Patents

Literature

60results about How to "Large lifting capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

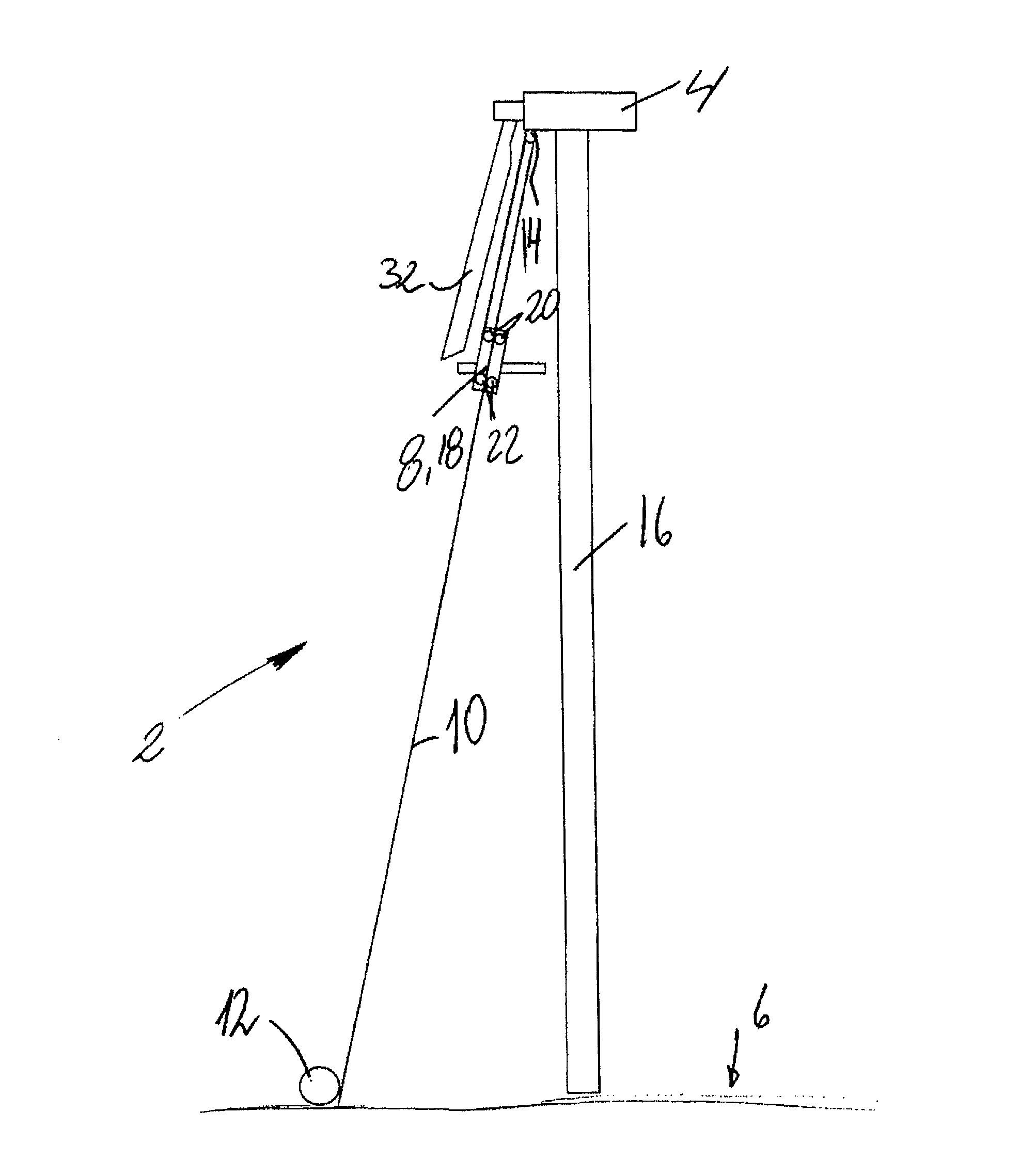

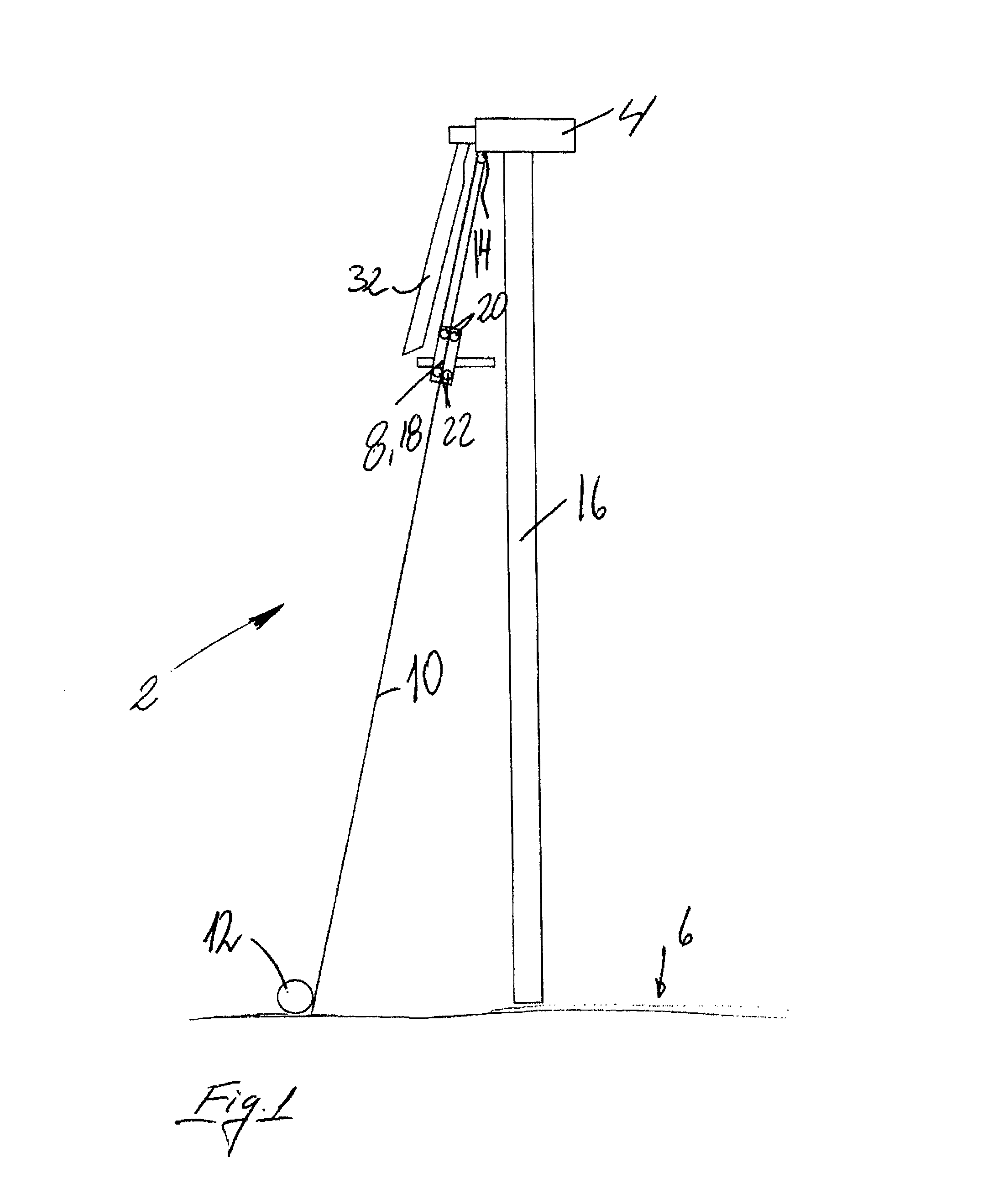

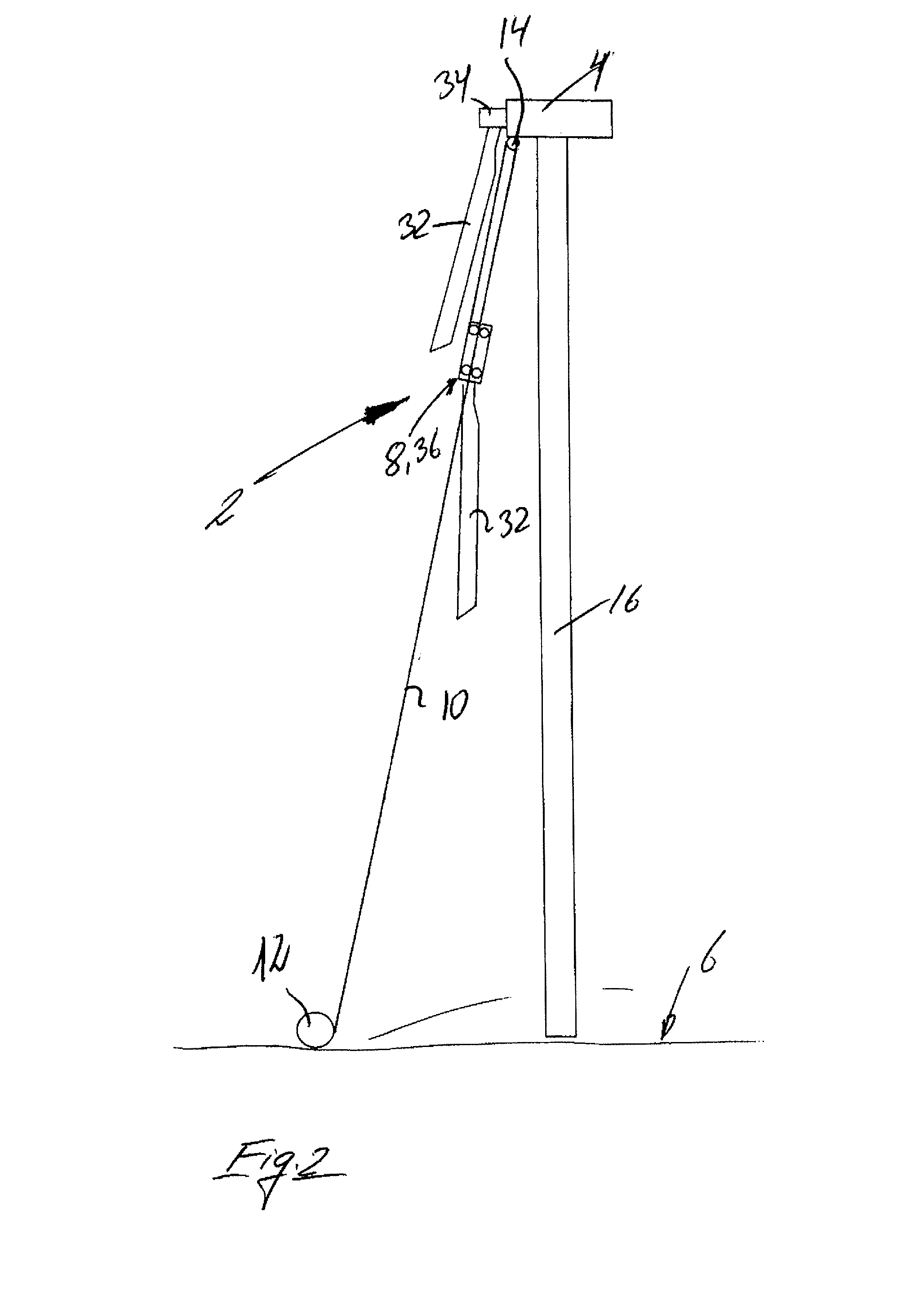

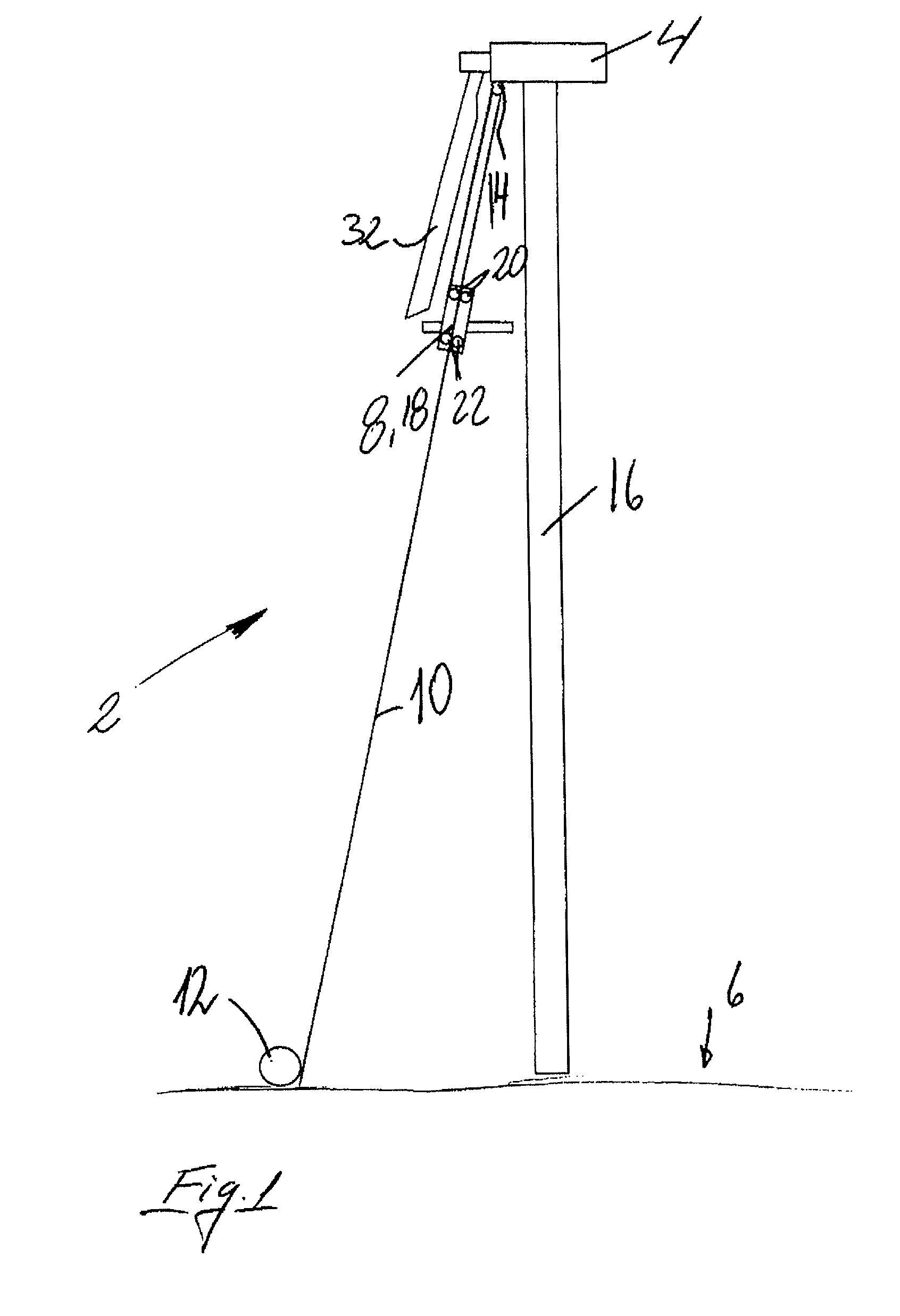

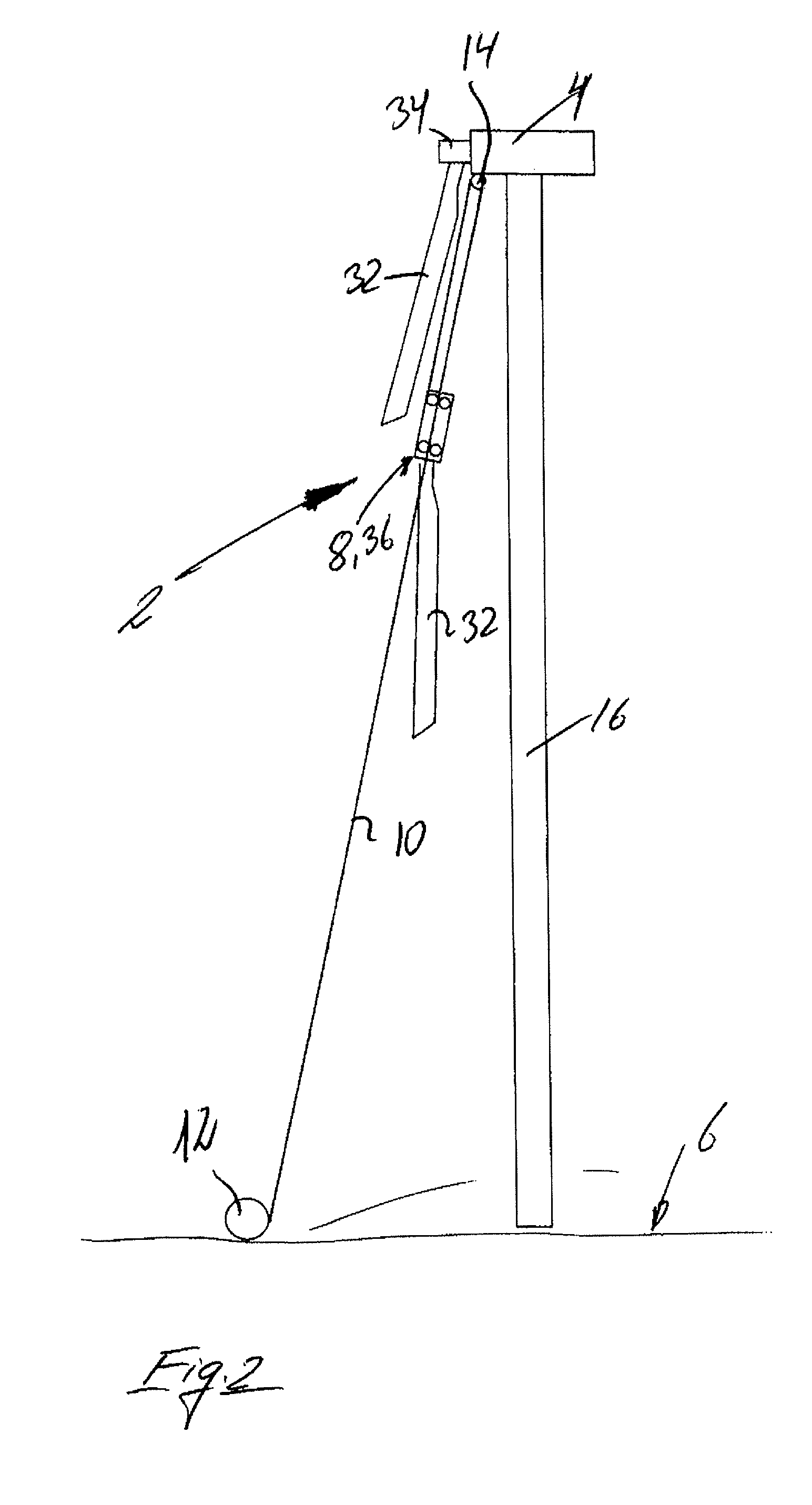

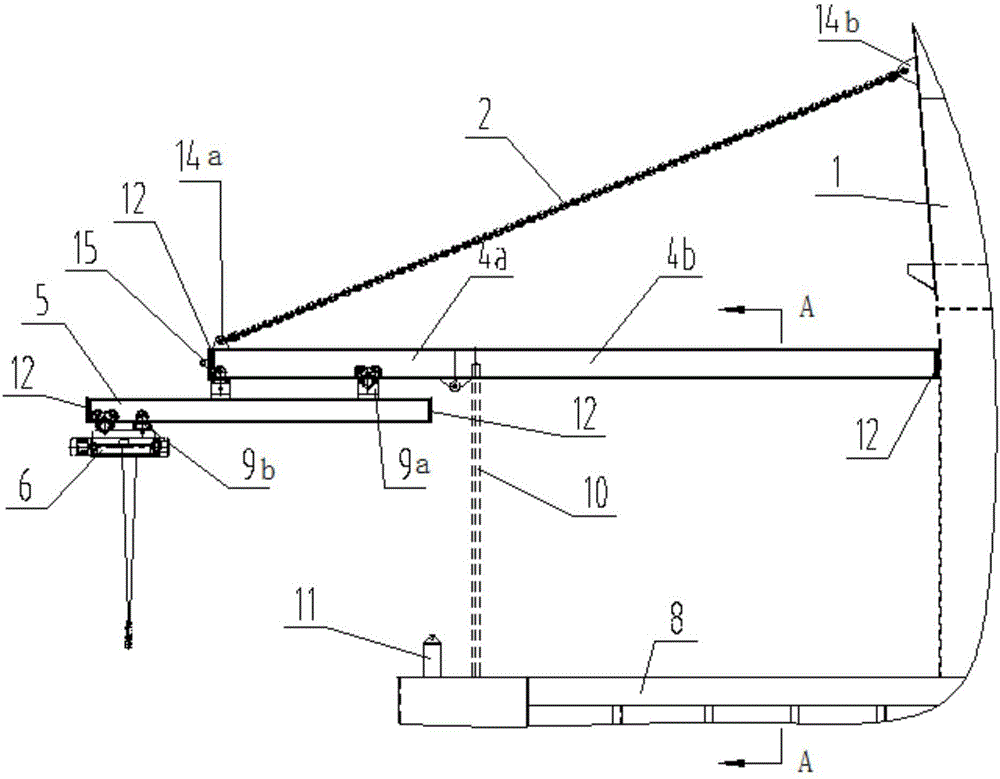

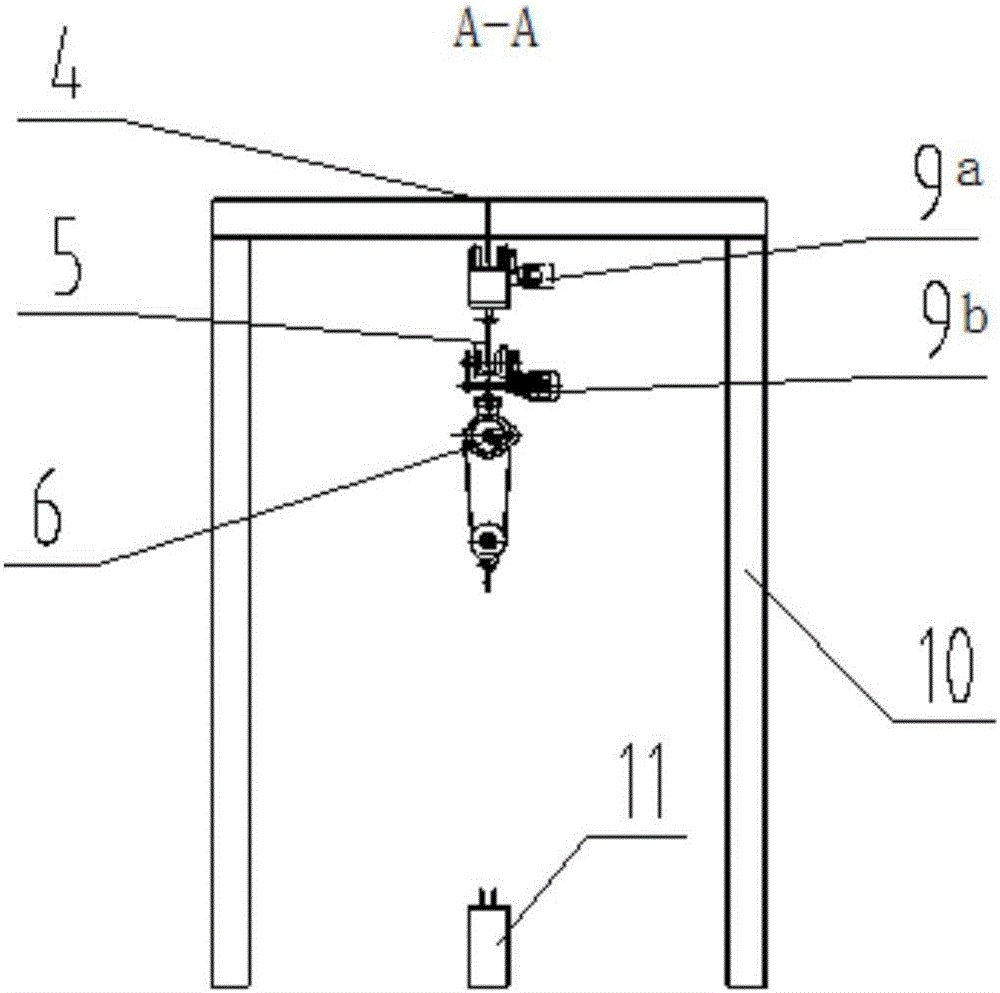

Device for establishing admittance and transport of cargo to and from a wind turbine construction above ground level

ActiveUS20120217089A1Improve securityAvoid liftingMachines/enginesEngine componentsAbove groundTurbine

A device for establishing admittance and transport of cargo to and from a wind turbine construction above ground level and having a part which can be raised and / or lowered by wires and winches located at ground level and connected with snatch blocks attached to a part so that it can be raised and / or lowered in relation to the construction. The part has a number of travelling crabs according to the numbers of winches and the travelling crabs are guided of the wires between the winches and the snatch blocks, and that the part with the travelling crabs is displaced upwards or downwards by the wires. Advantageously, the wires are used for both hoisting the part and as guide for the travelling crabs.

Owner:ELEVATORRA IP APS

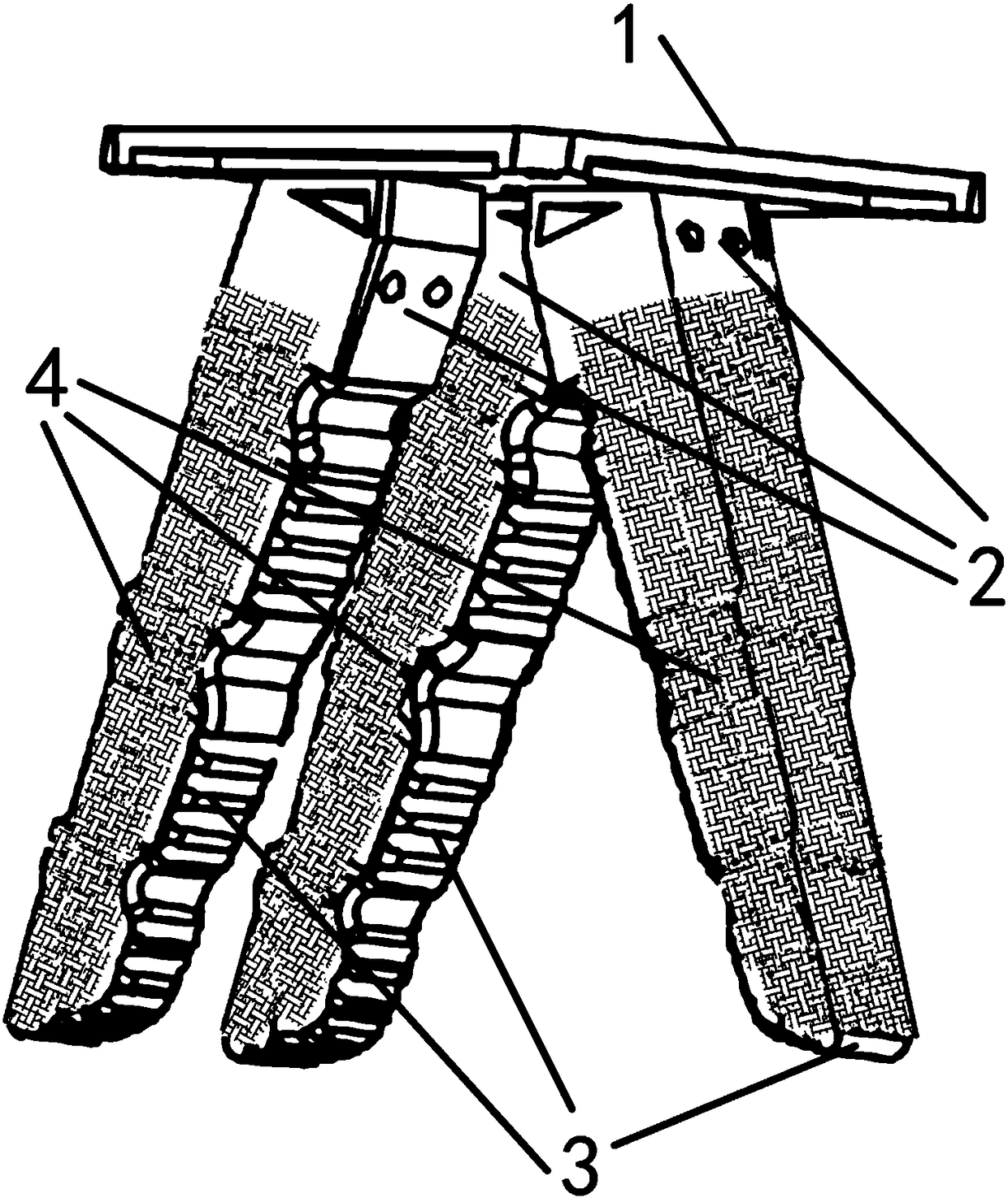

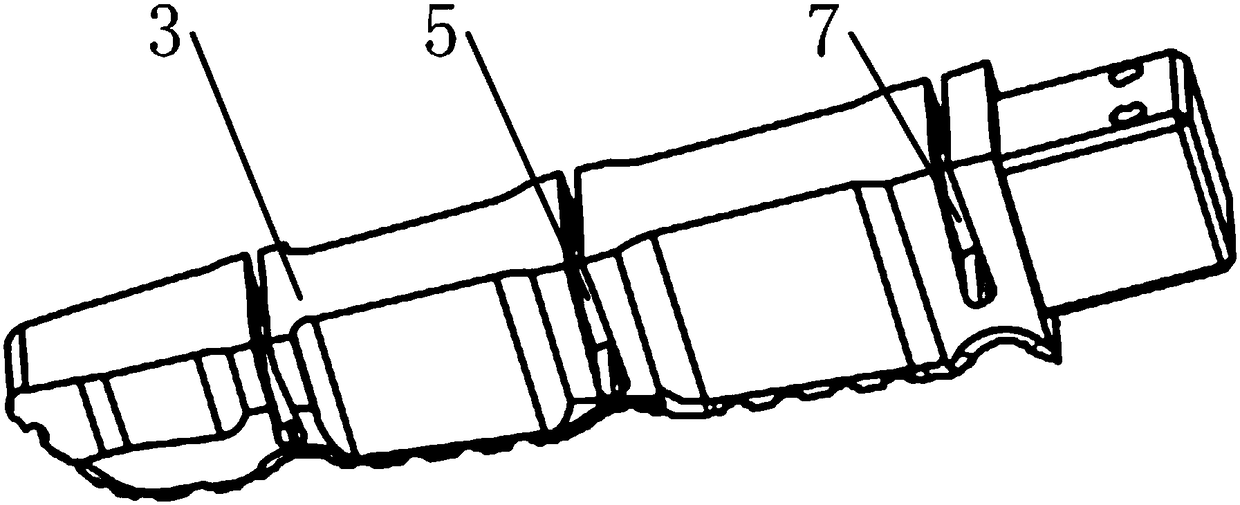

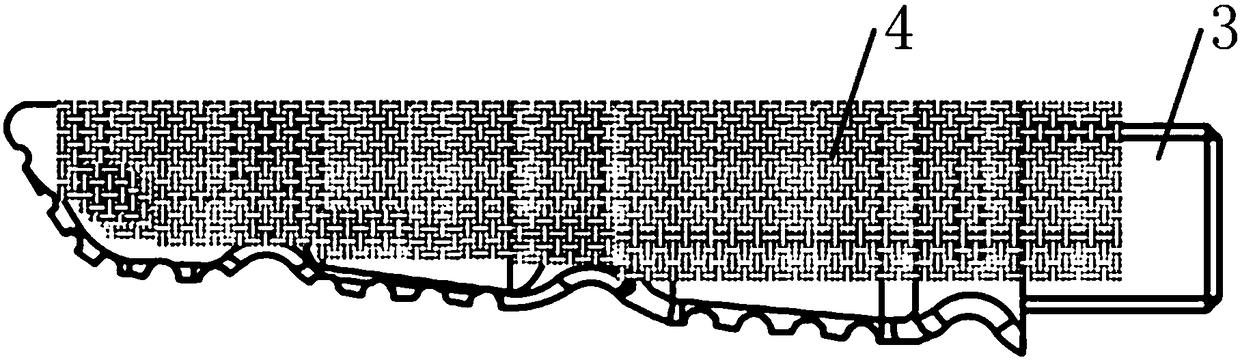

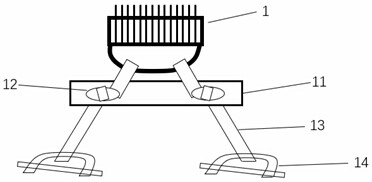

Humanoid finger inflatable soft three-finger gripper

The invention discloses a humanoid finger inflatable soft three-finger gripper, and relates to a three-finger gripper. The problem that existing soft grippers are low in load capacity is solved. Eachsoft finger module is installed on one end face of a bottom plate through a module base, a soft finger module body is internally provided with a first air cavity and a second air cavity in sequence, the first air cavity communicates with one end of a first interphalangeal joint air pipe, and the second air cavity communicates with one end of a second interphalangeal joint air pipe. The finger backof each soft finger module body is provided with at least two phalangeal joint clearance grooves through machining in the length direction of the finger back, the positions, except the finger prominence side, of the soft finger module body is wrapped with an elastic bandage, the finger prominence of the soft finger module body is provided with an elastic body, and a limiting layer is arranged between the finger prominence and the elastic body of the soft finger module body and made of a material which is easy to bend and cannot be stretched. The humanoid finger inflatable soft three-finger gripper is applied to manufacturing of a soft gripper, a robot hand, an artificial limb, a rehabilitation hand and the like.

