Assembled half-exposed framework high-pressure seal ring

A high-pressure sealing ring, half-exposed skeleton technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as poor pressure resistance and extrusion resistance, heat generation, and increase installation space, and achieve Stable anti-extrusion ability, good friction and lubricating properties, and the effect of lowering the ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

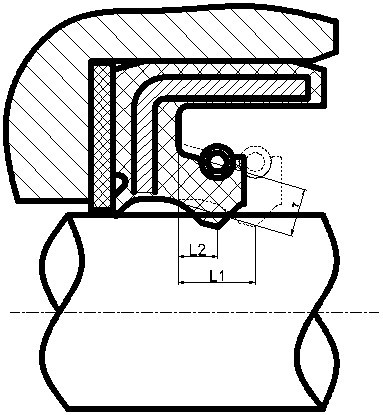

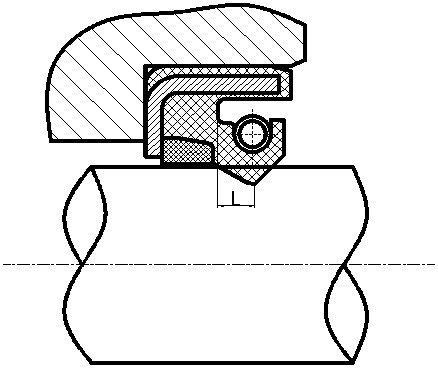

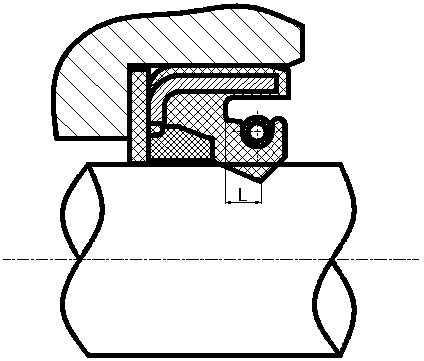

[0046] Figure 4 —13 is the structure diagram of the present invention, as shown in the figure: the assembled semi-exposed frame high-pressure sealing ring includes an annular rubber body with a sealing lip 3, a metal frame 6, a semi-exposed frame 5, and a composite pressure ring 4 and spring 2. The metal skeleton 6 and the rubber body 1 are thermally vulcanized and bonded as a whole; the annular rubber body 1 is provided with a sealing lip 3 with a certain amount of interference between the matching shaft, and the sealing lip 3 is molded by a mold at a time form. The composite bearing pressure ring 4 is assembled behind the sealing lip 3 after the metal frame and rubber are vulcanized as a whole; the half exposed frame 5 is finally assembled with the rubber body 1 and the composite pressure ring 4 as a whole. The extension spring 2 is connected end to end and installed in the spring groove behind the sealing lip 3. The extension spring 2 exerts a stable radial pressure on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com