Combined energy-saving oil cylinder

A combined type and oil cylinder technology, which is applied in the field of energy-saving oil cylinders, can solve the problems of large hydraulic system, system noise, high energy consumption, and increased cost, and achieve the reduction of valve parts and pipeline specifications, simple structure, and low power consumption. Effect of oil pump flow reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

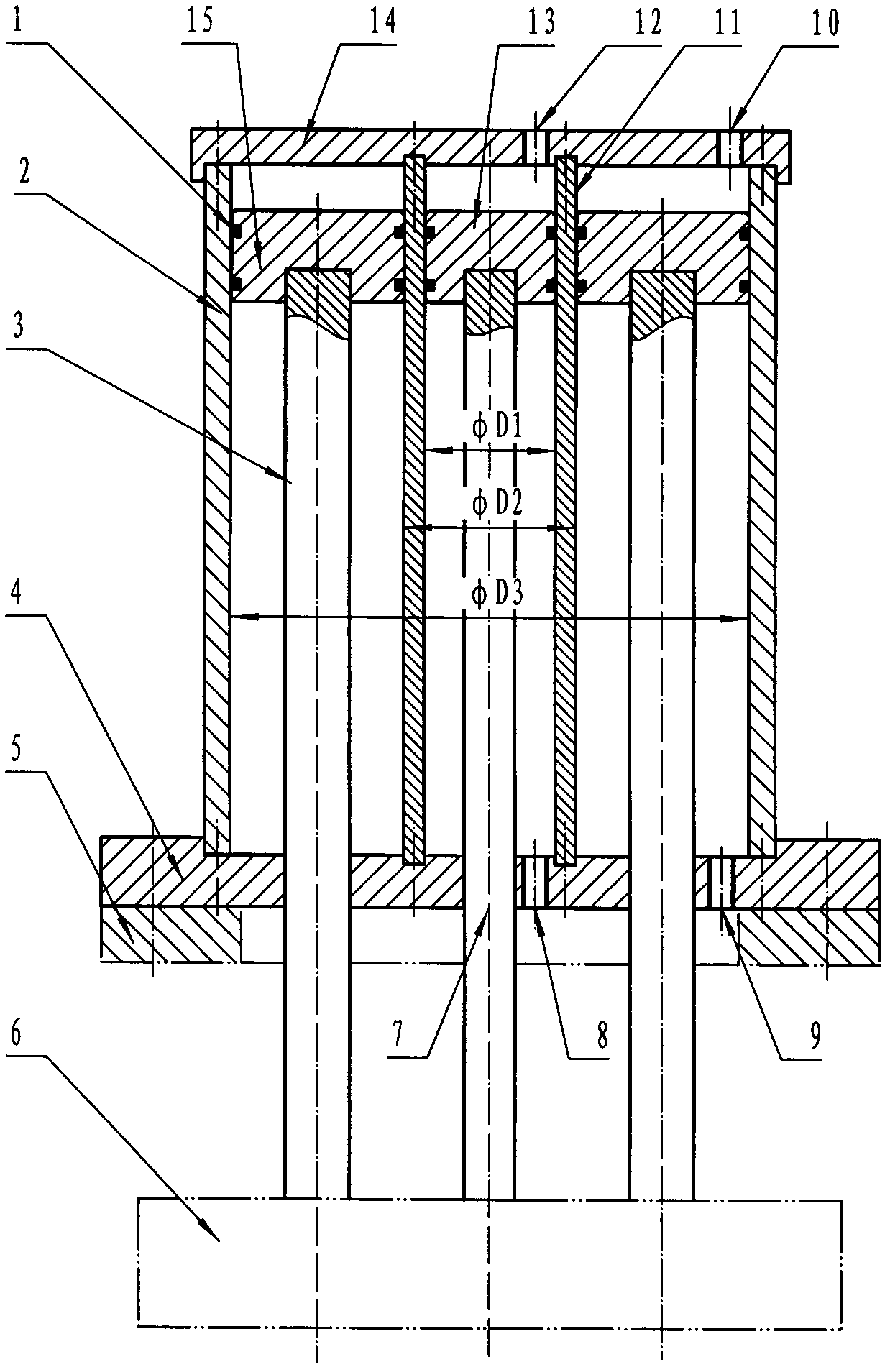

[0012] In Fig. 1, the large oil cylinder passes through the oil cylinder rear cover (14), the large oil cylinder body (2), the oil cylinder front cover (4), 4 large oil piston rods (3) evenly distributed on the circumference and an outer diameter D3, The annular piston (15) of inner hole D2 is formed; The small oil cylinder passes through the oil cylinder rear cover (14), the small oil cylinder body (11), the oil cylinder front cover (4), the small oil piston rod (7) and an outer diameter D1 Piston (15) forms. The large oil cylinder and the small oil cylinder share the oil cylinder rear cover (14) and the oil cylinder front cover (4). The strokes of the two are exactly the same, and the large oil piston rod (3) and the small oil piston rod (7) act together on the plastic molding machine to close the mold. On the formwork (6), the assembly of large and small oil cylinders is fixed on the oil cylinder installation flange plate (5) through the oil cylinder front cover (4). The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com