Owner:HARBIN INST OF TECH

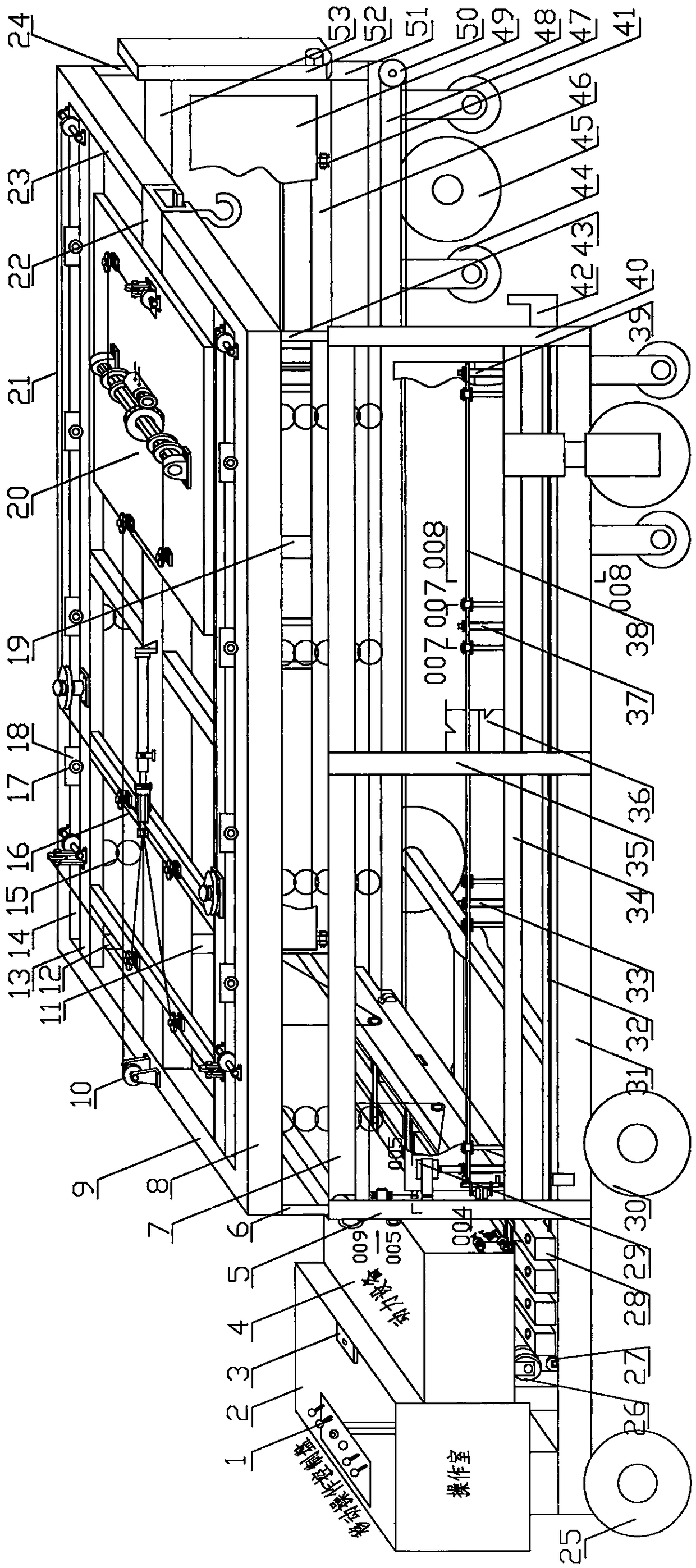

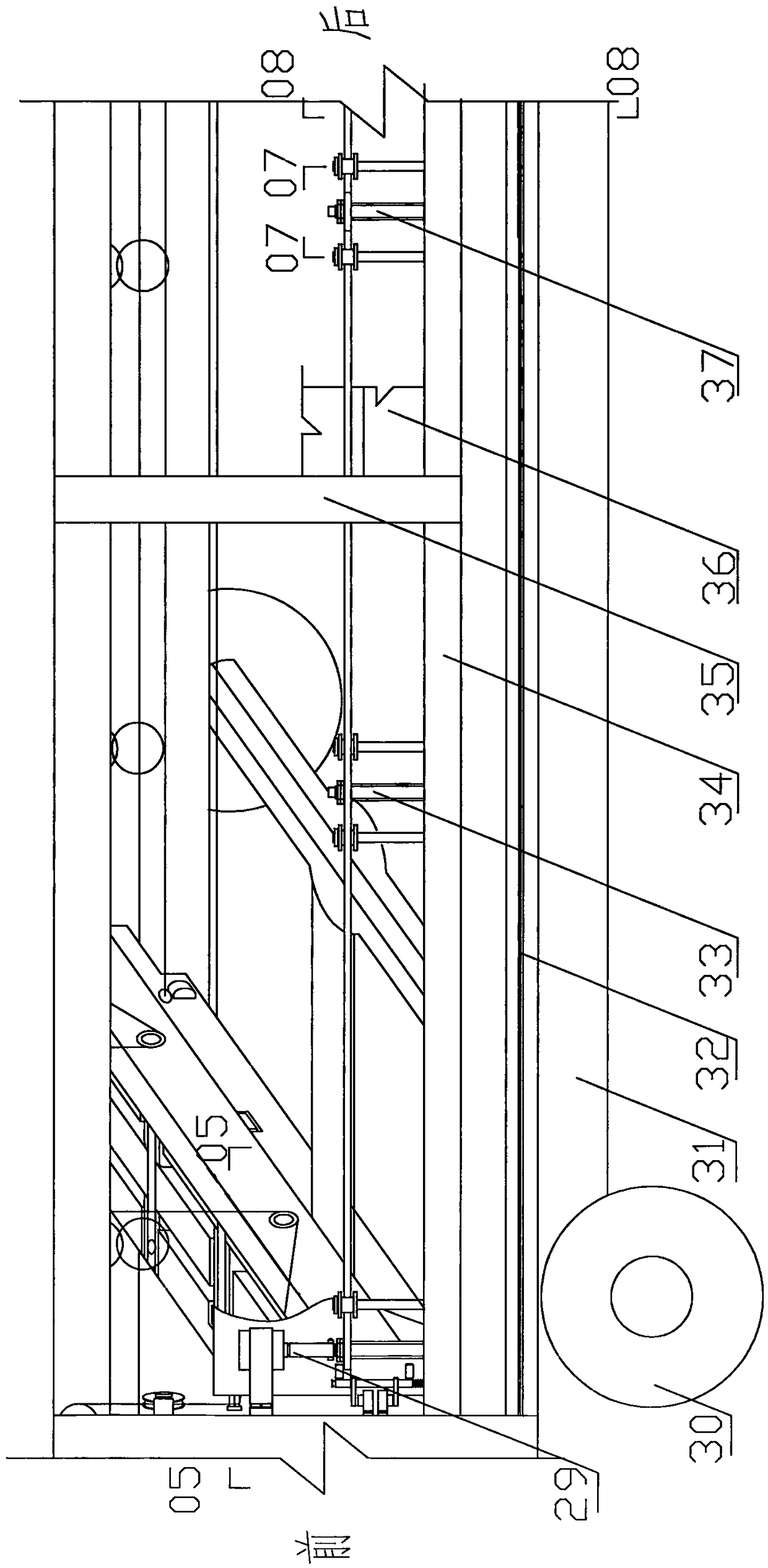

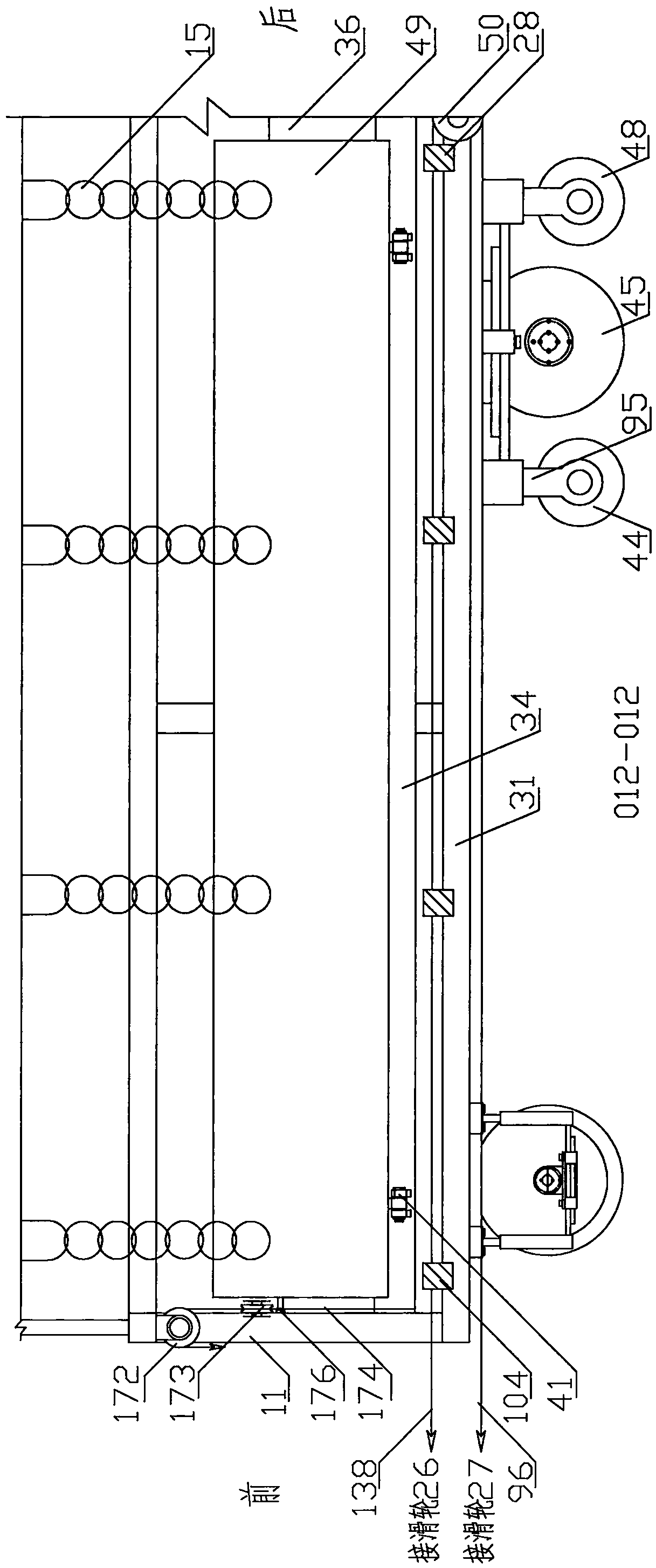

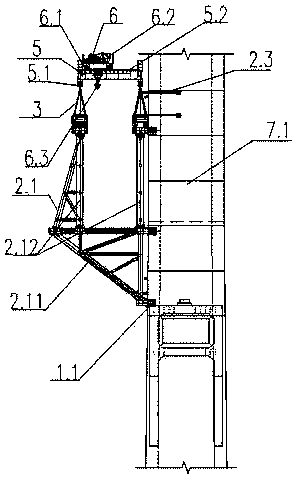

Mounting equipment car

InactiveCN108178074ARealize mechanized constructionReasonable structural stressLifting devicesTravelling gearAutomatic controlMechanical equipment

The invention discloses a mounting equipment car. The mounting equipment car consists of power equipment, a chassis, a car body, electric equipment and the like, and is characterized in that a first extension column 6, a second extension column 12, a third extension column 24 and a fourth extension column 43 are correspondingly mounted at the upper sections of inner cavities of stand columns at four corners of a box; the other end of each stand column is connected to the top of the box; the top of the box can be vertically lifted to lift equipment; an extension lifting crane is mounted at thetop in the box; more than one layers of cross beam support structures and drive connecting devices are mounted on the inner and outer sides of a channel between longitudinal components on the two sides of the box to form a rotary recovered movable plane support structure; the equipment can be carried on cross beams; the cross beams can be automatically recovered on the two sides of the box; and the section of the box is n-shaped. The mounting equipment car reduces the equipment mounting construction flow, removes various cranes, vehicles, forklifts and tools in traditional construction, once finishes lifting, transportation and installation on one car, achieves automatic control and precise installation, realizes mechanical equipment installation, and greatly improves the equipment mounting efficiency.

Owner:白天海

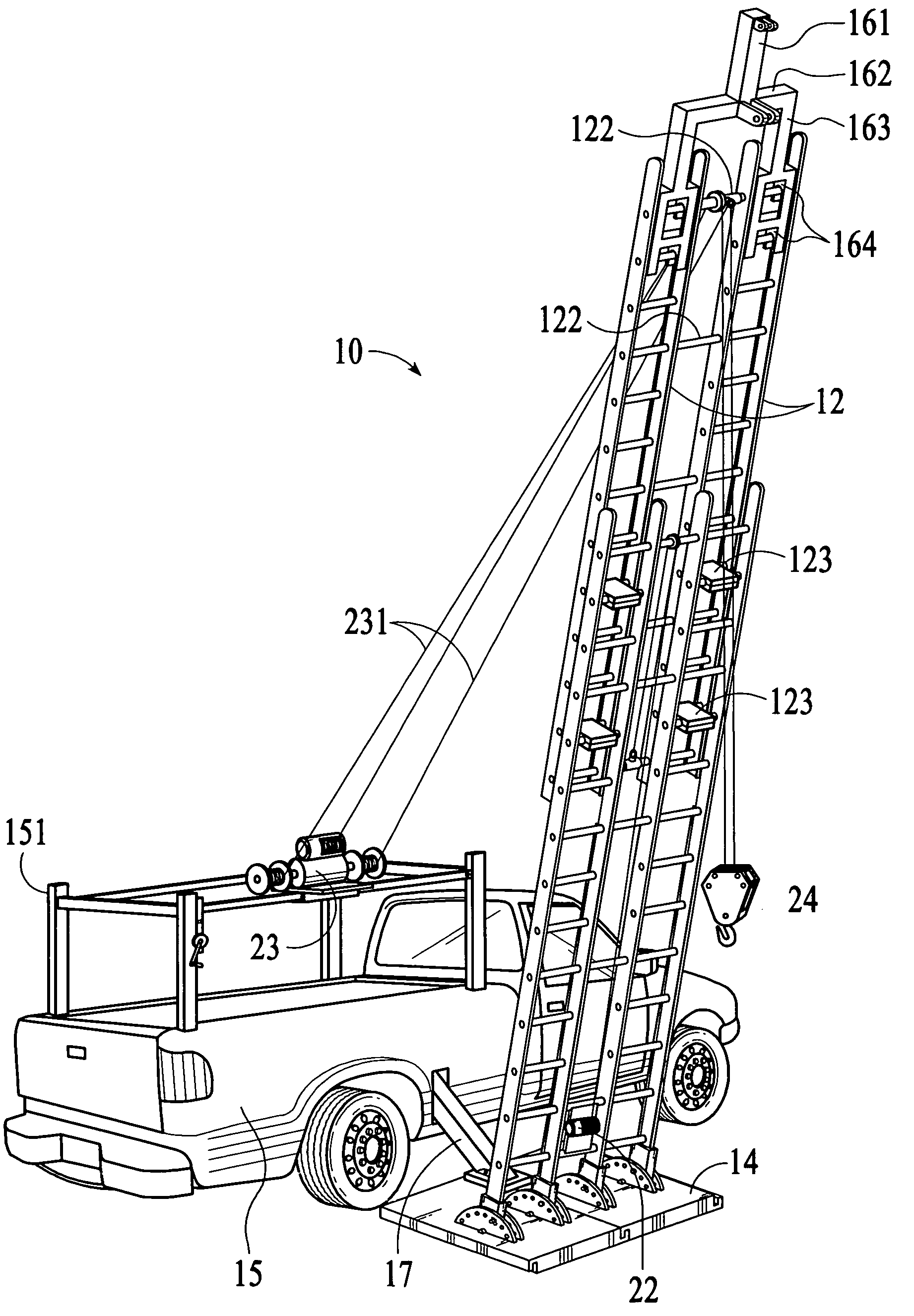

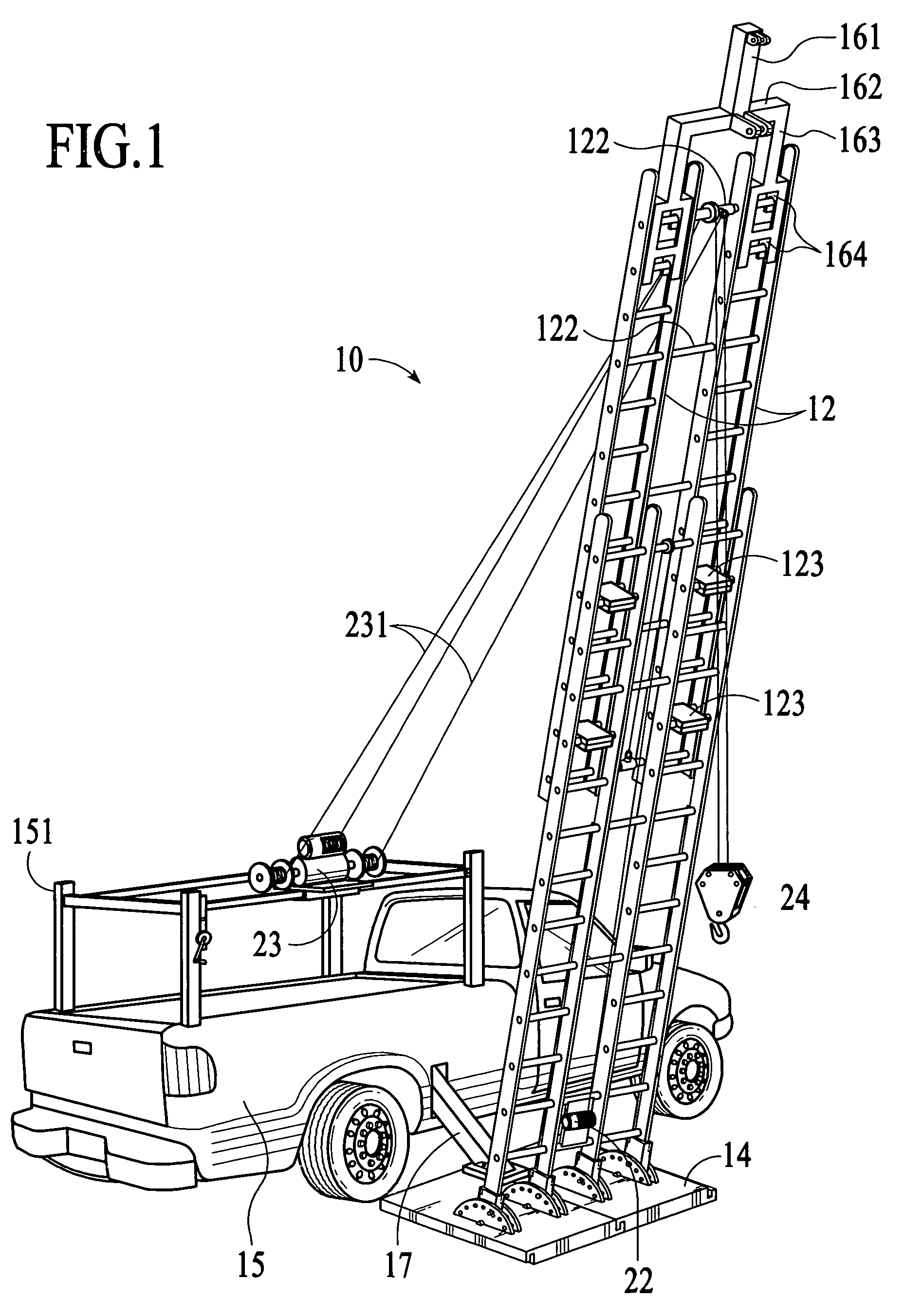

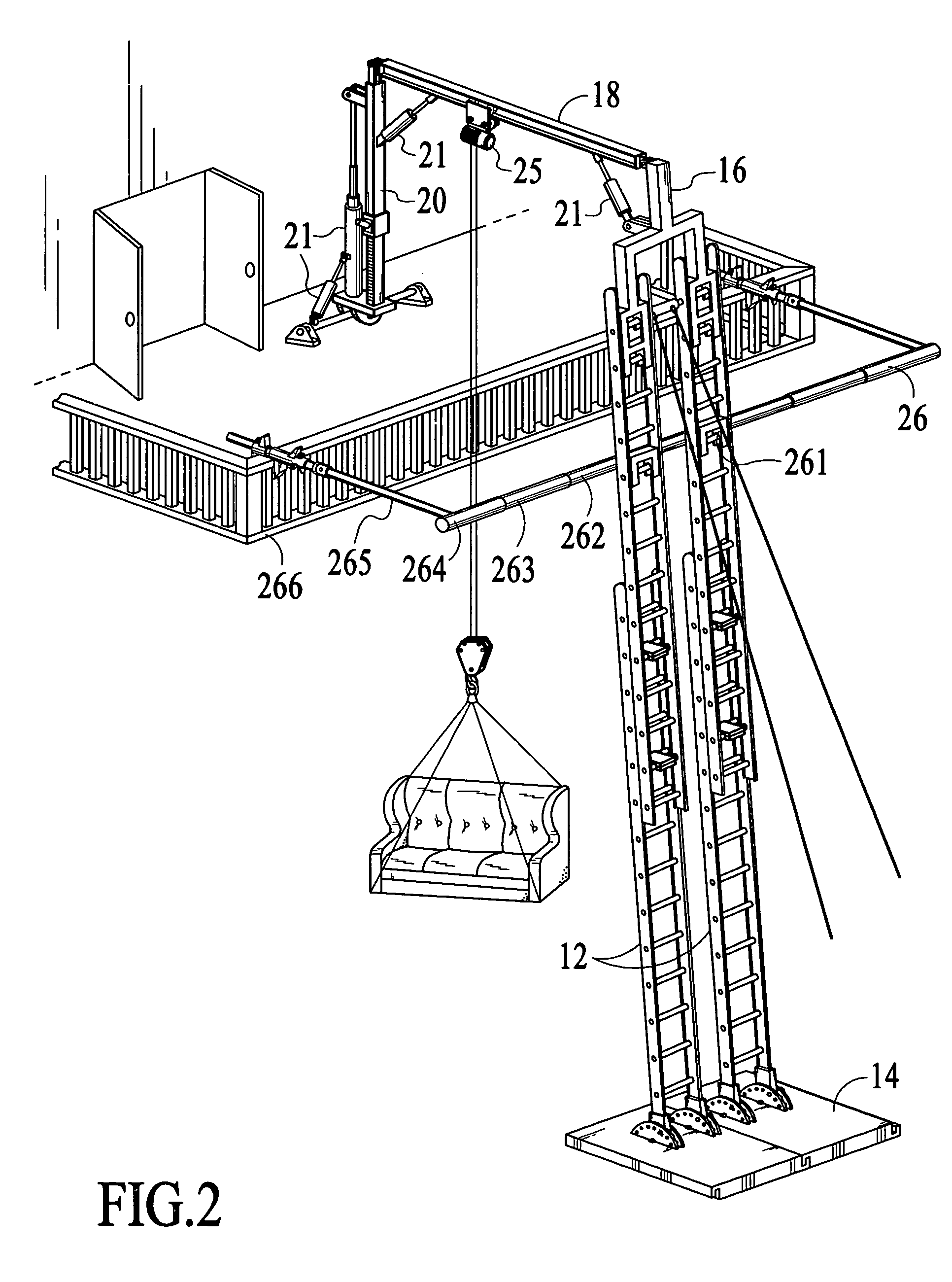

Ladder elevator device

An elevator device that is installed on one or more ladders to lift loads from the ground to a desired position on a roof. A base securing device can be added to each of the ladders to insure stability. An outrigger mounted on a user's truck can be employed to further stabilize the ladders. The elevator device includes a ladder attachment assembly to affix the device to a ladder or ladders, a lateral travel section, and a roof top mounting device. A ladder stabilization bracket that affixes the ladder to a parapet or balcony can be employed for additional stability of the device. Several winch mechanisms are utilized to position the device and raise loads. The device can be easily adapted for use on flat roofs with a parapet through the addition of a ladder stabilization bracket. The elevator device can also readily be used on flat roofs without parapets, pitched roofs, and even to load trucks.

