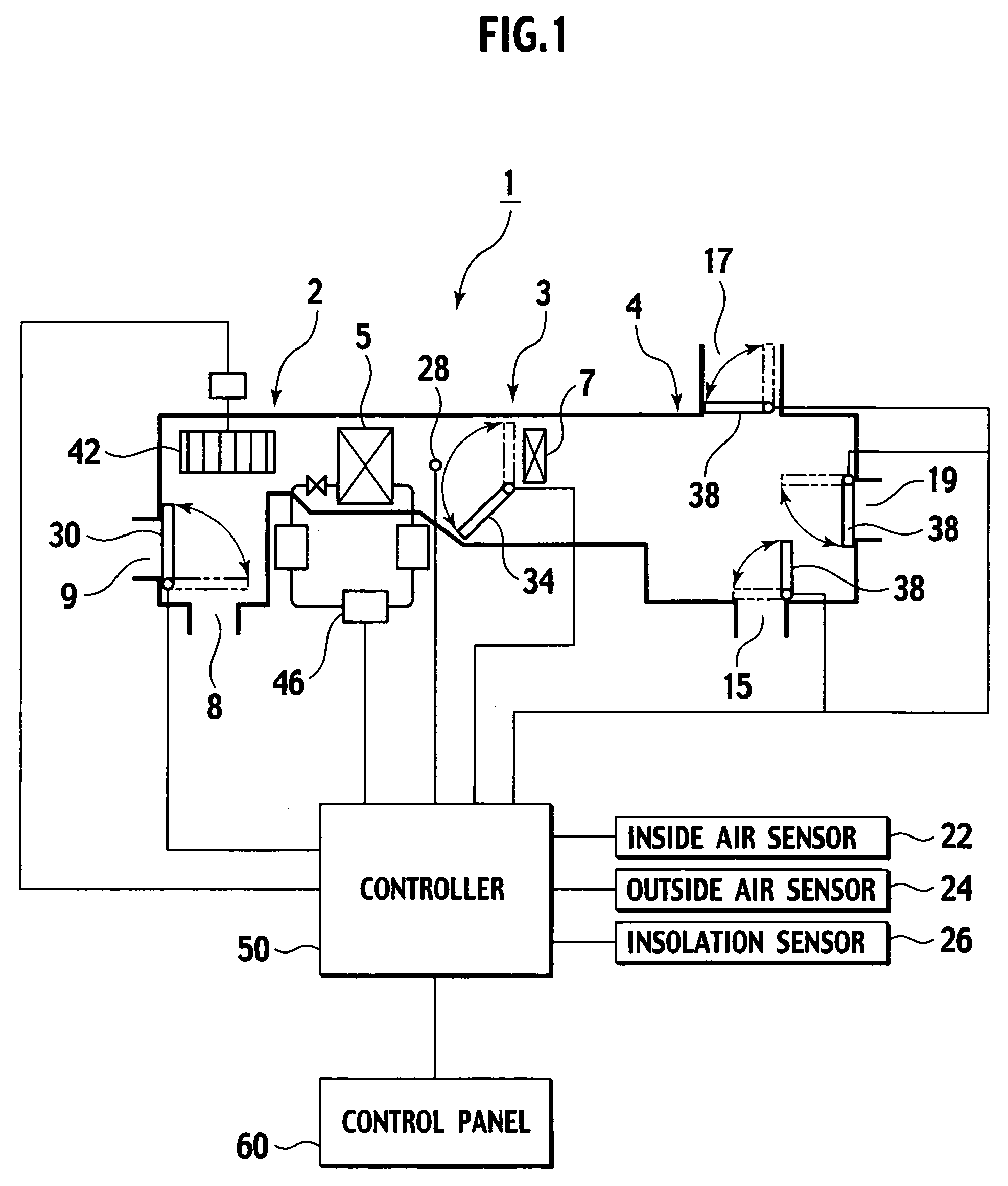

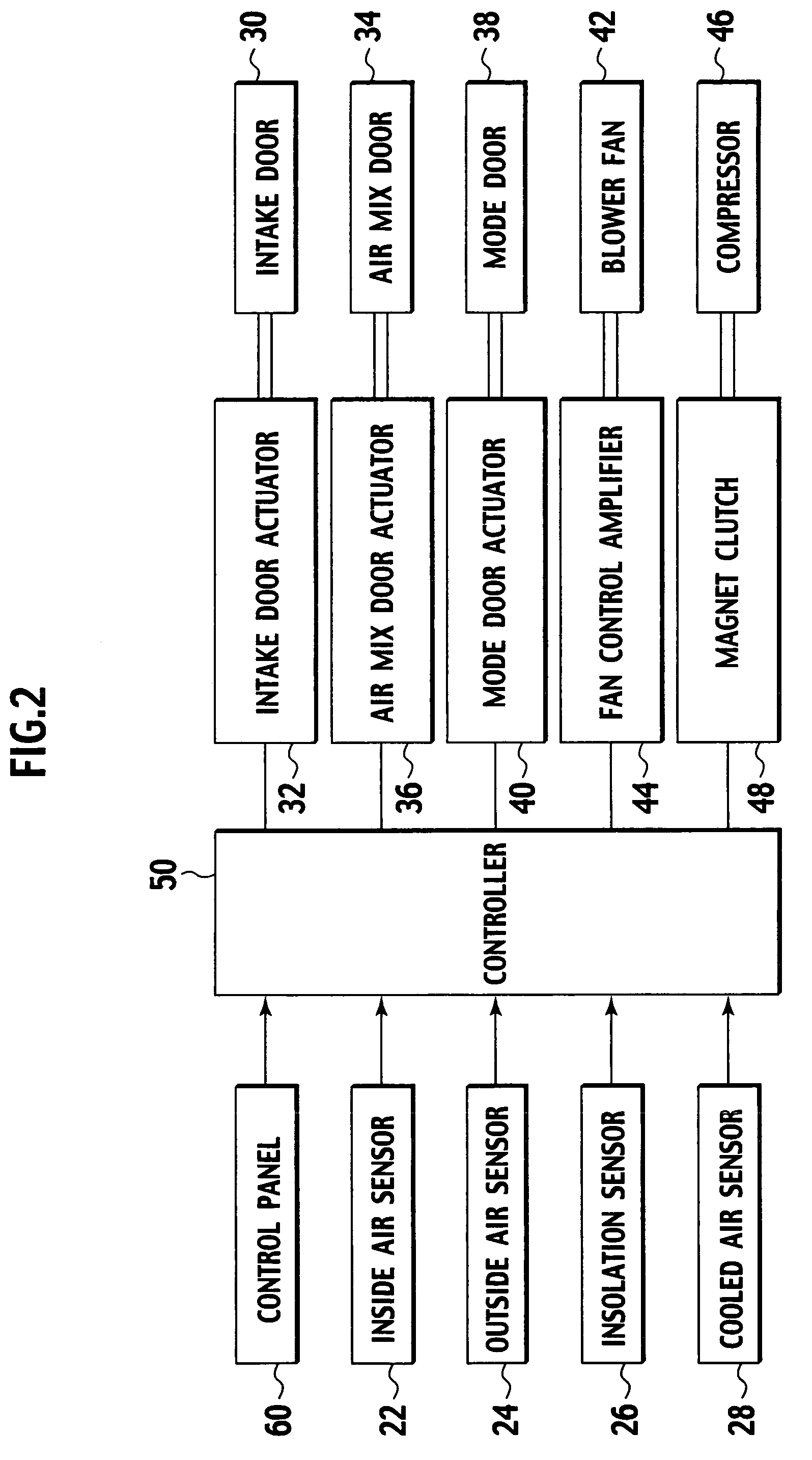

Control panel for vehicle air conditioner

InactiveUS20060163045A1Easy to operateQuick changeStampsVehicle heating/cooling devicesDisplay device

Owner:CALSONIC KANSEI CORP

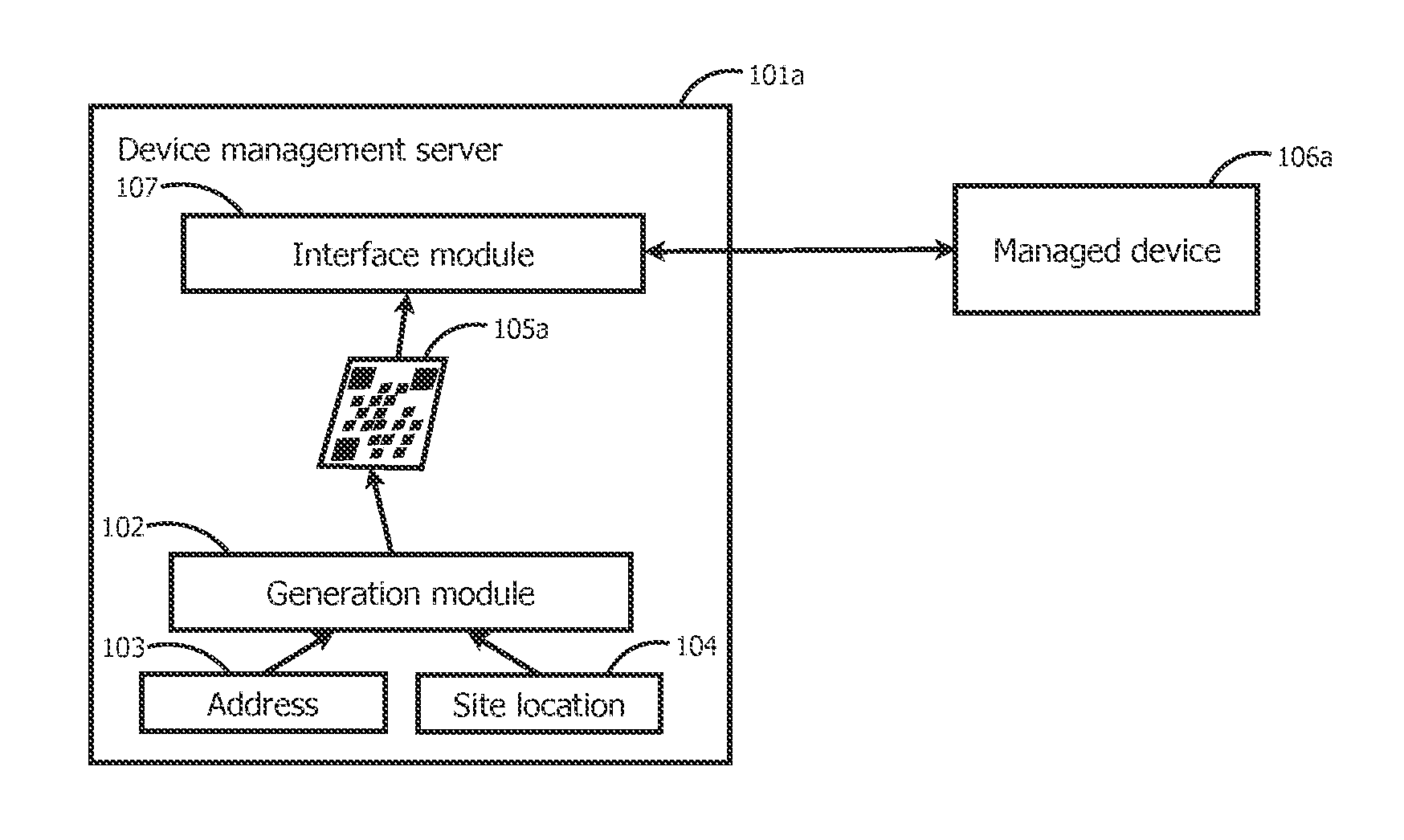

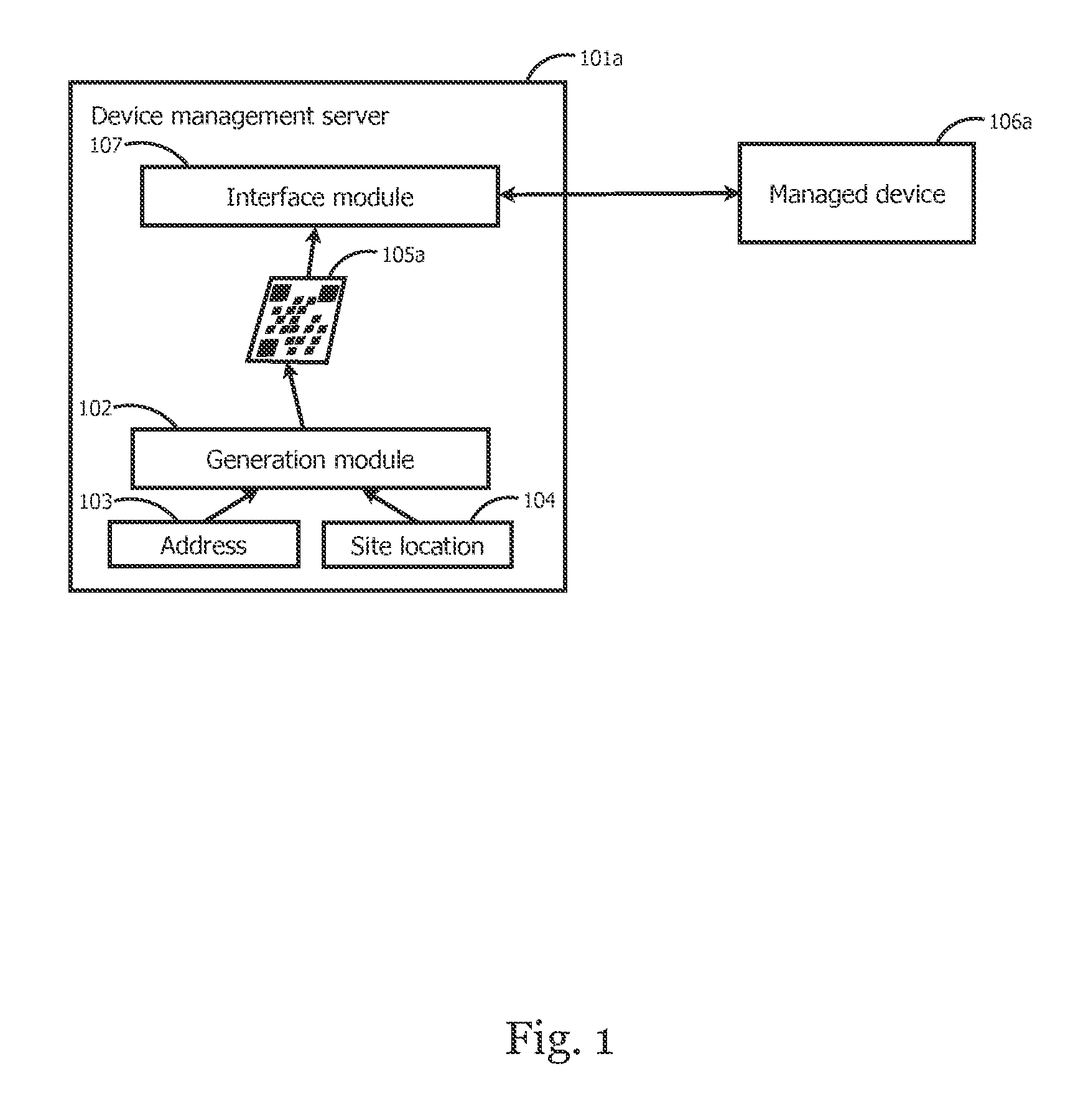

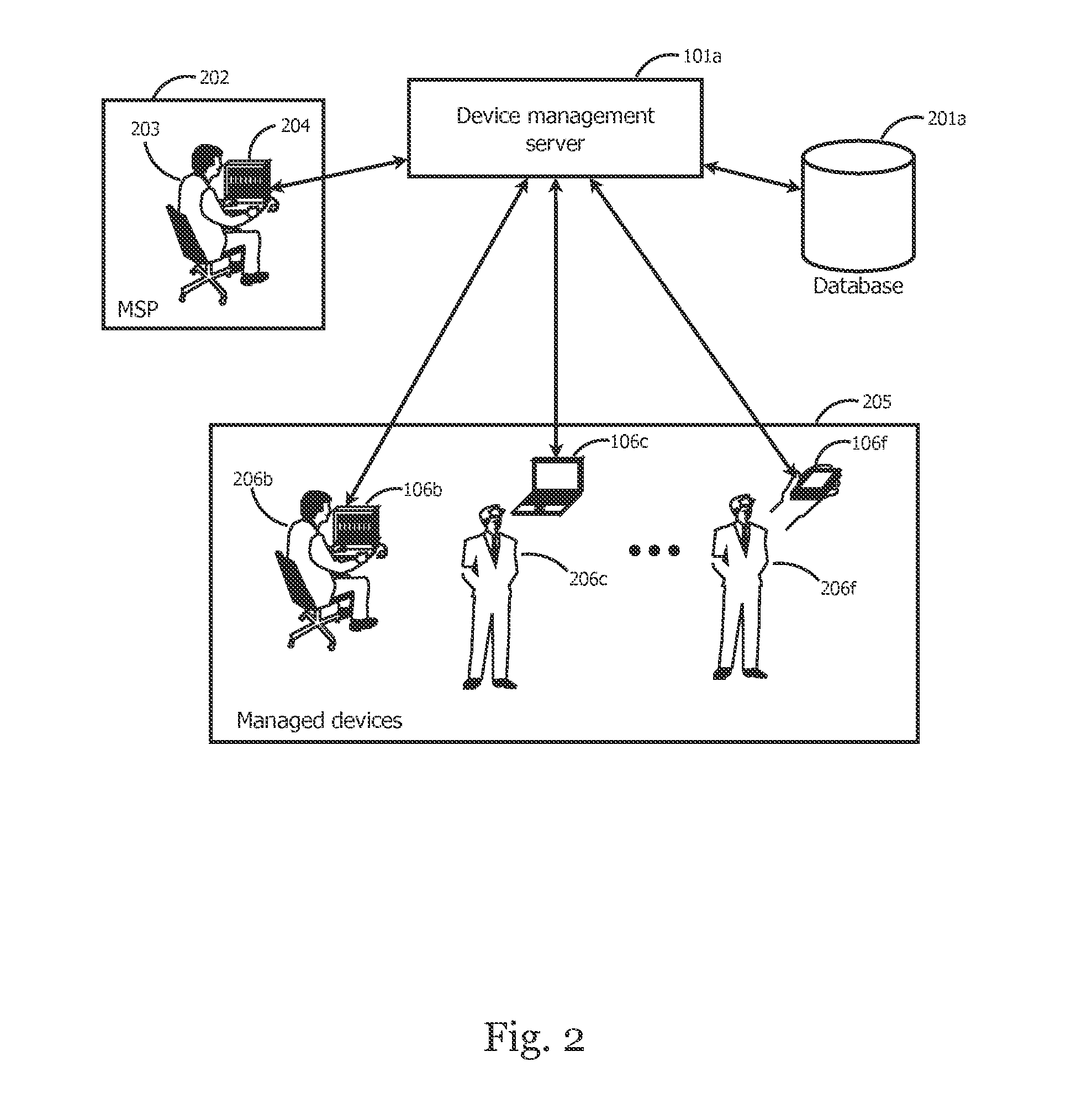

Systems and methods for configuring a managed device using an image

ActiveUS20140164580A1Easy to manageHigh cost of controlDigital computer detailsPayment architectureComputer hardwareSite location

Systems and methods of the present disclosure can facilitate managing a computing device. The computing device can be a managed device that is managed by a device management server. In some embodiments, the system includes a generation module and an interface module. The generation module may be configured to receive a site location for the computing device, identify an address of the device management server, and generate an optical representation of a configuration based on the site location and the address. The interface module may be configured to provide the optical representation to the computing device and receive a communication from the computing device, the communication corresponding to the configuration.

Owner:CONNECTWISE LLC

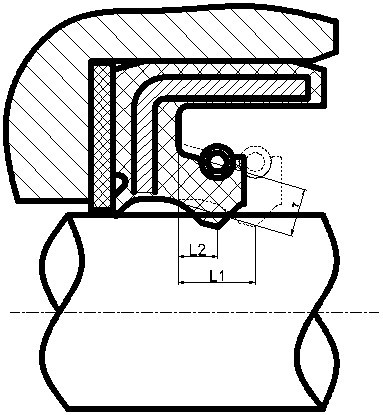

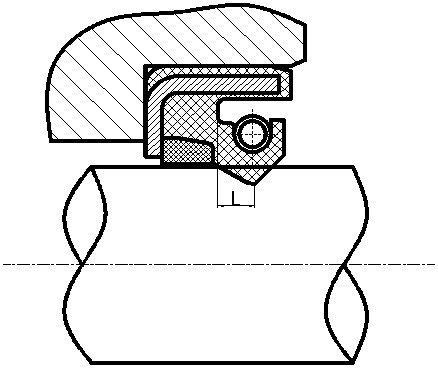

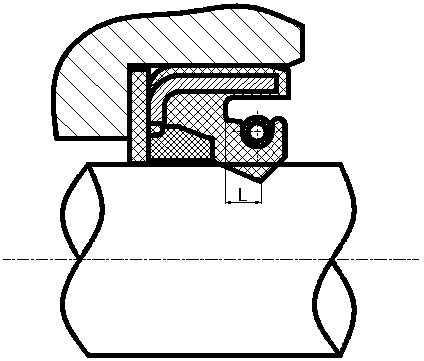

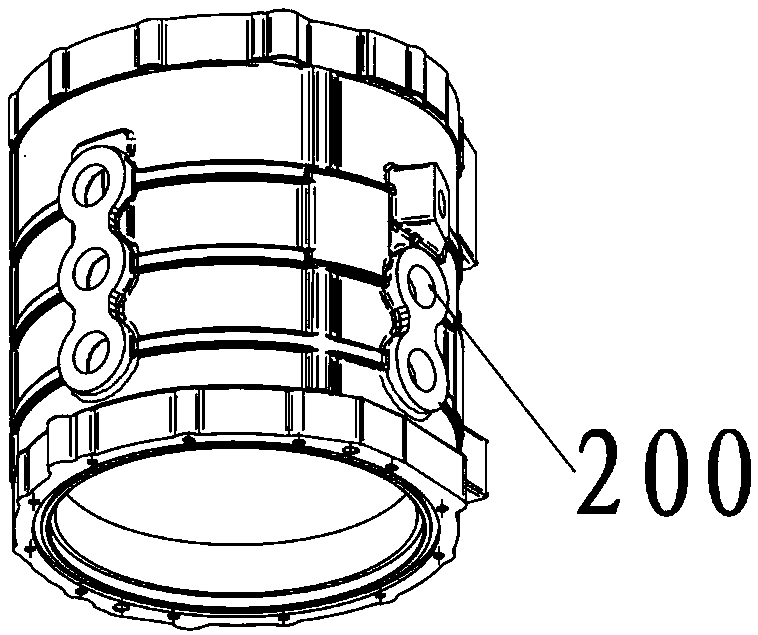

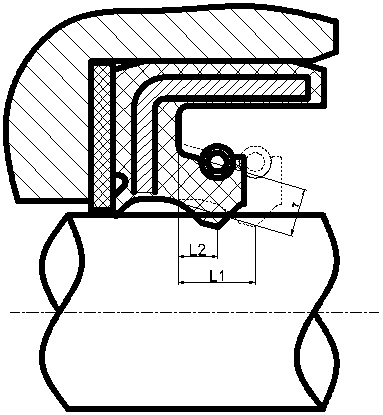

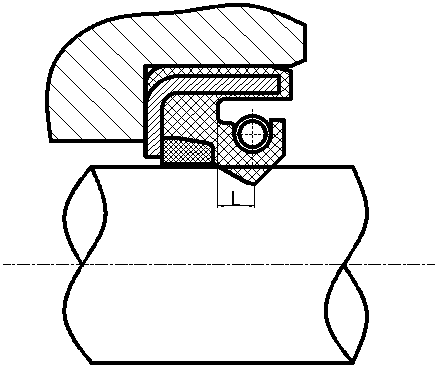

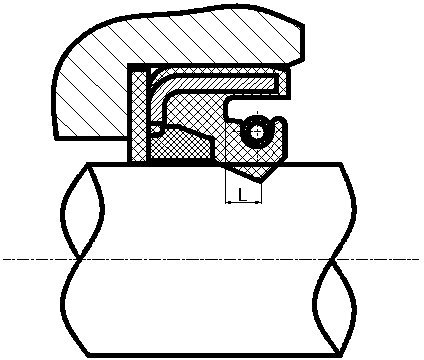

Assembled half-exposed framework high-pressure seal ring

ActiveCN102537360AImprove carrying capacityIncrease stiffnessEngine sealsVulcanizationMetal framework

The invention discloses an assembled half-exposed framework high-pressure seal ring, which not only can seal in a rotating way, but also can seal in a reciprocating way. The seal ring includes a rubber body with a sealing lip, a metal framework vulcanized in the rubber, and a half-exposed framework, a pressure bearing ring taking a metal or non-metal composite material and a spring that are assembled on the rubber body. The half-exposed framework, the composite material pressure bearing ring and the rubber body of the seal ring are designed in an assembling way; and the composite material pressure bearing ring is arranged between the half-exposed framework and the sealing lip, and the pressure bearing ring bears a large amount of working pressure. The assembled half-exposed framework high-pressure seal ring has extremely high high-pressure resistance, outstanding and stable extrusion resistance, excellent heat dissipation and friction lubricating property, good eccentricity adaptability, extremely long service life, simple process, and efficient and stable machining.

