Gantry crane device with lengthways and transverse traveling functions and hoisting method

A gantry lifting, vertical and horizontal technology, which is applied to the crane of the trolley, the braking device of the hoisting equipment, the crane, etc. The effect of construction process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

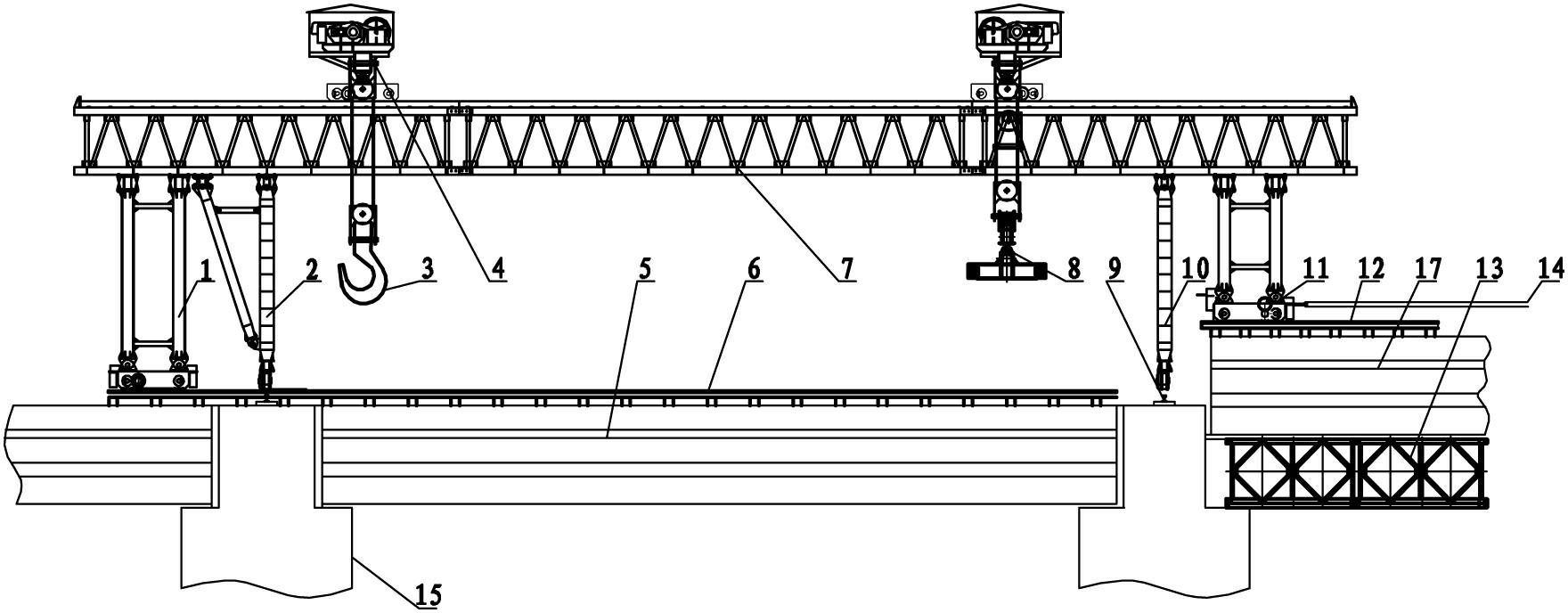

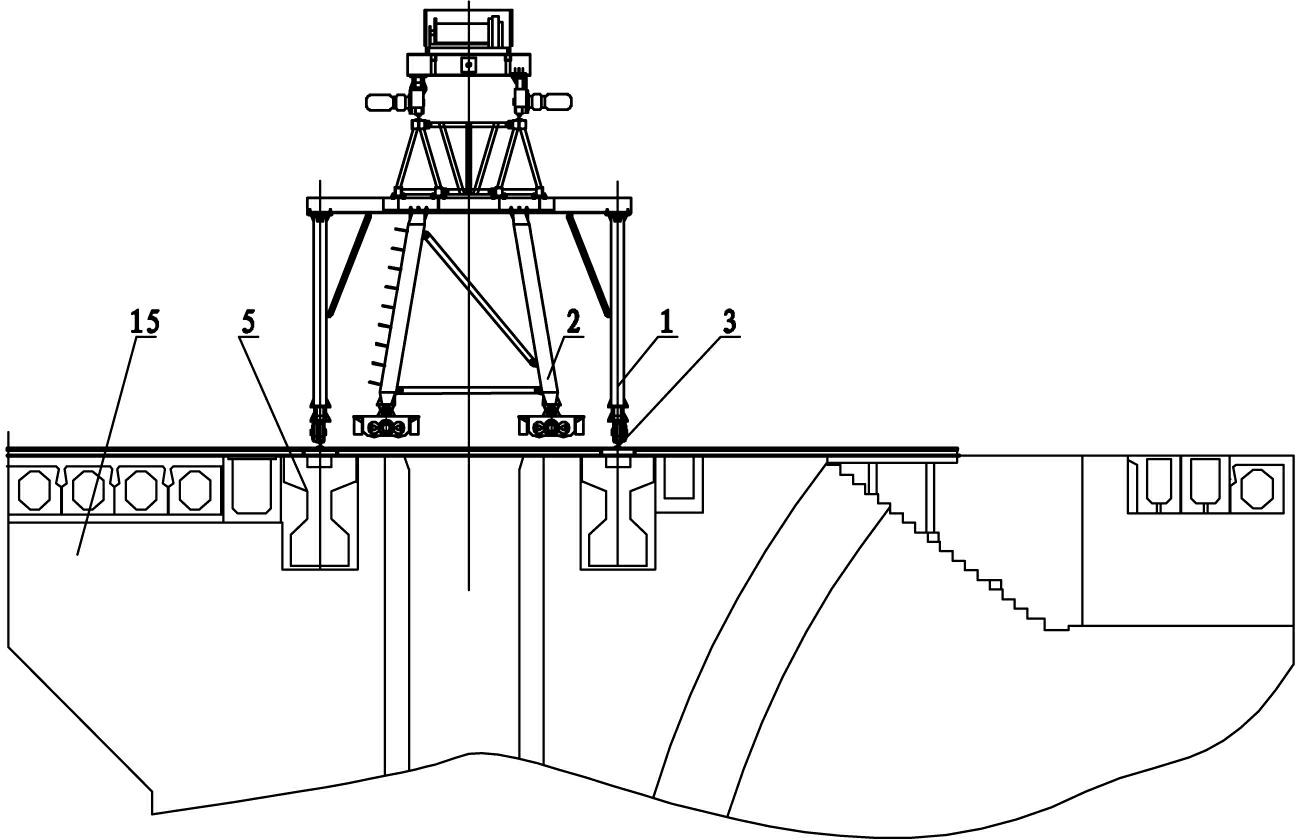

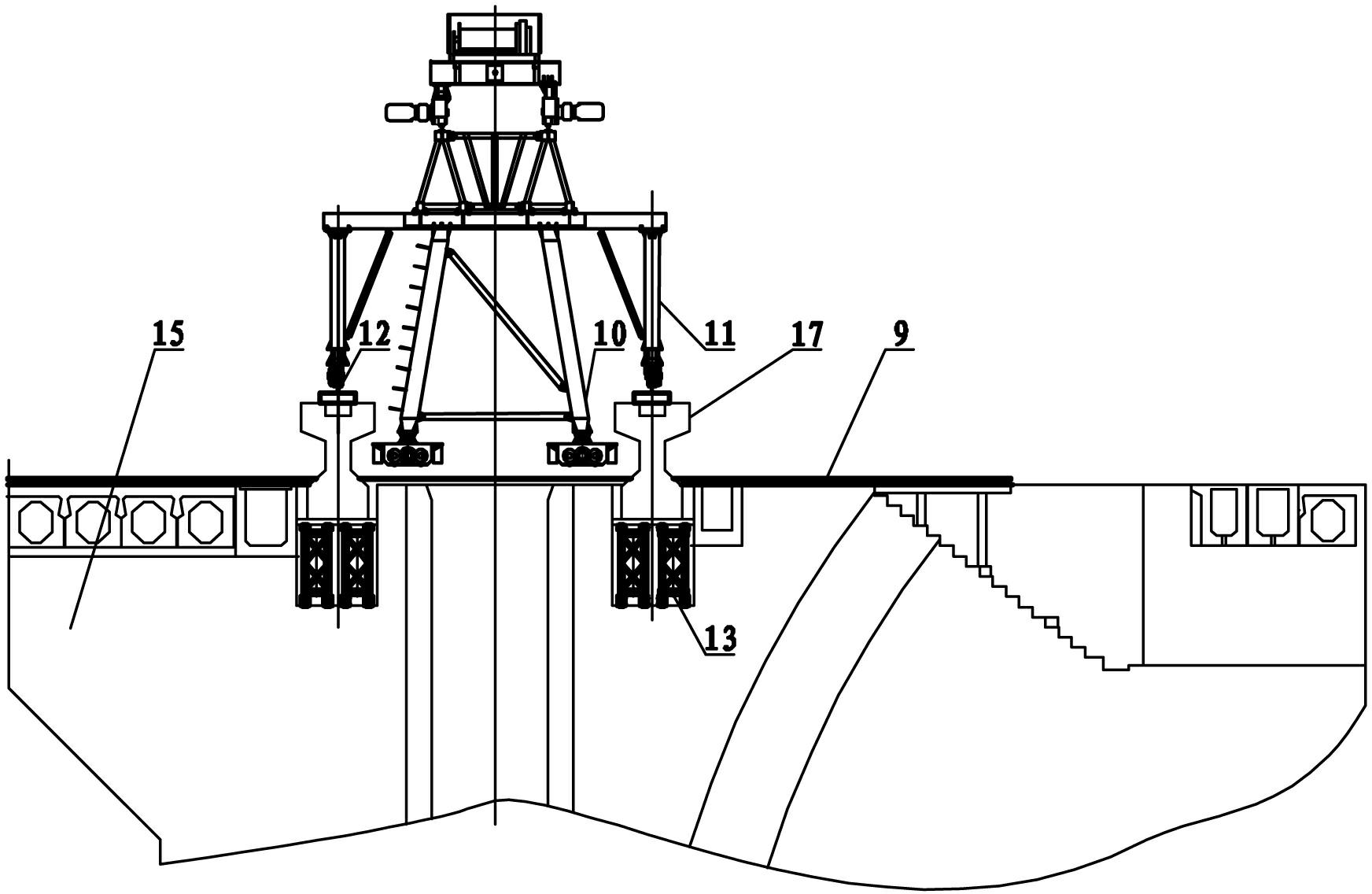

[0032] Such as figure 1 Among them, a gantry lifting device with vertical and horizontal walking functions, including a main steel beam 7, a lifting mechanism 4, and a first auxiliary leg 1, a first main leg 2, a second Two main outriggers 10 and a second auxiliary outrigger 11;

[0033] The wheel box running direction of the first main leg 2 and the second main leg 10 is perpendicular to the wheel box running direction of the first auxiliary leg 1 and the second auxiliary leg 11, so as to realize the function of walking laterally;

[0034] The height of the wheel box of the first main leg 2 and the second main leg 10 is different from the height of the wheel box of the first auxiliary leg 1 or the second auxiliary leg 11 . The difference in height is beneficial to the passage through the hole and the laying of the main outrigger running track 9 in the later stage. In this example, the first auxiliary outrigger 1 is higher than the second auxiliary outrigger 11, and the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com