Owner:HATCH BARLOW

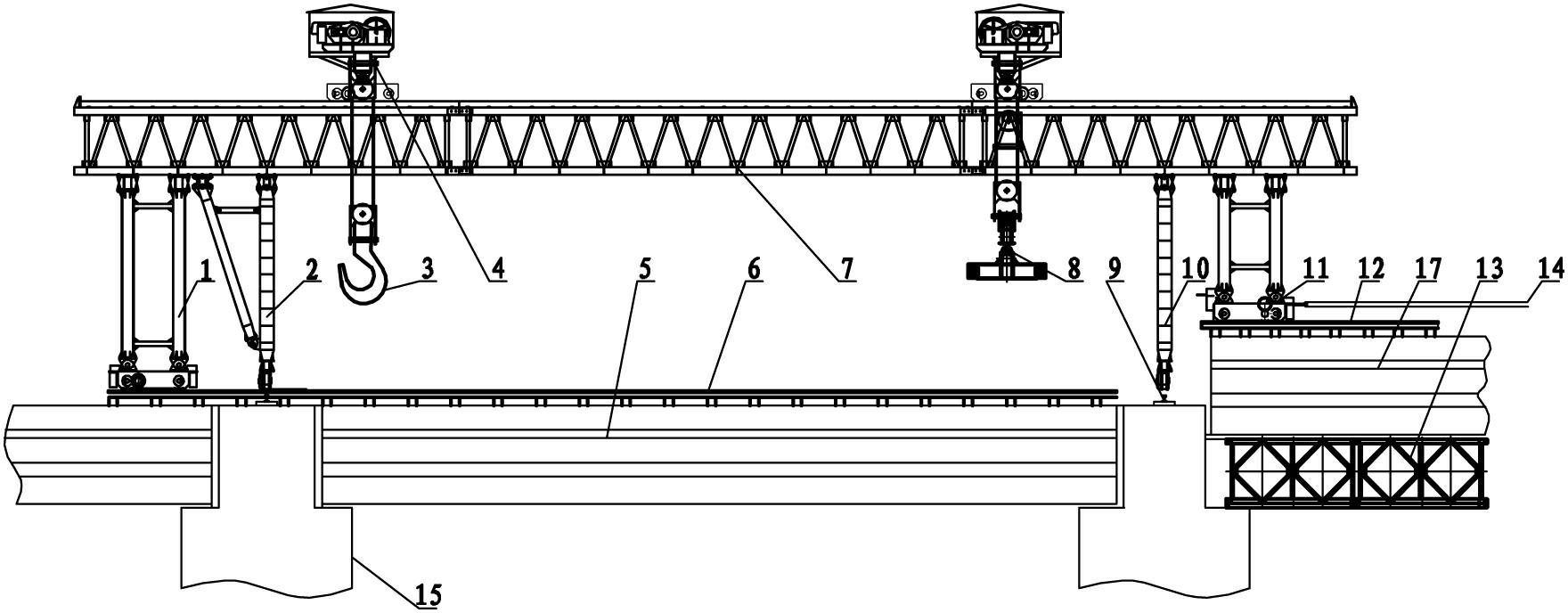

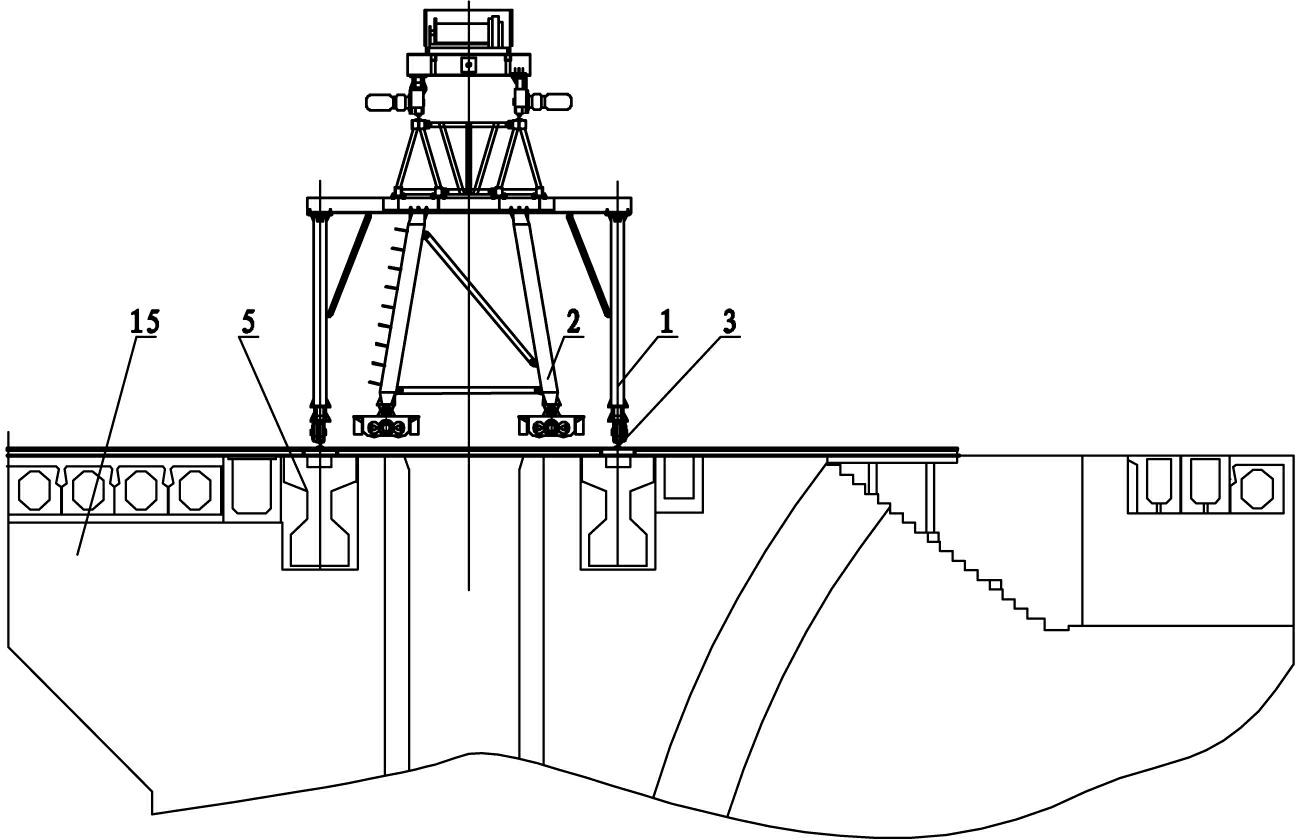

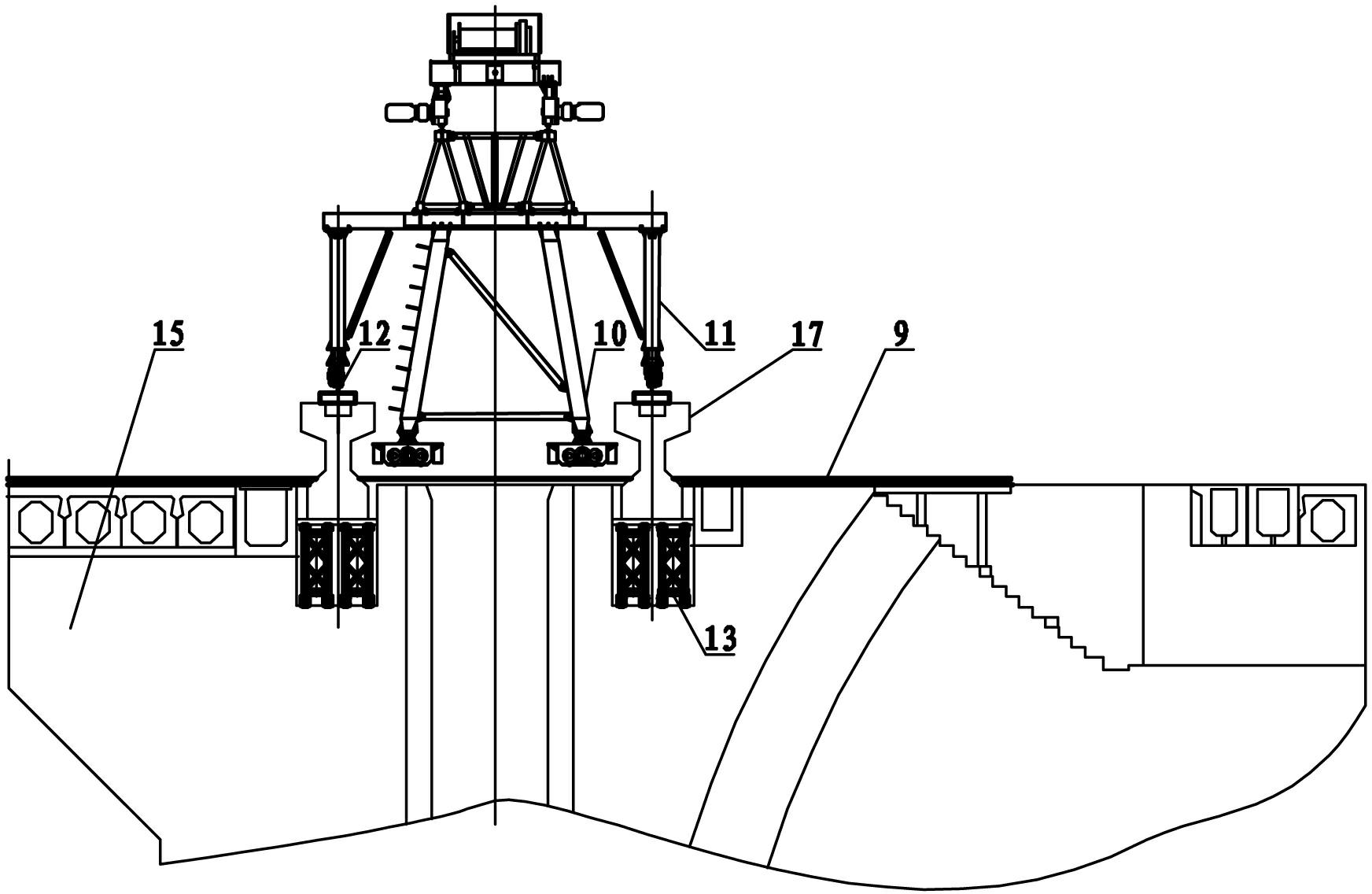

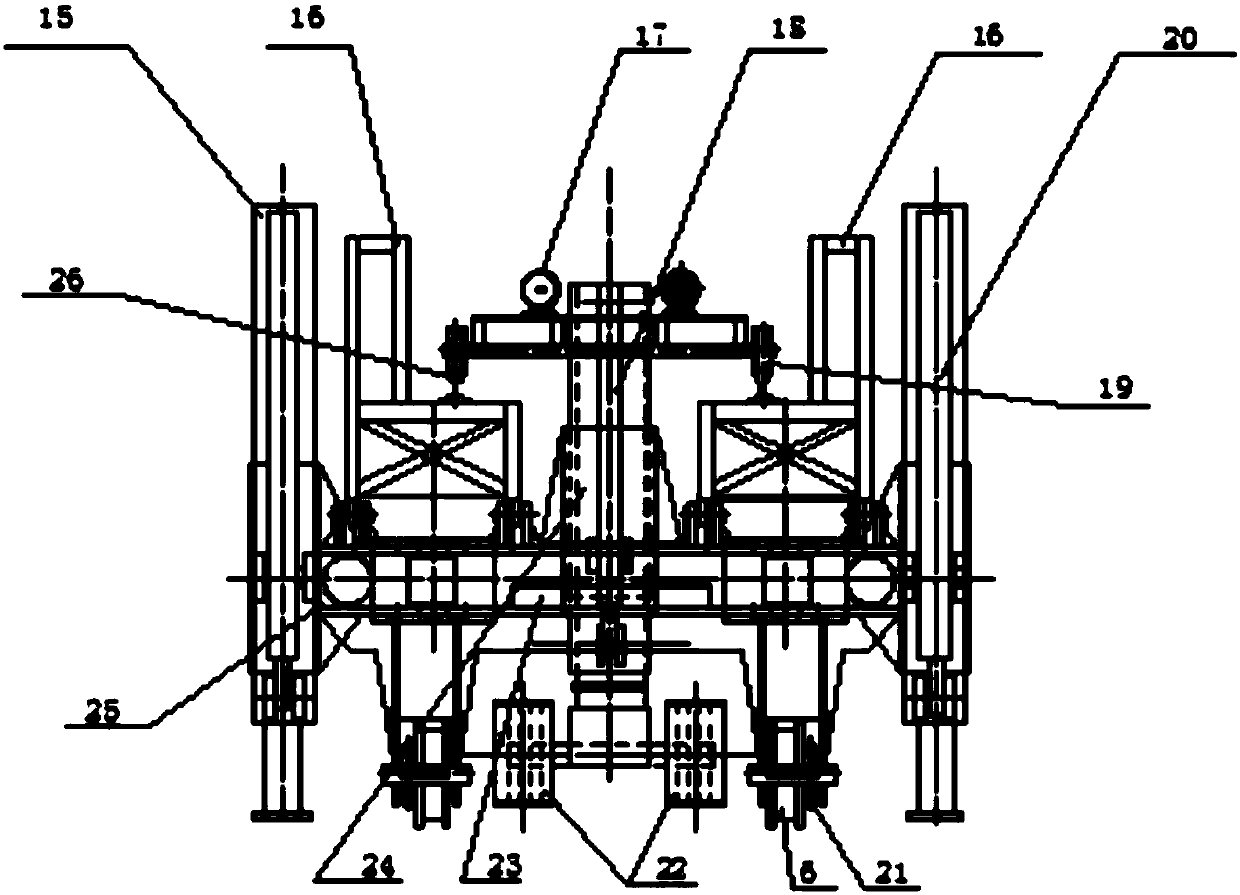

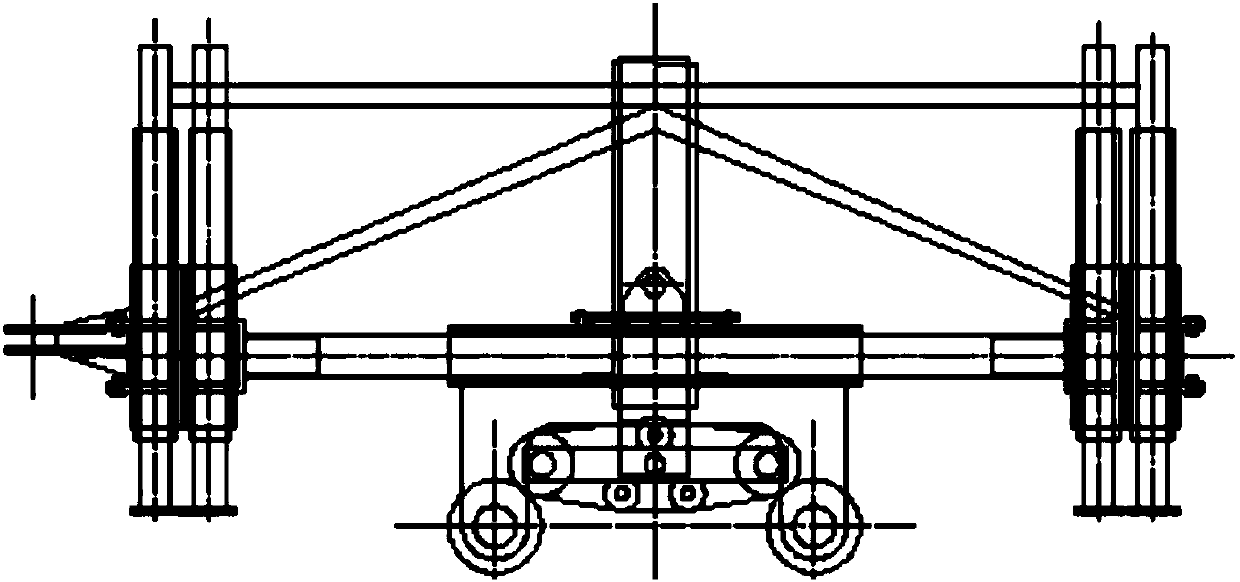

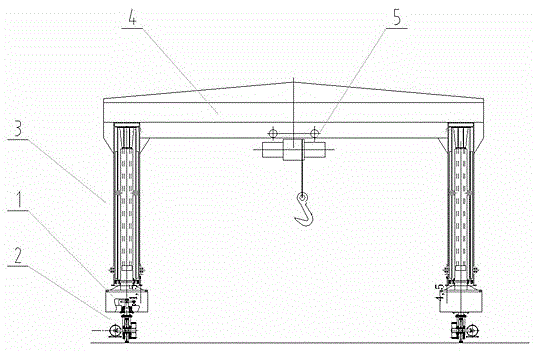

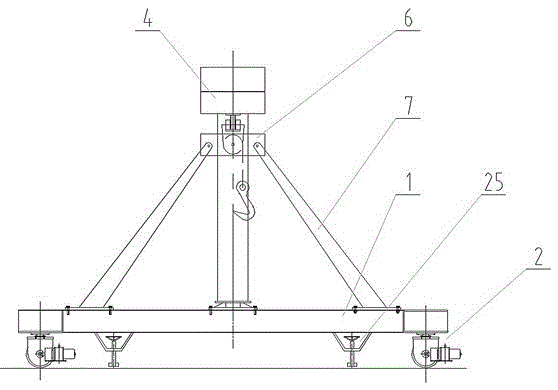

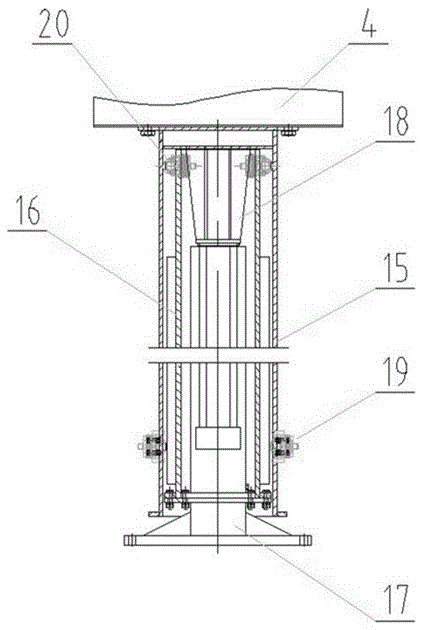

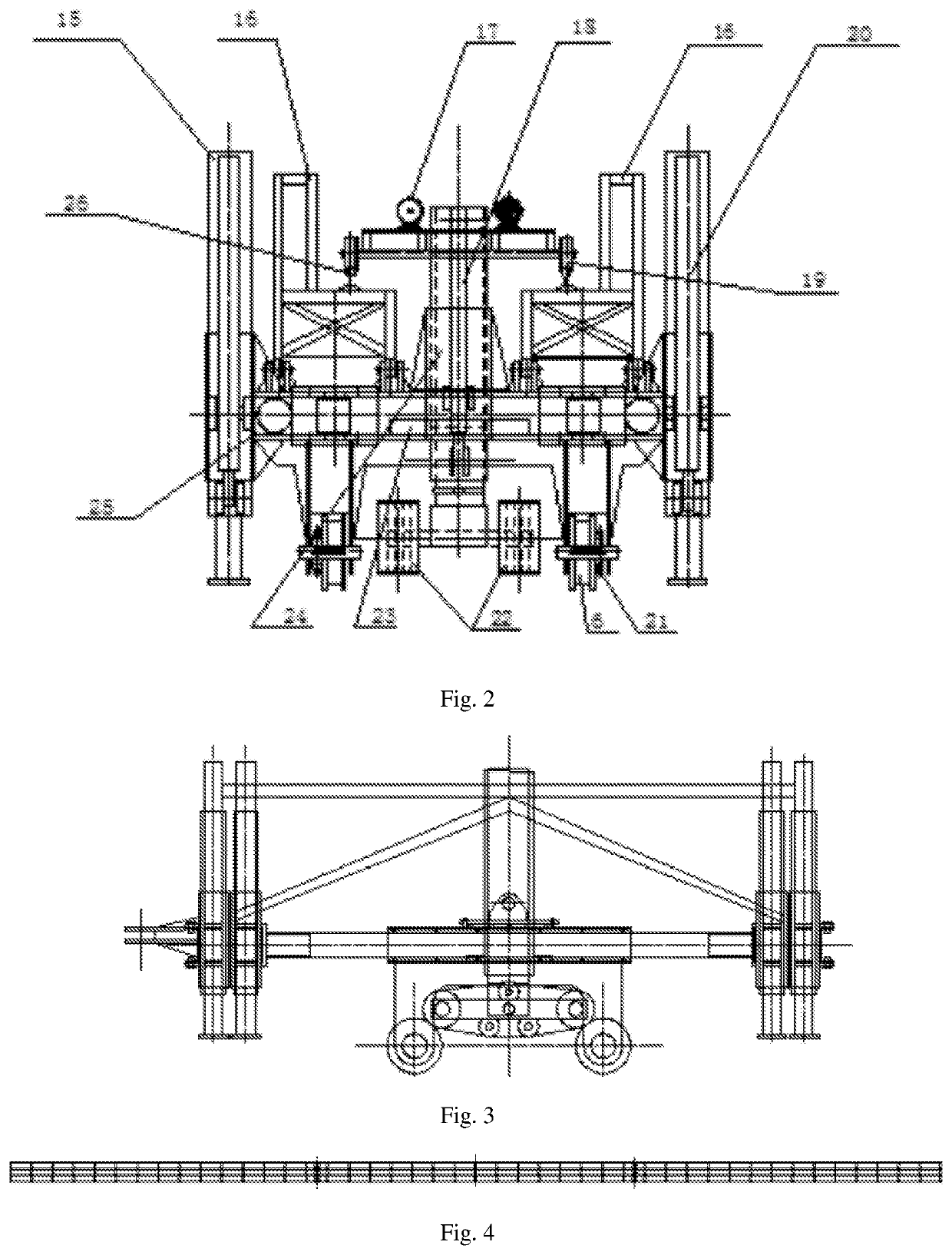

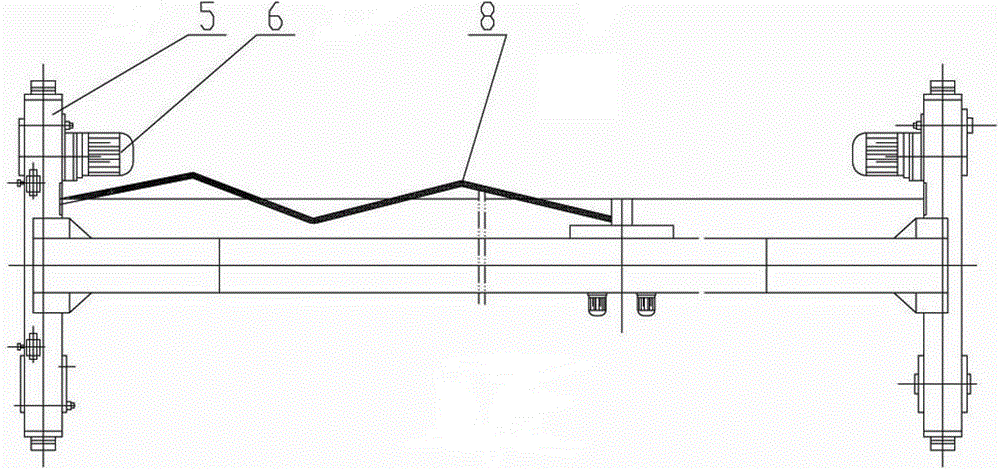

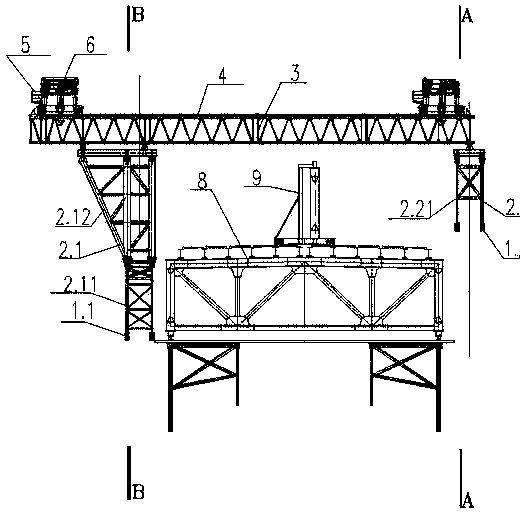

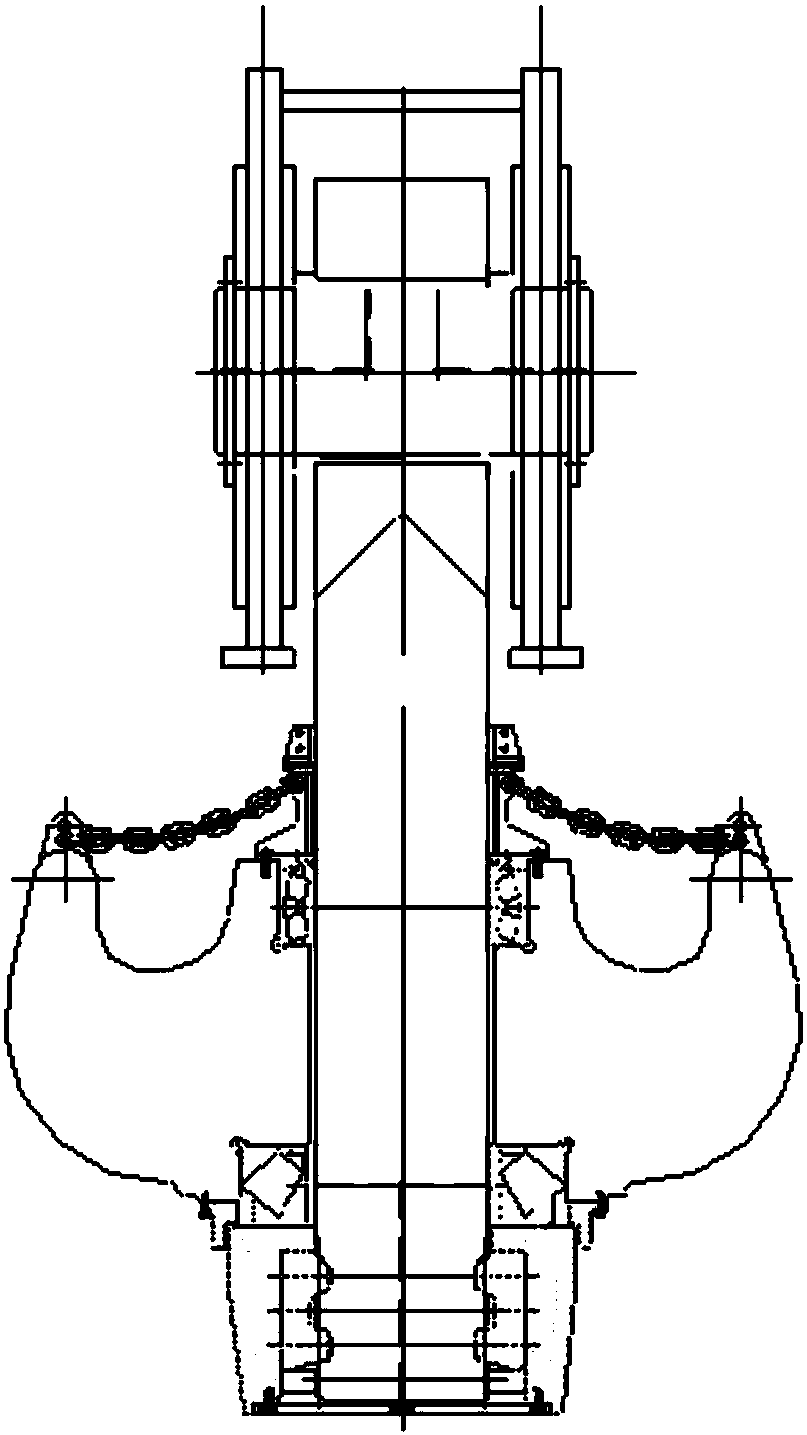

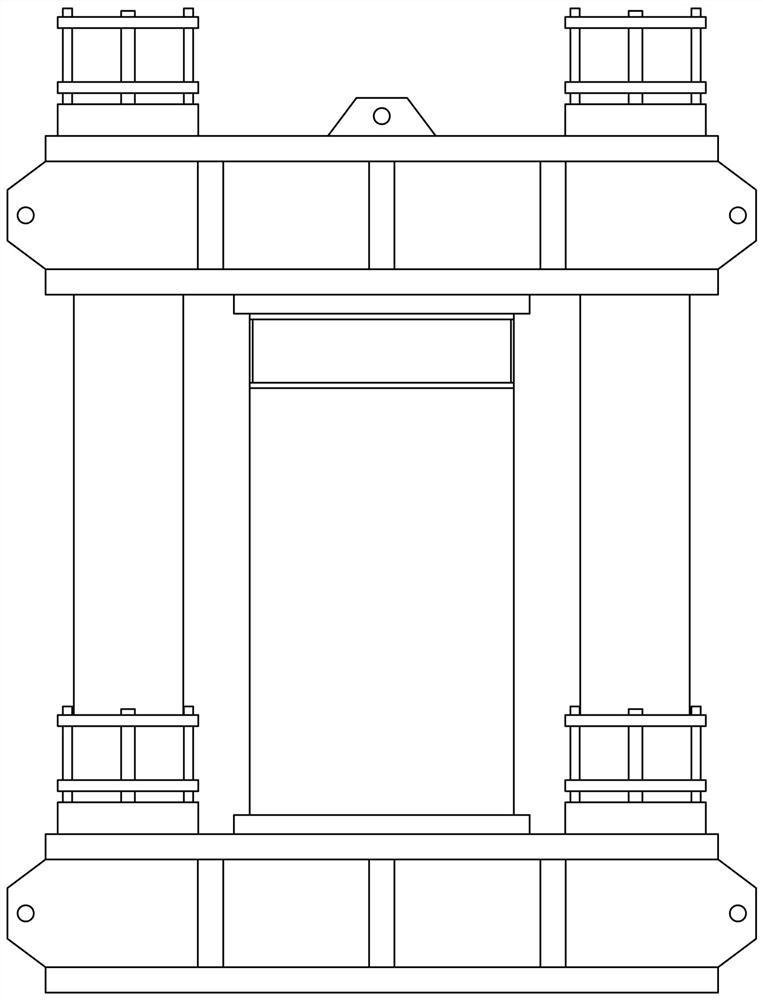

Gantry crane device with lengthways and transverse traveling functions and hoisting method

InactiveCN102139832ASave on rental costsImprove the safety of hoisting constructionBase supporting structuresBraking devices for hoisting equipmentsEngineeringMechanical engineering

The invention discloses a gantry crane device with lengthways and transverse traveling functions. The gantry crane device comprises a main steel girder and a hoisting mechanism, wherein a first auxiliary supporting leg, a first main supporting leg, a second main supporting leg and a second auxiliary supporting leg are arranged on the main steel girder in turn; the roller box traveling direction of the first main supporting leg and the second main supporting leg is vertical to that of the first auxiliary supporting leg and the second auxiliary supporting leg; and the roller box height of the first main supporting leg and the second main supporting leg is different from that of the first auxiliary supporting leg or the second auxiliary supporting leg. The gantry crane device has the advantages of high hoisting capacity, novel concept, and simple structure and is convenient to operate, is safe and reliable and is not affected by a rainy season and a flood season. In the water conservancyproject flood discharge gate hoisting construction technology, compared with the normal large crane, the gantry crane device has great advantages in economy and technology, and can simplify construction procedures to adapt to various hoisting working conditions, speed up a construction progress and highly reduce a safety hazard.

