Ring beam formwork bricks and building secondary structure filler wall ring beam construction method

A technology of beam formwork and formwork, which is applied in the direction of building structure, building components, construction, etc., can solve the problems of construction period impact, waste of resources, etc., and achieve the effects of reducing labor costs, saving materials, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below with reference to accompanying drawing and embodiment:

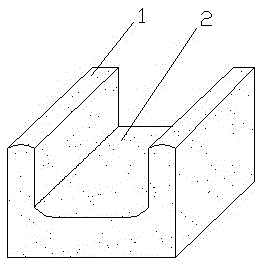

[0028] attached Figure 1-2 It can be seen that a ring beam formwork brick includes a formwork brick body 1, a groove 2 penetrating through the beam formwork brick body is arranged in the middle of the formwork brick body 1; the cross section of the formwork brick body is U-shaped.

[0029] The bottom of the groove 2 is an arc surface.

[0030] The template brick body 1 is rectangular, and the groove 2 is arranged along the length direction of the template brick body.

[0031] The formwork brick body 1 is L-shaped.

[0032] The formwork brick body 1 is arc-shaped.

[0033] A construction method for building secondary structure filled wall ring beams, comprising the following steps:

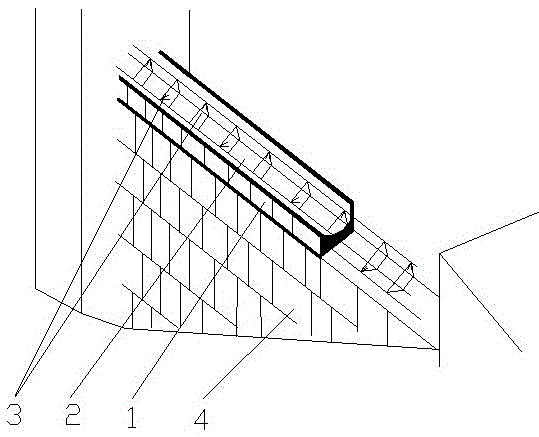

[0034] Build the lower body of wall 4, and build the lower body of wall 4 to the design height;

[0035] Formwork bricks are built on the top of the lower wall body 4, and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com