Owner:重庆杜马斯克科技有限公司 +2

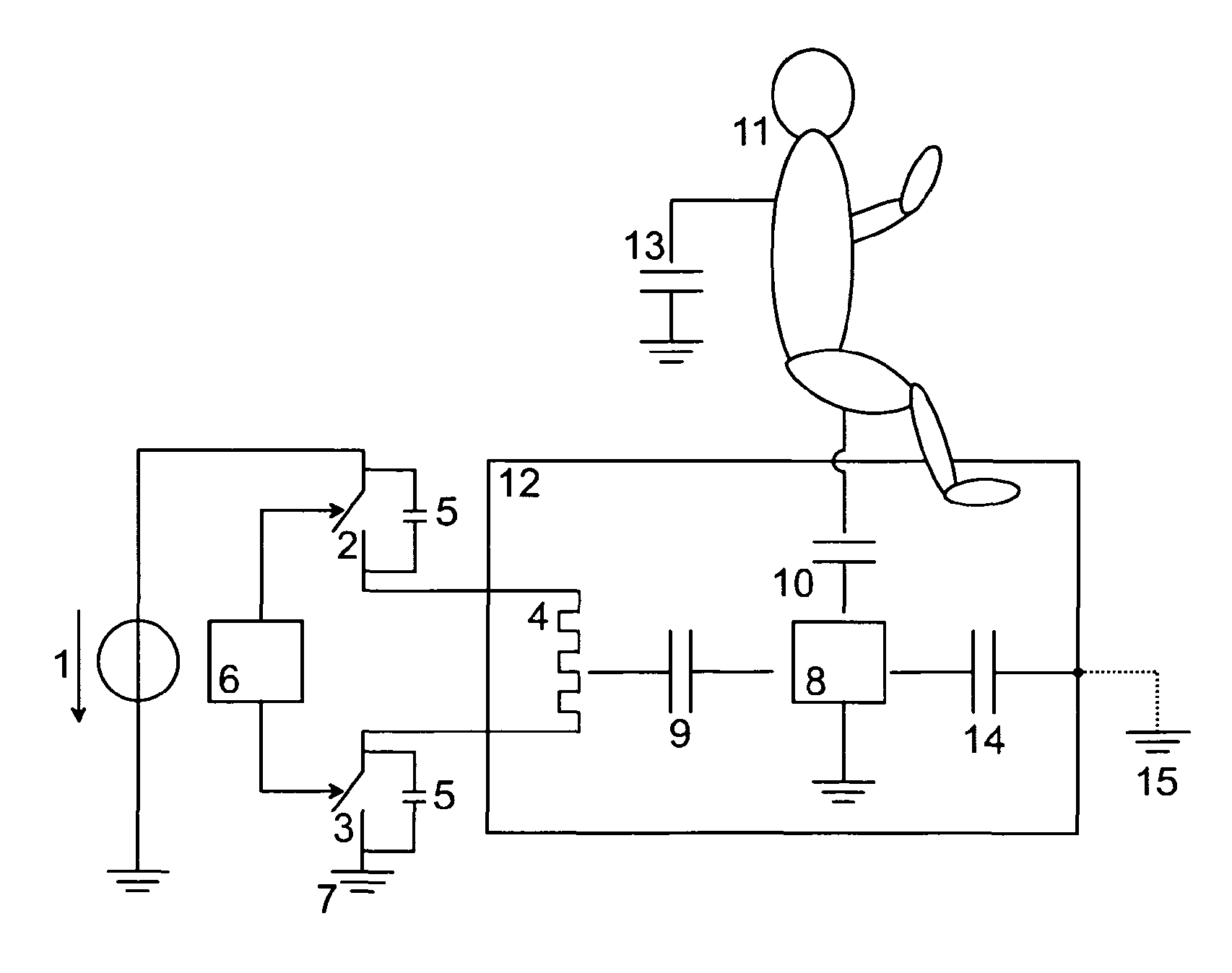

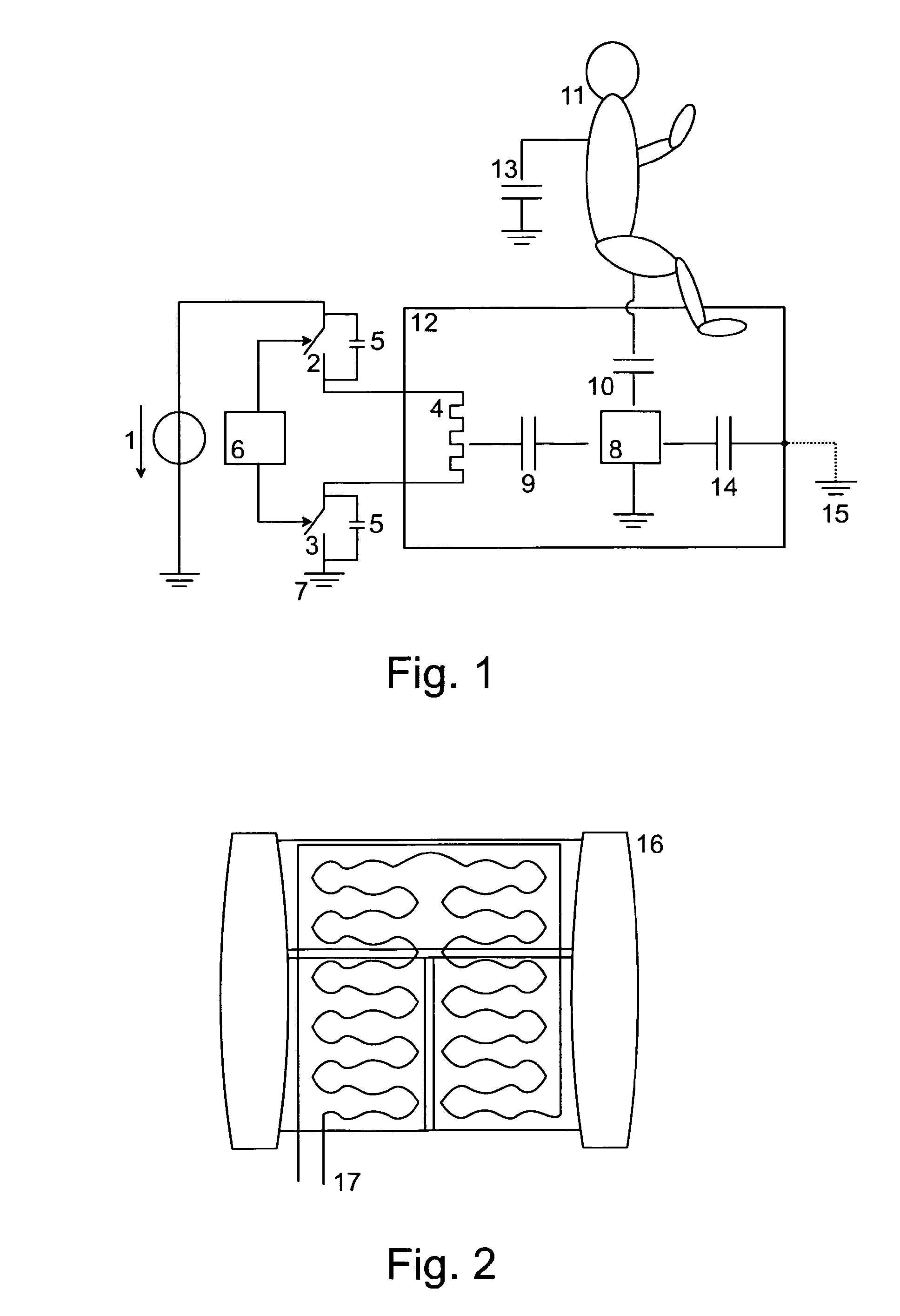

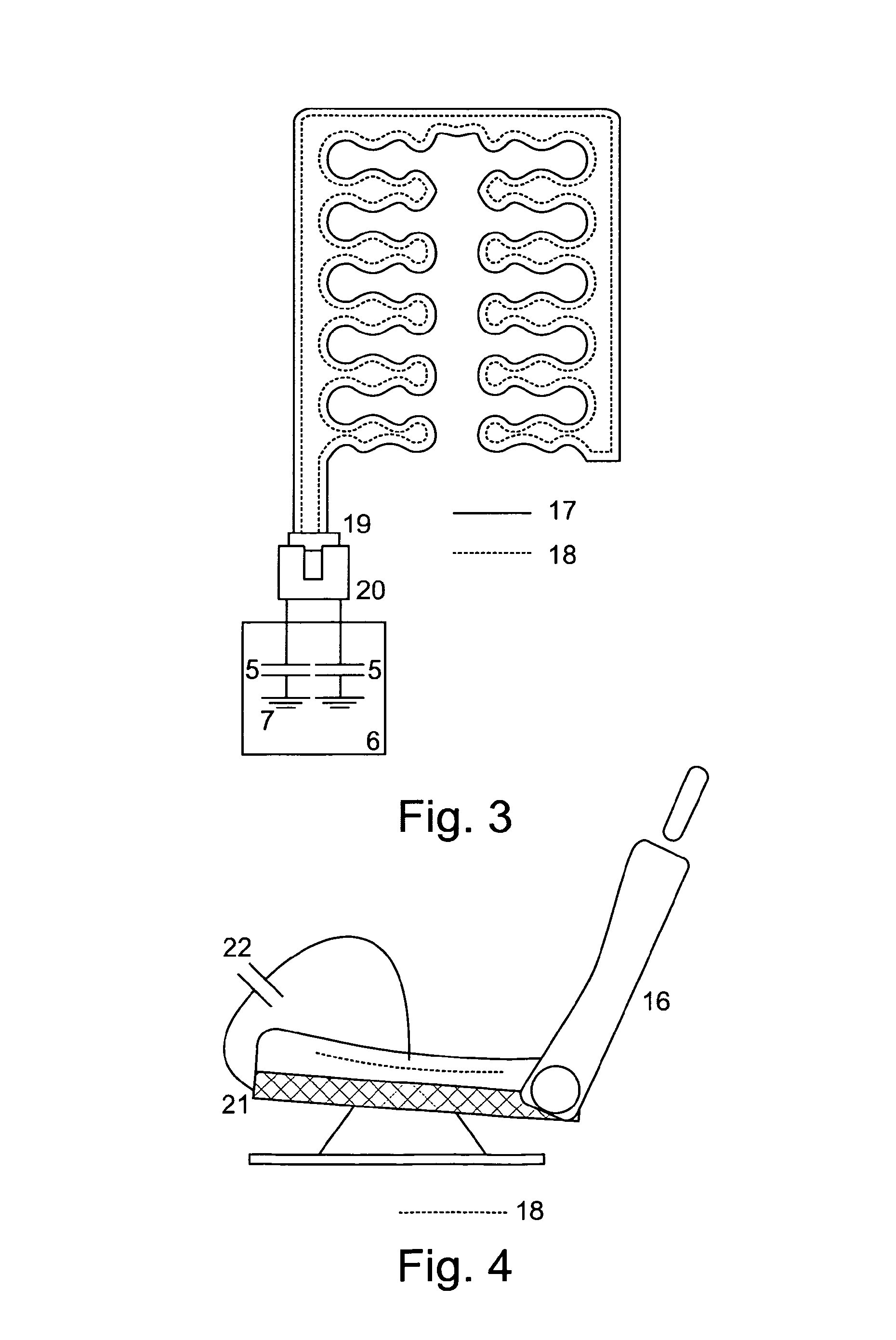

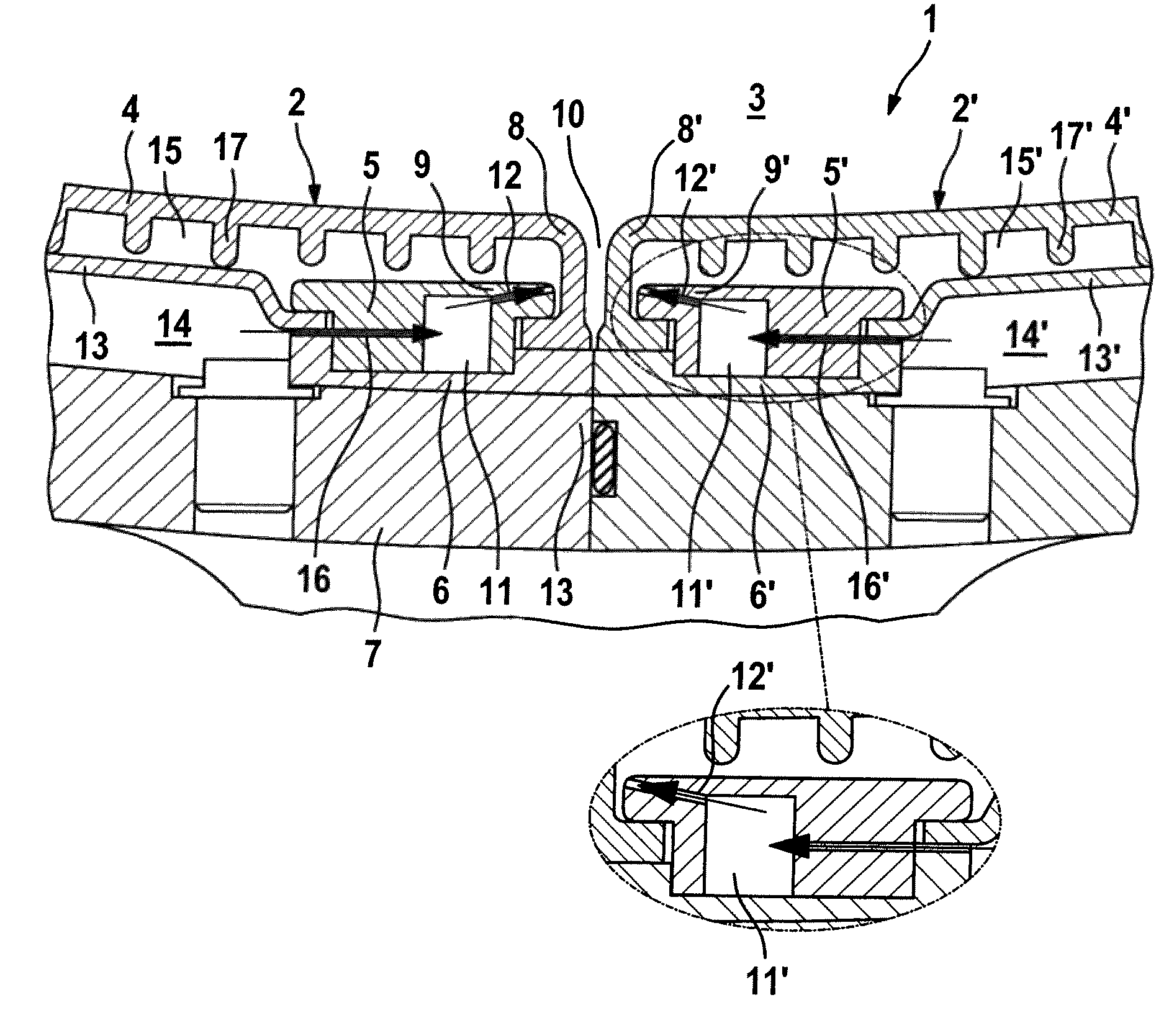

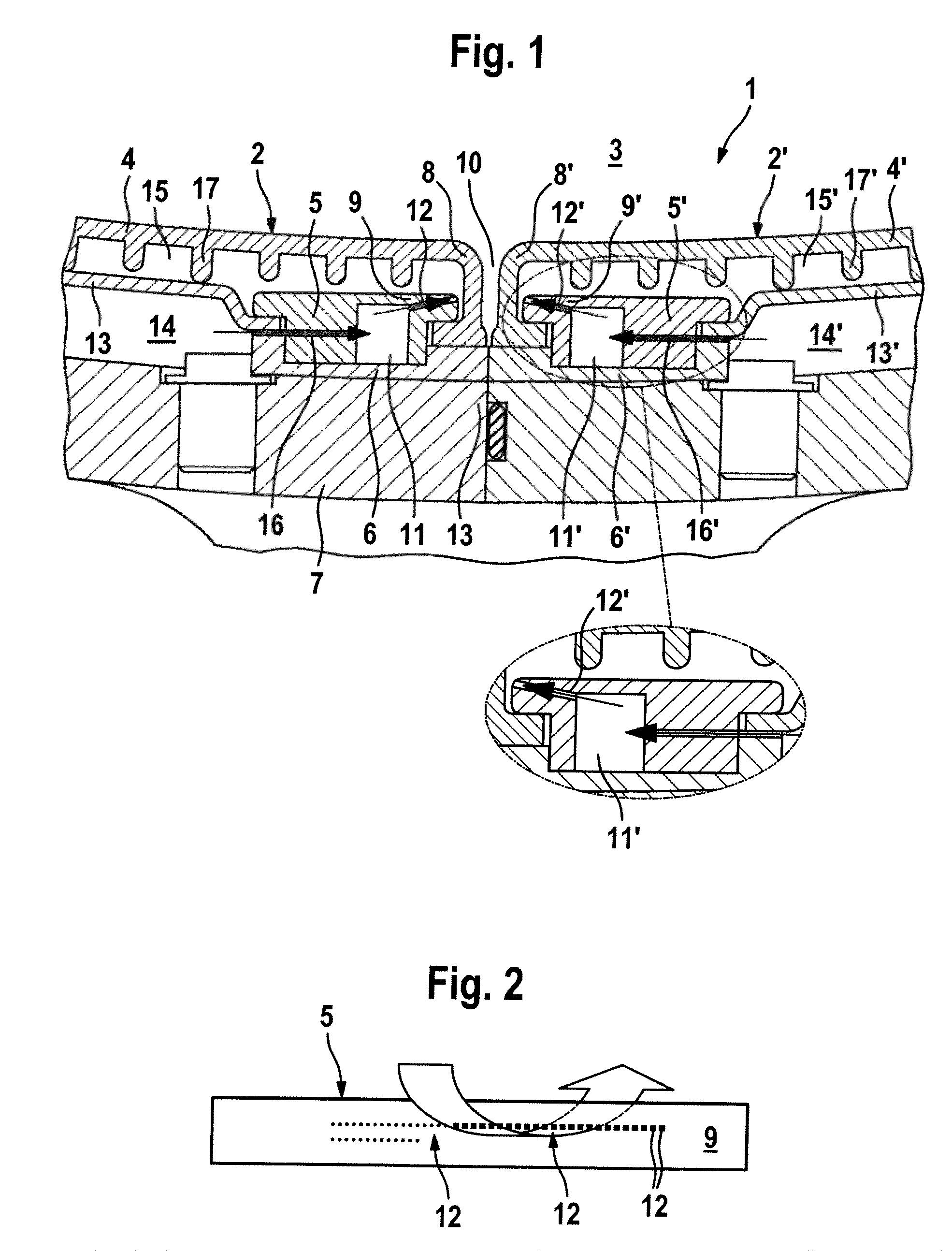

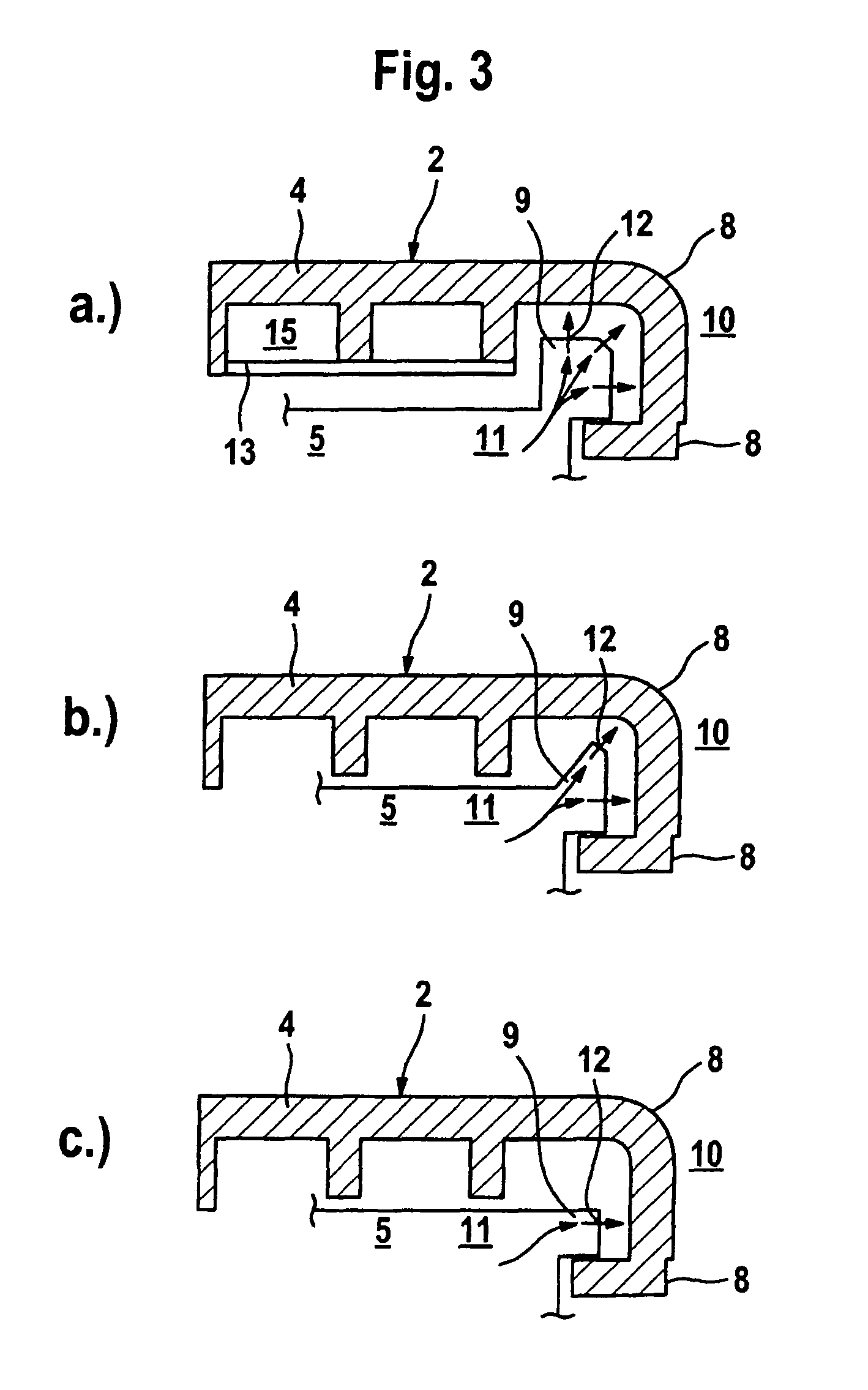

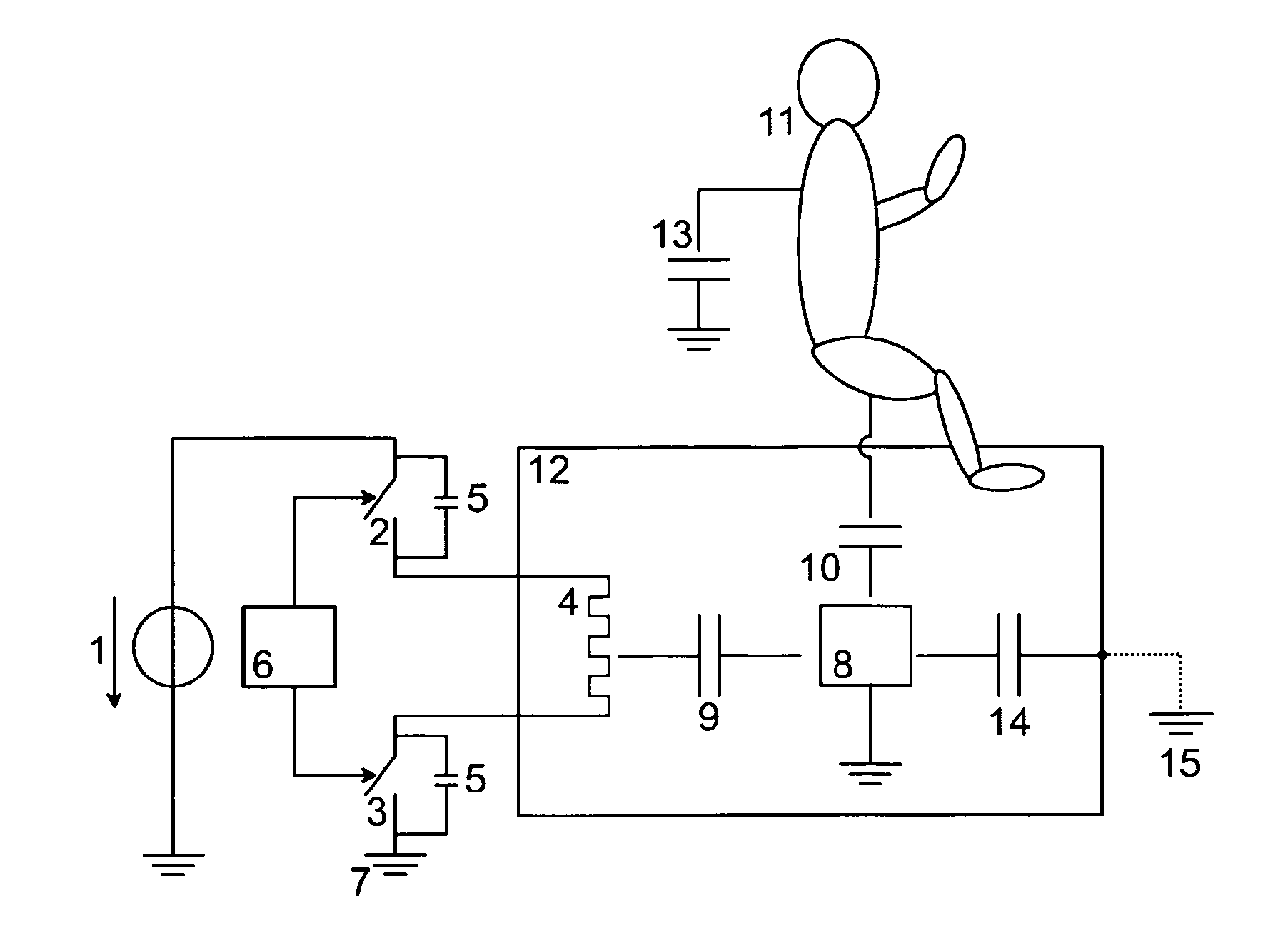

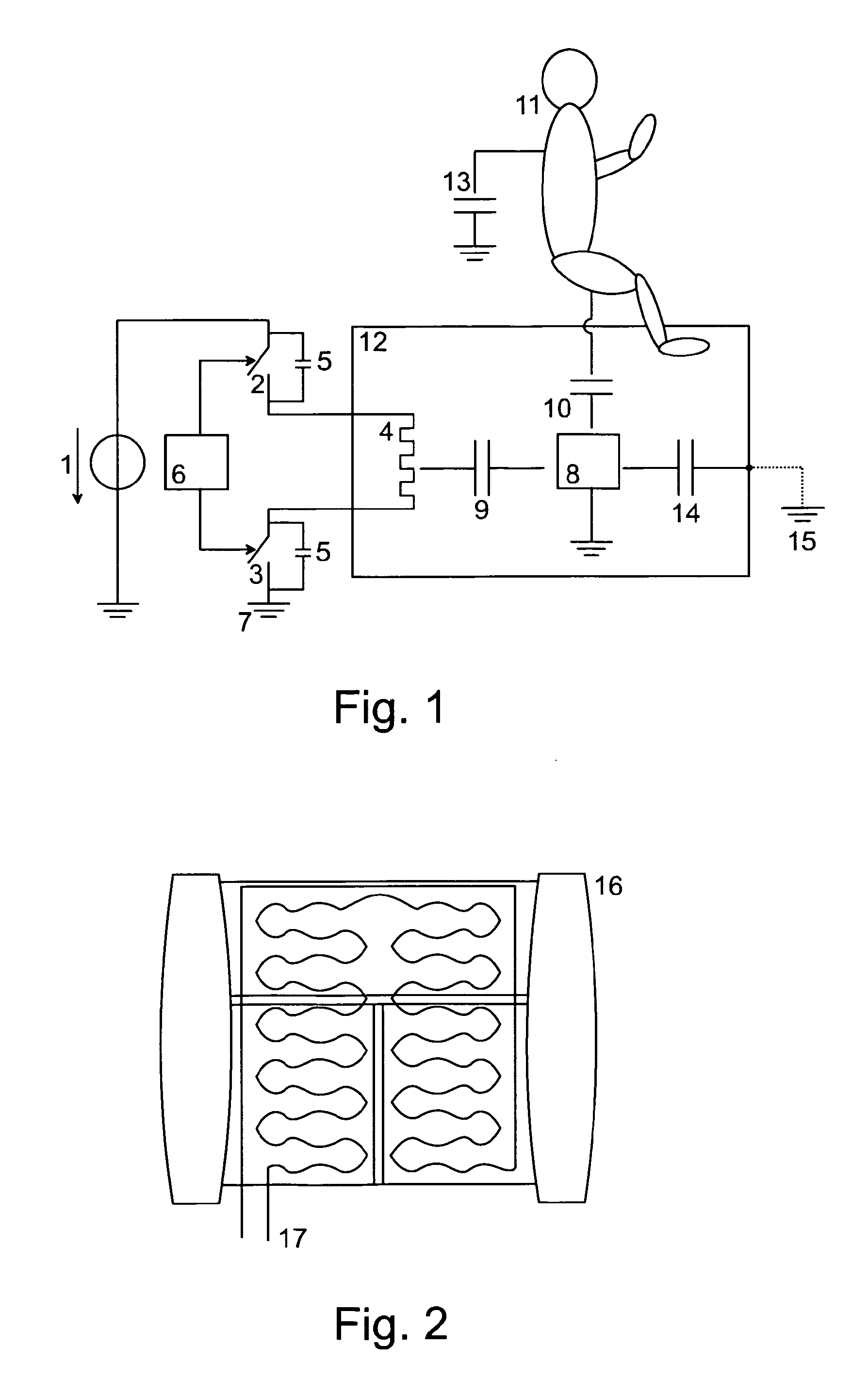

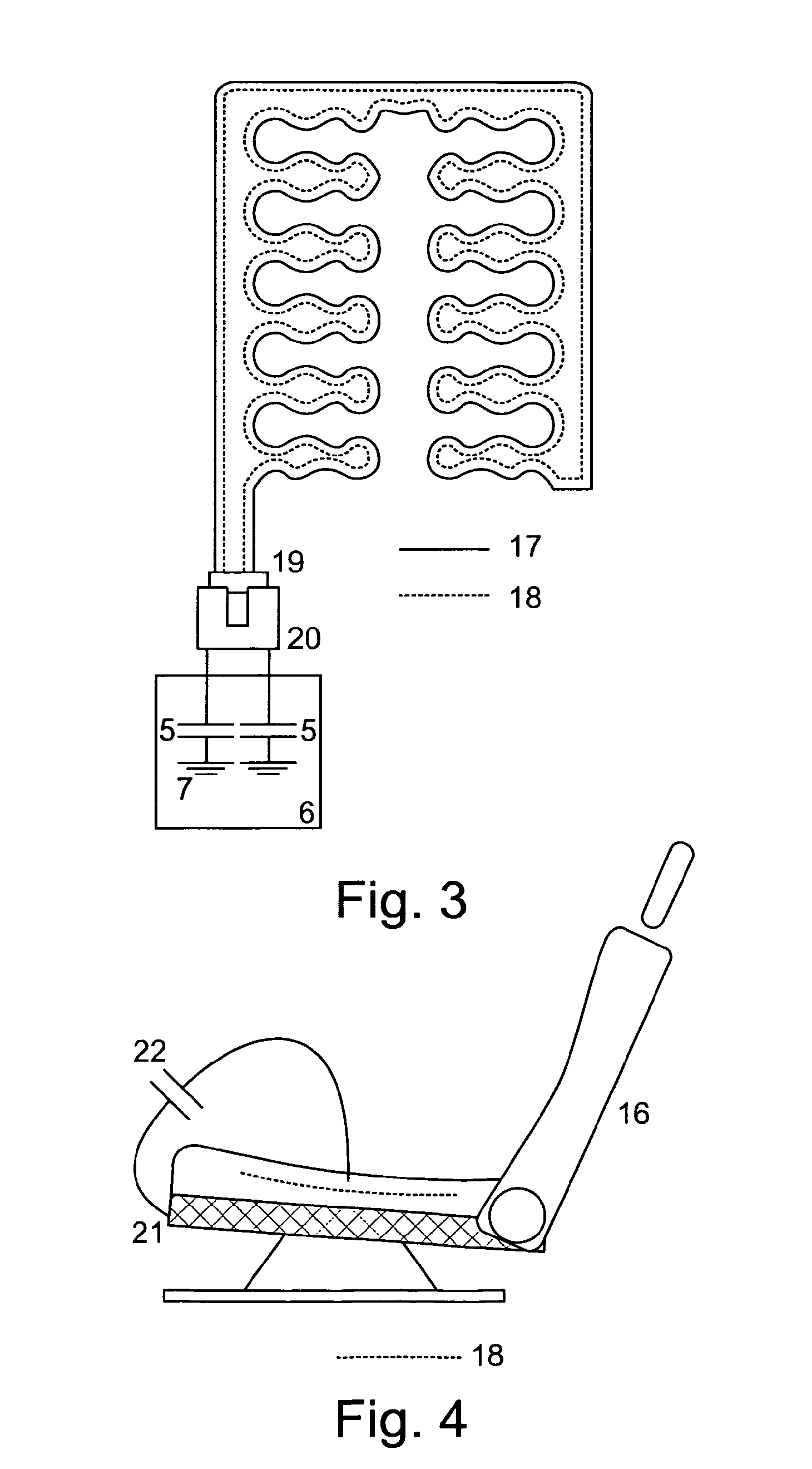

Capacitive occupant detection system

InactiveUS8957689B2Large capacityReduces thusSeat heating/ventillating devicesCapacitance measurementsElectrical conductorEngineering

A capacitive occupant detection system comprises at least one antenna electrode to be arranged in a seat and an evaluation unit operatively coupled to said at least one antenna electrode, said evaluation unit being configured for applying, during operation, an alternating voltage signal to said antenna electrode and for detecting an amplitude and / or phase of a displacement current flowing from said antenna electrode towards ground. According to the invention said antenna electrode comprises an antenna electrode conductor and at least one dedicated ground electrode, said ground electrode being arranged at a predetermined distance of said antenna electrode conductor and extending along said antenna electrode conductor.

Owner:IEE INT ELECTRONICS & ENG SA

Combustion chamber of a combustion system

InactiveUS8122726B2Locally increased or decreased cooling of the edge regionAvoid damageBurnersContinuous combustion chamberCombustion systemCombustion chamber

A combustion chamber of a combustion system has a combustion space, a support structure, a support element, and a heat shield. The heat shield has at least two segments, and each segment includes a liner element facing the combustion space and has an edge region, a gap communicating with the combustion space being formed between edge regions of adjacent segments, and a retaining device. The retaining device fixes the respective liner element on the support structure via the support element and forms a flange region that fits over the edge region of the respective liner element. The retaining device forms a first cooling passage with the support element and has at least one through-opening in the flange region. A cooling gas flows through the through.opening from the first cooling passage to the edge region.