Owner:CHINA GEZHOUBA GROUP CO LTD +1

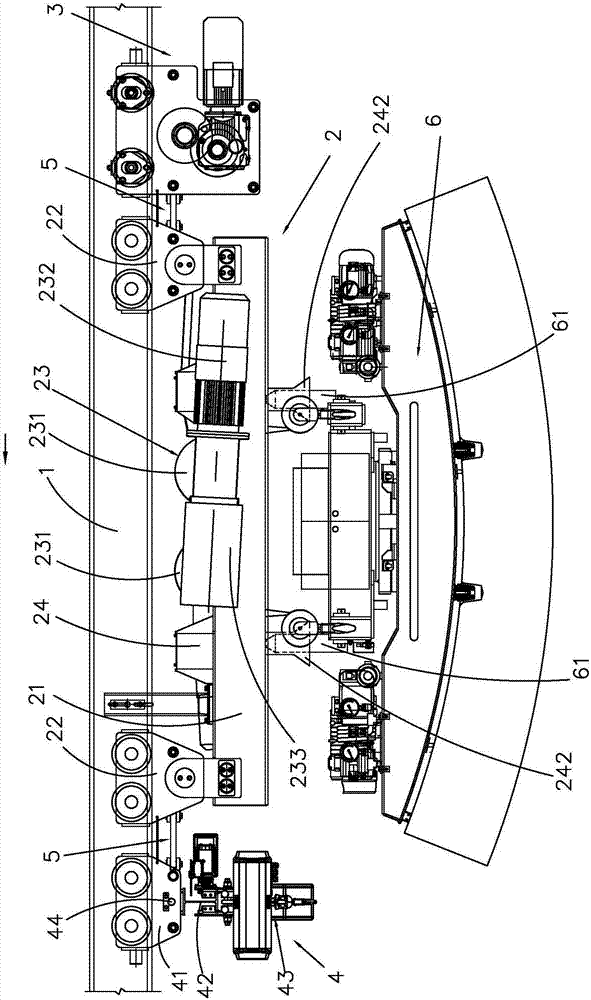

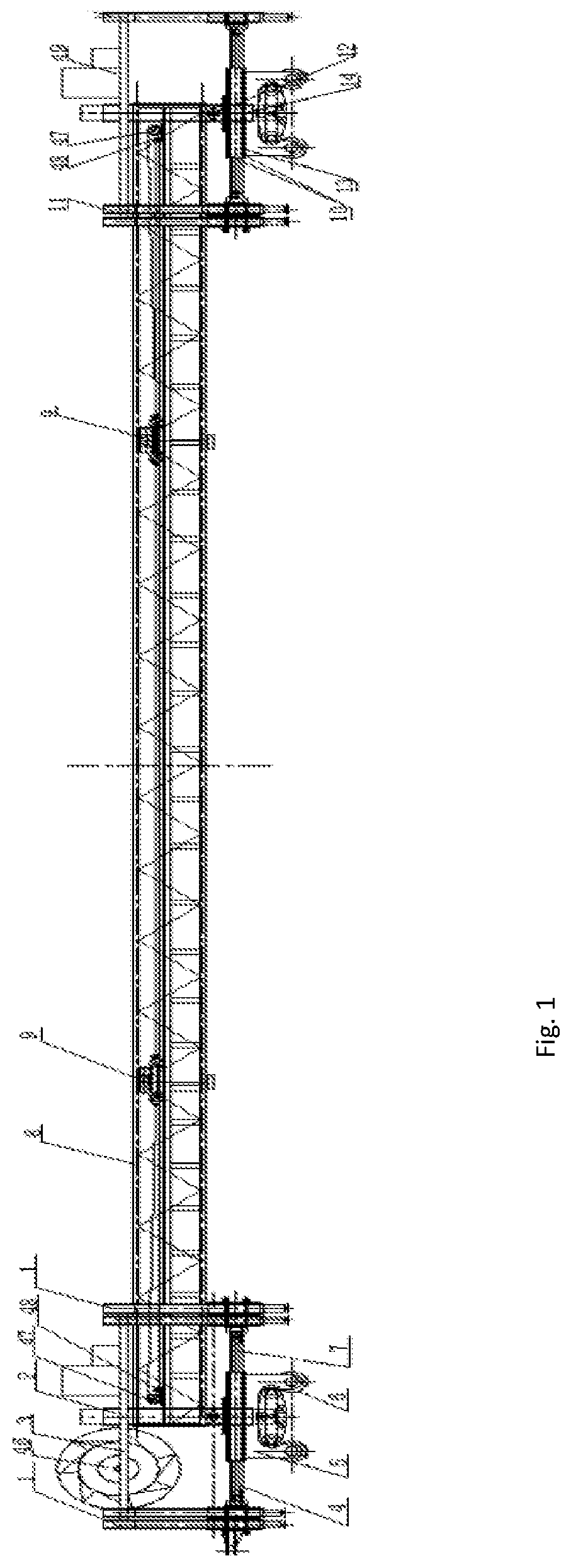

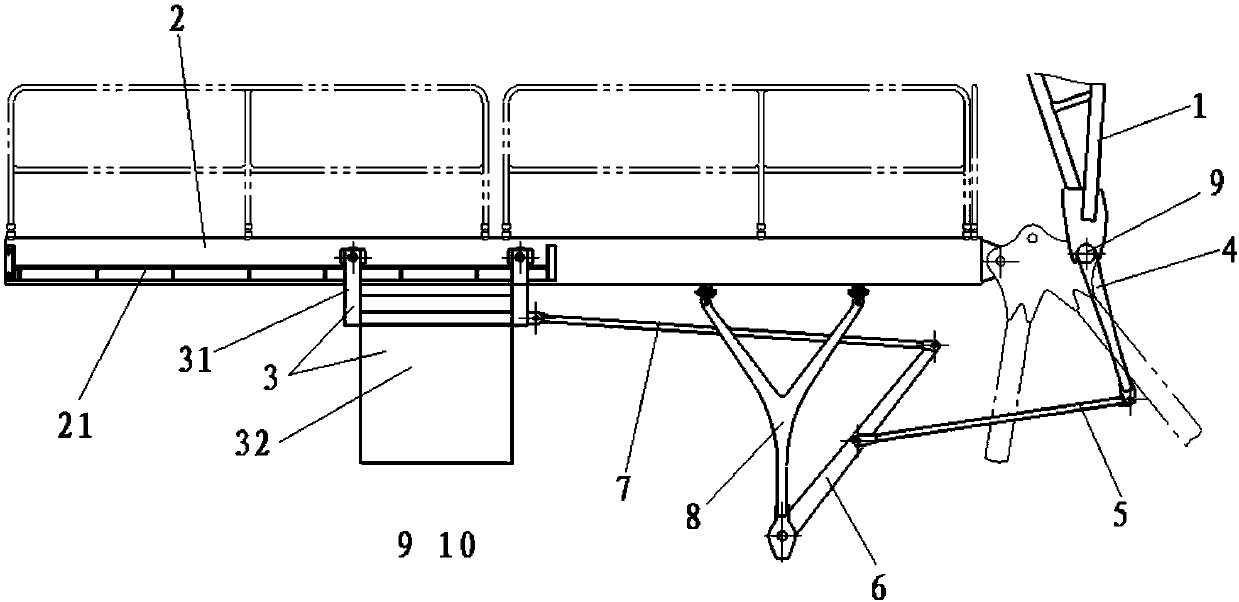

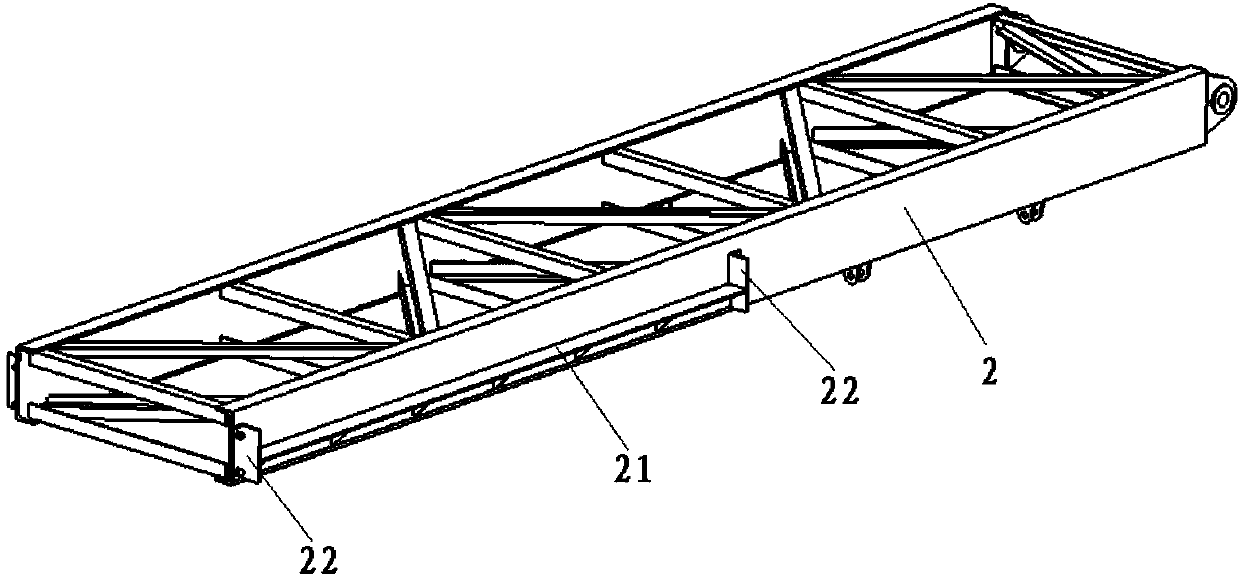

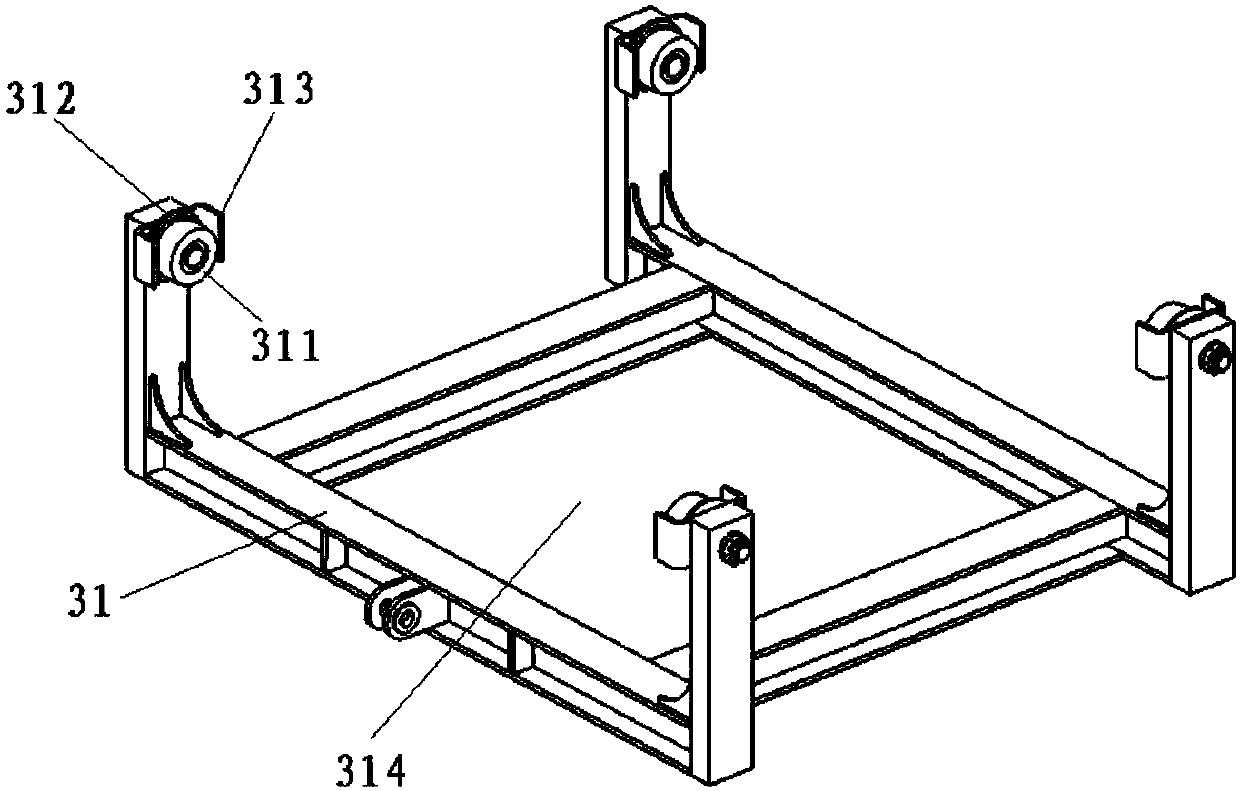

Novel track layer for urban rail traffic engineering and its construction method

PendingCN107642012AEasy to operateEasy to driveRailway track constructionIndustrial engineeringUrban rail

The invention relates to the engineering technology science and particularly relates to a novel track layer for urban rail traffic engineering and its construction method. The device comprises a lifting walking work trolley, a connection truss beam, a track walking mechanism and a supporting structure; horizontal stretching and vertical supporting structures of the lifting walking trolley are operated firstly so as to lift the whole novel track layer to the height of a track hanging and dismounting material; a hoisting trolley lifts up the track material to leave a flat trunk and a material pad; the novel track layer is forwards walked to the installing position of a track section, and then the track material is dismounted; a steel track is connected and the track section is mounted to temporarily support and fix the newly installed track section; the track is walked towards the track section hoisting position in next time to arrive at the unloading place, then the track section is hoisted to the next cycle. The device is simple in structure, convenient to operate, and low in cost; meanwhile, the safety during the working process is ensured and the efficiency is improved.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

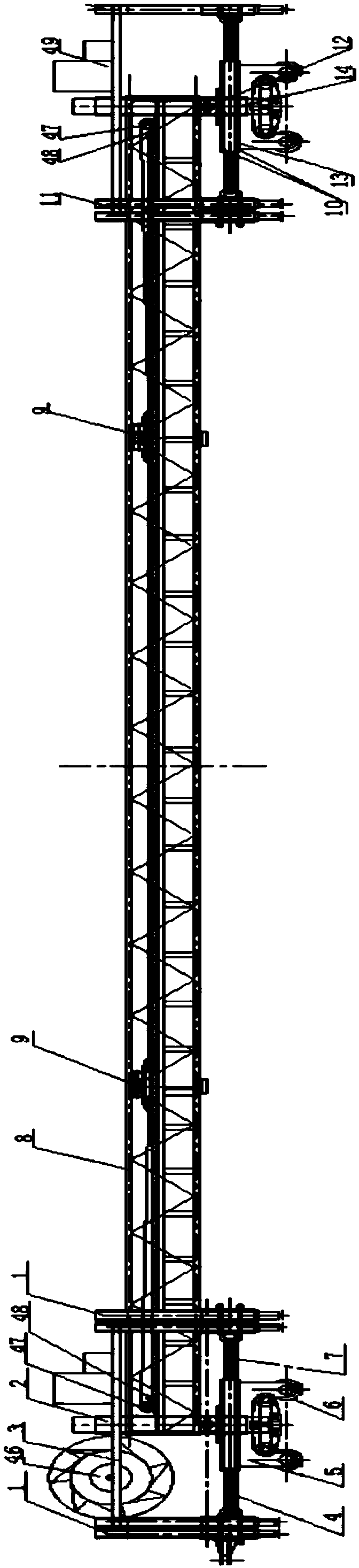

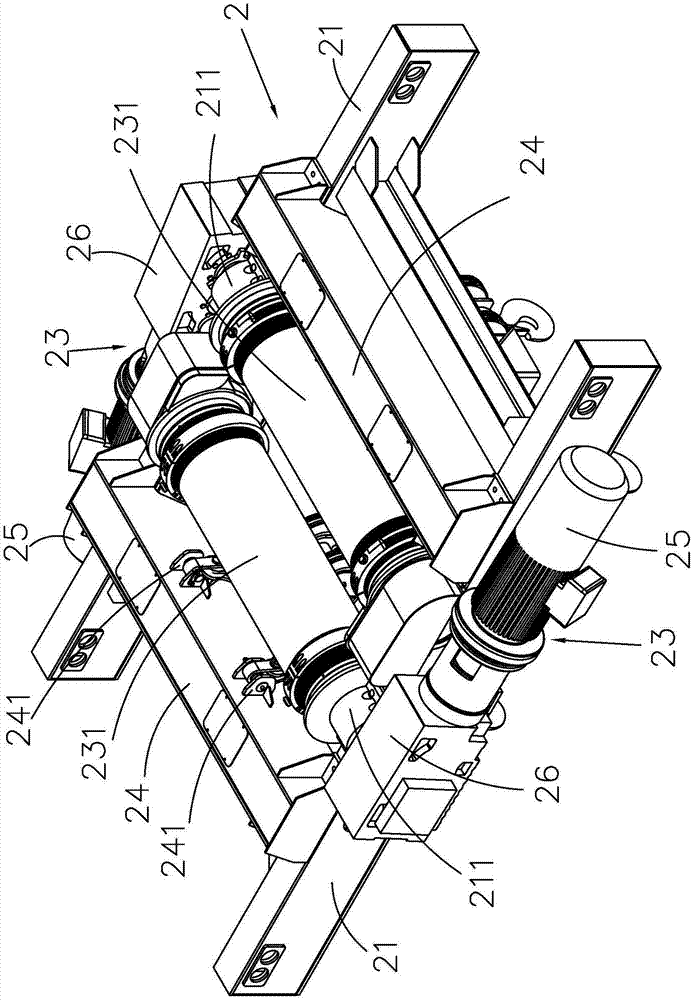

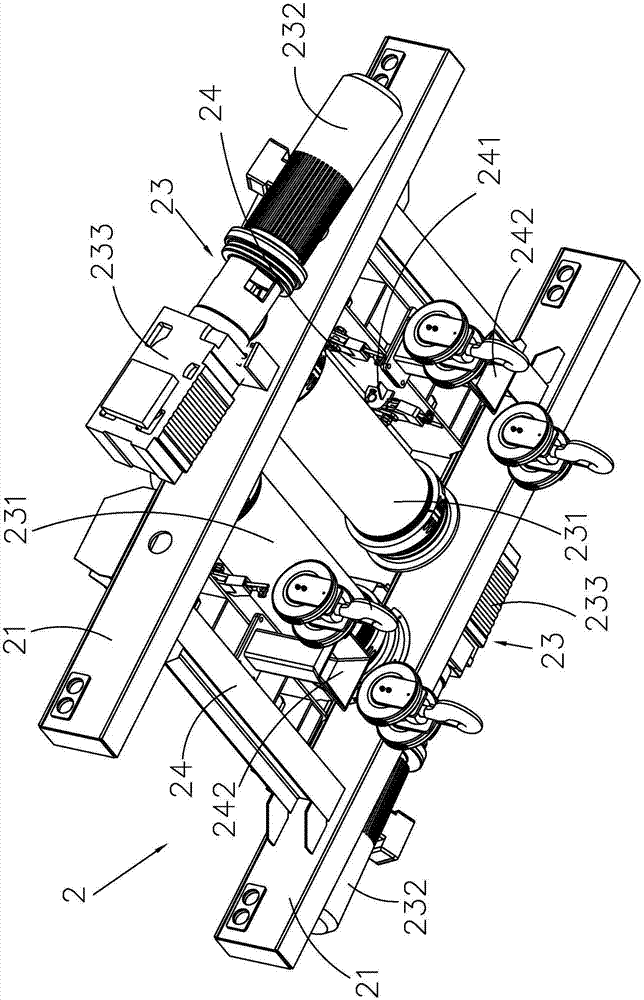

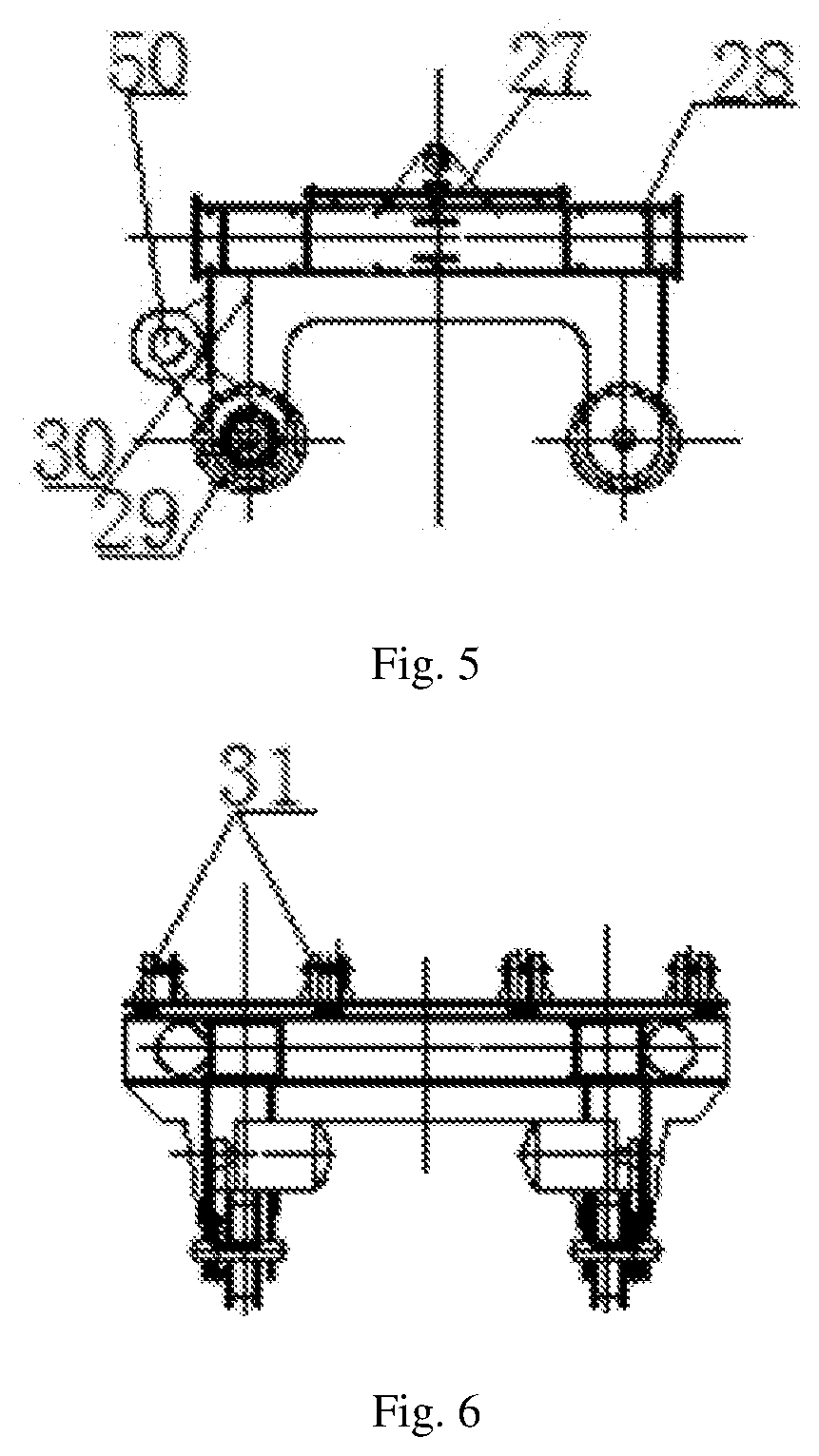

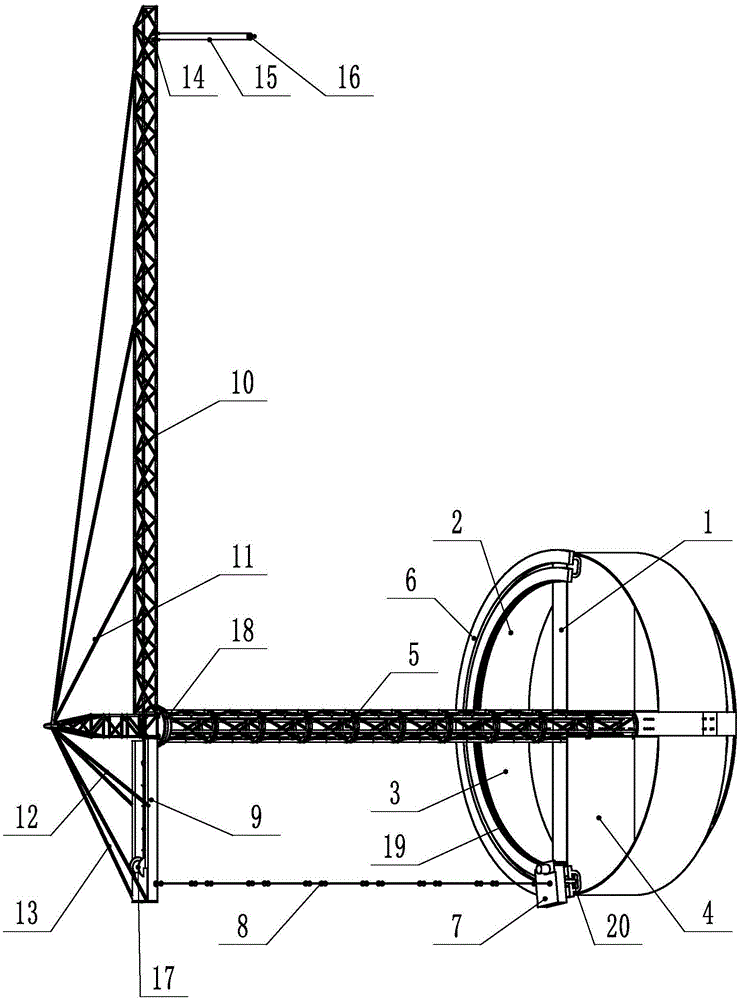

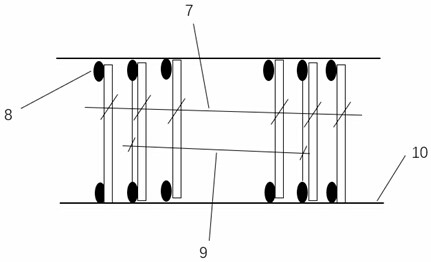

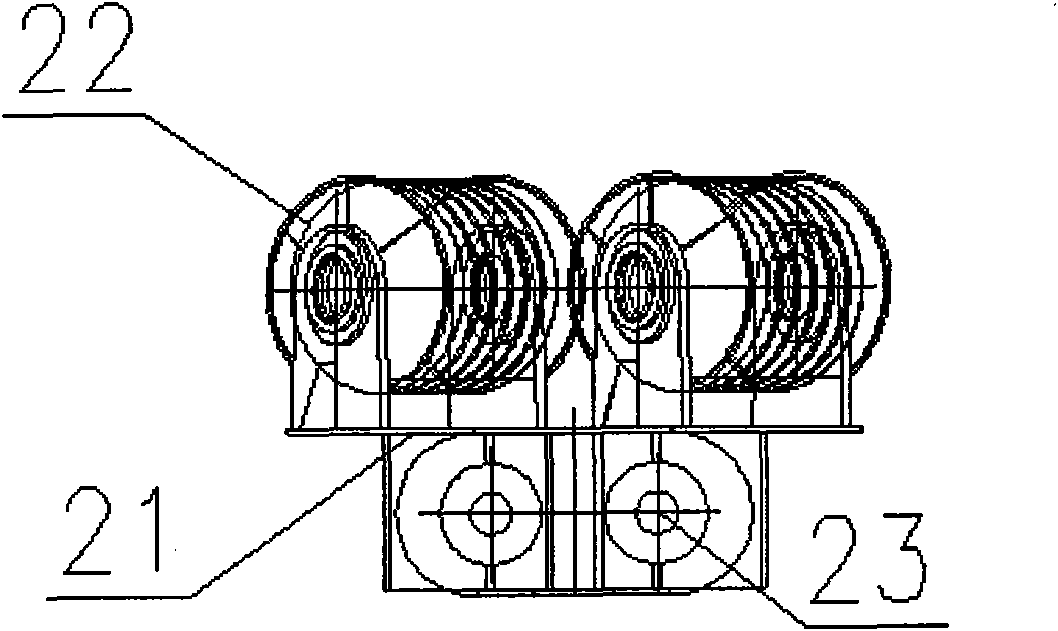

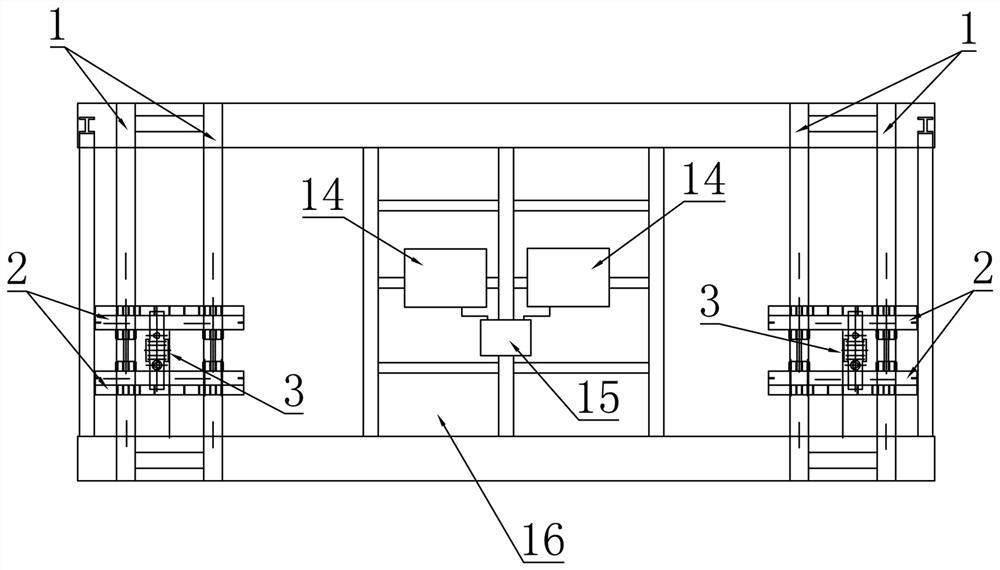

Winch type pipe sheet hanging machine suitable for large shield tunneling machine

ActiveCN106892360AMeet construction schedule requirementsMinimum weightTrolley cranesTrolleysEngineeringShield tunneling

A winch type pipe sheet hanging machine suitable for a large shield tunneling machine comprises a pipe sheet hoisting device arranged between two parallel running tracks, and a power trolley used for driving the pipe sheet hoisting device to move along the running tracks. The pipe sheet hoisting device comprises two carrying beams located below the running tracks, four first driven trolleys arranged between the two carrying beams and the two running tracks, and two winch mechanisms arranged between the two carrying beams. The two winch mechanisms are rotationally and symmetrically arranged in a 180-degree manner. The two winch mechanisms are hung on the running tracks through the four first driven trolleys, the clearance size of the trolleys is greatly reduced, the two winch mechanisms can achieve the independent ascending action and the simultaneous ascending action, ascending and descending are stable, the impact is small, the running speed is high, the structure protection level is high, the winch type pipe sheet hanging machine can well adapt to the severe tunnel construction environment, the daily 10-ring tunnel construction progress requirement is met, and accordingly the production efficiency is greatly improved.

