One-step integral hoisting method for Y-shaped three-way-type downcomer of blast furnace

An overall hoisting and general technology, applied in blast furnaces, blast furnace details, furnace types, etc., can solve the difficulty of positioning the Y-type three-way descending pipe, the easy swing of the Y-type three-way descending pipe, and the high rental cost of large cranes. problems, to achieve the effect of saving project cost and construction period, saving rental costs, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

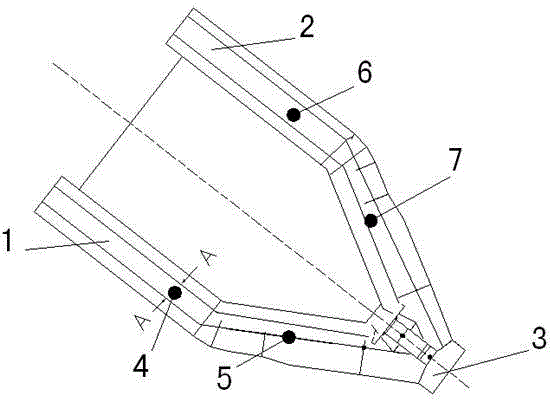

[0012] Referring to the accompanying drawings, the blast furnace Y-type three-way downcomer overall hoisting method for one-time placement includes the following process steps:

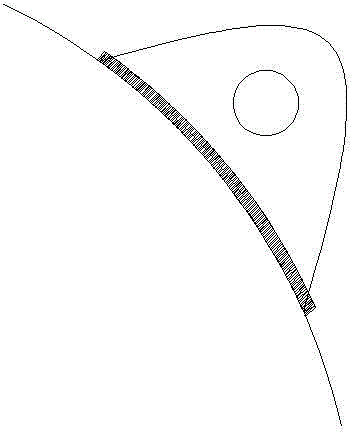

[0013] 1. For the welding of the Y-shaped three-way downcomer of the blast furnace, the left branch 1, the right branch 2 and the main pipe 3 are butt-welded on the assembly platform to form a Y-shaped tee. The structure, specification and model of the left branch and the right branch are exactly the same. The branch pipe and the right branch pipe are arranged symmetrically with the center of the main pipe as the central axis. Both the left branch pipe and the right branch pipe include straight pipes and inclined pipes. The lifting points are respectively set at the gravity center of the straight pipe and the inclined pipe. Lifting point 5 of the inclined pipe of the branch pipe, lifting point 6 of the straight pipe of the right branch pipe, and lifting point 7 of the inclined pipe of the right branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com