Owner:ANSALDO ENERGIA IP UK LTD

Capacitive occupant detection system

InactiveUS20130207676A1Reduced measurement dynamicSmall coupling between dimensionsVehicle seatsCapacitance measurementsElectrical conductorEngineering

A capacitive occupant detection system comprises at least one antenna electrode to be arranged in a seat and an evaluation unit operatively coupled to said at least one antenna electrode, said evaluation unit being configured for applying, during operation, an alternating voltage signal to said antenna electrode and for detecting an amplitude and / or phase of a displacement current flowing from said antenna electrode towards ground. According to the invention said antenna electrode comprises an antenna electrode conductor and at least one dedicated ground electrode, said ground electrode being arranged at a predetermined distance of said antenna electrode conductor and extending along said antenna electrode conductor.

Owner:IEE INT ELECTRONICS & ENG SA

Aluminum alloy material for manufacturing lead wire

The invention relates to an aluminum alloy material for manufacturing a lead wire. The aluminum alloy material comprises the following components in percentage by weight: 0.2%-0.8% of Fe, 0.01%-0.05% of Zr, 0.08%-2.5% of Si, 0.01%-0.35% of Mg, 0.02%-0.06% of Ni and the balance of aluminum and inevitable impurities.

Owner:吴高峰

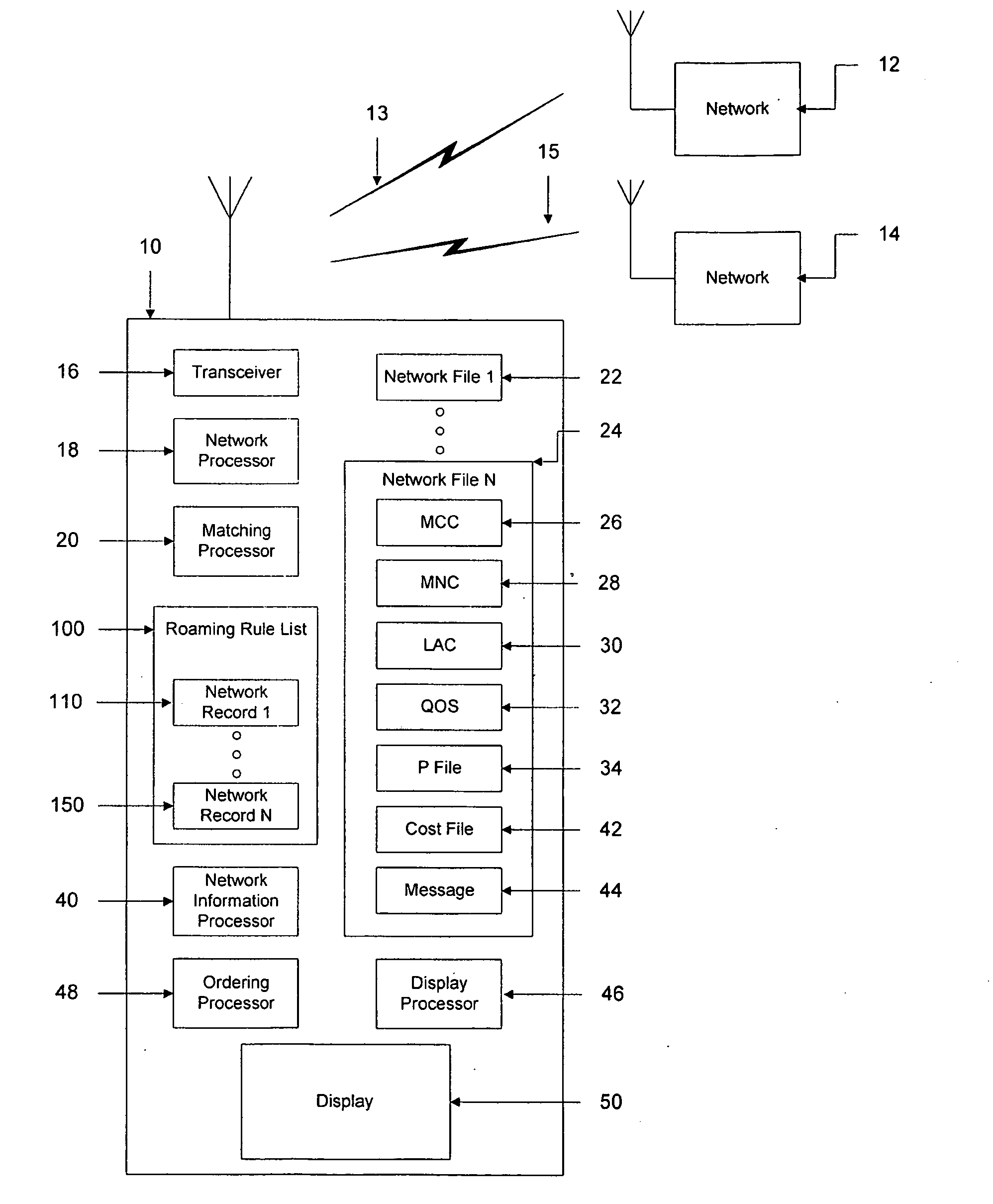

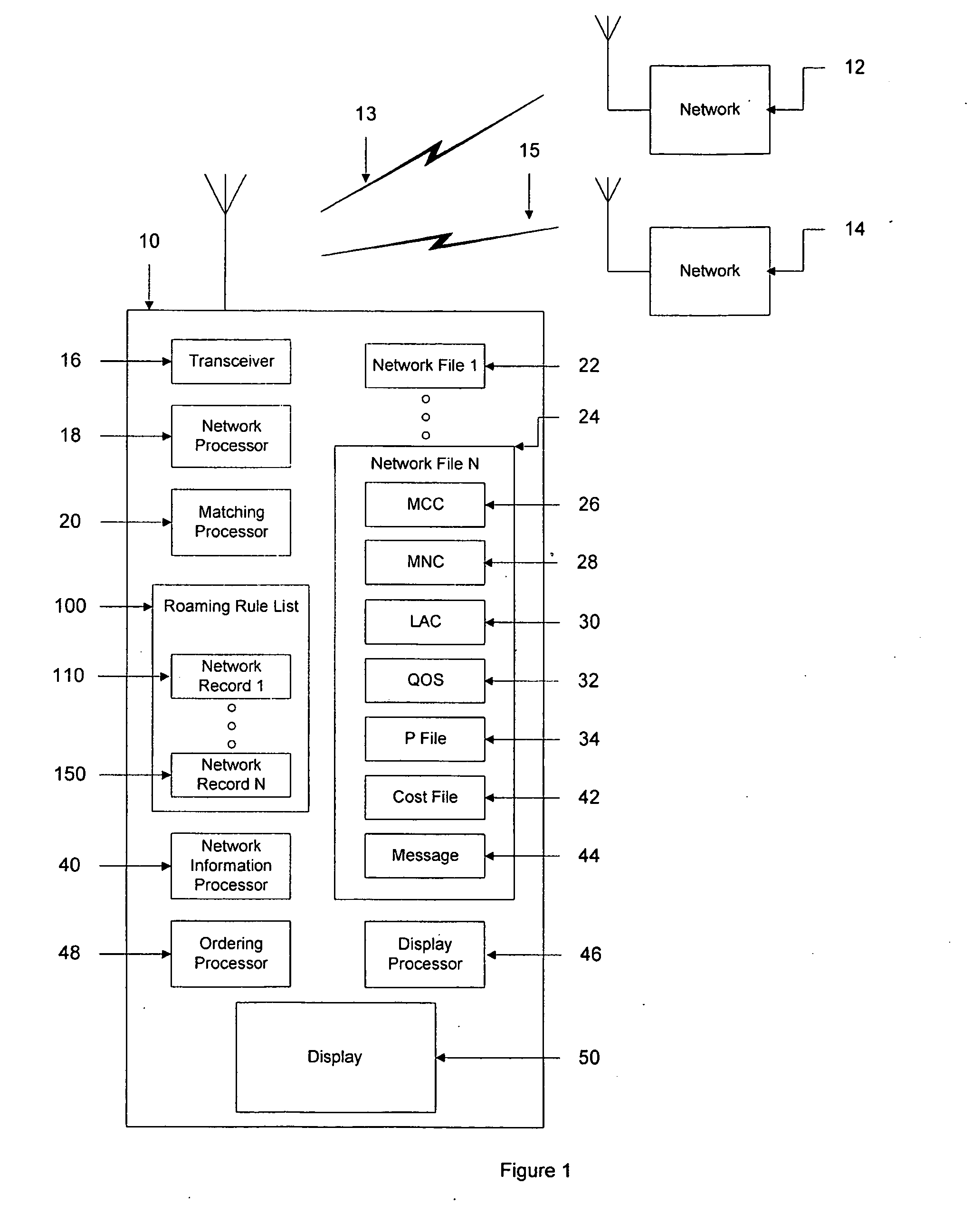

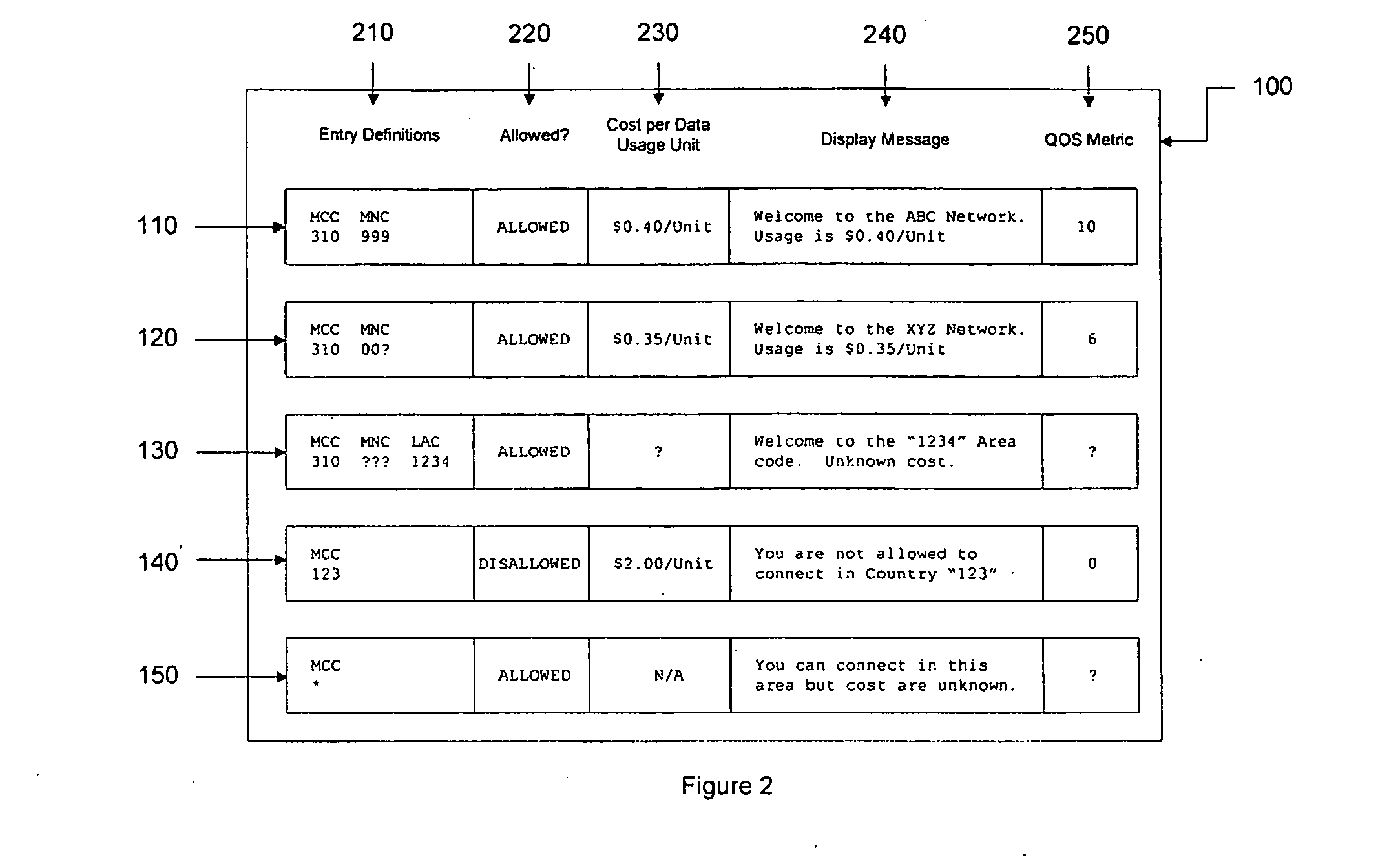

System for extended roaming messages

InactiveUS20090082014A1High performance linkLow costAssess restrictionRadio/inductive link selection arrangementsTelecommunicationsWireless network

A method and apparatus are provided for the display of extended roaming messages to a user of a WWAN device. The method includes the steps of retrieving a list of one or more available wireless networks, loading a roaming rule list which contains an ordered list of records, matching each of the available networks against said roaming rule list, selecting a roaming message for at least one match and, and displaying at least one roaming message to the end user.