Owner:EUROCRANE

Trackless portal crane

InactiveCN105540447AGood value for moneyLarge lifting capacityTrolley cranesTravelling gearTrackwayStructural engineering

Owner:DALIAN LIANCHUAN HEAVY IND

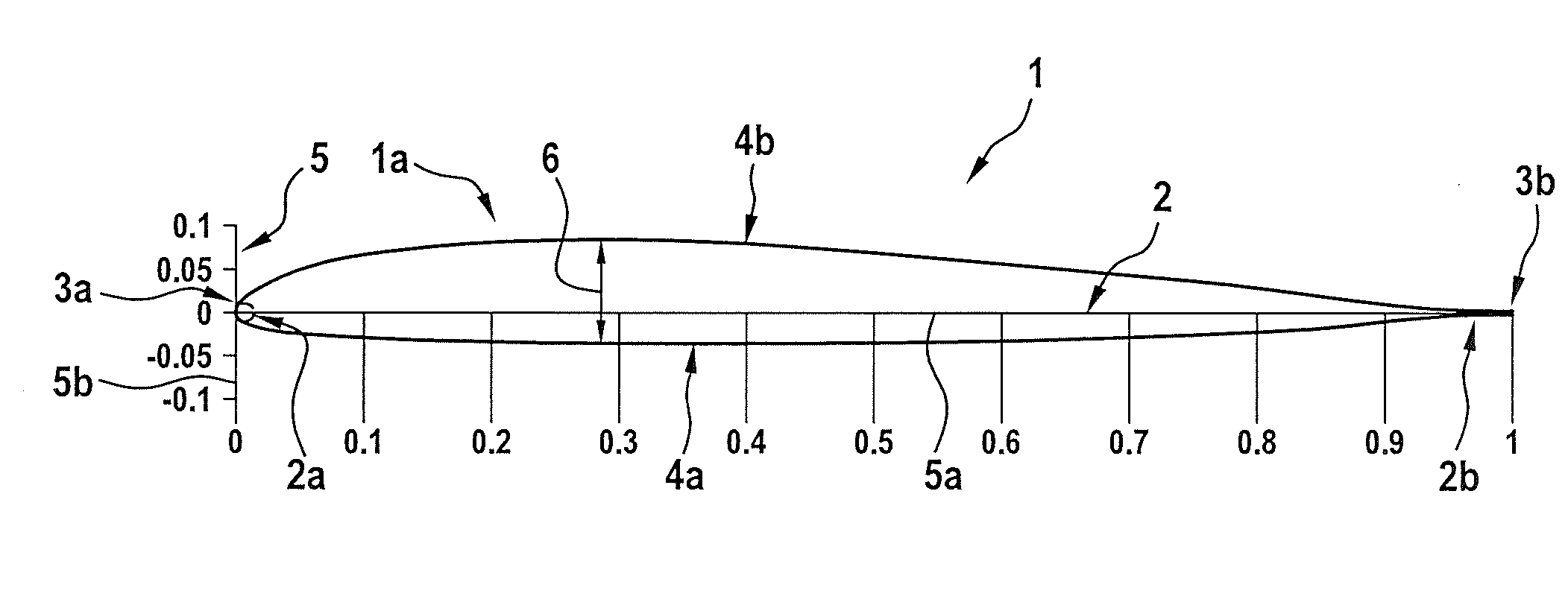

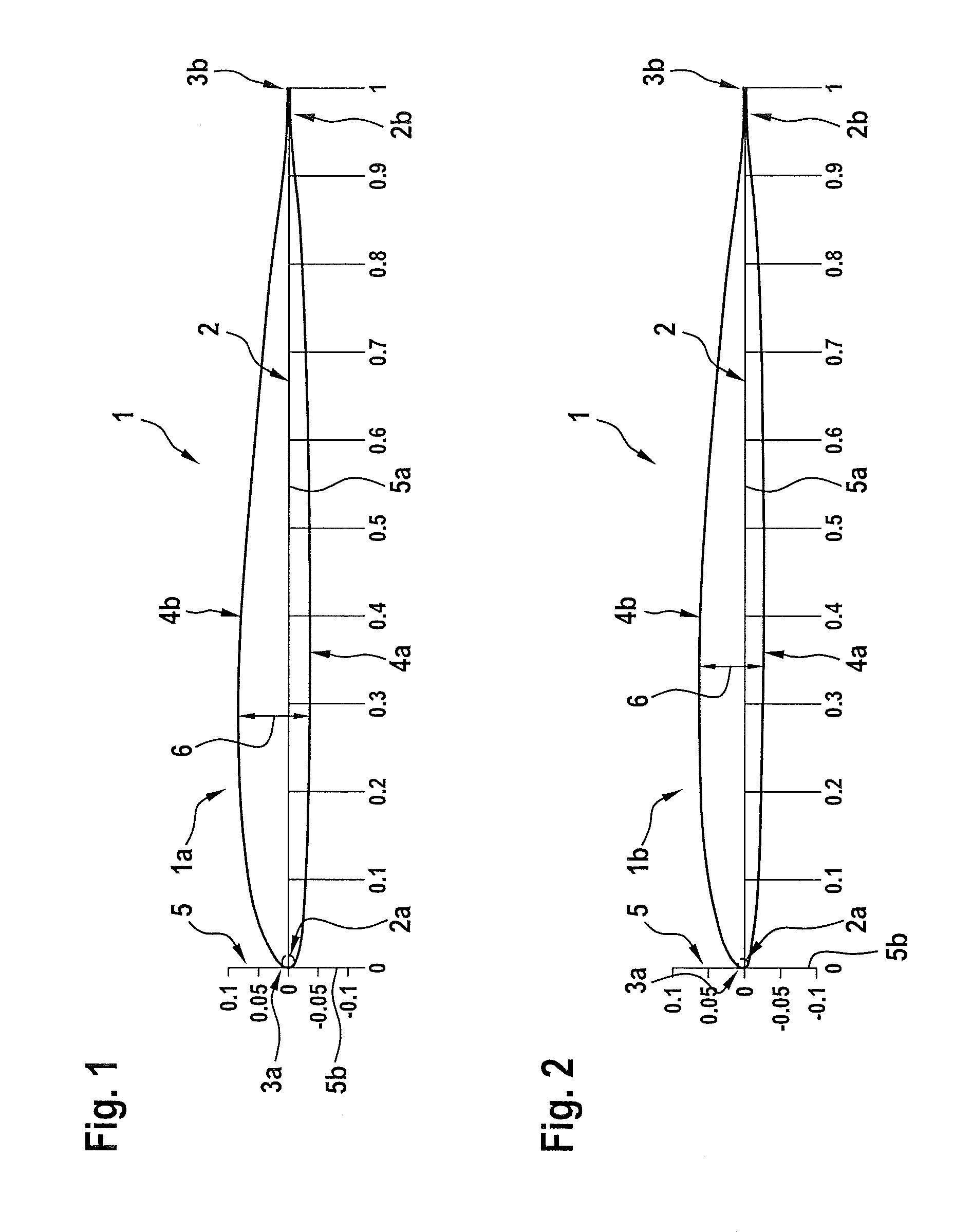

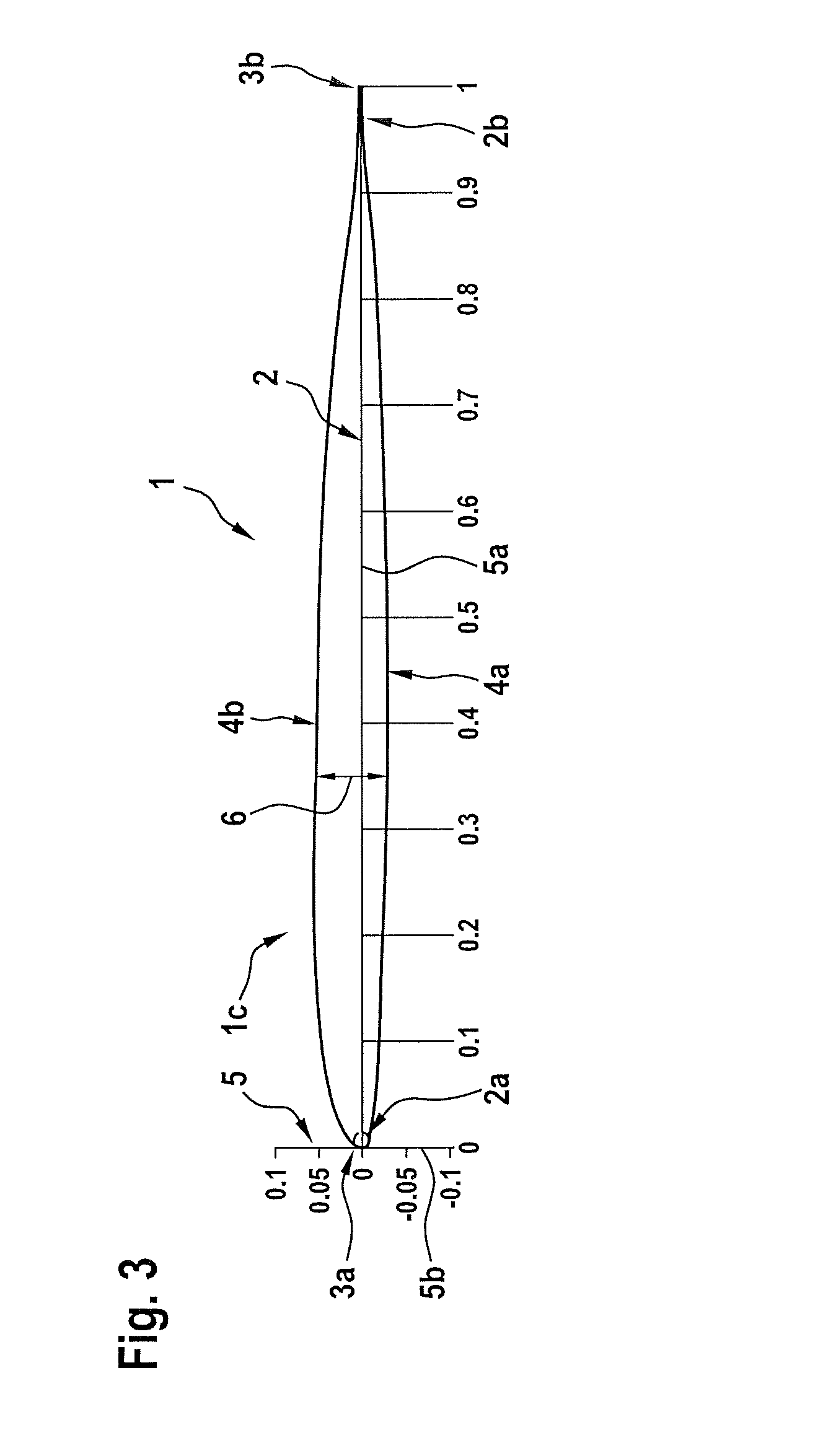

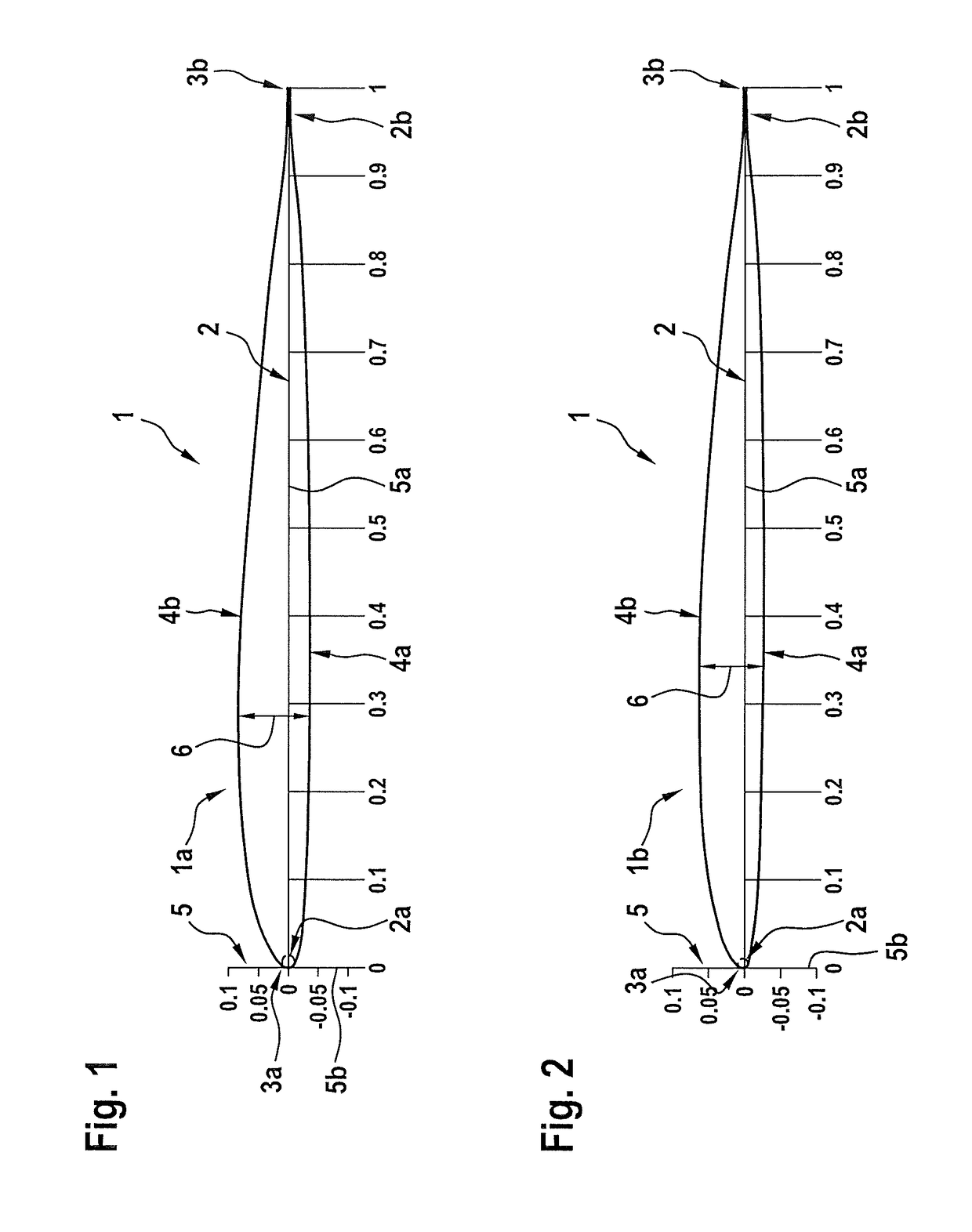

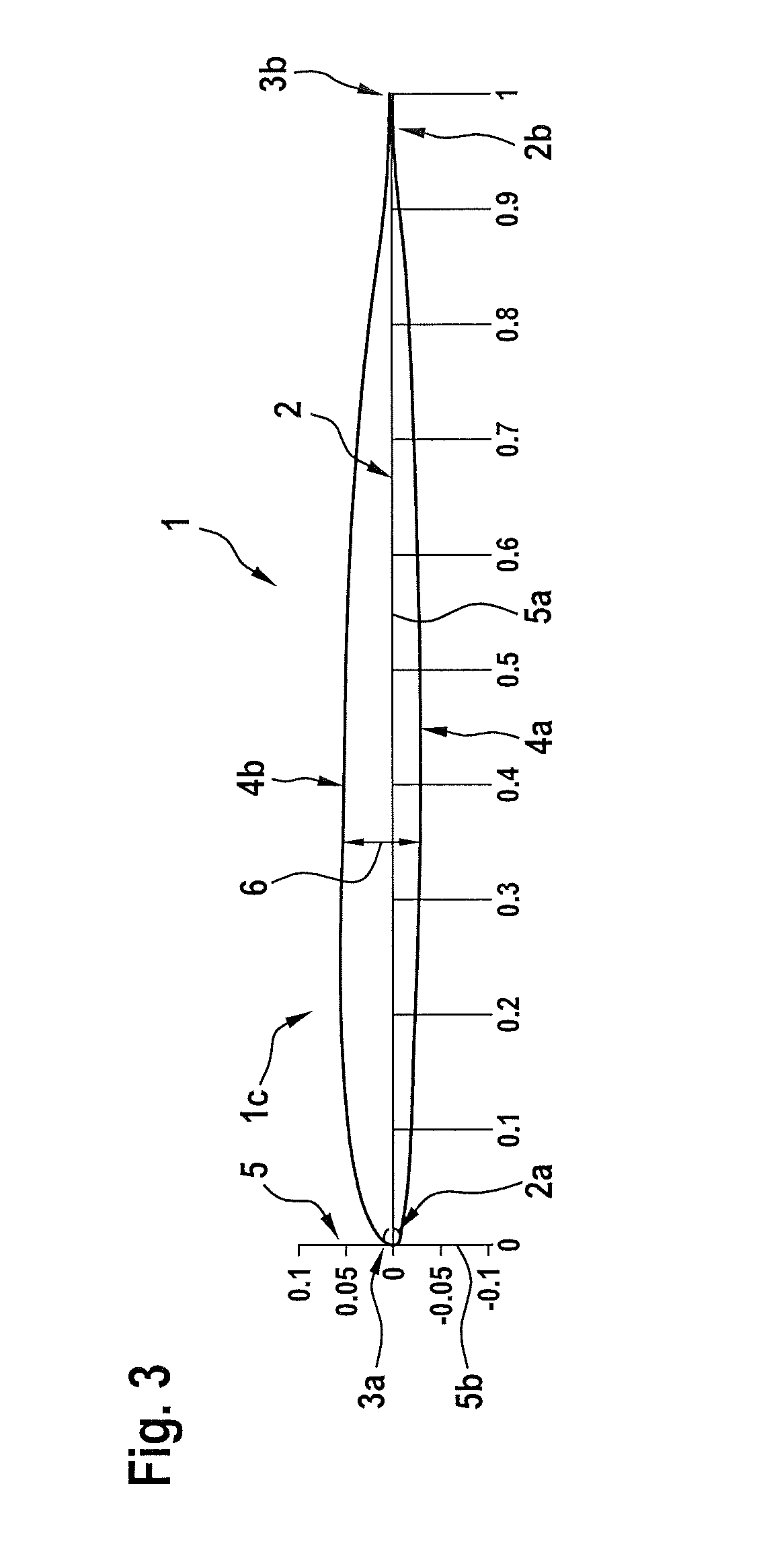

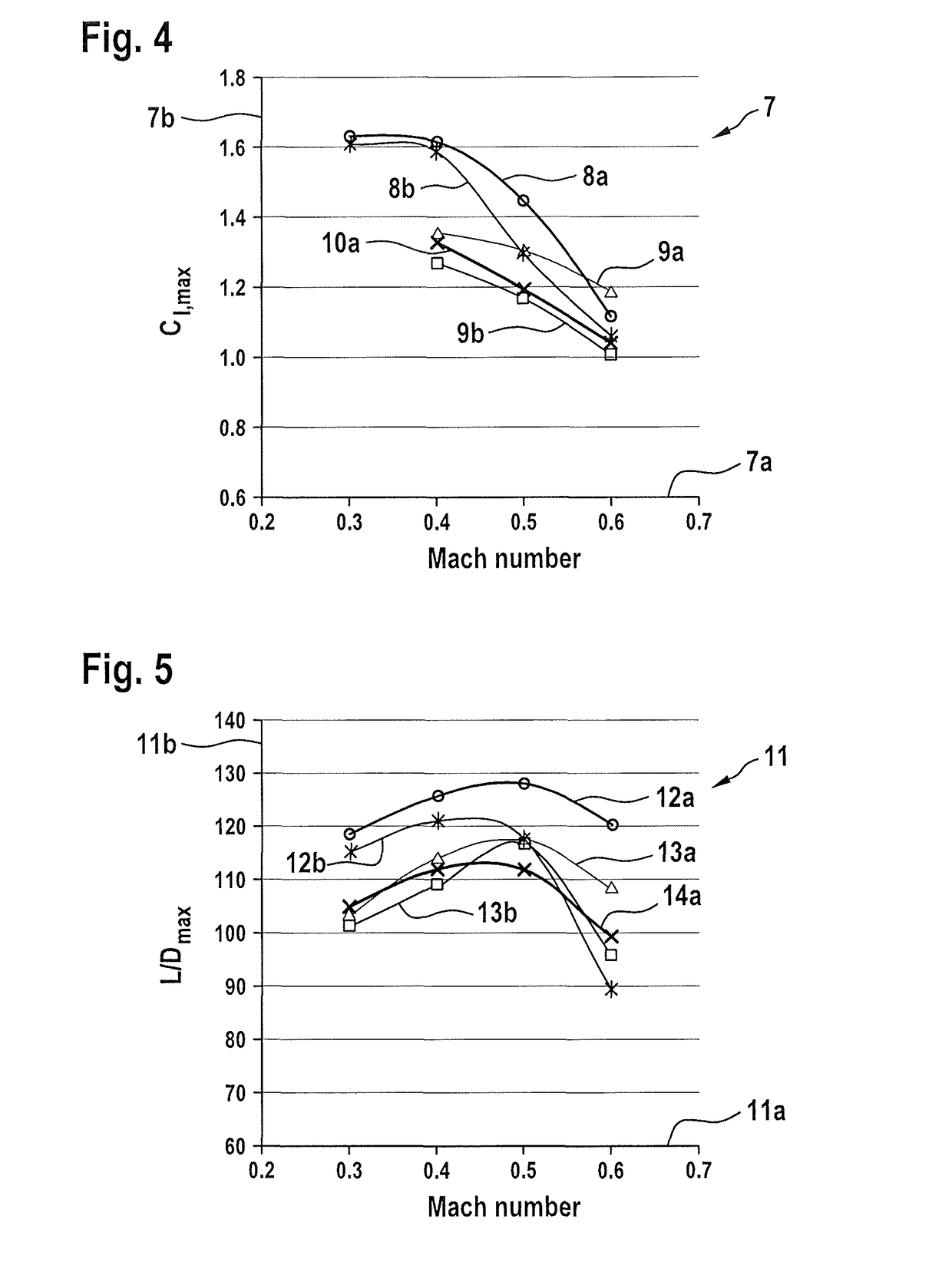

Airfoils for rotor blades of rotary wing aircrafts

ActiveUS20170001710A1Reduced aerodynamic dragLarge lifting capacityPump componentsWing shapesAirplaneTrailing edge

An airfoil for a rotor blade of a rotary wing aircraft, the airfoil having a predetermined maximum thickness to chord ratio and comprising, between a leading edge and a trailing edge, an extrados and an intrados, the intrados being defined by predetermined intrados coordinate value pairs and the extrados being defined by predetermined extrados coordinate value pairs, wherein a maximum error of each one of the predetermined intrados coordinate value pairs and the predetermined extrados coordinate value pairs amounts to ±3%.

Owner:AIRBUS HELICOPTERS DEUT GMBH

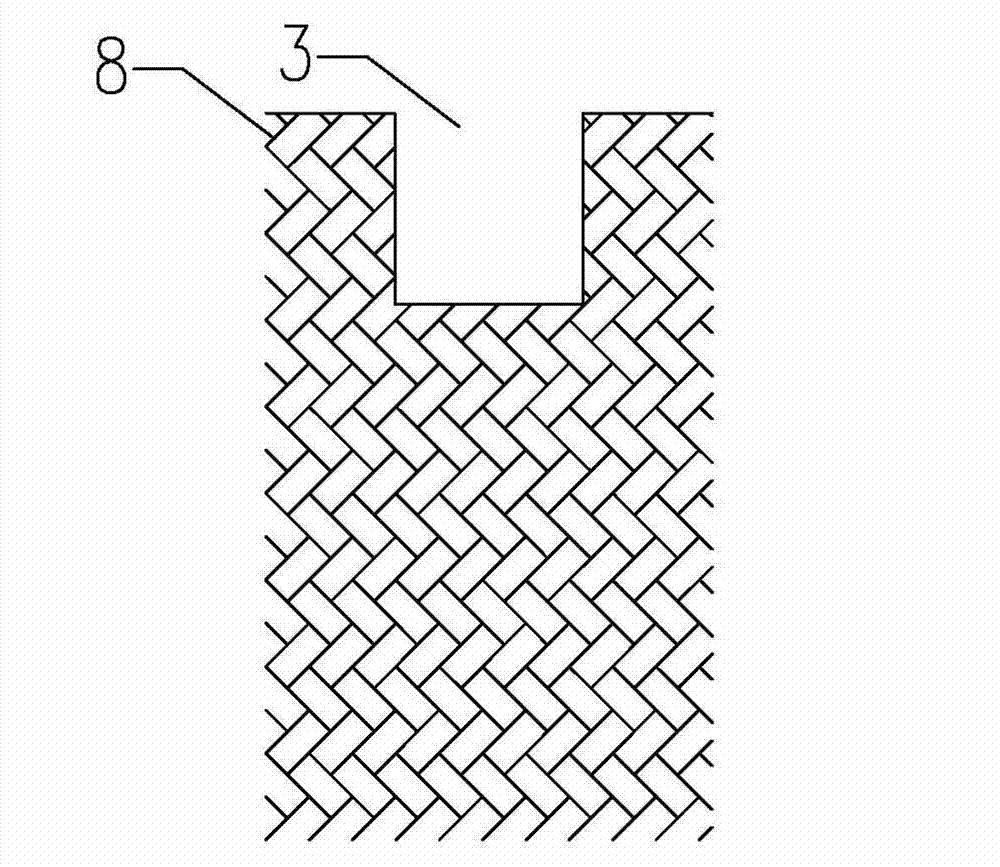

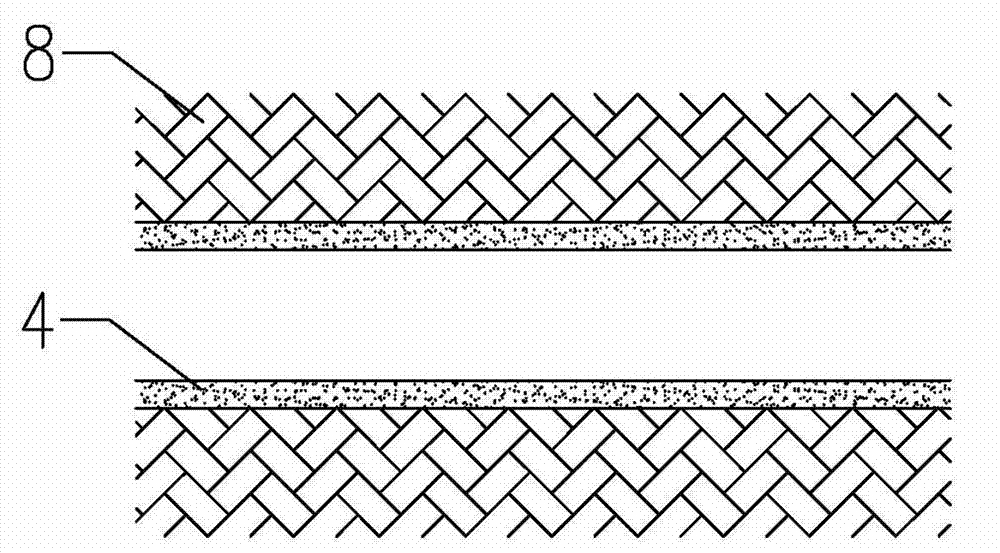

Foundation pit support and water stop integrated structure and construction method thereof

ActiveCN104775439ALower performance requirementsThe degree of mechanization of Dacheng SlotProtective foundationExcavationsSlurry wallRebar

The invention discloses a foundation pit support and water stop integrated structure and a construction method thereof. The foundation pit support and water stop integrated structure comprises a concrete wall, wherein the concrete wall is arranged under the ground of the periphery of a foundation pit, and a plurality of cylindrical reinforcement cages are vertically arranged in the concrete wall. The construction method of the foundation pit support and water stop integrated structure is characterized by comprising the following steps of excavating a guide channel, casting a guide wall, forming a channel in the channel section, arranging the reinforcement cages, casting concrete, and the like. The foundation pit support and water stop integrated structure and the construction method have the characteristics that the rigidity of an underground continuous wall is large, and the water stop effect is good; the installation of the reinforcement cages of a row pile support structure is convenient and rapid, the technology difficulty is low, the construction is rapid, the quality can be easily controlled, and the foundation pit support and water stop integrated structure is especially suitable for water-rich sandy gravel ground layers.

