Extra-large fiber reinforced plastic (FRP) combined storage tank structure with floating roof, and construction method of storage tank structure

A construction method and FRP board technology are applied in the field of storage tanks in the field of civil and architectural structures, which can solve the problems that steel storage tanks cannot meet development needs well, save rental costs and labor, and reduce the axial pressure ratio. , the effect of preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

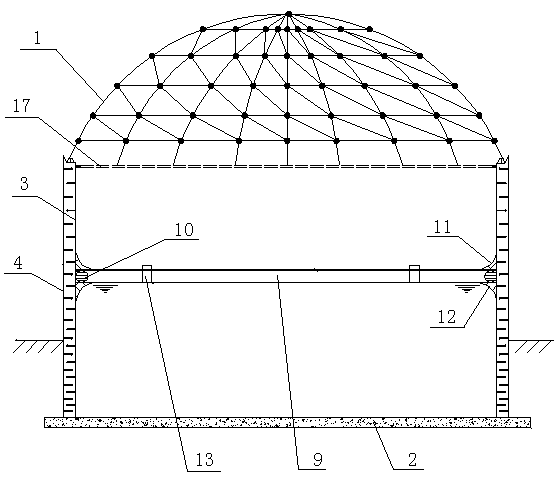

[0037] Such as figure 1 As shown, the super large FRP combined storage tank structure with floating roof includes tank roof 1, tank wall, tank bottom 2, combined with Figure 12 As shown, the tank roof 1 adopts FRP (fiber reinforced plastic) reticulated shell structure, and the FRP board is laid on the FRP reticulated shell structure; the tank bottom 2 is an active powder concrete bottom plate; It is composed of active powder concrete in the middle, and the floating roof 9 is installed inside the tank wall; connecting pieces are arranged between the inner and outer FRP boards, such as Figure 5 As shown, the connector 5 is a fiberglass connector, and the two ends of the connector 5 are respectively connected with two layers of FRP boards inside and outside. Figure 7, Figure 8 As shown, concrete trapezoidal grooves 7 are sequentially arranged between the inner and outer layers of FRP slabs along the circumferential direction, and the prestressed tendons 8 are stretched in s...

Embodiment 2

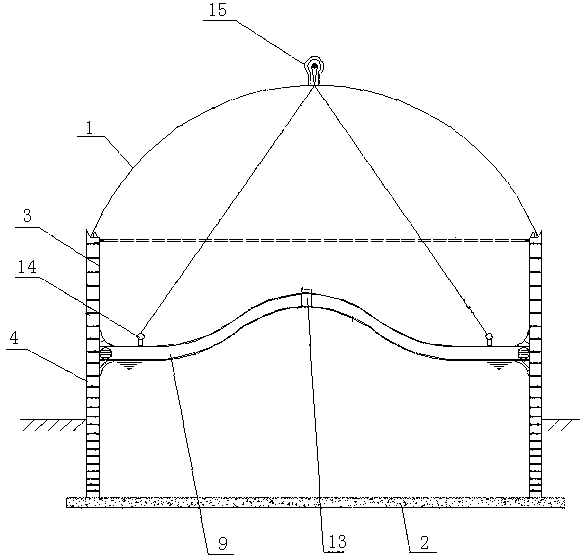

[0046] Such as figure 2 As shown, the super-large FRP composite storage tank structure with floating roof includes tank roof 1, tank wall, and tank bottom 2. Two layers of FRP boards are sandwiched between active powder concrete, and the floating roof 9 is installed inside the tank wall; connecting pieces are arranged between the inner and outer layers of FRP boards, such as Image 6 As shown, the connectors 6 are arranged horizontally, and one end of some connectors is fixed on the outer FRP board 4, and one end of some connectors is fixed on the inner FRP board 3, and the two connectors are arranged alternately on the inner and outer sides. between two layers of FRP slabs; between the inner and outer layers of FRP slabs, concrete trapezoidal grooves 7 are sequentially arranged along the circumferential direction, and the prestressed tendons 8 are stretched in sections between two adjacent concrete trapezoidal grooves 7; the inner layer of FRP slabs 3 and the outer layer La...

Embodiment 3

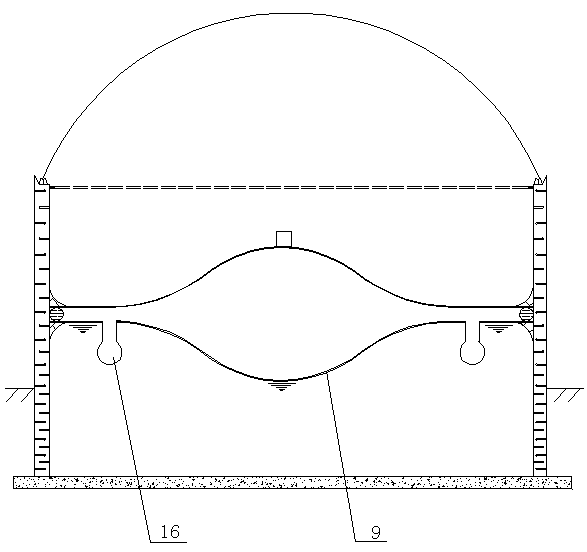

[0054] Such as image 3 As shown, the super large FRP composite storage tank structure with floating roof includes tank roof 1, tank wall and tank bottom 2. The tank roof adopts FRP reticulated shell structure, and FRP plates are laid on the FRP reticulated shell structure; The active powder concrete is sandwiched between the layers of FRP boards, and the floating roof 9 is installed inside the tank wall; connecting pieces are arranged between the inner and outer FRP boards, and concrete trapezoidal grooves 7 and prestressed tendons 8 are arranged in sequence along the circumference between the inner and outer FRP boards Sectional stretching is between two adjacent concrete trapezoidal grooves 7; the inner layer FRP board 3 and the outer layer FRP board 4 are both formed by connecting FRP splicing boards through a tongue and a groove. The floating roof 9 is a self-floating hydrogen-filled floating roof. The hydrogen-filled floating roof is formed by a light FRP sheet, and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com