Owner:SMITH MICRO SOFTWARE INC

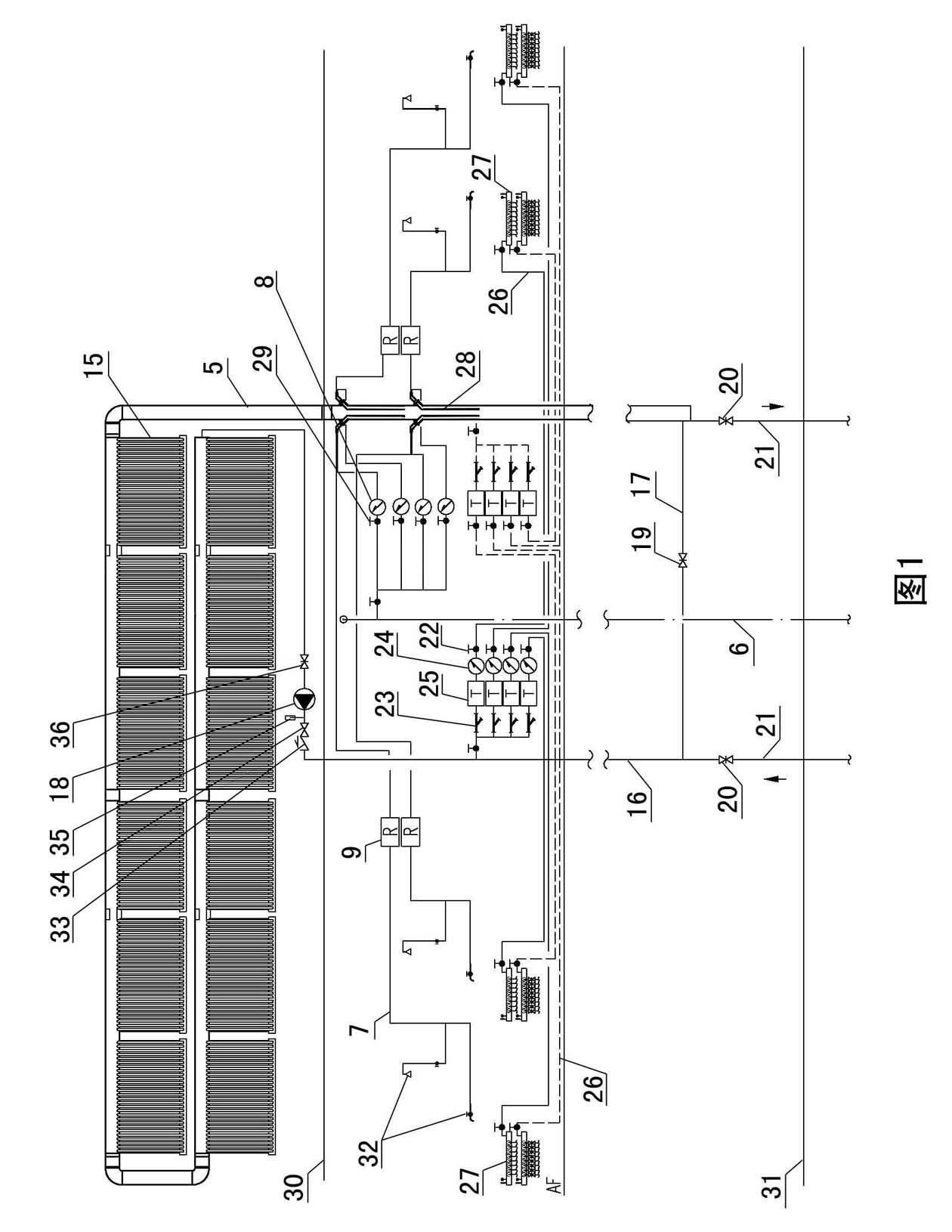

Solar comprehensive heating system capable of supplying heat and hot water integrally for house

ActiveCN102661615AAvoid pipe burstAvoid technical problems such as air blockageSolar heating energySolar heat devicesWater useCollector device

A solar comprehensive heating system capable of supplying heat and hot water integrally for a house comprises a vacuum tube solar collector, a collector water inlet pipe, a collector water outlet pipe, a heat storage pipeline, a heat exchanger, a domestic hot water pipe and a hot water use terminal. The collector water inlet pipe and the collector water outlet pipe are communicated with the solar collector. The collector water outlet pipe is communicated with the heat storage pipeline and is part of the heat storage pipeline. The heat storage pipeline is communicated with the collector water inlet pipe through connecting water pipes provides with switch valves. The collector water inlet pipe and the heat storage pipeline are connected with a low temperature radiation heating manifold through heating pipes so as to form water circulation. Water circulation between the vacuum tube solar collector and municipal heating hot water pipes are formed by the aid of the collector water inlet pipe and the heat storage pipeline. The solar comprehensive heating system is simple in structure, low in manufacture and maintenance cost, and low in maintenance difficulty.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

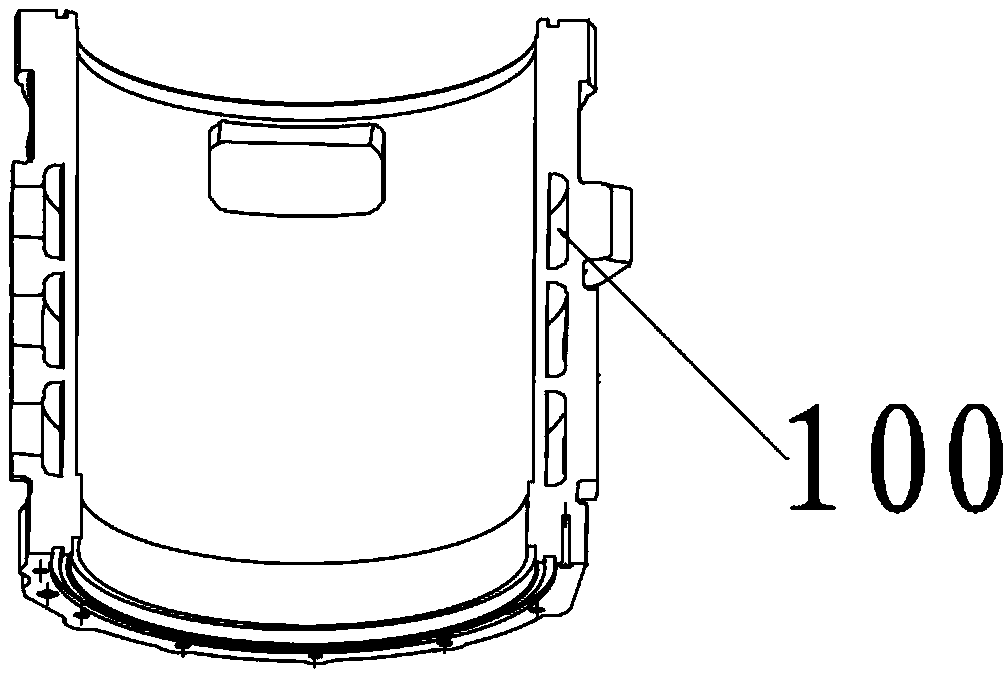

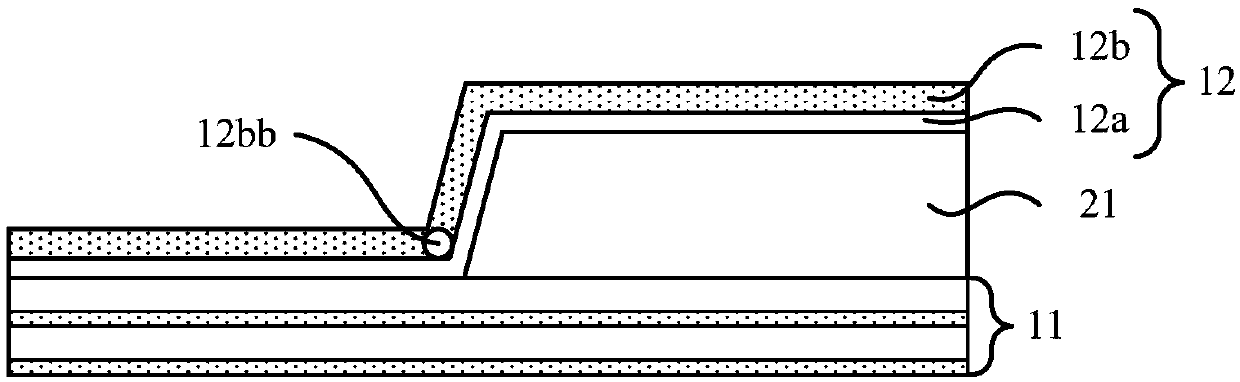

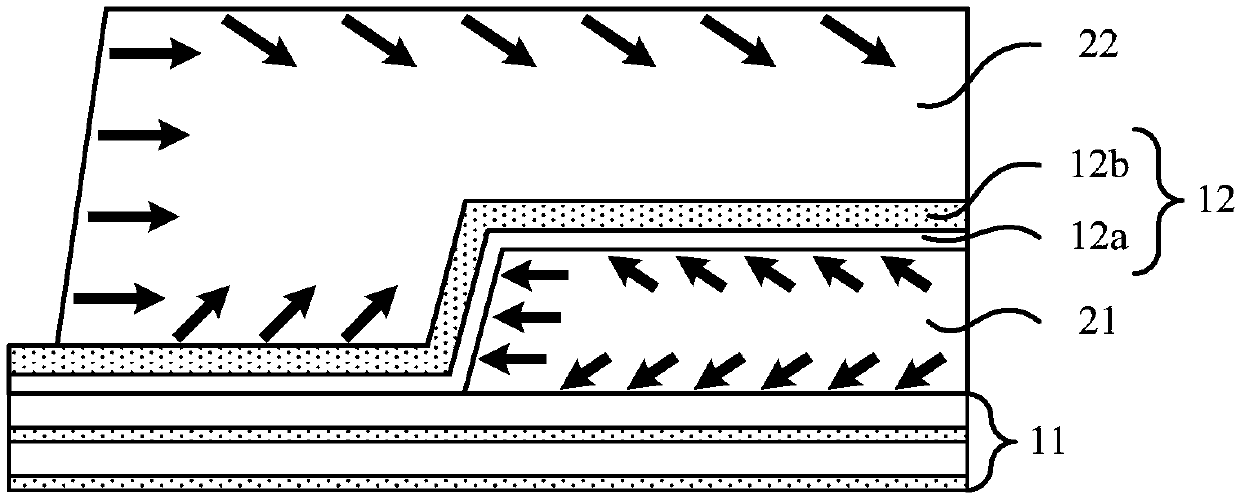

Motor shell of new-energy vehicle,sand core,mold and motor shell processing method

PendingCN108649735AImprove sealingSolve the leakFoundry mouldsManufacturing dynamo-electric machinesWater circulationEngineering

The invention provides a motor shell of a new-energy vehicle,a sand core,a mold and a motor shell processing method,and relates to the technical field of motor shell casting. The motor shell comprisesa cylindrical main body,and a water channel is formed in the side wall of the main body; the water channel comprises multiple annular passages and connecting passages,the multiple annular passages are arranged at intervals in the depth direction of the main body,the connecting passages are connected between any two adjacent annular passages,and the connecting passages are used for making any twoadjacent annular passages communicated. By using the integrated sand core,in the die-cast formation process,the integrated water channel can be formed,welding or other combination modes are avoided,therefore,the sealing property is improved,and the water leakage problem can be solved. The integrated water channel exists in the inner wall of the main body,one-step molding is only needed for processing,and the production cost is low; the shell water channel is good in sealing property; the water circulation cooling effect is good,and reliability is high.

Owner:KUNSHAN ZHONGYITE MACHINERY IND

Control panel for vehicle air conditioner

InactiveUS7414206B2Easy to operateQuick changeStampsVehicle heating/cooling devicesDisplay deviceEngineering

Owner:CALSONIC KANSEI CORP

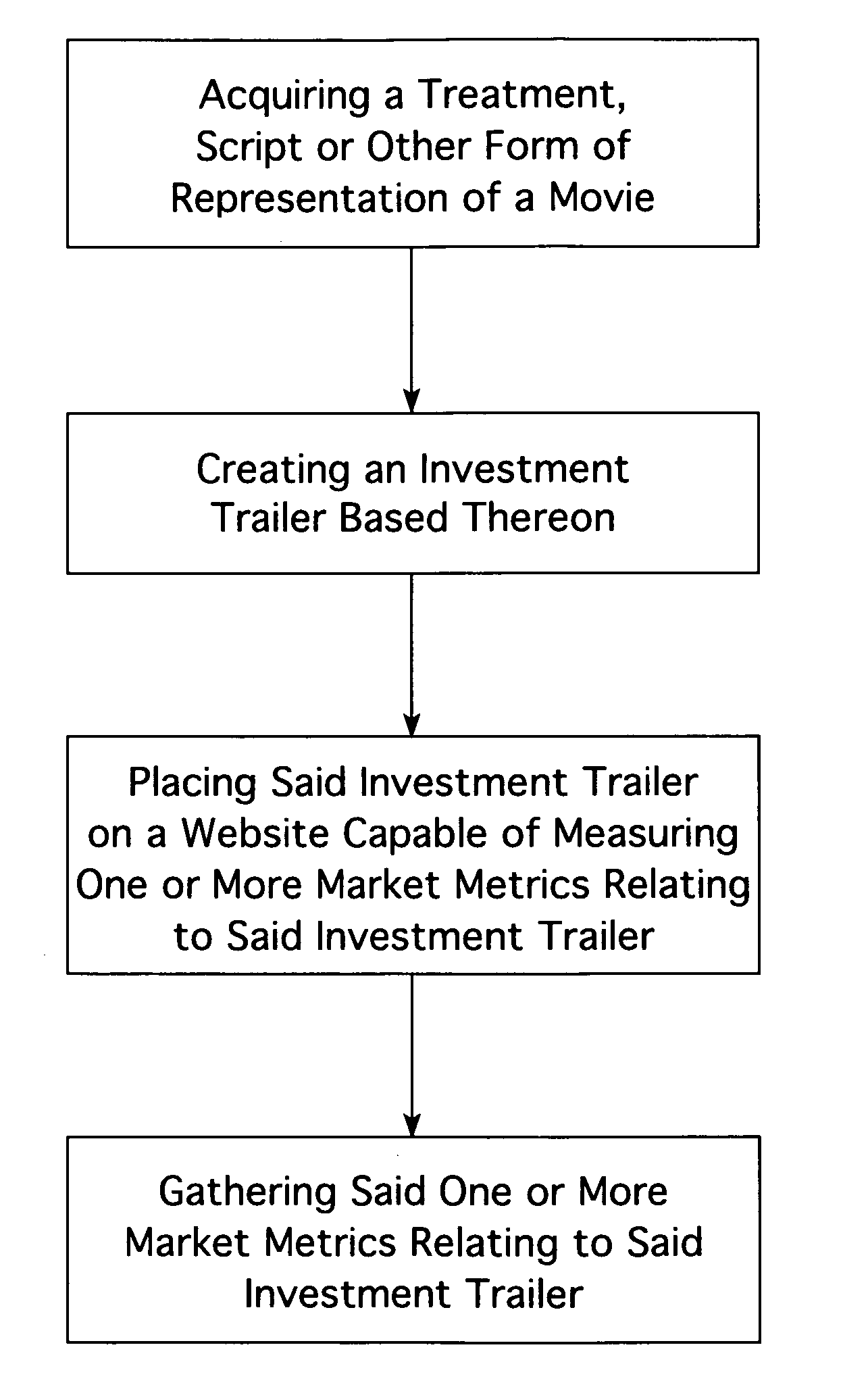

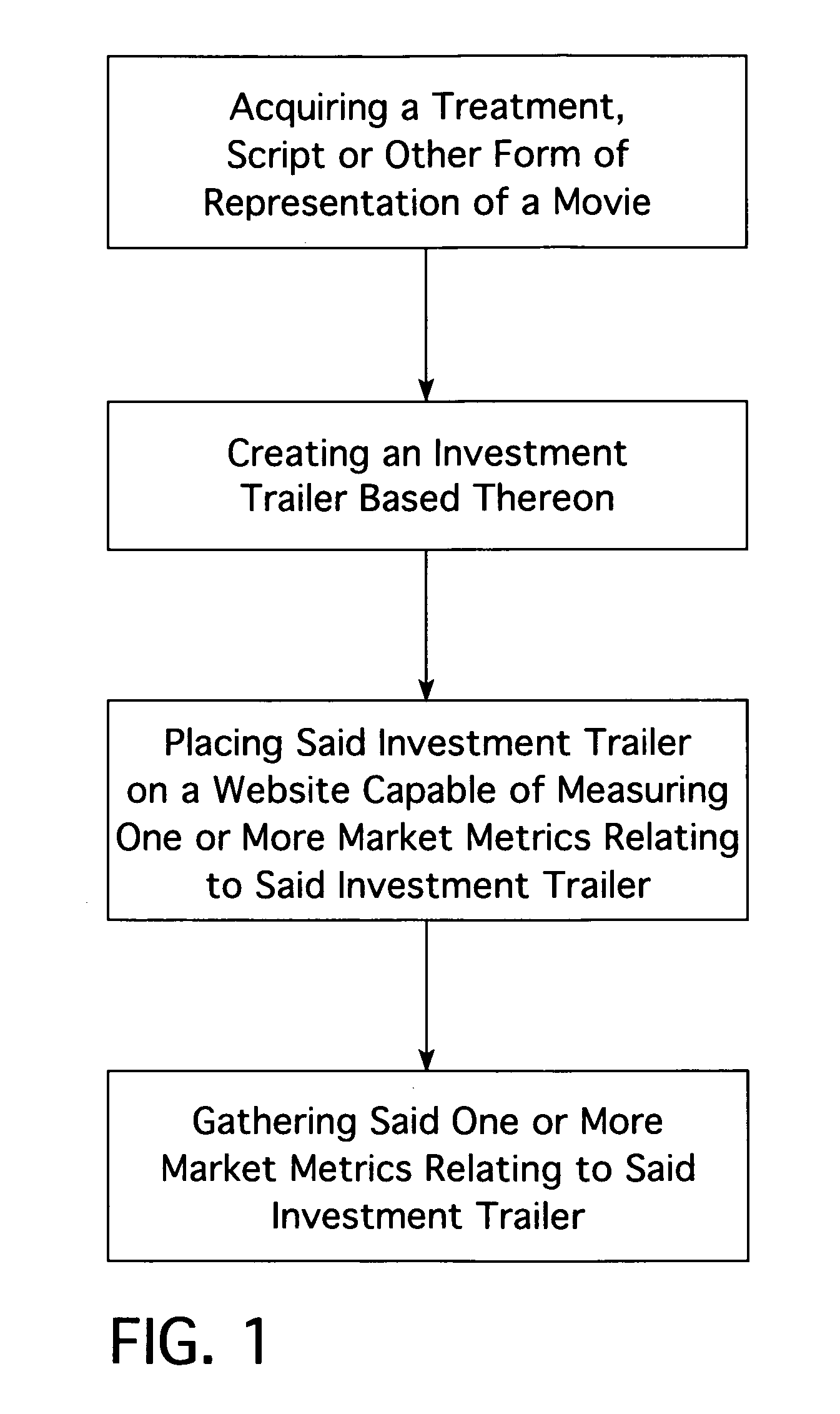

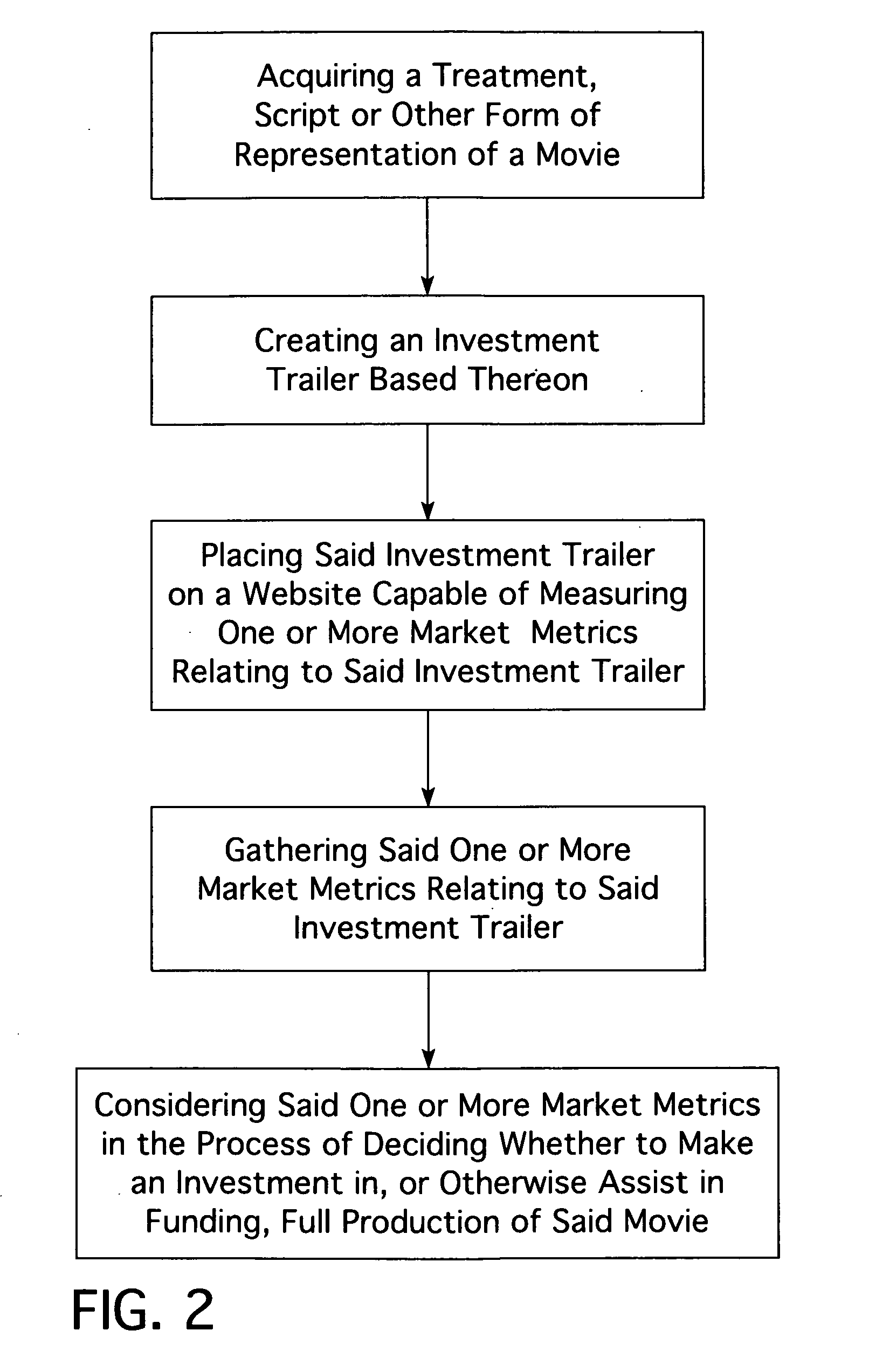

Method for quantifying the relative value of movies prior to spending substantial amounts of money on full production thereof

InactiveUS20110087518A1Accurate captureEfficient investmentFinanceMarket data gatheringThe InternetEngineering

This invention relates to methods for quantifying the relative value of a movie concept, script, treatment or other representation of a movie prior to spending substantial amounts of money on fully producing it. The decisions to make major investments in large budget movies and smaller investments in mid sized budget movies, and even to make what might be considered comparatively minor investments, such as by indie filmmakers—although not necessarily minor investments to the indie filmmakers—in what are small budget movies, are greatly enhanced by a method that allows for some quantitative feedback on the potential for success of a movie before the bulk of the investment in its full production is made. The present invention provides such methods, and does so through the use of “investment trailers,” or “ITs”, a movie trailer that is different from ones used to promote a movie after it has been produced. The purpose of ITs is to create a vehicle, at a very low price, that can be placed on the internet for viewing. By monitoring various market metrics, such as the numbers of views for each IT, and collecting data on the market performance of those movies that are ultimately produced and distributed, one can create a basis for comparison with future movies to allow for data-supported predictions about the potential for success of a given movie, and do so very fast, very inexpensively and reasonably accurately.