Owner:中国建设基础设施有限公司

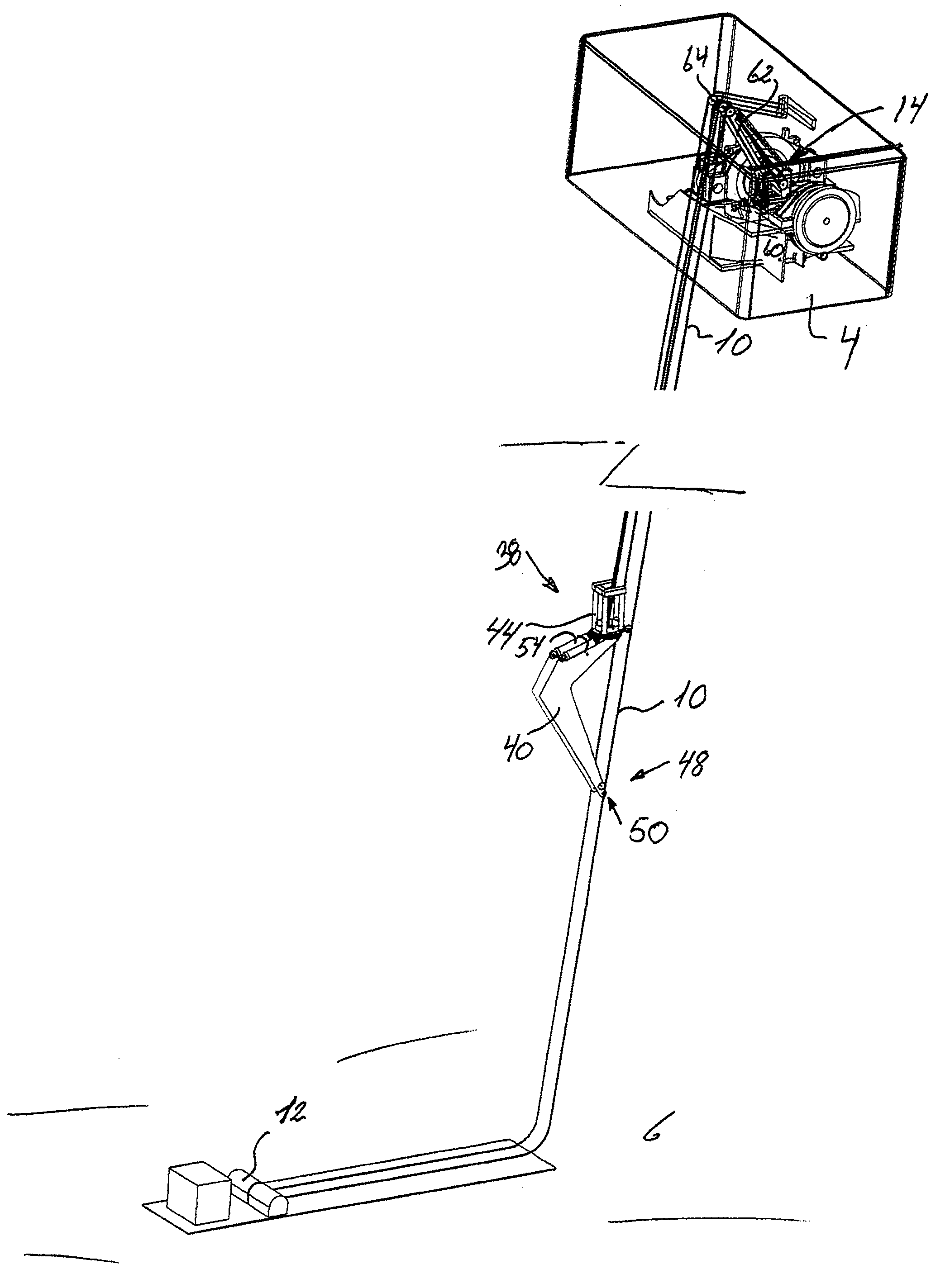

Device for establishing admittance and transport of cargo to and from a wind turbine construction above ground level

ActiveUS9115693B2Good equipment stabilityExtension of timeMachines/enginesEngine componentsAbove groundTurbine

Owner:ELEVATORRA IP APS

Airfoils for rotor blades of rotary wing aircrafts

ActiveUS10137976B2Large lifting capacityReduce air resistancePump componentsWing shapesMaximum errorLeading edge

An airfoil for a rotor blade of a rotary wing aircraft, the airfoil having a predetermined maximum thickness to chord ratio and comprising, between a leading edge and a trailing edge, an extrados and an intrados, the intrados being defined by predetermined intrados coordinate value pairs and the extrados being defined by predetermined extrados coordinate value pairs, wherein a maximum error of each one of the predetermined intrados coordinate value pairs and the predetermined extrados coordinate value pairs amounts to ±3%.

Owner:AIRBUS HELICOPTERS DEUT GMBH

Novel track layer for urban track traffic engineering and its construction method

InactiveUS20210332533A1Save energy resourcesLight weightRailway track constructionTrackwayArchitectural engineering

It relates to the engineering technology science, in particular to a novel track layer for urban rail traffic engineering and its construction method. The novel track layer comprises lifting and walking trolleys, a connecting truss beam, a track running mechanism and a supporting structure. Horizontal extending and vertical supporting structures of each lifting and walking trolley are operated firstly so as to lift the whole novel track layer to a height at which a track material is hoisted and unloaded. A hoisting car is used to lift up the track material to leave from a flat trunk and a material supporting cushion. The novel track layer continues to walk forward to a designed mounting position of a track section, and then the track material is unloaded. Steel tracks are connected and a temporary track section support is mounted to fix a newly mounted track section.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

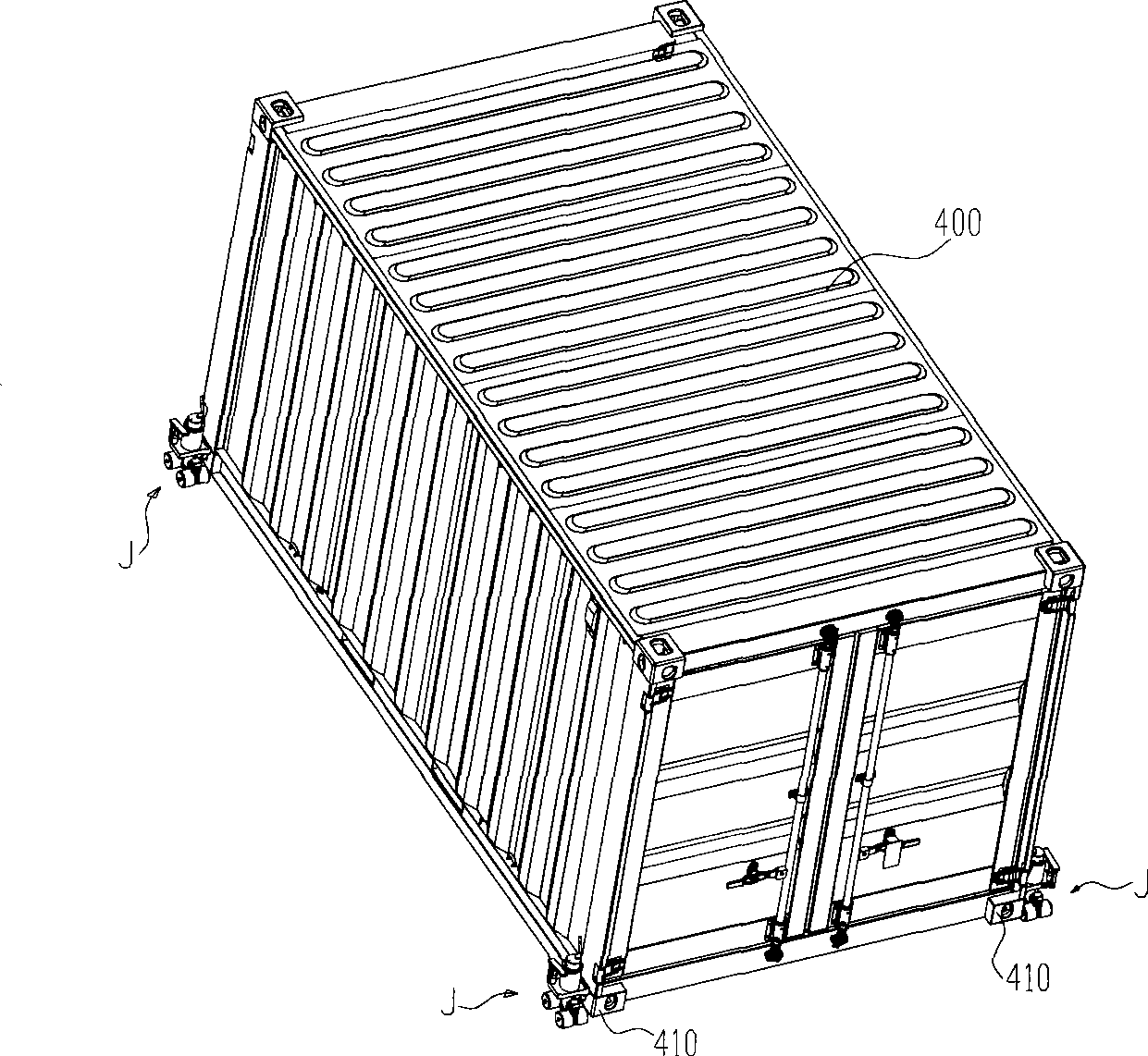

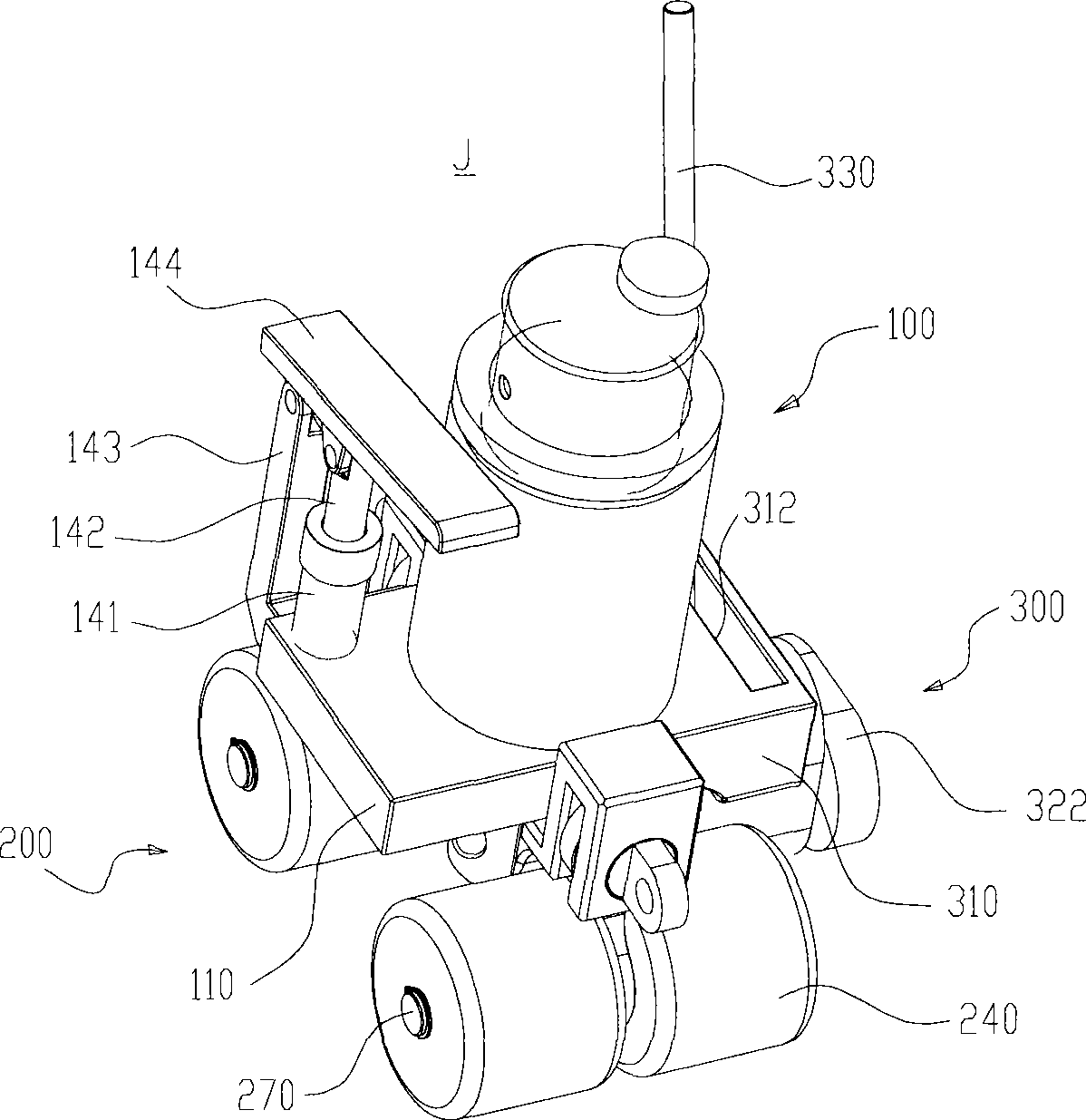

Hydraulic unit, castor assembly and container moving device and method

InactiveCN101435450ACompact structureNot easy to damageServomotor componentsServomotorsPistonOil supply

The invention discloses a hydraulic unit, a trundle component with the hydraulic unit, a device utilizing the trundle component to move a container and a method thereof. The hydraulic unit comprises a hydraulic mechanism, an oil tank, a foot pump, a supporting seat, an oil supply passage, an oil suction passage and an unloading oil passage, wherein the hydraulic mechanism comprises an oil cylinder and a piston arranged in the oil cylinder; the oil tank circles the oil cylinder and is used for accommodating hydraulic oil; the foot pump comprises a pump body and a pump core arranged in the pump body; the supporting seat is used for fixing the hydraulic mechanism, the oil tank and the foot pump; the oil supply passage is communicated with the pump body and the oil cylinder; the oil suction passage is communicated with the oil tank and the pump body; and the unloading oil passage is communicated with the oil cylinder and the oil tank. The hydraulic unit is provided with the foot pump, so the hydraulic unit can drive the hydraulic mechanism to work without needing external equipment in order that the hydraulic unit has a compact integral structure and convenient operation.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

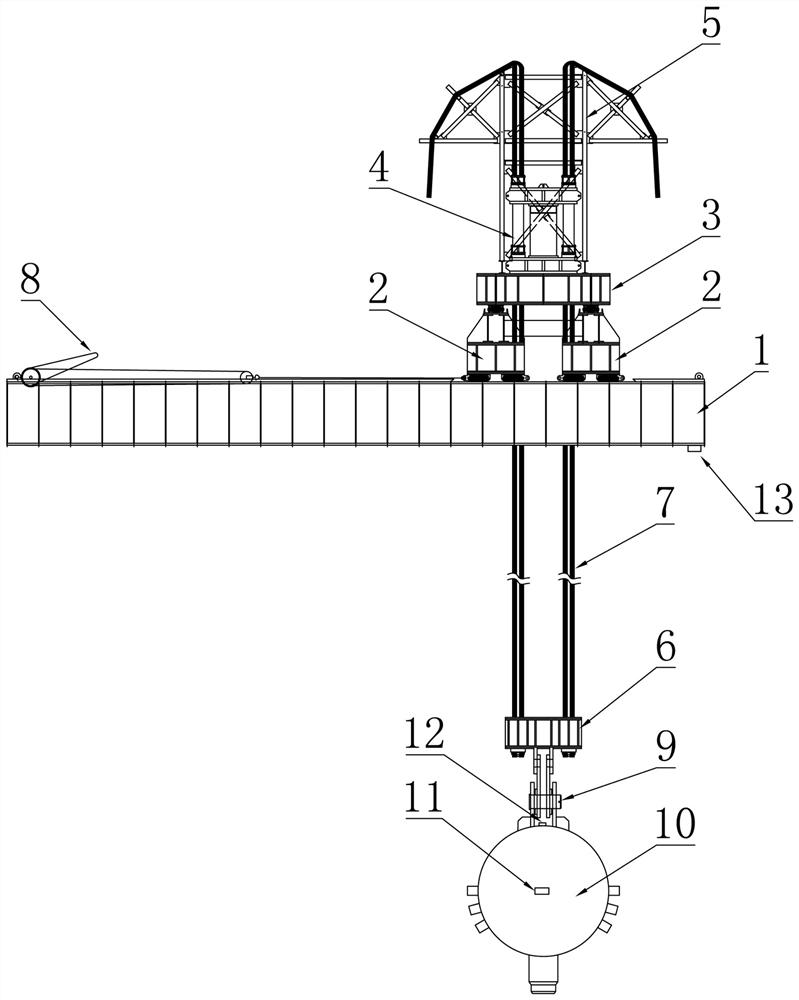

Novel large-lifted-weight high-safety tower crane for counterweight balance mechanism and reforming and upgrading of tower crane

InactiveCN105060134AReduce hoisting workLarge lifting capacityCranesBalancing machineLifting capacity

The invention relates to a novel tower crane for a counterweight balance mechanism and reforming and upgrading of the tower crane. The lifting capacity is improved. The implementation scheme is characterized in that the counterweight force on a counterweight arm of the tower crane is changed into a tension mode of a steel zipper; the upper end of the steel zipper is fixed to the tail part of a balance arm of the tower crane, and the lower end of the steel zipper is connected with a track sliding vehicle mechanism in a sliding chute integrally embedded through a tower crane base foundation and a counterweight water tank by pulling. During lifting operation, a sliding vehicle dynamically transmits the counterweight pulling force to the foundation by sliding the sliding chute, and the counterweight pulling force is counteracted with the pressure of a tower body, and meanwhile the sliding vehicle and a crane jib synchronously carry out rotating and lifting operation at the same angle. The lifting weight is transmitted to the crane jib through a lifting steel wire rope, and then the crane jib transmits the lifting weight to the top of the tower body by obliquely pulling the steel zipper. The pulling forces of the crane jib and the balance arm are changed into pressure through top of the tower body and transmitted to a ground foundation through the tower body. The pulling force of the crane jib to the tower top is larger than that of the crane jib to the balance arm and is the counterweight force of the novel tower crane of the counterweight balance mechanism, and the force is automatically increased and decreased along with the increasing and decreasing of the weight of a lifting object. The automatic counterweight balance of the tower crane is realized, and the lifting capacity and the safety are improved.

Owner:高阳

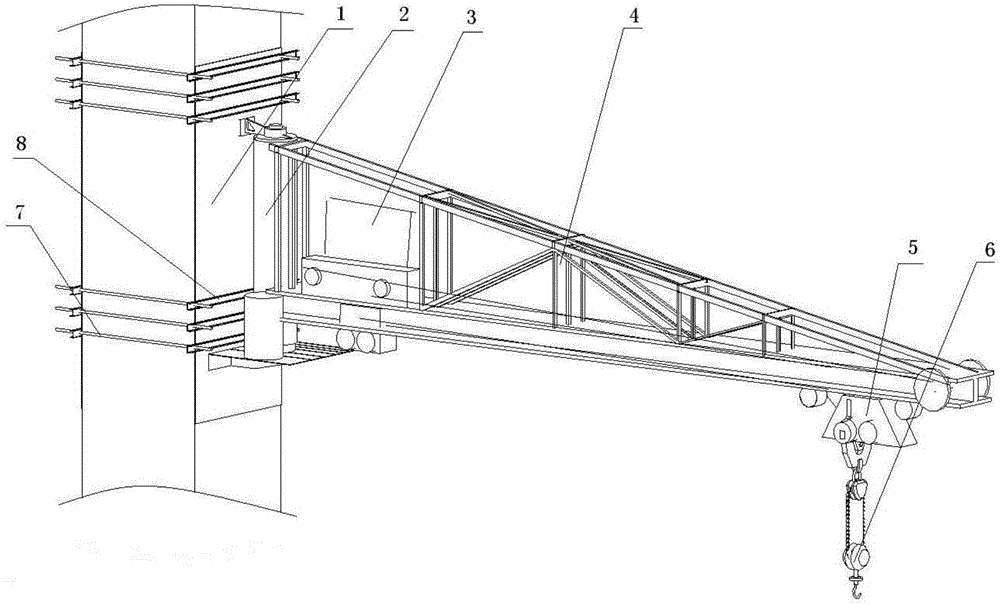

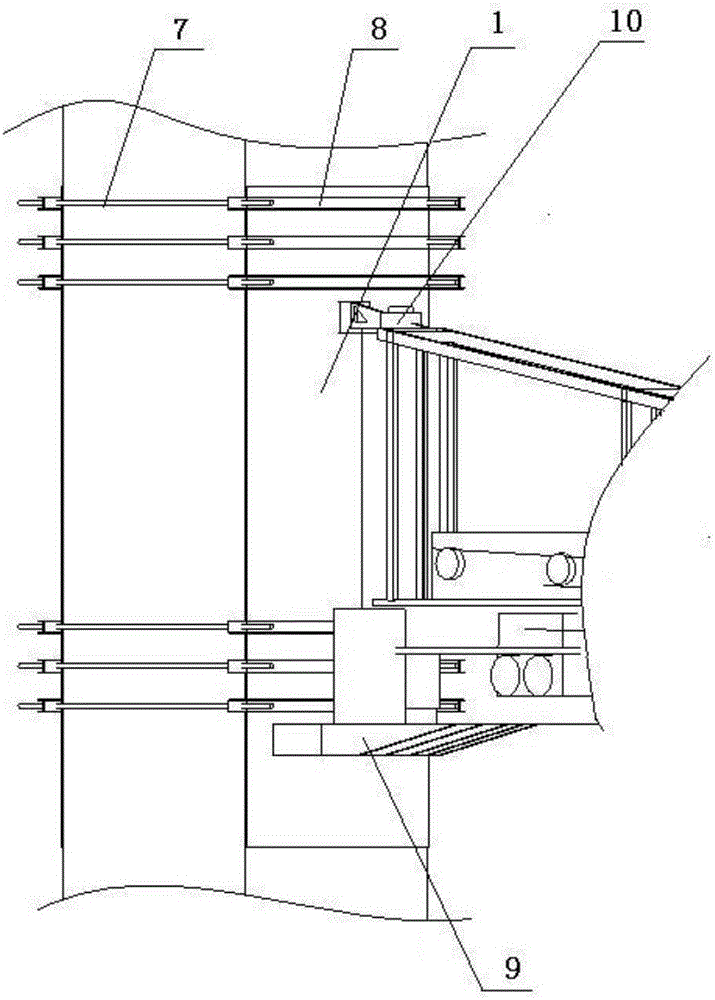

High-rise building fabricated interlayer hoisting machine and construction method

The invention relates to a high-rise building fabricated interlayer hoisting machine. The high-rise building fabricated interlayer hoisting machine comprises a cantilever beam, a rotary mechanism, a lifting winch and an operating trolley. The cantilever beam is of a right triangle structure, the rotary mechanism is installed on the vertical right-angle side of the right triangle structure and is installed on a concrete column through a bracket assembly, and the cantilever beam is driven by the rotary mechanism to rotate horizontally. The lifting winch is installed on the cantilever beam close to the concrete column. The sliding operating trolley is installed at the bottom of the cantilever end of the cantilever beam and is driven by the lifting winch. A lifting hook is installed at the bottom of the operating trolley. The high-rise building fabricated interlayer hoisting machine is light in overall weight, has no requirement for a floor and is large in hoisting amount and easy and convenient to assemble and disassemble, and a storey can be moved only through cooperation of a tower crane. The high-rise building fabricated interlayer hoisting machine can construction in advance according to the storey condition without using the tower crane, the processes of an upper main body and the like needing to be constructed by the tower crane are not influenced, and the engineering period is shortened; the hoisting machine is not influenced by an upper frame body and can lift materials onto the storey in one time, and workers do not need to pull the materials towards the inner side of a building.

Owner:ZHONGTIAN CONSTR GROUP

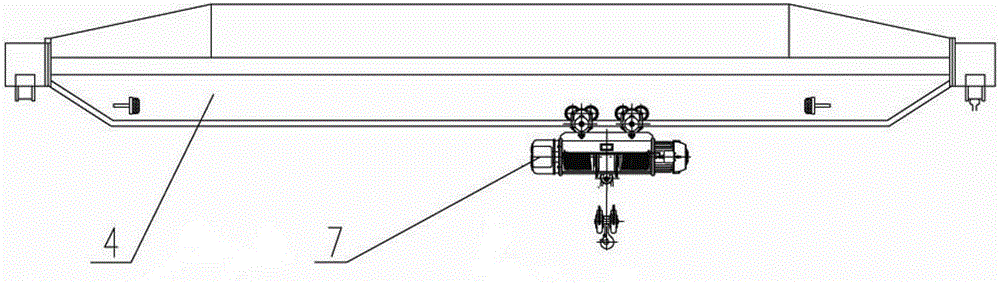

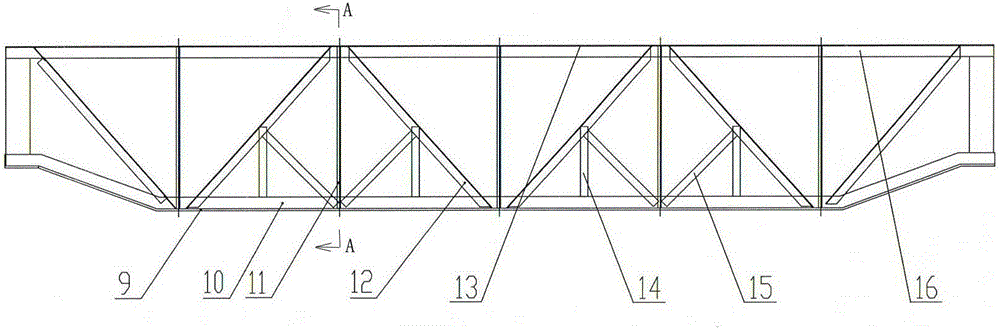

Improved-type single-girder crane

InactiveCN105217444ALarge lifting capacityIncrease productivityLoad-engaging girdersTrolley cranesElectric machineStructural engineering

The invention discloses an improved-type single-girder crane. The improved-type single-girder crane comprises a main girder and two end girders, wherein the main girder comprises a steel plate at a bottom part and an upper cover plate at the top part; the flange of the steel plate serves as a walking track for an electric hoist; a plurality of vertical plates are vertically connected between the steel plate at the bottom part and the upper cover plate; oblique plates are obliquely arranged on two sides of each vertical plate; except for the oblique plates on two horizontal ends of the steel plate at the bottom part, the position between each oblique plate and the steel plate at the bottom part is vertically connected with a welding plate I and is obliquely connected with a welding plate II, and the upper end of each welding plate I and the upper end of the corresponding welding plate II are connected onto the same position of the corresponding oblique plate; the two end girders are connected onto two ends of the main girder; the two end girders are separately provided with a cart walking reducer and a motor; and the electric hoist and an electric-control component are arranged on the main girder. The improved-type single-girder crane is light in self-weight, low in production cost, more stable in operation and good in ventilation and heat dissipation, and the quantity of used materials is small; the service life of each component is long; the post-maintenance work is less; triangular support at multiple angles is realized, so that the bearing capacity is larger, and the elevating capacity of the crane is larger; and the production efficiency is greatly improved.

Owner:河南省黄河防爆起重机有限公司

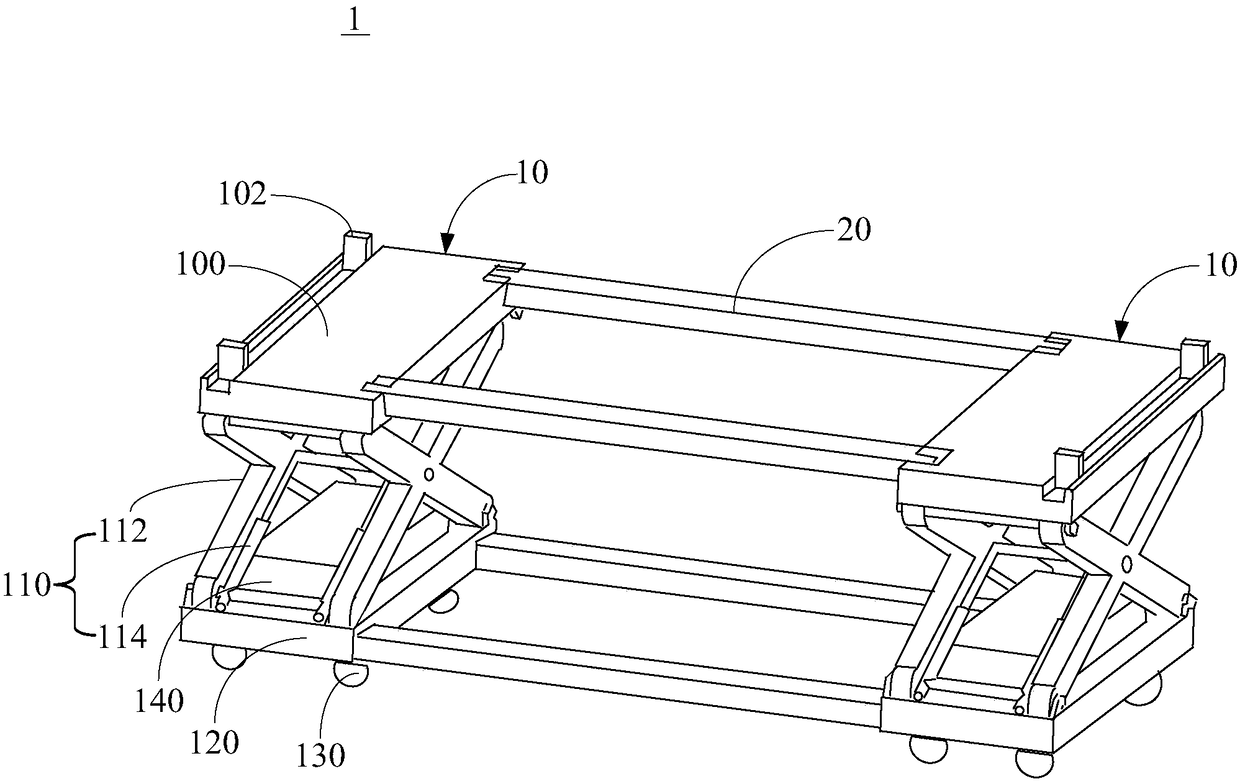

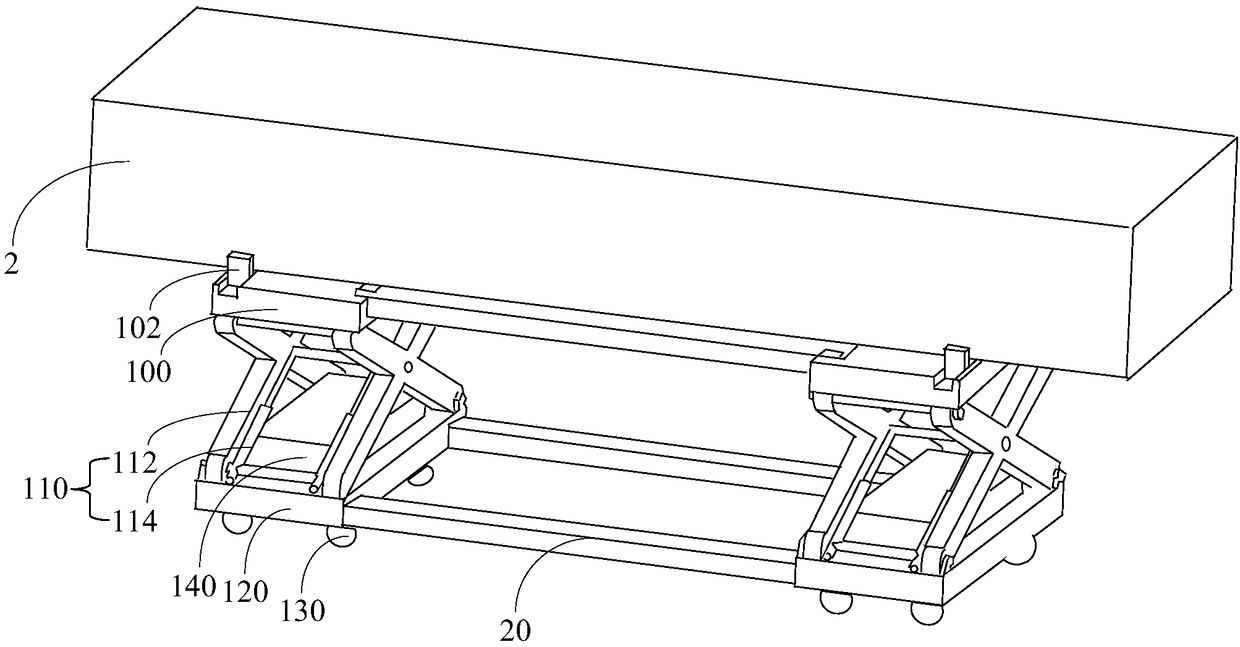

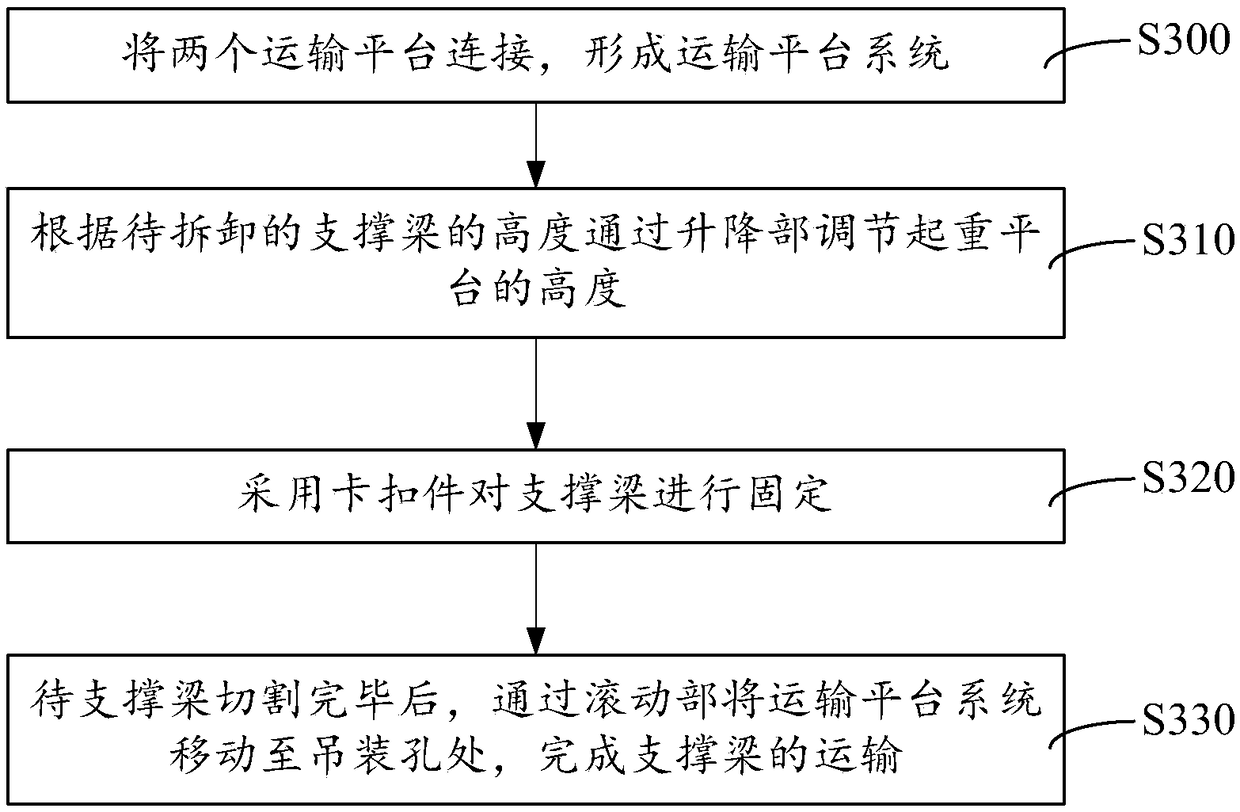

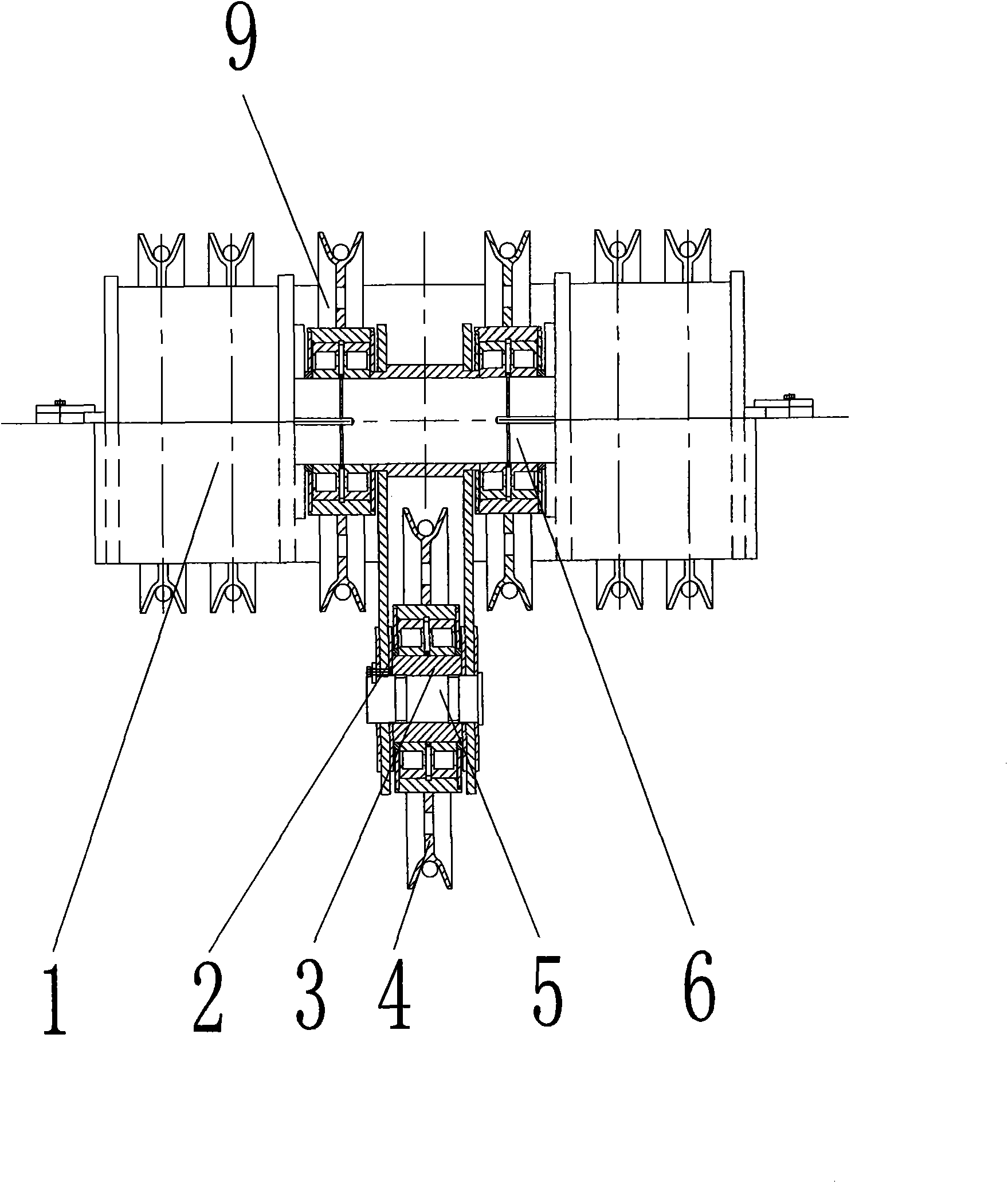

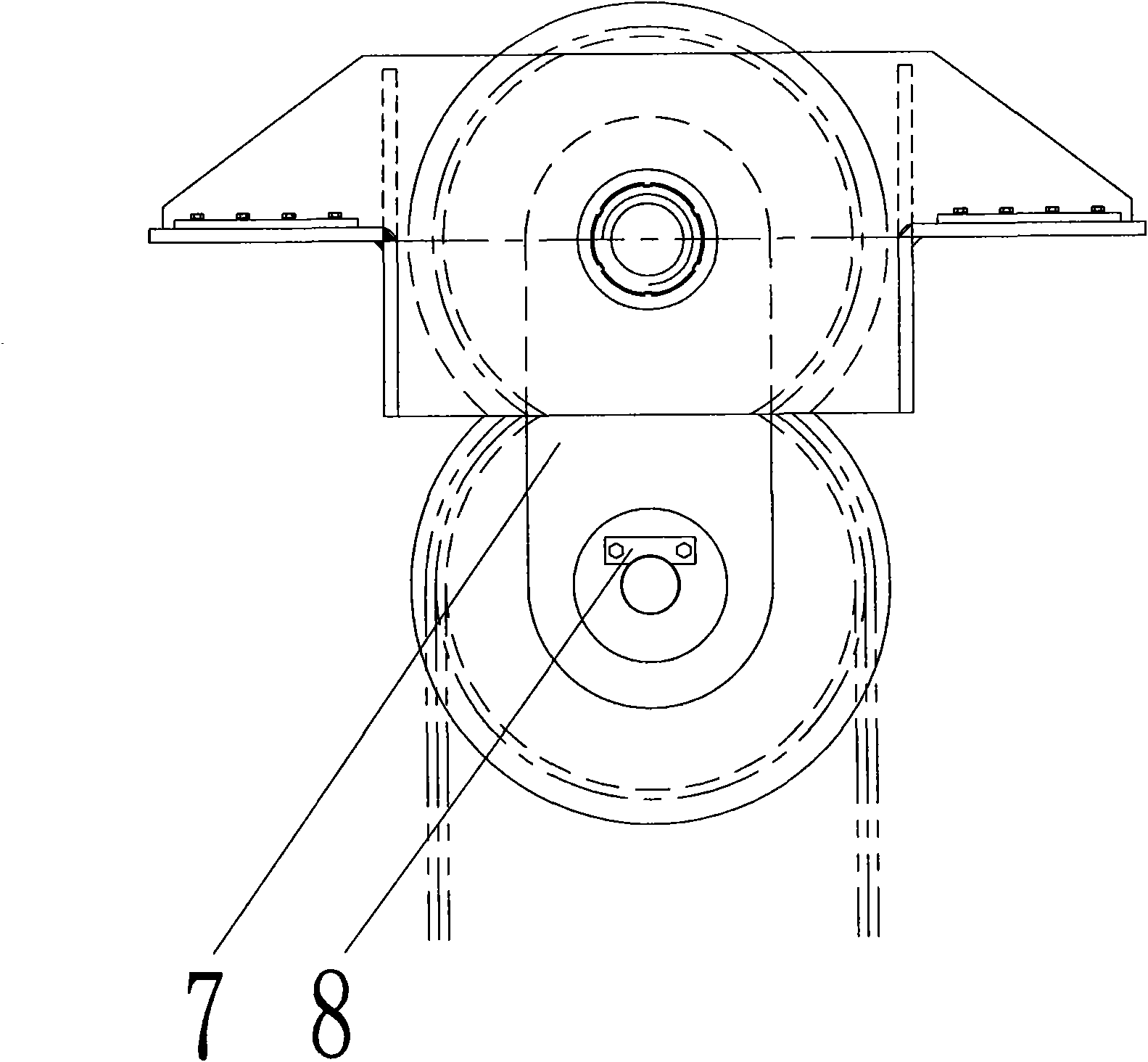

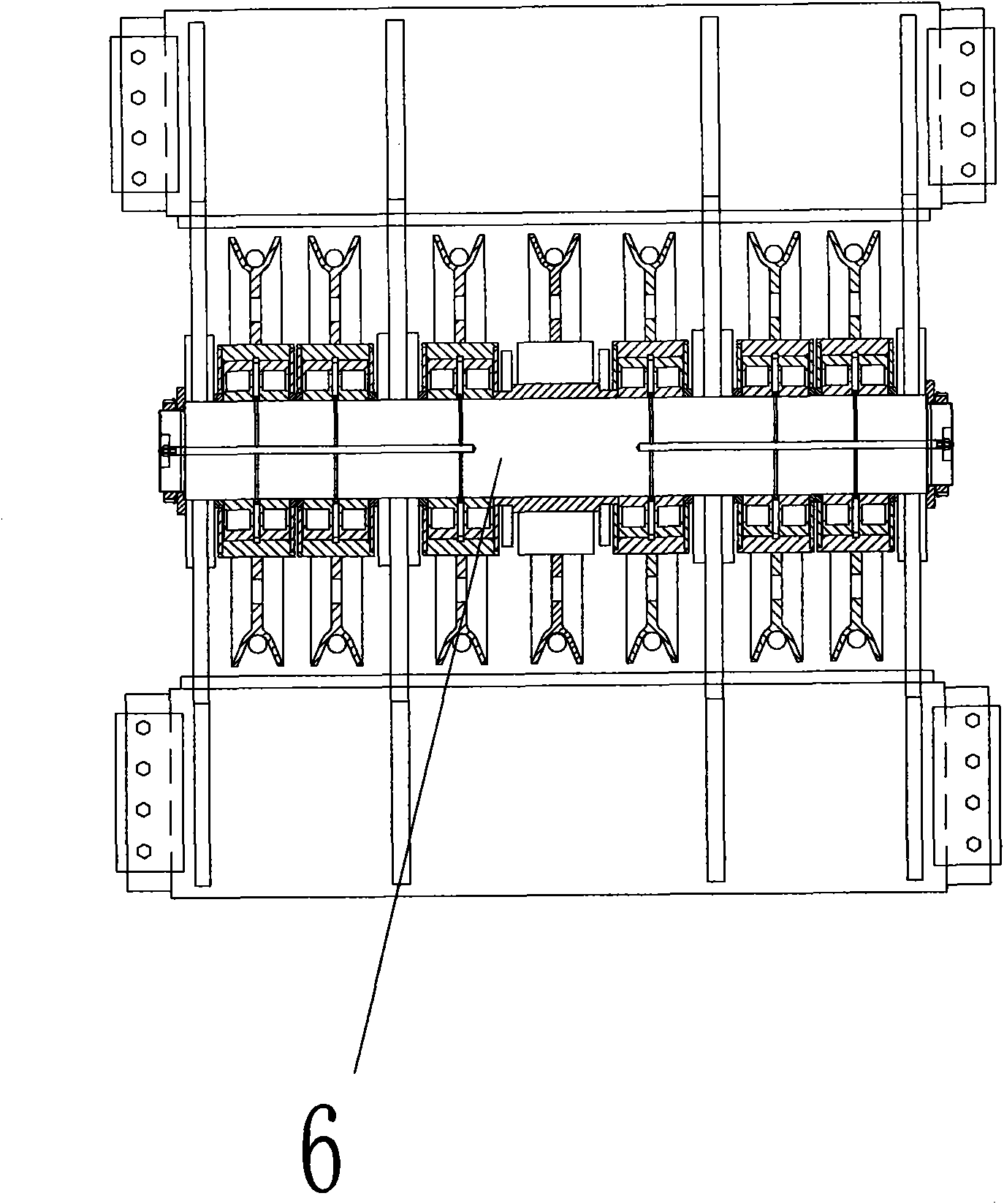

Transport platform system and application construction method thereof

The invention relates to a transport platform system and an application construction method thereof. The transport platform system includes at least two transport platforms, and each transport platform includes a lifting platform, a lifting part, a base and a rolling part, wherein the lifting platform is provided with a fastening piece, the lifting part is positioned under the lifting platform andconnected with the lifting platform, the lifting platform goes up or down through the lifting part, the base is positioned under the lifting part and connected with the lifting part, and the rollingpart is arranged at the bottom of the base and connected with the base. Through the platform system, combination of supporting and carrying in the process of dismantlement of a support beam is achieved, in the middle of the dismantlement process, no apparatus replacement is needed, the lifting quantity is large, and the process is simple and safe; meanwhile, the transport platform system itself has a lifting function and is less affected by height restriction, thereby being suitable for transport of the support beams of all kinds of floor-height areas. The application construction method of the transport platform system has simple steps and convenient operation.

Owner:SHANGHAI CONSTRUCTION GROUP

Novel weighing device structure of shipbuilding gantry crane

InactiveCN102718143ALarge lifting capacityIncrease the lifting heightLoad-engaging elementsGantry craneEngineering

The invention discloses a novel weighing device structure of a shipbuilding gantry crane, characterized in that: the structure is provided with a pulley yoke, a fixed pulley shaft is fixed on the pulley yoke, no less than two fixed pulleys are sleeved on the fixed pulley shaft symmetrically; a weighing pulley yoke is sleeved on the fixed pulley shaft and arranged between the fixed pulleys, the lower end of the weighing pulley yoke is provided with a weighing pulley; the center of the weighing pulley is provided with a shaft pin sensor which can simultaneously serve as a pulley shaft, between the sensor and the pulley is sleeved with a shaft sleeve II, the side surface of the sensor is provided with a baffle plate, and the baffle plate is fixed on the weighing pulley yoke; a shaft sleeve I is sleeved on the sensor, and the bearing in the weighing pulley is arranged in the shaft sleeve I. The weighing device can weigh accurately, and is not affected by lifting height and the arrangement structure of lifting mechanism when weighing.

Owner:ELEPHANT KING HEAVY IND

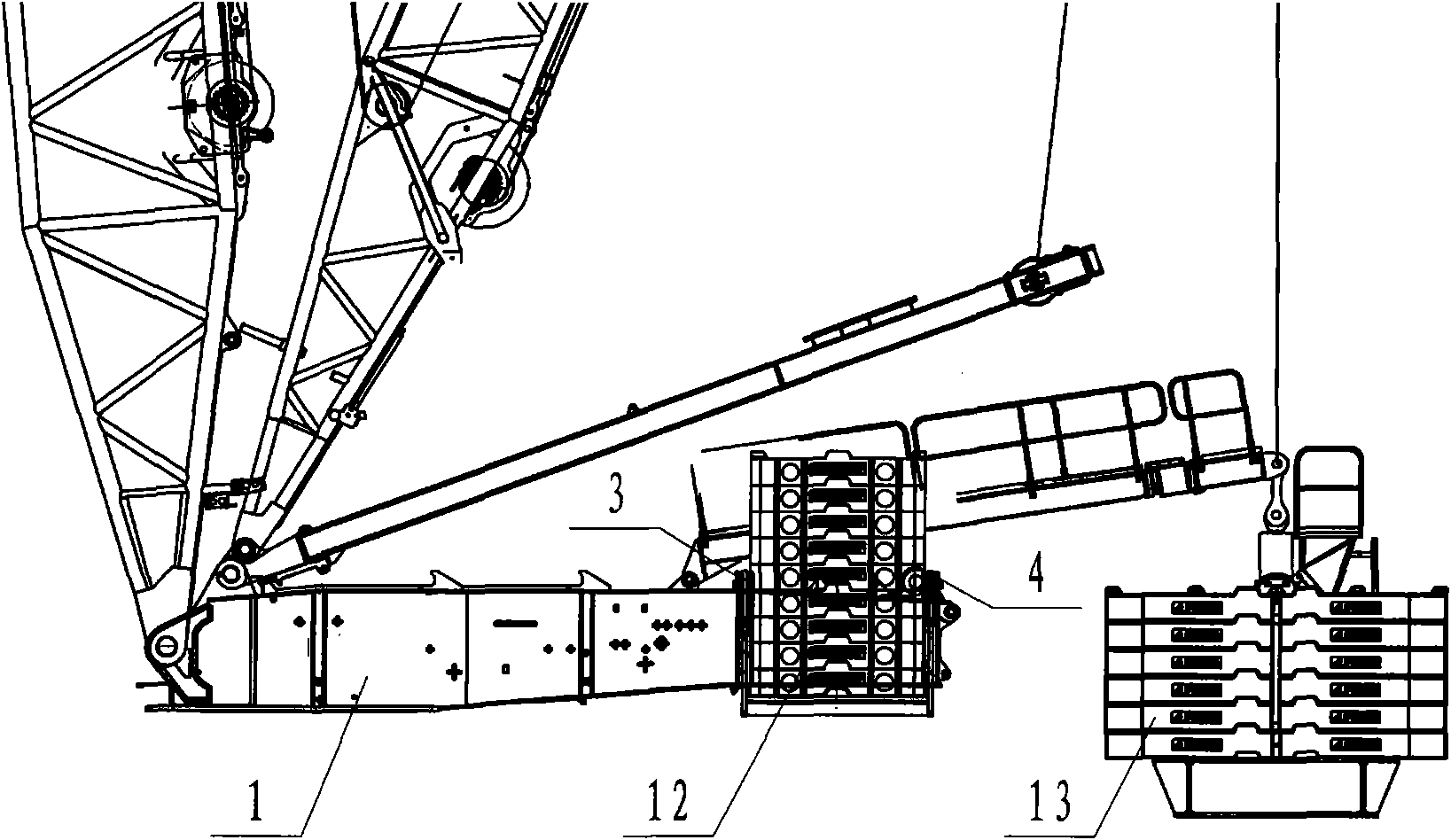

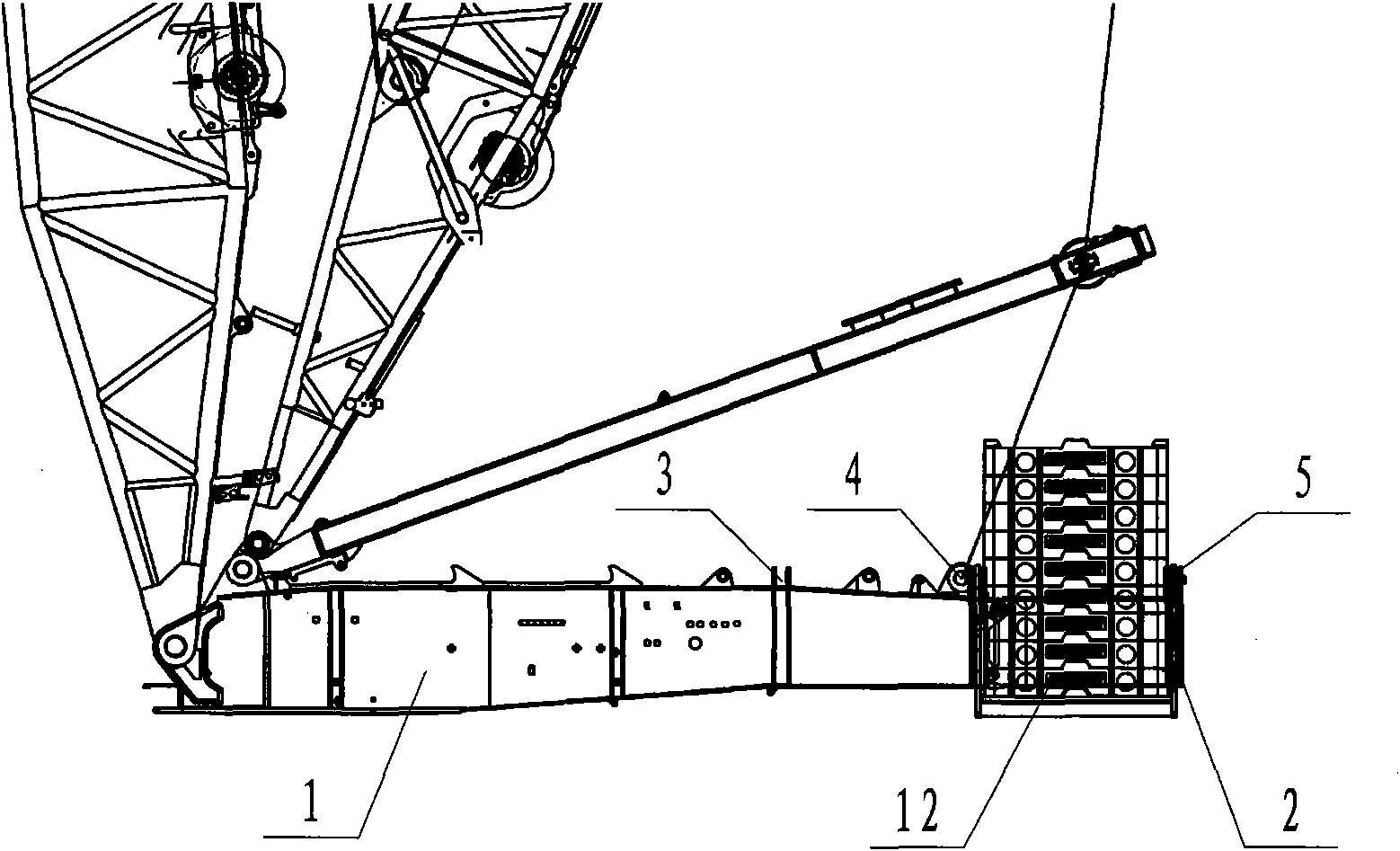

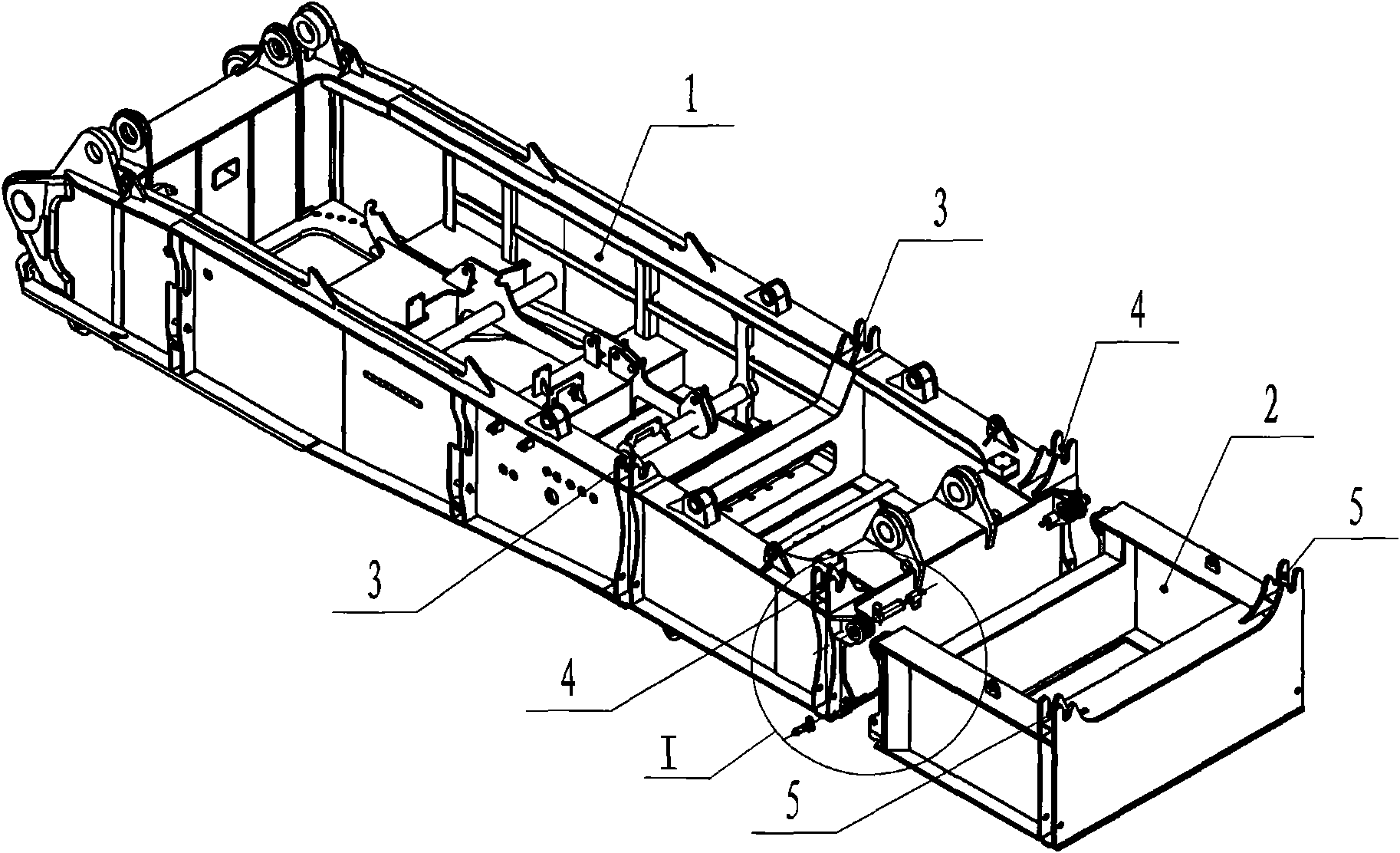

Combined turntable of crawler crane

InactiveCN101913537AIncrease the lifting heightLarge lifting capacityCranesEngineeringWork productivity

The invention discloses a combined turntable of a crawler crane. The combined turntable comprises a standard turntable; a counterweight mounting lug is arranged on the standard turntable; the combined turntable also comprises an additional turntable; the combined turntable is formed by connecting the standard turntable and the additional turntable; and a counterweight mounting lug is also arranged on the additional turntable. The combined turntable changes the gravity center of the whole crane by changing the mounting position of a counterweight, and increases a steady torque to improve the hoisting performance. The combined turntable changes a traditional single standard turntable structure, is designed into a combined piece and consists of the standard turntable and the additional turntable. The combined turntable can realize full automation of the working condition of a long main arm, improves the hoisting height, increases the hoisting weight, has small rotary radius, can work in a small space, can be matched according to the practical need of a user, is easy to transport and transfer, has high work efficiency, and reduces the using cost. The combined turntable has reasonable design, is convenient for production and manufacture, and is particularly suitable for the large-tonnage crawler crane.