Owner:SCHERMER PHILLIP FALLER

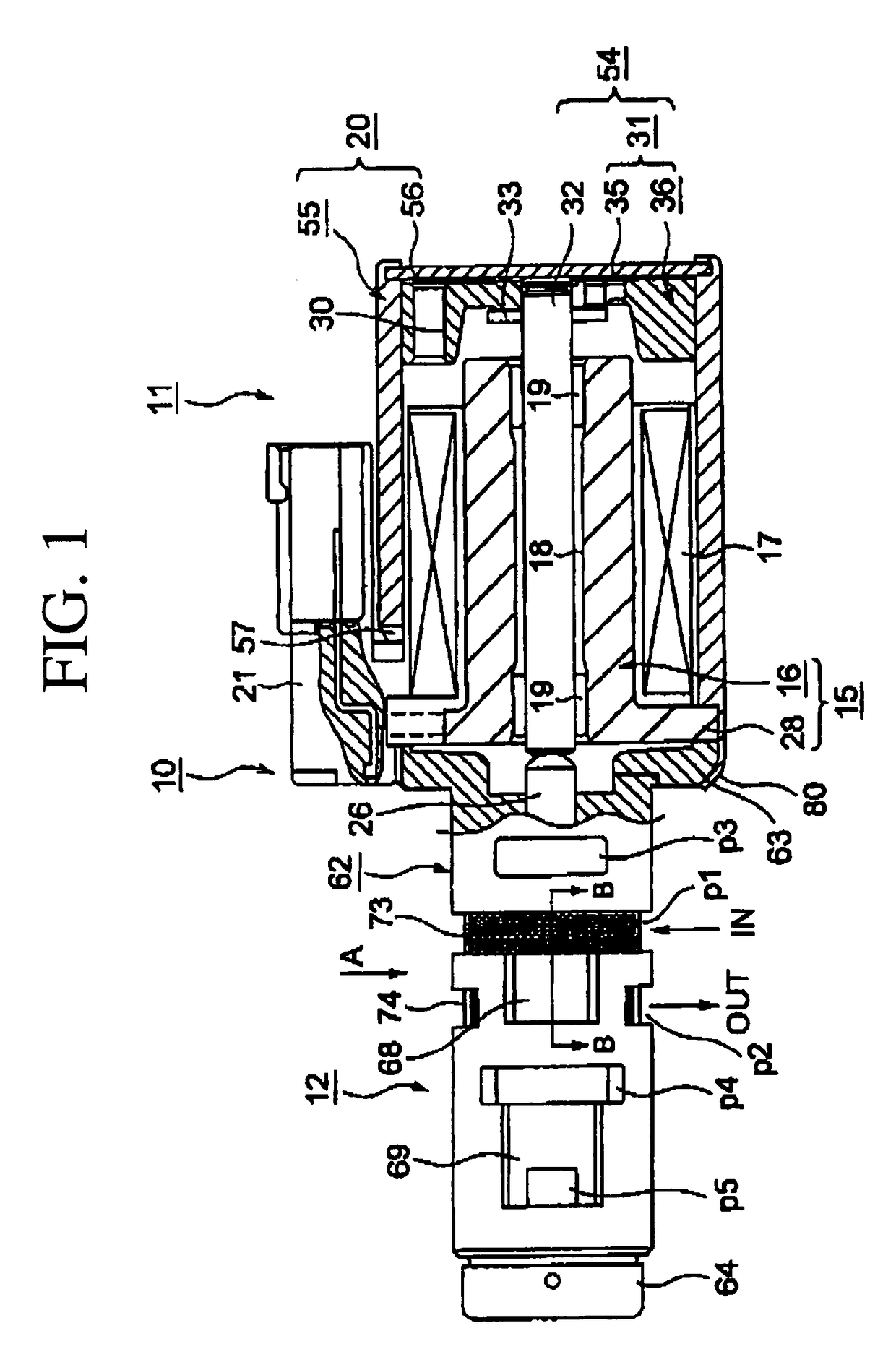

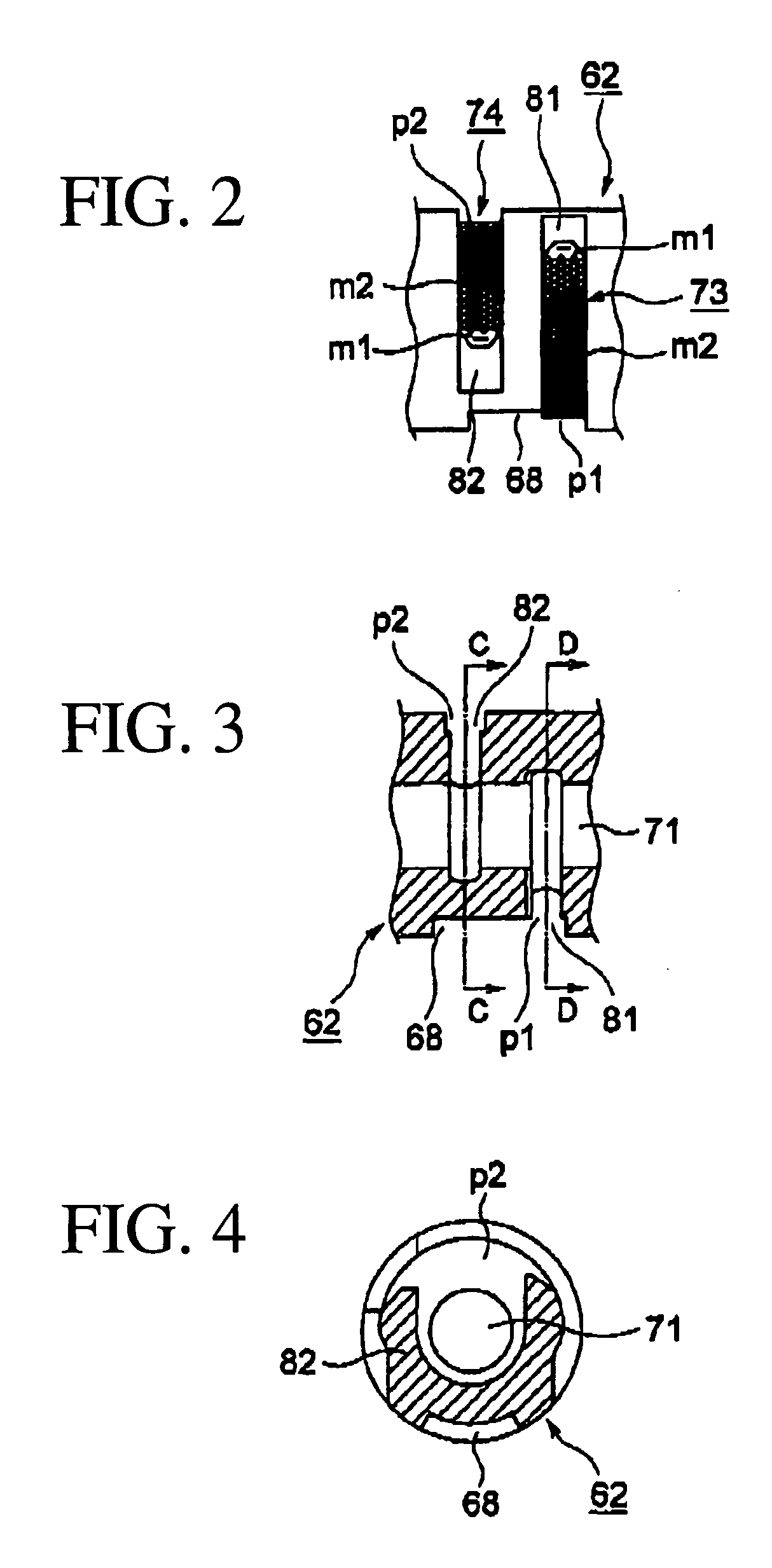

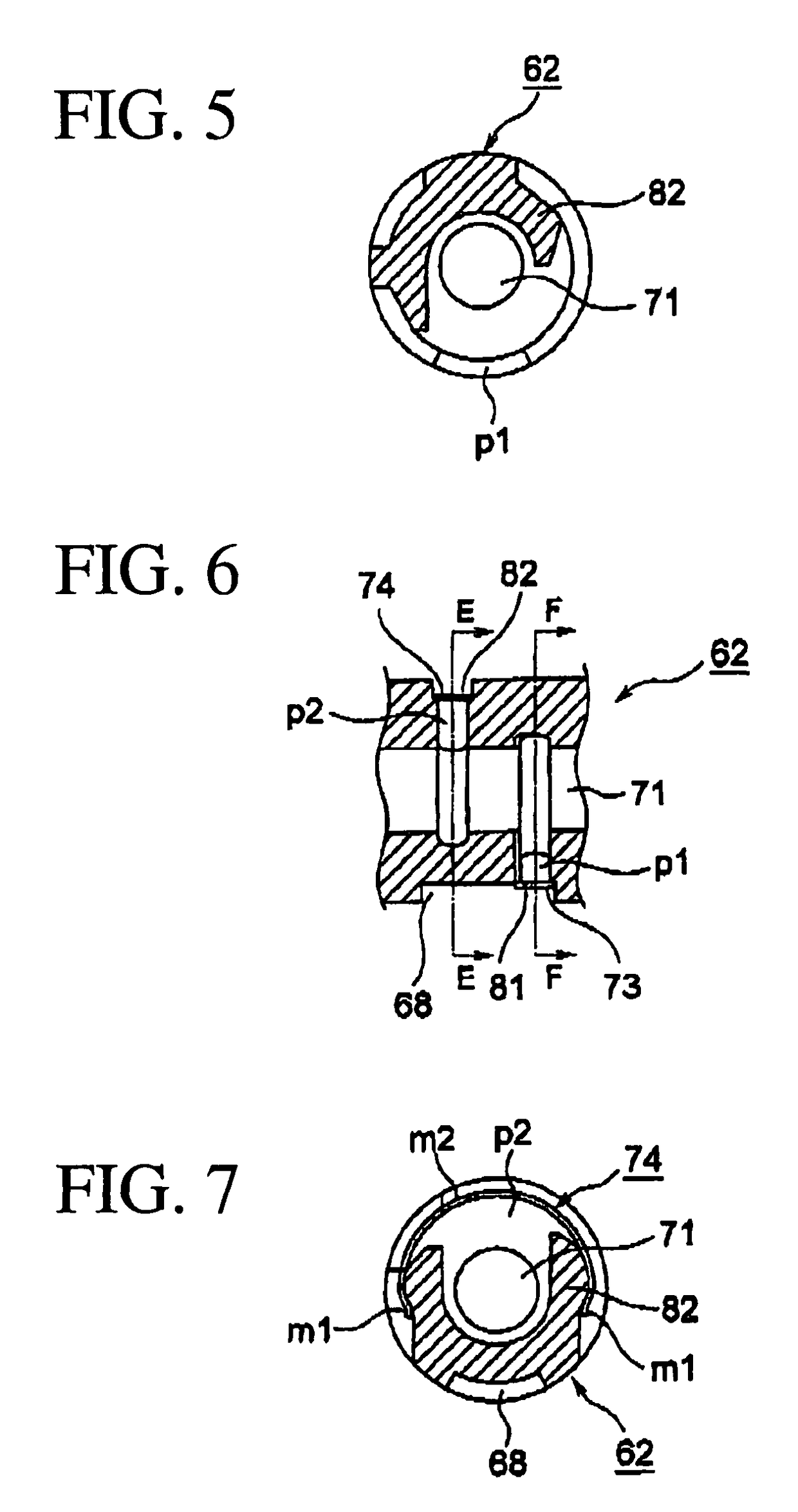

Strainer and control valve

InactiveUS7905248B2Improve sealingReduced specificationsOperating means/releasing devices for valvesSettling tanks feed/dischargeForeign matterControl valves

The present invention prevents foreign matter from infiltrating into a control valve and enables reduction in the cost of the valve. A strainer is mounted on an attachment portion of a valve sleeve, and a valve spool is disposed in the sleeve so as to be free to slidably advance and retreat. The strainer includes engagement portions m1 contacting first contact sites ε1 and ε2 formed on the attachment portion and a contact portion contacting second contact sites ε3 and ε4 formed on the attachment portion. Since the strainer includes the engagement portions m1 in contact with the first contact sites ε1 and ε2 and the contact portion in contact with the second contact sites ε3 and ε4, the sleeve has sufficient sealing contact with the strainer 73 at the first and second contact sites ε1 to ε4.

Owner:AISIN AW CO LTD

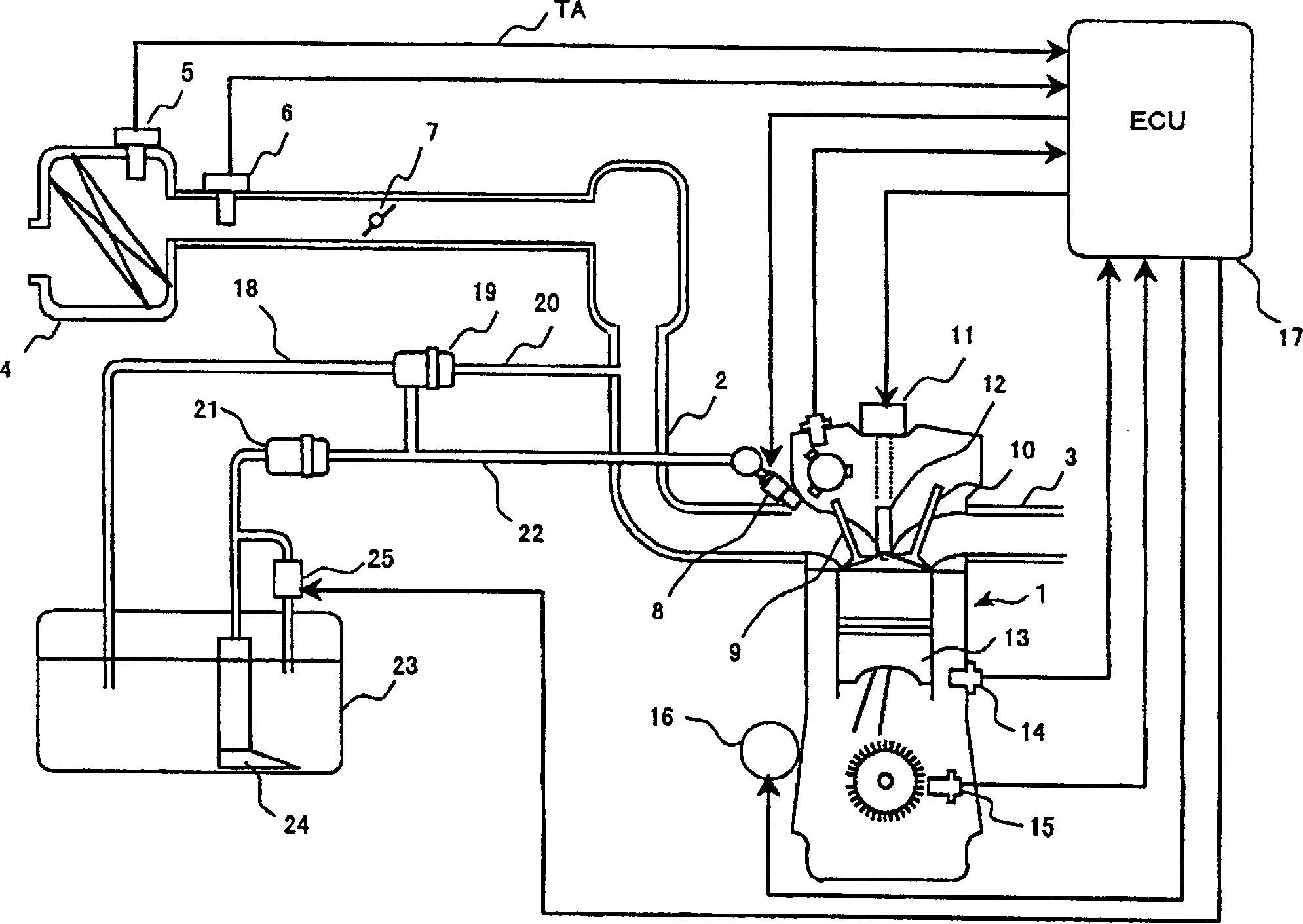

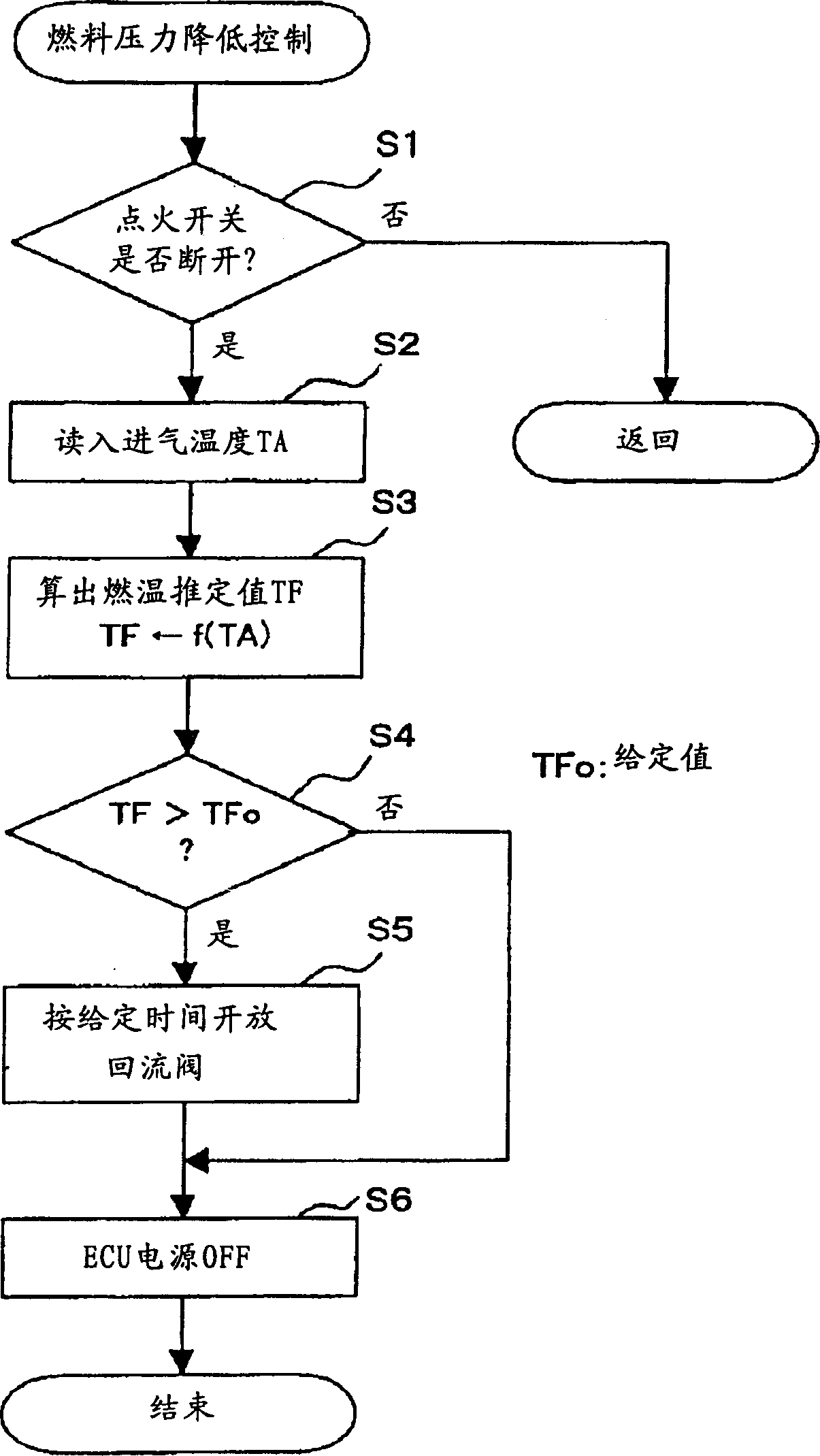

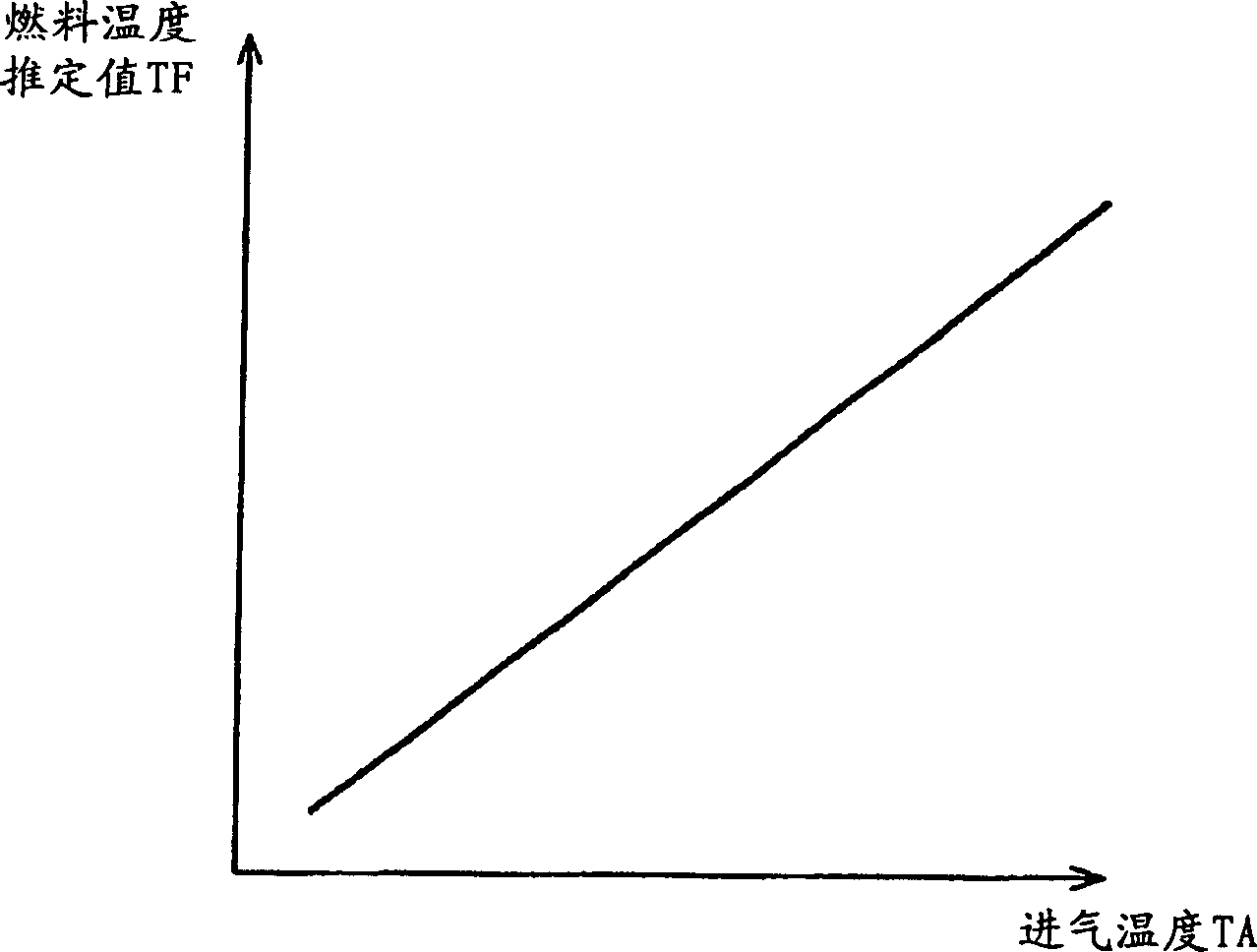

Fuel jetting controller for internal combustion engine

InactiveCN1384278APrevent leakageHigh cost of controlElectrical controlFuel injection apparatusFuel tankInternal combustion engine

There can be obtained a fuel injection control device for an internal combustion engine capable of reliably preventing fuel from leaking from an injection nozzle while the engine is stopped. Contains various sensors (5), (6), (14), (15) for detecting operating conditions, fuel pump (24) and fuel piping (22) for supplying fuel in the fuel tank (23), and nozzles for injecting fuel (8) An engine stop detecting device (17) for detecting a stopped state of the internal combustion engine (1), a fuel temperature estimating device (17) for estimating a fuel temperature, a fuel pressure reducing device (17) for reducing a fuel pressure, the fuel pressure reducing device is After the internal combustion engine stops, the fuel pressure in the fuel pipe (22) is reduced according to the fuel temperature estimation value of the fuel temperature estimation device.

Owner:MITSUBISHI ELECTRIC CORP

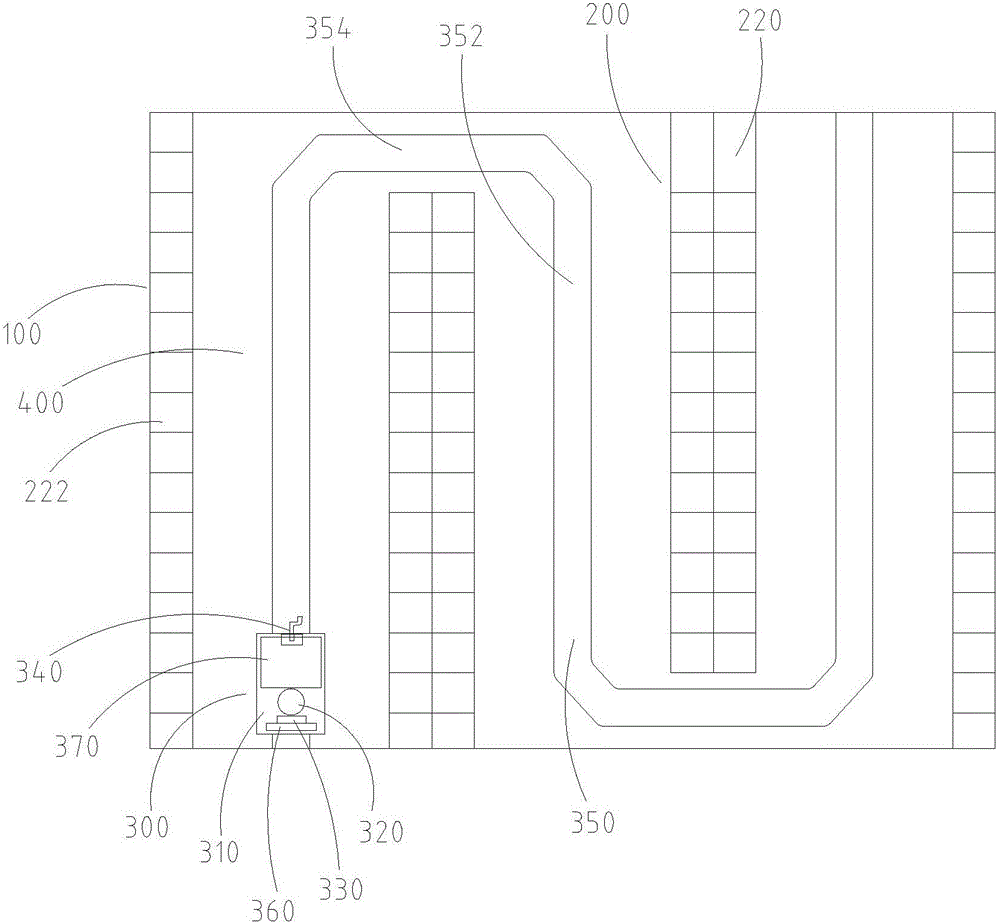

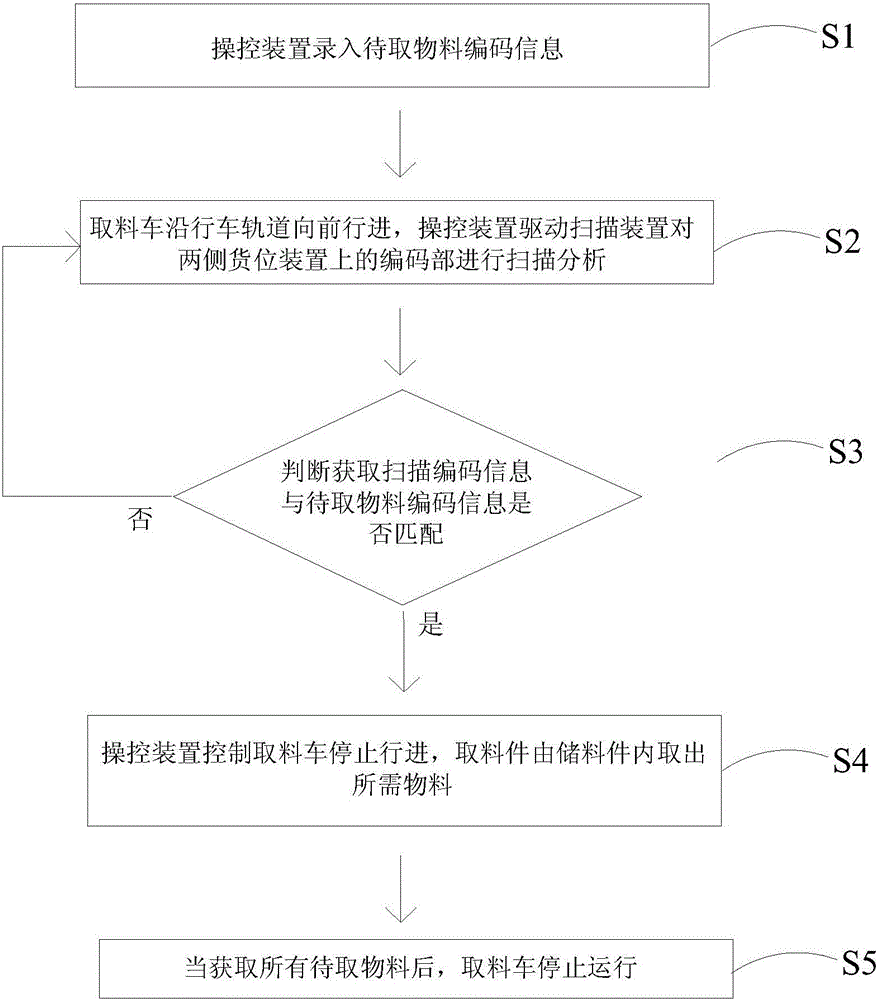

Material access system and control method

InactiveCN105858036AImprove production capacity and cost controlImprove work efficiencyStorage devicesSystem structureEngineering

The invention discloses a material access system and a control method, comprising a shelf system and a material retrieving system arranged in a warehouse, the shelf system including a cargo location controller, and a storage device connected to the cargo location controller , the storage device is provided with an encoding unit, and the reclaiming system includes a reclaiming car, a retrieving piece arranged on the reclaiming car, and a control device arranged on the reclaiming car and electrically connected and a scanning device, the manipulation device is electrically connected to the cargo position controller, and the scanning device cooperates with the coding part. Through the above-mentioned material access system, the production capacity and cost control of the production workshop can be effectively improved and enhanced, the work efficiency is high, the system structure is simple and easy to operate.

Owner:GUANGZHOU WANON ELECTRIC & MACHINE

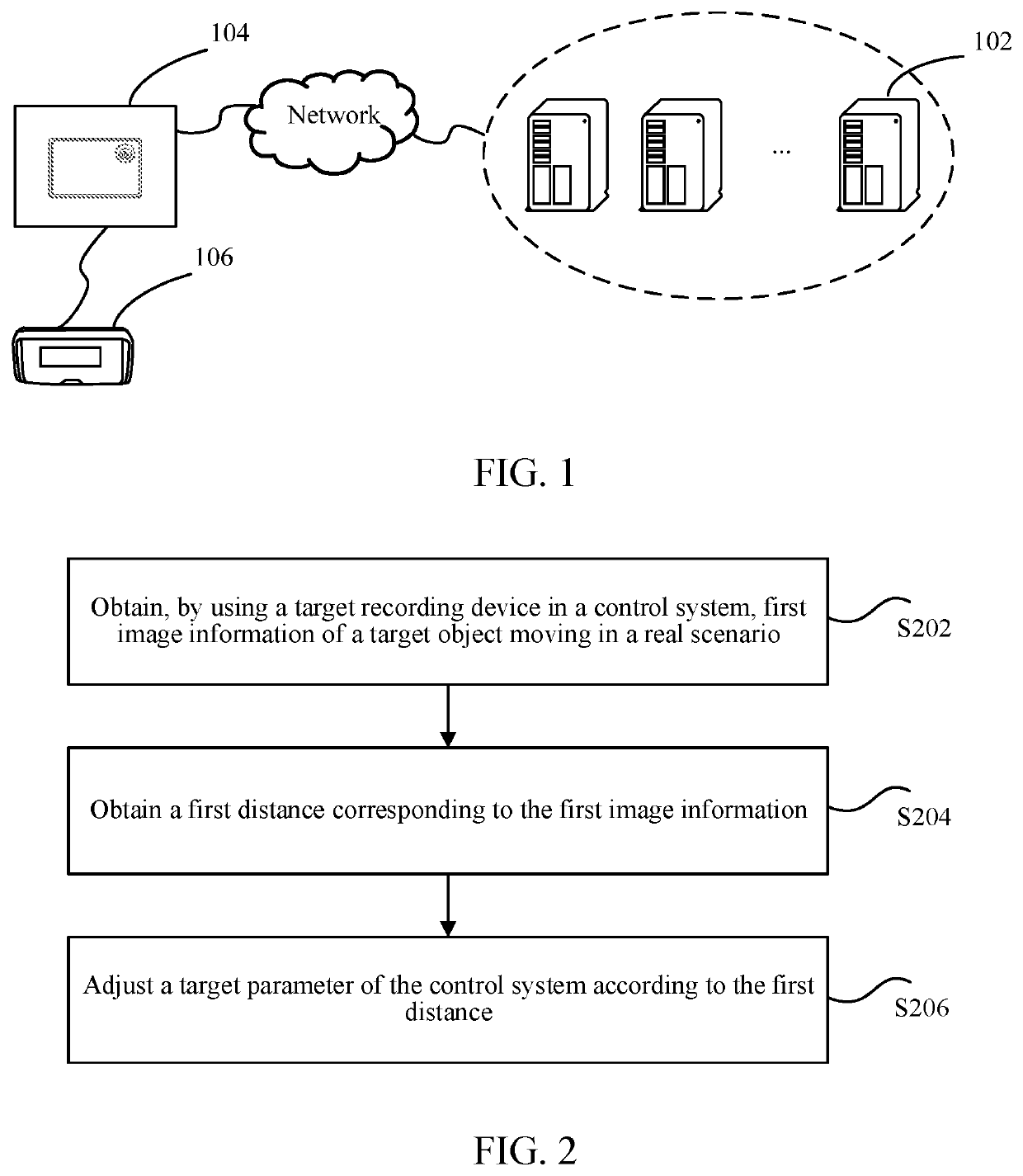

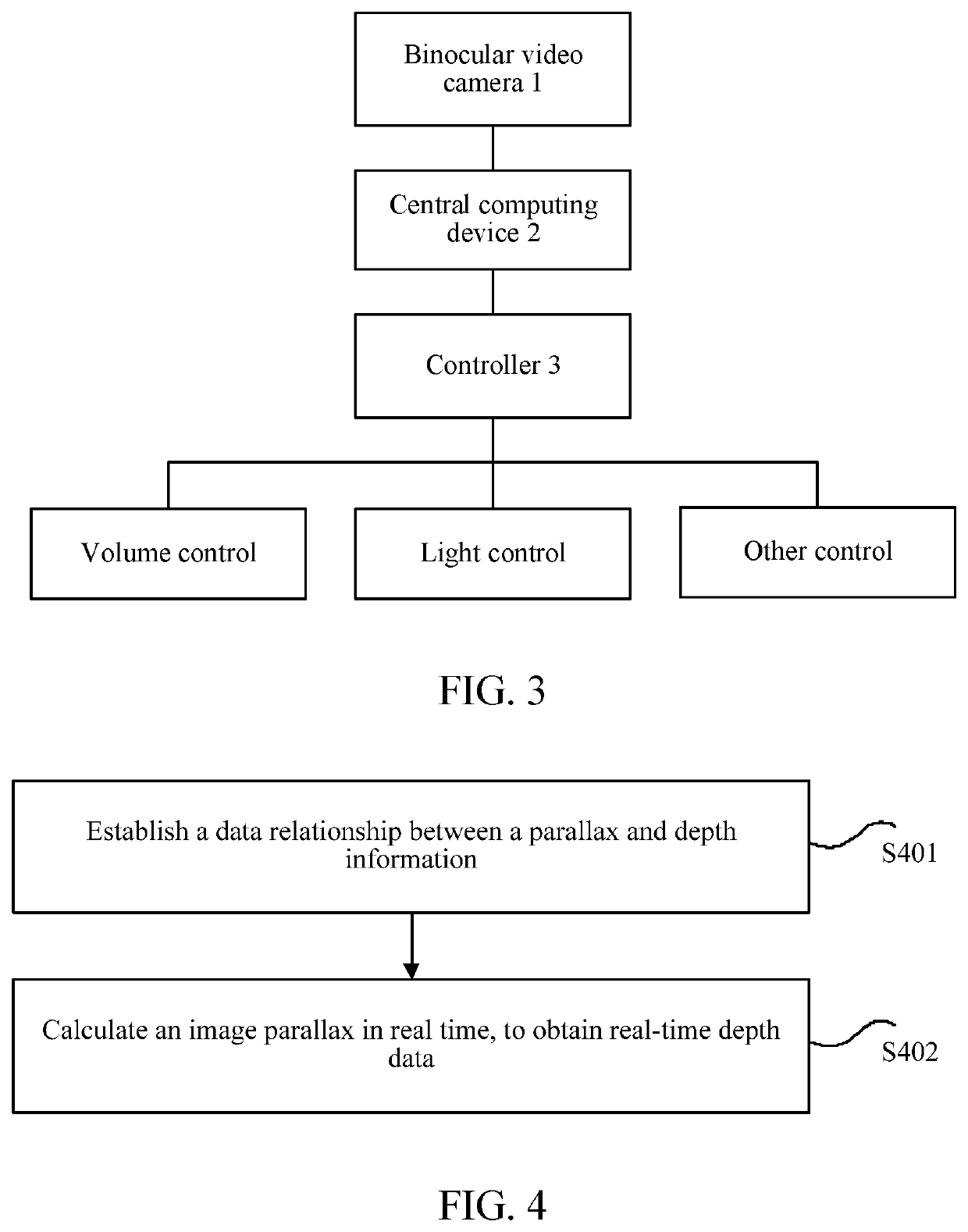

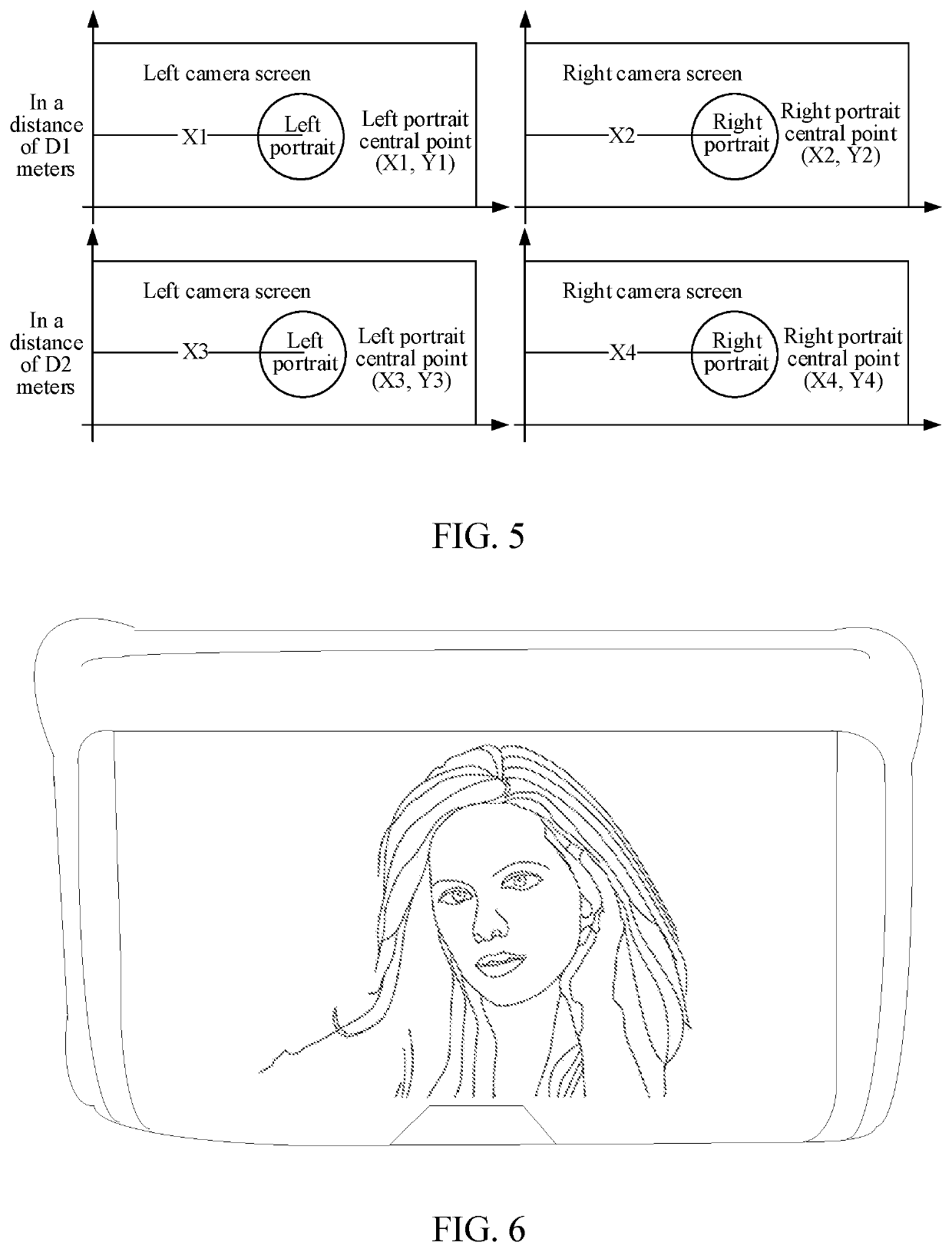

Method and apparatus for operating control system, storage medium, and electronic apparatus

ActiveUS20200033599A1Low costLower control costsInput/output for user-computer interactionImage analysisComputer visionEngineering

Embodiments of the present disclosure disclose a method and an apparatus for operating a control system, a storage medium, and an electronic apparatus. The method includes: obtaining, by using a target recording device in a control system, first image information of a target object moving in a real scene; obtaining a first distance corresponding to the first image information, the first distance being a distance between the target recording device and the target object; and adjusting a target parameter of the control system according to the first distance, the target parameter being used for outputting media information to a virtual reality (VR) device, the VR device being connected to the control system, the media information being corresponding to movement information of the target object moving in the real scene, and the movement information comprising the first distance.

Owner:TENCENT TECH (SHENZHEN) CO LTD

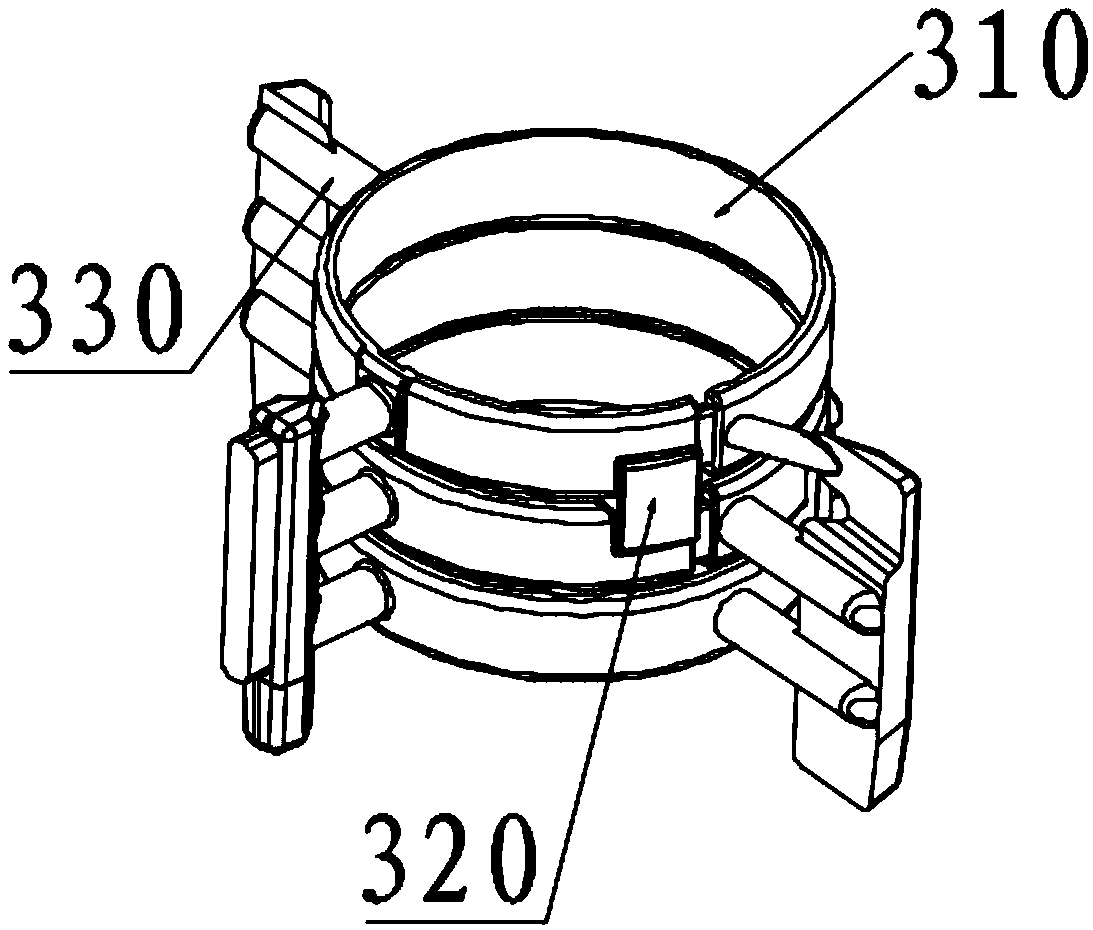

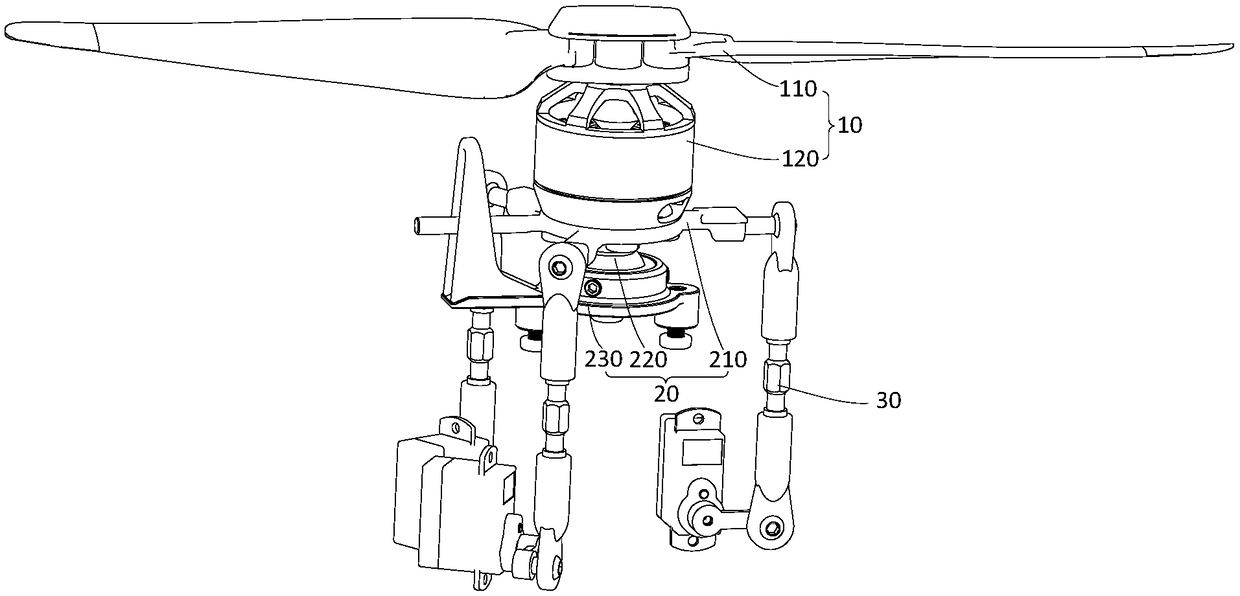

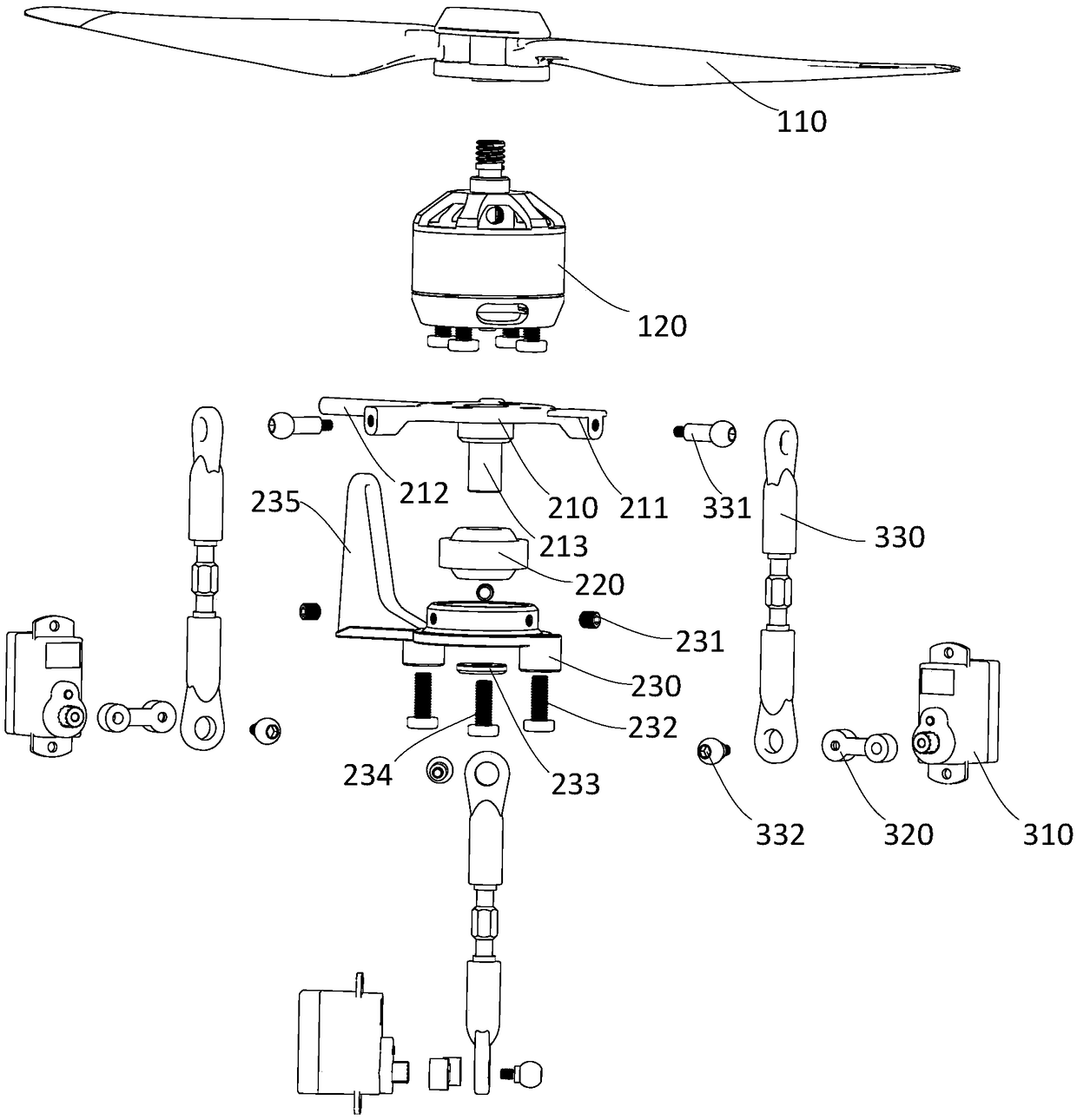

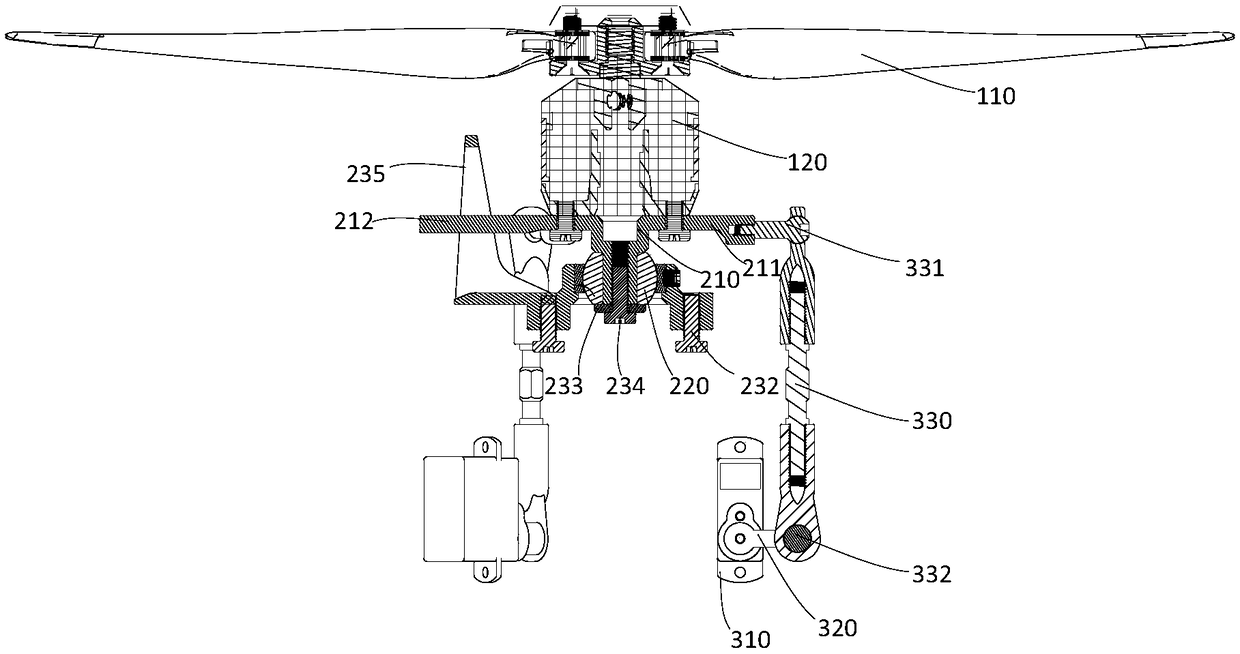

An unmanned aerial vehicle rotor structure and an unmanned aerial vehicle

The invention discloses an unmanned aerial vehicle rotor structure and an unmanned aerial vehicle are disclose, the rotor structure of the unmanned aerial vehicle comprises a cross plate connecting assembly, a power connecting rod assembly and a rotor assembly, wherein, the cross plate connecting assembly comprises a cross tilting plate, an articulated bearing and a bracket, an outer ring of the articulated bearing is embedded in the bracket, and the articulated bearing is fixedly connected with the inner ring of the articulated bearing; the output end of the power connecting rod assembly is rotatably connected with the cross tilting plate; the rotor assembly comprises a main rotor and a driving device, wherein the driving device is used for driving the main rotor to rotate, and the driving device is arranged on a cross tilt plate; as for that rotor structure of the unmanned aerial vehicle, only one power connecting rod assembly is required to realize the reciprocating swing of the cross tilt plate in one direction, the rotor structure and control logic can be simplified, which helps to control the cost and reduce the failure rate.

Owner:GOERTEK ROBTICS CO LTD

Vacuum pressure impregnation system

InactiveCN107696204AAdapt to different requirements of changing natureImprove processing efficiencyPressure impregnationVacuum pressureEngineering

The invention discloses a vacuum pressure impregnation system, comprising: a pressure impregnation tank, a circulating water tank, a liquid medicine pool, a centrifugal pump, a vacuum pump, a pressure pump, a suction and discharge valve, a partial pressure pump, a pressure gauge, a vacuum gauge, and a press; The circulating water tank is fixedly connected to the centrifugal pump and the vacuum pump, the centrifugal pump is connected to the empty pump, the centrifugal pump is connected to the vacuum gauge, the vacuum gauge is connected to the pressure gauge, the pressure gauge is connected to the pressure dipping tank, and the pressure gauge is connected to the press machine. The partial pressure pump is fixedly connected to the pressure dipping tank, and the partial pressure pump is fixedly connected to the liquid medicine pool; the pressure dipping tank is fixedly connected to the booster pump, and the booster pump is fixedly connected to the liquid medicine pool. Pool fixed connection. The vacuum pressure impregnation of the present invention can not only make the modifying agent enter the deeper part of the material in a short time, but also can use the size of the pressure and vacuum to adjust the entering depth and amount, adapt to different requirements of material property changes, and improve processing efficiency and control costs.

Owner:南宁科城汇信息科技有限公司

Injection mould and mould opening method thereof

InactiveCN107030978AGuaranteed appearance quality effectCost controlCoatingsInjection mouldingMaterials science

The invention discloses an injection mould and a mould opening method thereof. The mould opening method includes the steps that a part template to be subjected to injection moulding is manufactured, a part to be subjected to injection moulding is divided into at least two portions according to different shrinkage amounts, reserved shrinkage amounts are set on the portions with the large shrinkage amounts, and the at least two portions are in transition connection in sequence; and a mould cavity is manufactured according to the part template to be subjected to injection moulding. In the mould opening method mentioned above, differences between the shrinkage amounts of all the portions of the part to be subjected to injection moulding are taken into consideration, the part to be subjected to injection moulding is divided into the at least two portions, and in other words, the portions with the large shrinkage amounts are separated from the portion with the small shrinkage amount. When the template is manufactured, the reserved shrinkage amounts are set on the portions with the large shrinkage amounts, then, the portions with the large shrinkage amounts are in transition connection with the other portion in sequence, and therefore in the cooling shrinkage process, all the portions gradually tend to be consistent, in this way, it can be effectively ensured that injection moulding meets the design requirement, meanwhile, the appearance quality effect can be ensured, mould repair does not need to be repeatedly conducted in the production process, and cost control is facilitated.

Owner:SHENZHEN TINNO WIRELESS TECH

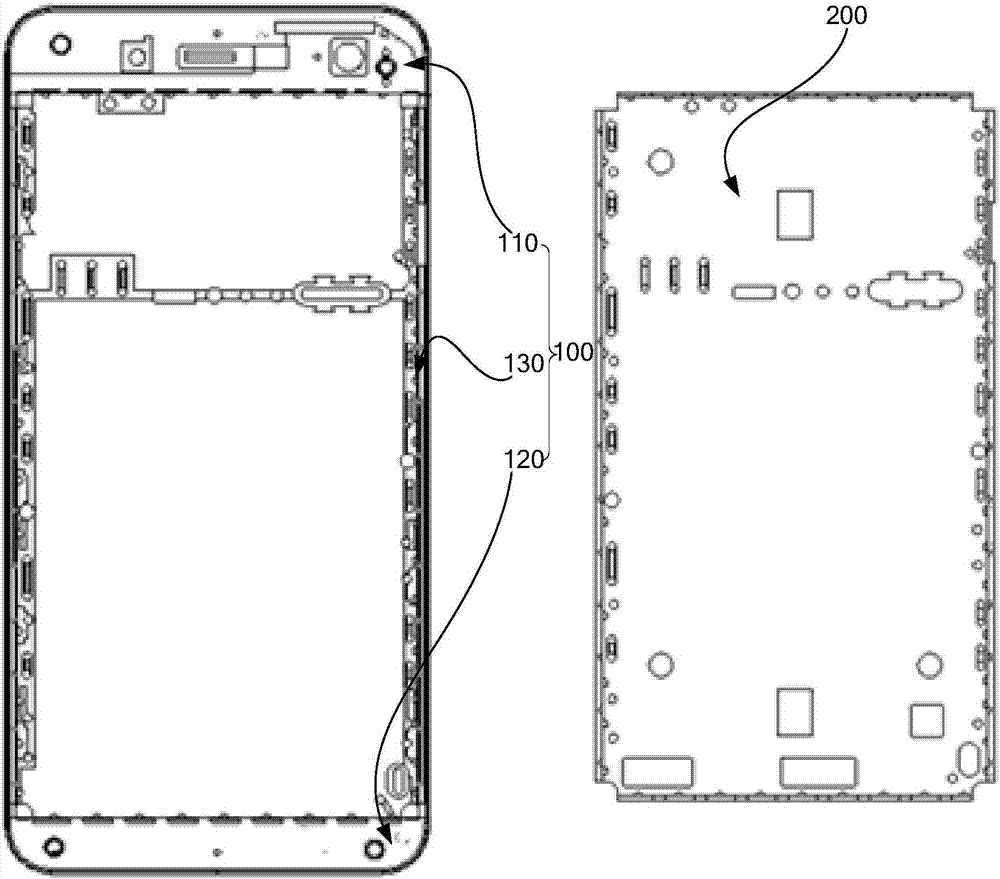

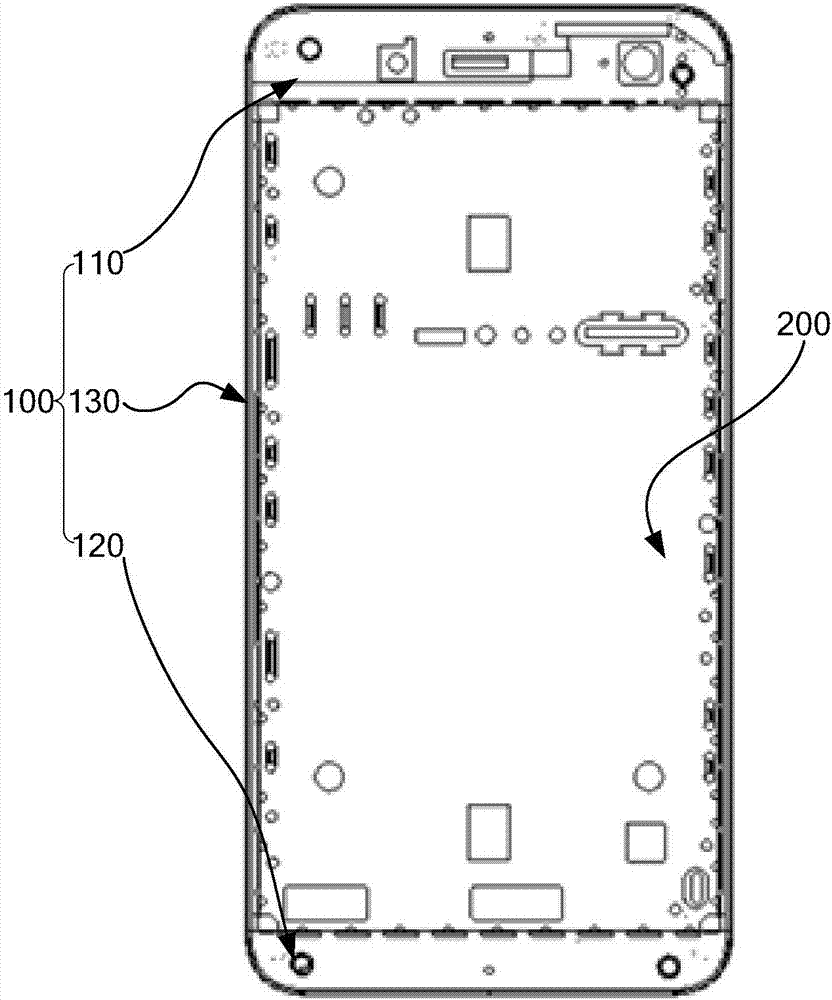

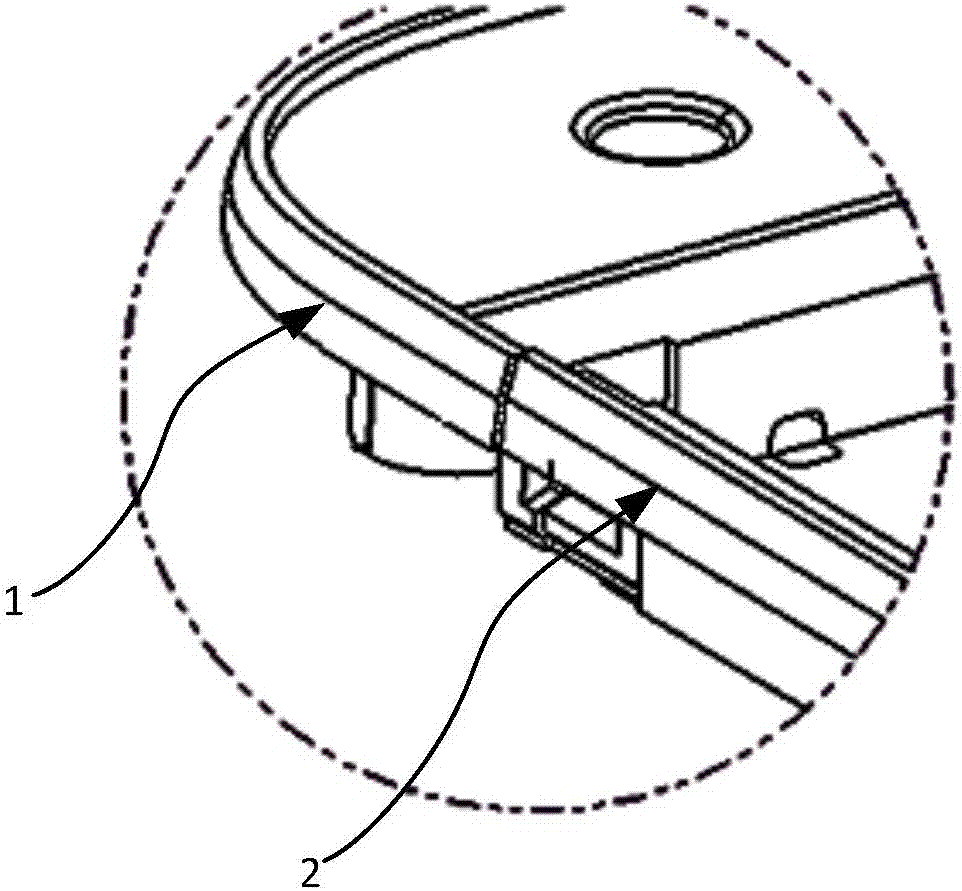

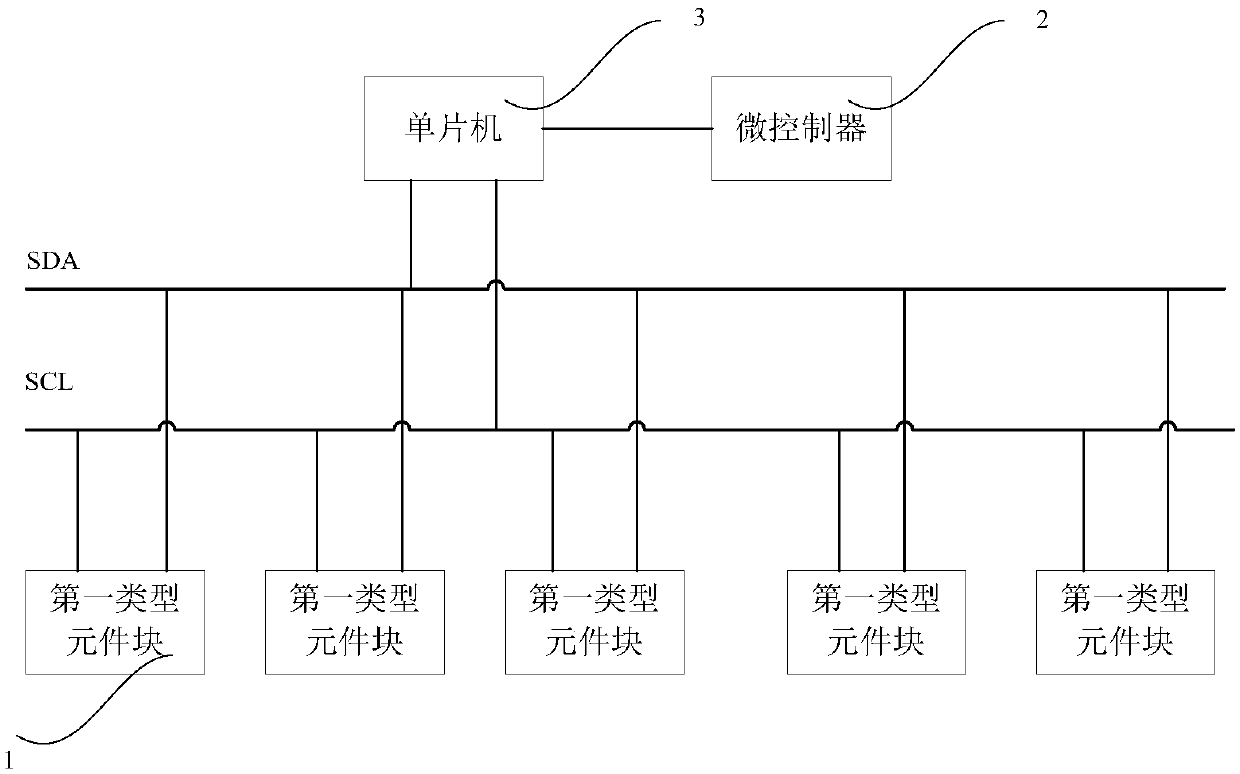

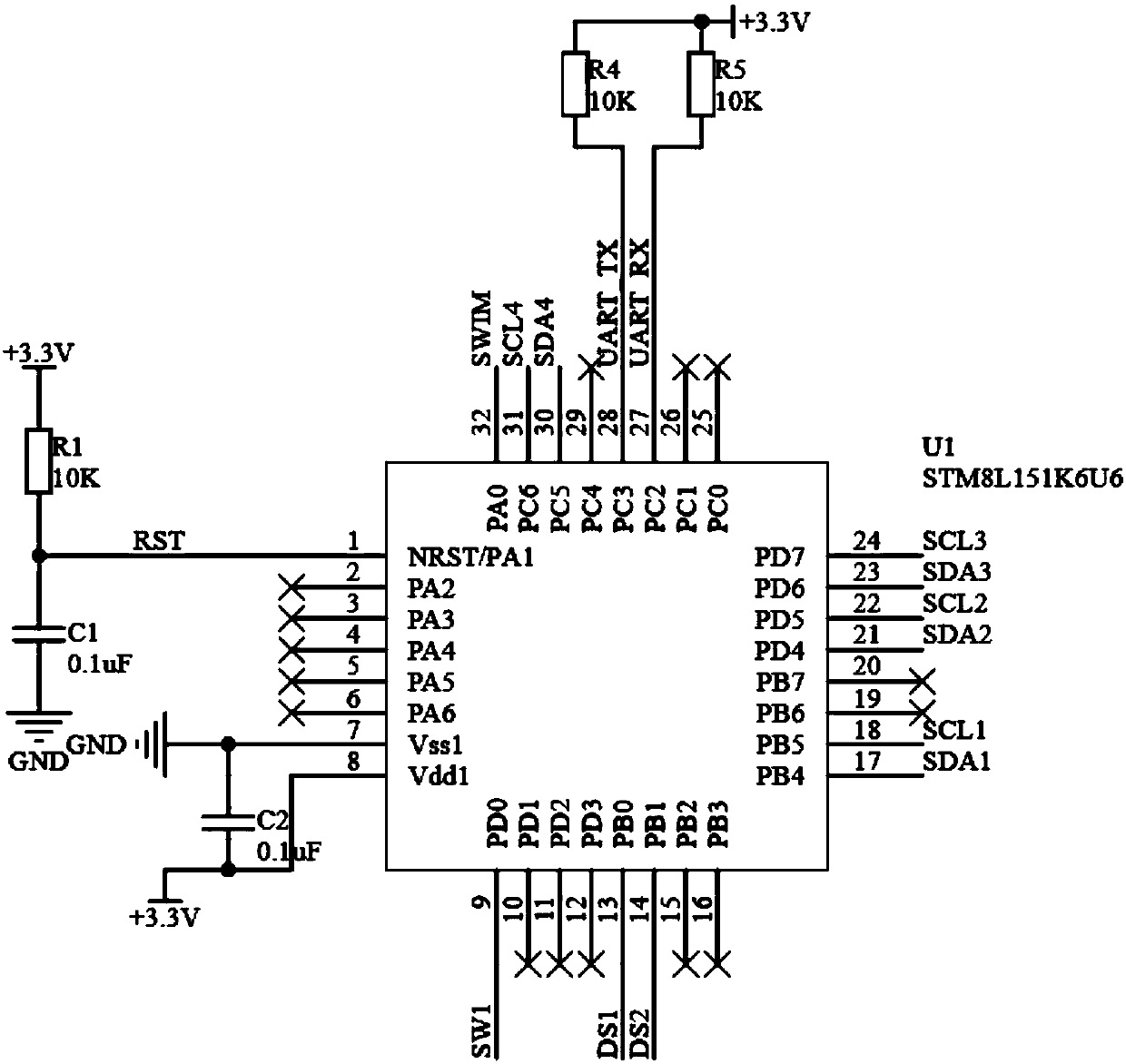

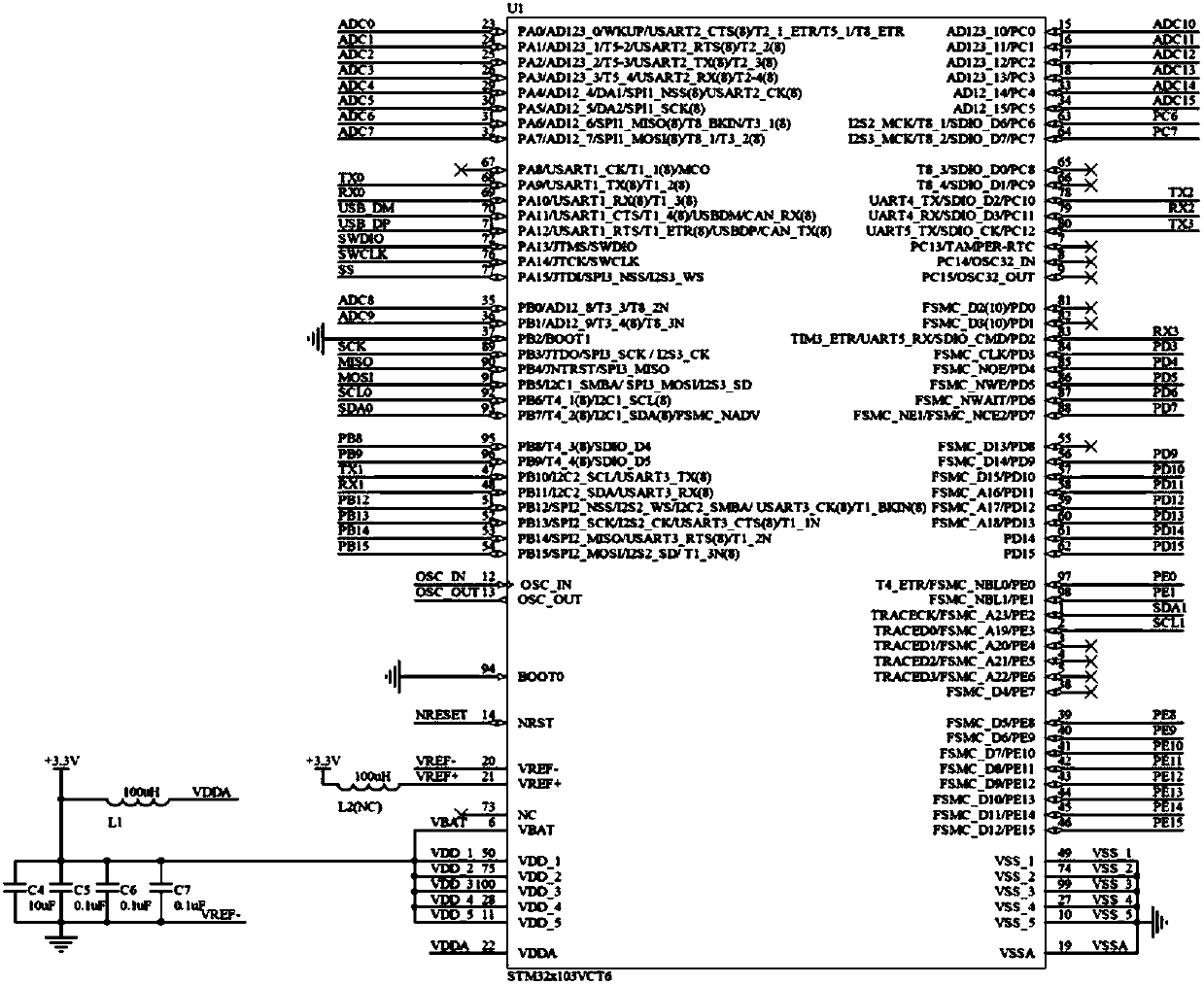

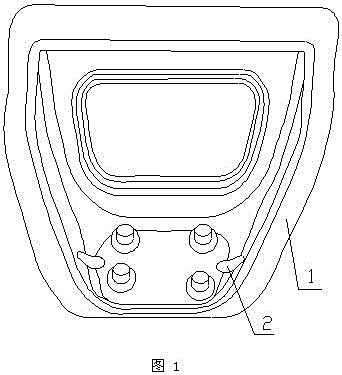

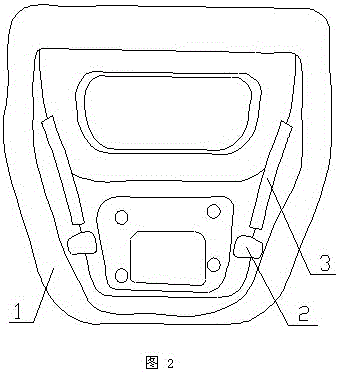

Electronic brick based on I2C interface

PendingCN107583288AReduce difficulty of useIncrease richnessToysEducational modelsMicrocontrollerMicrocomputer

The invention discloses an electronic brick based on an I2C interface. The electronic brick comprises a base and component blocks installed on the base in a pluggable mode. The component blocks are configured to different addresses; the base is provided with a microcontroller and a single-chip microcomputer for managing the communication data flow between the microcontroller and the component blocks, each component block comprises a first type component block based on I2C communication, the first type component blocks and the single-chip microcomputer are configured to be communicated in an I2C communication mode, and the microcontroller and the single-chip microcomputer are configured to be communicated in an I2C communication mode. Due to the fact that only two data lines need to be arranged between the first type component block and the base, connection is easy, plugging is easy, the child's using difficulty is lowered, the playability is improved, the cost is controlled due to thesimple hardware connection requirement, and the good economy is achieved; an I2C bus can be hooked to multiple peripheral devices, the expansibility is good, the varieties of peripheral modules are greatly enlarged, and product upgrading is more convenient.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Vacuum pressure impregnating full-load processing method for wood

InactiveCN106142253AAdapt to different requirements of changing natureAdapt to different requirementsPressure impregnationVacuum pressurePulp and paper industry

The invention discloses a vacuum pressure impregnating full-load processing method for wood. The vacuum pressure impregnating full-load processing method for the wood has the following steps of (1) conducting a pre-vacuum period, specifically, placing the wood in a pressure impregnating tank and then vacuumizing the pressure impregnating tank through a vacuum pump; (2) adding modifying agents, specifically, under the condition that the vacuum pump is not closed, that is, under the condition that the original vacuum degree is kept, adding the modifying agent solution; (3) conducting pressurization; (4) discharging the modifying agent solution; and (5) achieving post-vacuum. According to the vacuum pressure impregnating full-load processing method for the wood, cells of the wood are filled with the modifying agent solution and the maximum quantity of modifying agents are kept in the wood. The method is strict in condition so that the maximized modifying agent chemical sucking amount and the maximized penetration depth can be achieved.

Owner:潘杨基

Lock catch reinforcing plate

InactiveCN105003135AHigh strengthQuality assuranceVehicle locksStructural engineeringMechanical engineering

The invention discloses a lock catch reinforcing plate which comprises a body. The appearance of the body is trapezoid, the middle portion of the body is concaved inwards, protruding reinforcing ribs are arranged on the body, and a reinforcing plate body is welded to the back face of the body. The lock catch reinforcing plate is simple in structure and reasonable in design, the reinforcing ribs are additionally arranged, and the reinforcing plate body is welded to the back face of the body, so that the strength of parts is better improved; meanwhile, the process requirement for the body is lowered, the rate of finished products is improved, the control cost is lowered, the processing operability is increased, the quality is guaranteed better, the cost of the parts can be lowered better, and the quality of the parts is improved.

Owner:CHUZHOU DASHI AUTO PARTS

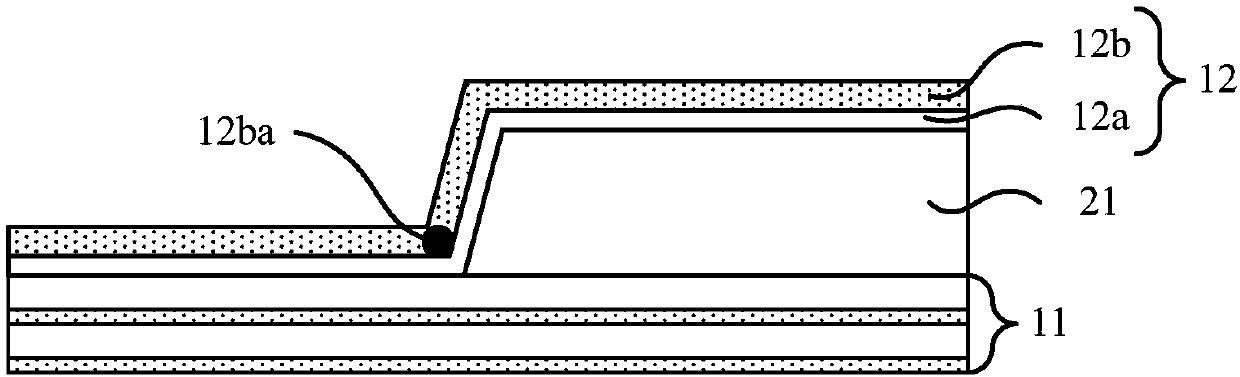

Assembled half-exposed framework high-pressure seal ring

ActiveCN102537360BImprove carrying capacityIncrease stiffnessEngine sealsWorking pressureMetal framework

Owner:重庆杜马斯克科技有限公司 +2

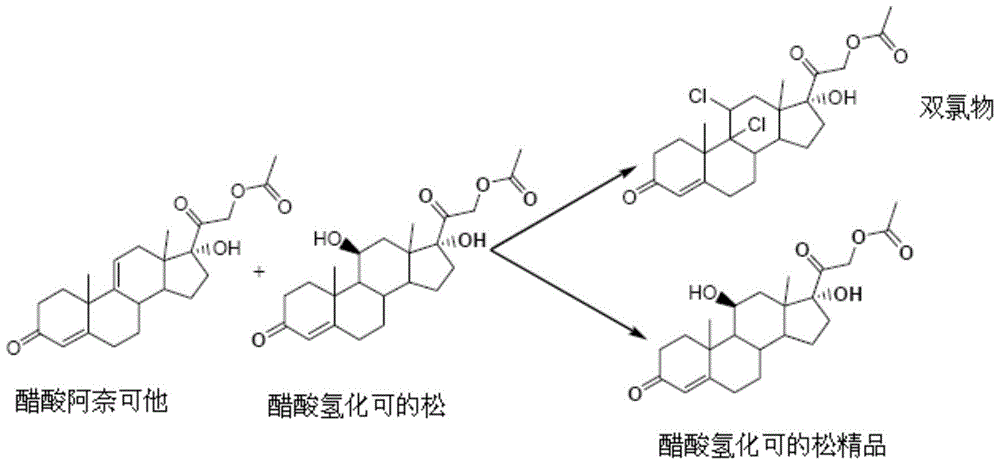

Refining method of hydrocortisone acetate

The invention discloses a refining method for hydrocortisone acetate. The refining method comprises the step of purifying a hydrocortisone acetate crude product with chlorine gas or with hypochorite, glacial acetic acid and sodium chloride, so as to obtain a hydrocortisone acetate refined product. The refining method is simple, convenient, low in manufacturing cost, high in yield and product purity, stable in process, and suitable for producing a large quantity of the hydrocortisone acetate refined product.

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

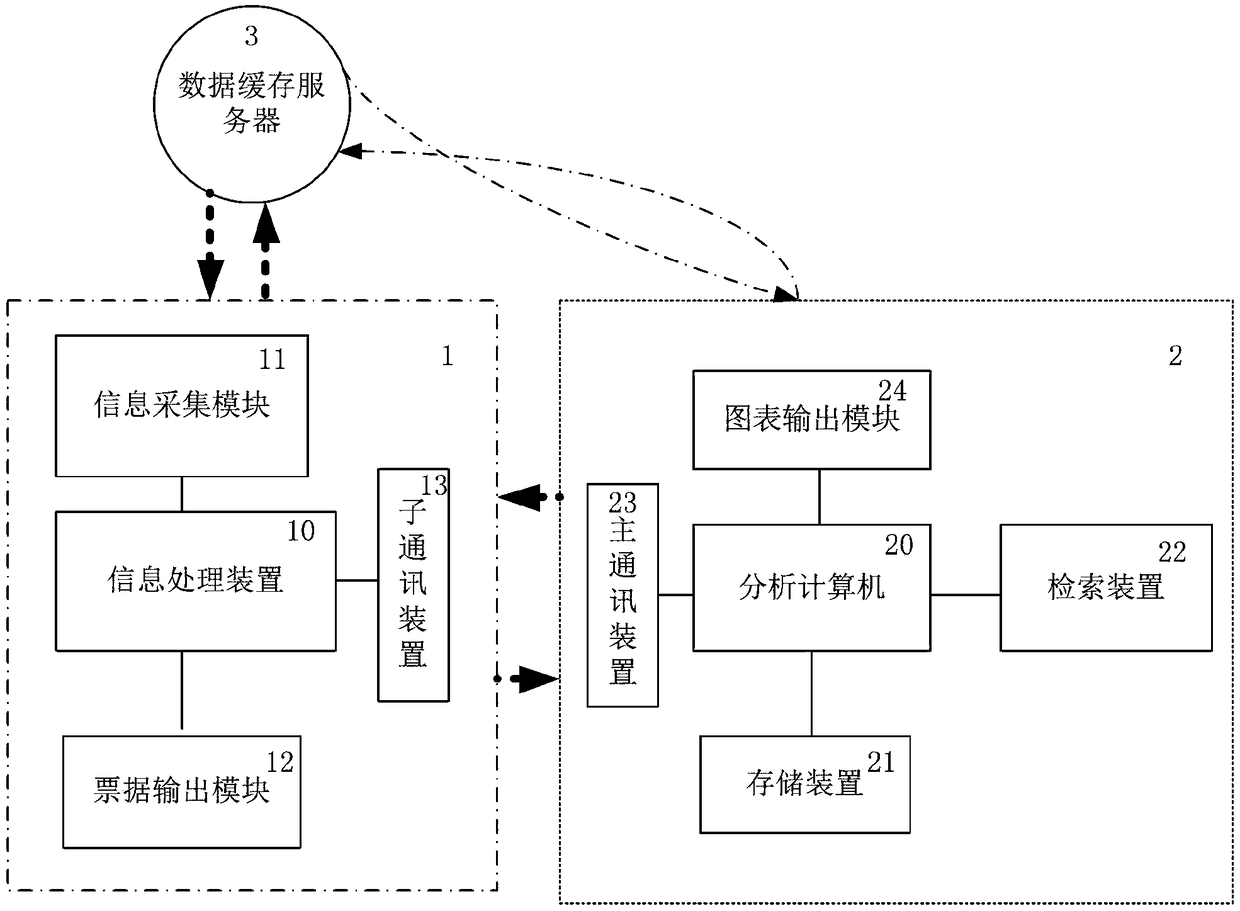

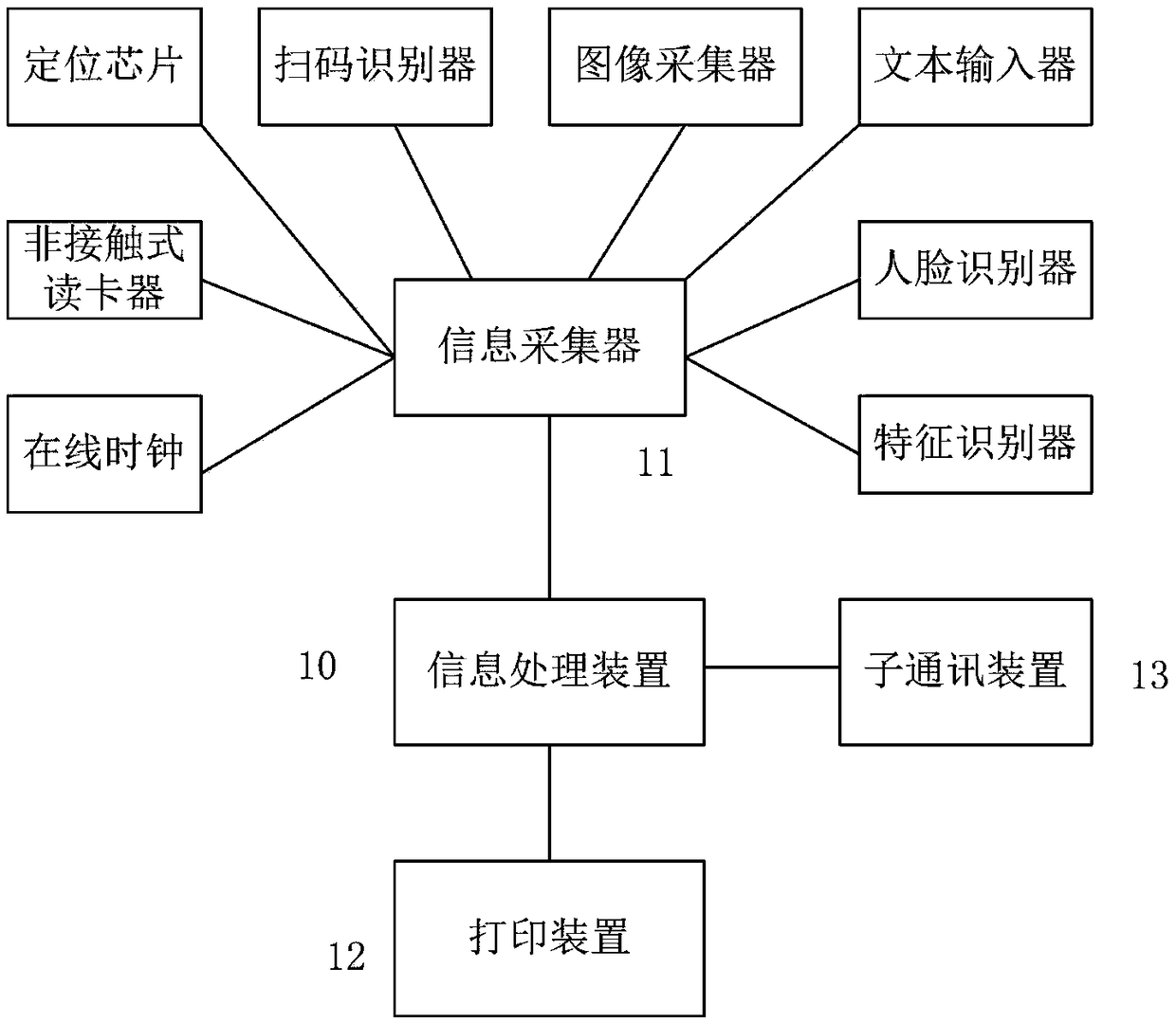

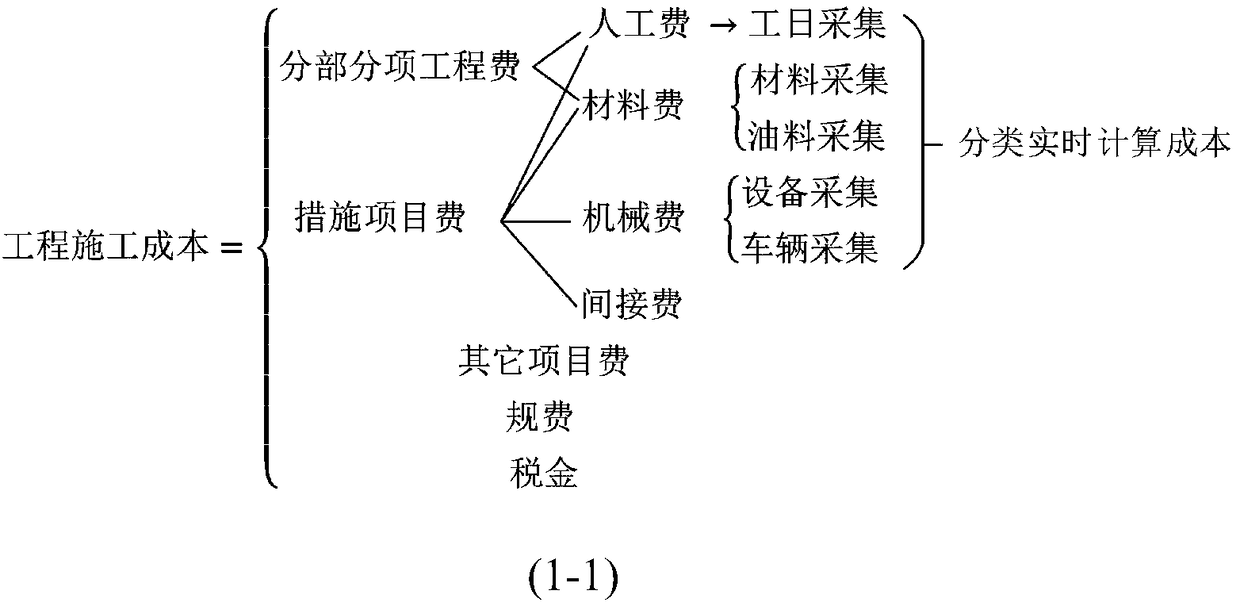

Construction engineering process control and management system

InactiveCN108960758ARealize data resumingMeet diverse needsOffice automationSpecial data processing applicationsInformation processingEngineering process control

The invention provides a construction engineering process control and project management system, and belongs to the technical field of a construction engineering management system. The construction engineering process control and management system comprises terminal equipment, a data caching server and a main server which interacts information with the terminal equipment through the network, wherein the terminal equipment includes a sub-communication device, an information acquisition module, a bill output module and an information processing device; the sub-communication device, the information acquisition module and the bill output module are connected with the information processing device; the main server includes a chart output module, a storage device, a retrieval device, a main communication device and an analysis computer; the chart output module, the storage device, the retrieval device and the main communication device are connected with the analysis computer; and the structure of the data caching server is the same as that of the main server, and the data caching server is in real-time connection with the terminal equipment and is in real-time synchronization with the main server. The construction engineering process control and management system has the technical advantages of high link response speed, visual output chart, convenient information acquisition and highsecurity performance.

Owner:北京鸿游科技有限公司

Packaging structure and forming method thereof

ActiveCN109920772ARelease stressStress reliefSemiconductor/solid-state device detailsSolid-state devicesIsolation layerEngineering

The invention discloses a packaging structure and a forming method thereof. The packaging structure comprises a wafer which comprises a chip region and a peripheral region which surrounds the chip region; a first wiring layer distributed on the wafer of the chip region in a discrete manner; an upper passivation layer covering the top and the side wall of the first wiring layer and extending to thewafer; and an isolation layer located on the upper passivation layer, arranged on the chip region and extending to a part of the peripheral region, wherein an isolation groove surrounding the chip region is formed in the isolation layer on the peripheral region, and the isolation groove penetrates through a part of the thickness of the isolation layer. The isolation groove can block the conduction of the internal stress action of the isolation layer to realize the release of the internal stress action of the isolation layer, thereby reducing the cracking probability of the upper passivation layer, reducing the occurrence of the exposure phenomenon of the first wiring layer, and improving the performance of the packaging structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com