Owner:LIAONING FUWA HEAVY IND MACHINERY

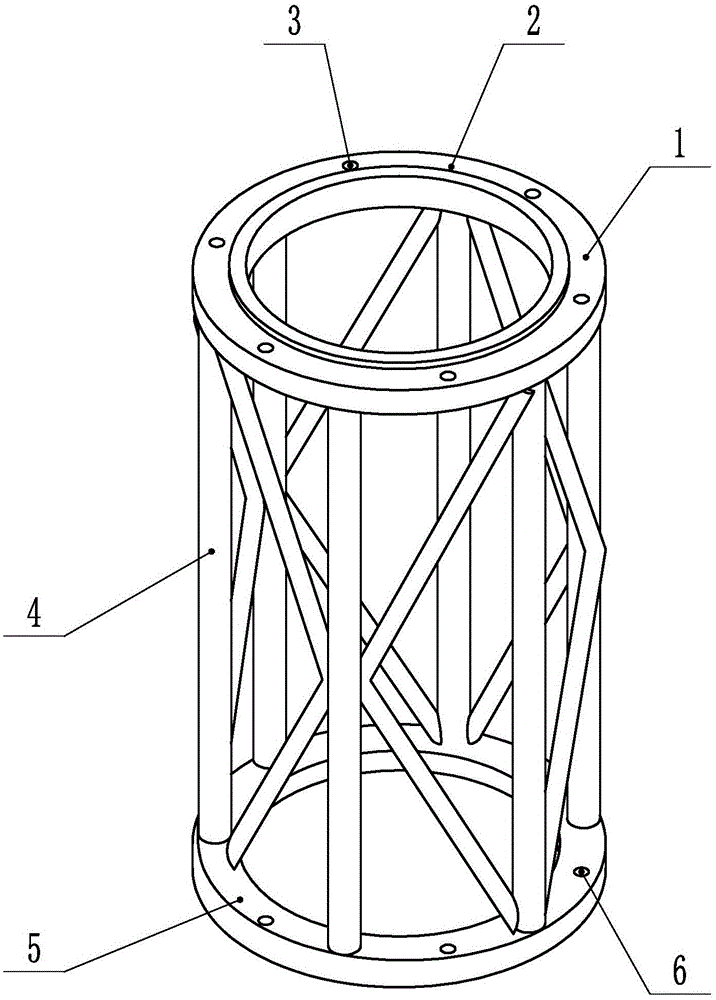

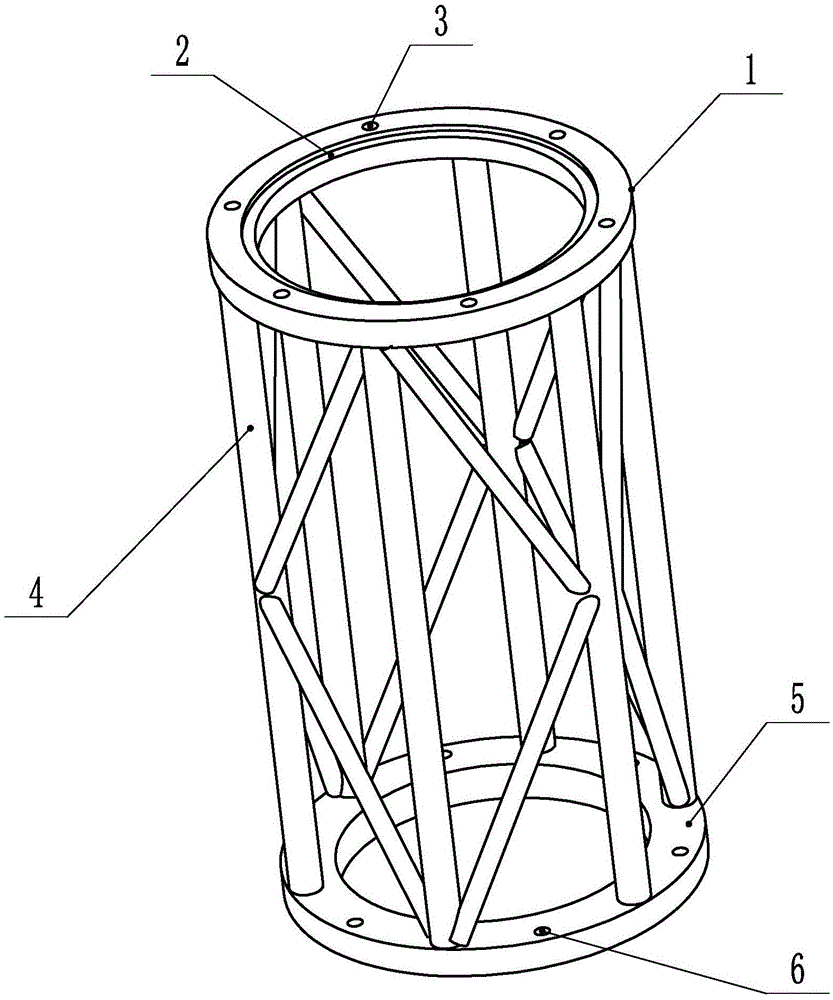

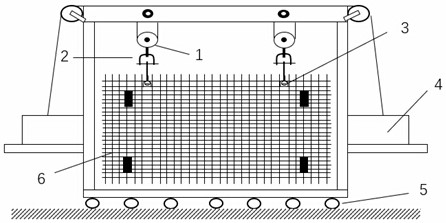

Rapid hoisting construction method for low-clearance diaphragm wall reinforcement cage

ActiveCN113353782AEasy to moveLarge lifting capacityWelding/cutting auxillary devicesHydro energy generationSlurry wallArchitectural engineering

The invention discloses a rapid hoisting construction method for a low-clearance diaphragm wall reinforcement cage. The method comprises a construction preparation process, a reinforcement cage manufacturing and processing process, a hoisting and lowering process and a reinforcement cage meeting the operation of each construction process, the upper part of the reinforcement cage is provided with main reinforcements, trusses, a cage top and horizontal reinforcements, a hoisting rigging, a winch and a hoisting point are arranged on the upper portion of the reinforcement cage, the hoisting rigging comprises a pulley block, a small carrying pole, a shackle A, a steel wire rope and a shackle B, and the two ends of the steel wire rope are connected with the small carrying pole and the shackle B respectively. The method has the beneficial effects that the problems of hoisting, turning and straightening, groove entering, connecting and the like of the underground diaphragm wall reinforcement cage are solved through a hoisting equipment hoisting frame suitable for the low clearance condition.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP +2

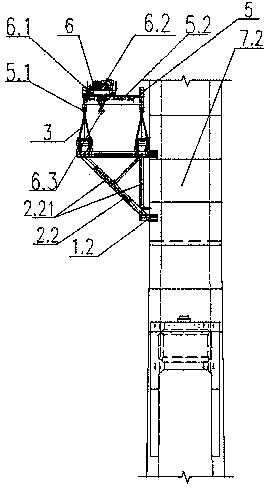

Attached type bridge crane and construction method thereof

The invention relates to an attached type bridge crane, belonging to the technical field of bridge construction equipment. The attached type bridge crane comprises a left support beam and a right support beam, which are distributed on the side surfaces of a left bridge pier stud and a right bridge pier stud respectively, wherein two horizontal jib crane main beams which are the same in height and are arranged in parallel are arranged between the top ends of the left support beam and the right support beam, the left ends of the two jib crane main beams are overhung on the left support beam, track beams are arranged on two jib crane main beams respectively, a bridge running mechanism is arranged on two track beams in a sliding connecting manner by a first roller, a bridge frame longitudinal beam is arranged on the bridge running mechanism, a crane carriage is arranged on the bridge frame longitudinal beam in a sliding connecting manner by a second roller, a hook is arranged at the bottom end of the crane carriage, and a winch connected with the hook is arranged on the crane carriage. The attached type bridge crane has the characteristics of requirement on set-up of an elevated trackway on the ground and small interference to the underside of the equipment.

Owner:CCCC SECOND HARBOR ENG

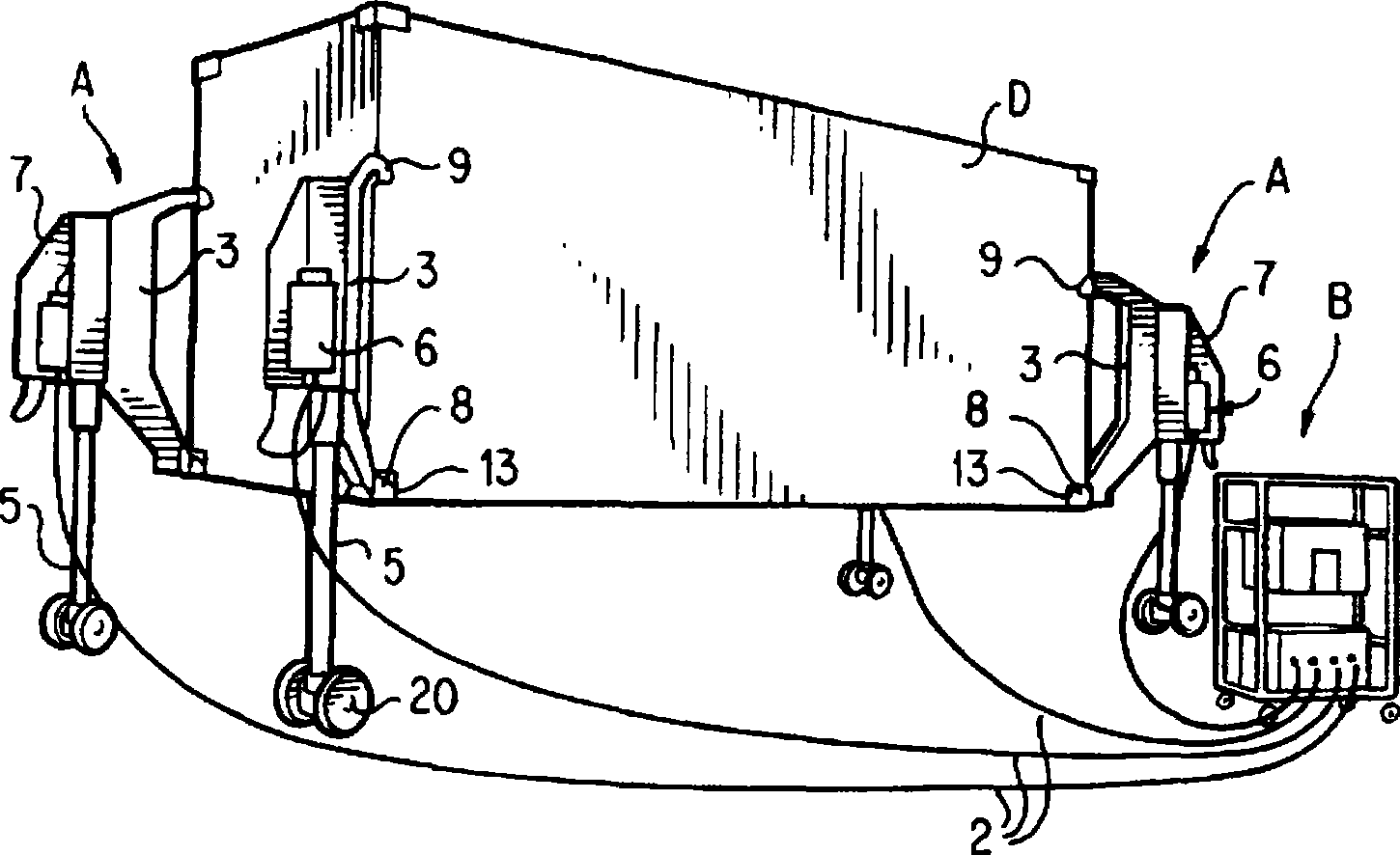

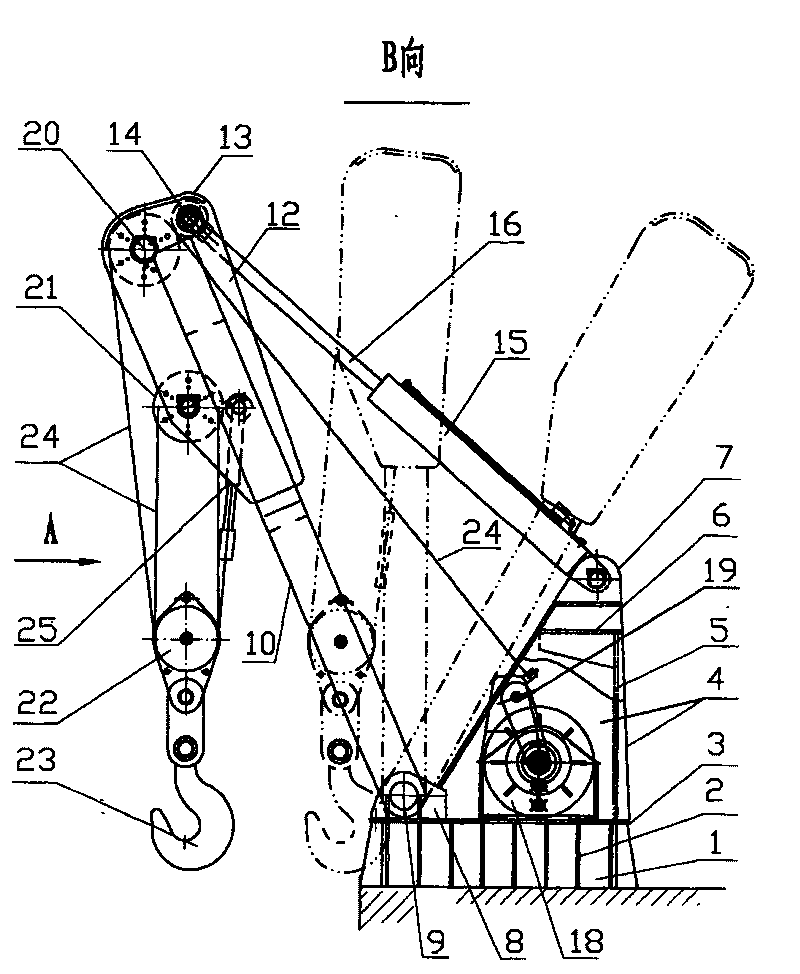

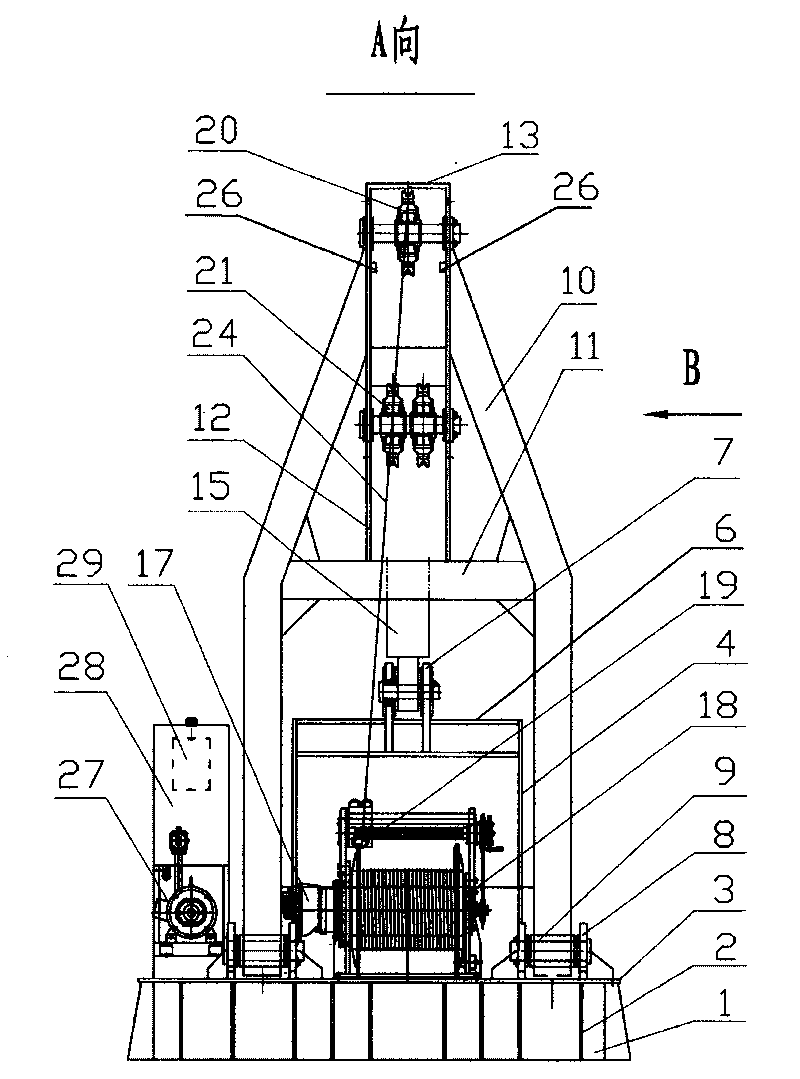

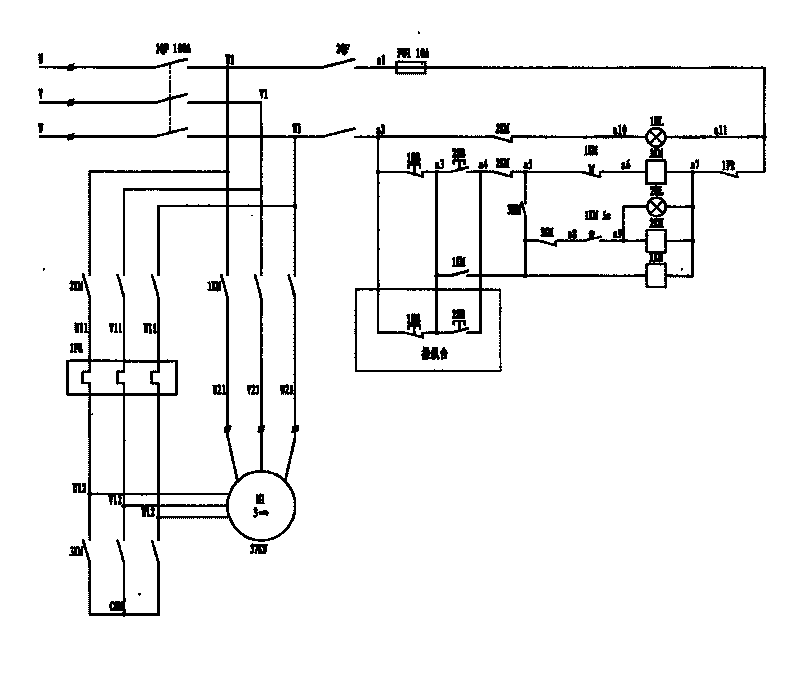

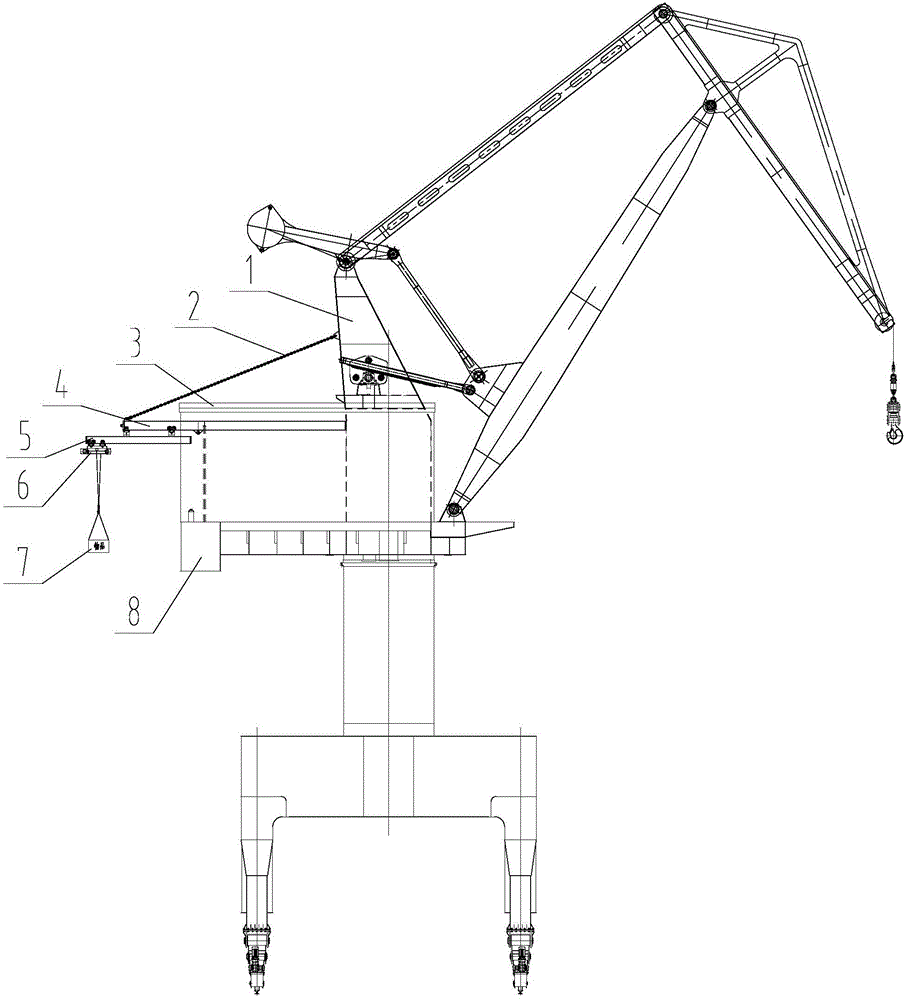

Gunwale hoisting device for pipe-laying ship

InactiveCN101691133ALow powerLarge lifting capacityCargo handling apparatusDavitsFuel tankEngineering

The invention provides a gunwale hoisting device for a pipe-laying ship, belonging to the field of davits of ships. The device mainly comprises a base, a winch bed and a boom. The winch bed is welded on the middle rear part of the base and the boom is installed in front of the base. A swing arm mechanism comprises hydraulic cylinders, a lower hinged support and an upper hinged shaft. The lower hinged support is welded at the top of the winch bed. The hydraulic cylinders are installed on the lower hinged support and the upper hinged shaft. The upper hinged shaft is installed at the top of the boom. A hoisting mechanism comprises a hydraulic winch, a rope-arranging pulley, two fixed pulleys, three movable pulleys, a hook, wire ropes, a weight sensor and length measurement sensors. The hydraulic winch is installed in the winch bed. Each fixed pulley is installed on a dual anchorage plate of the boom. A hydraulic oil tank, a motor and an oil pump are installed on the right of the base. An electric control box is installed above the oil tank. A control circuit is installed in the electric control box. The device mainly has the following advantages: the boom is short and wide, the dead-weight is lighter, the hoisting weight is great, the motor power is smaller and the electricity is saved, the manufacturing cost is 1 / 10 of the import price and the device can complete offshore pipeline aligning and shifting, vertical pipe and hoist boat manufacturing, etc.

Owner:KEWEI INTELLIGENT WELDING INSPECTION DEV DONGYING CITY

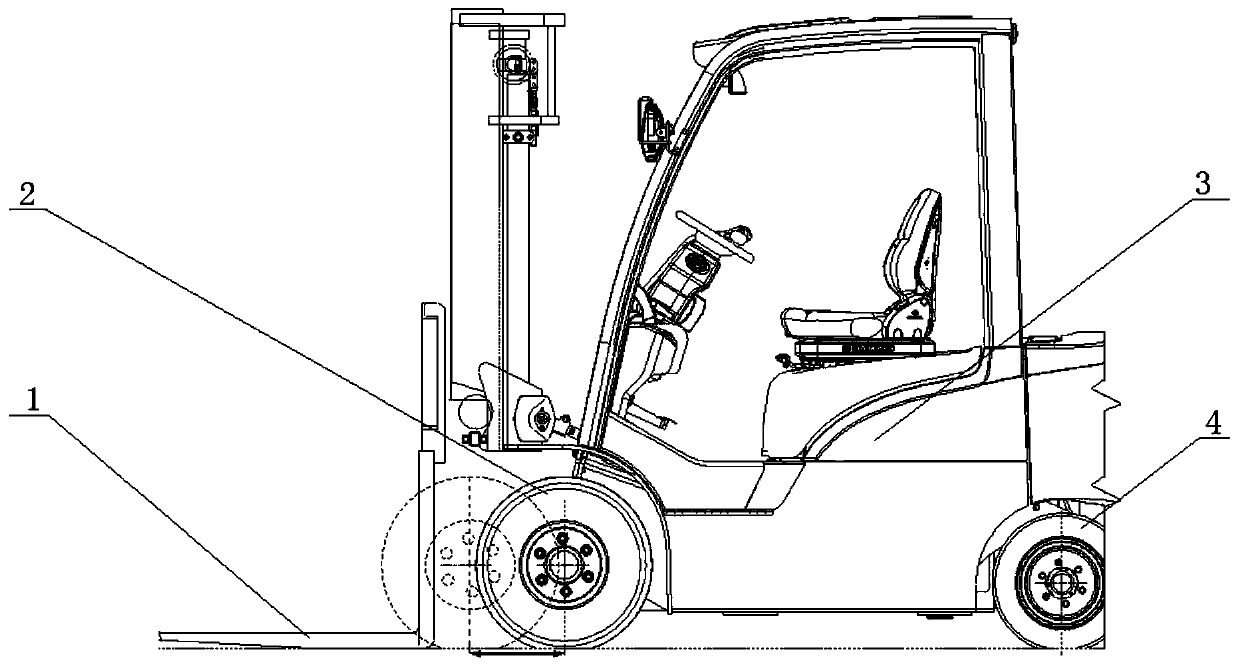

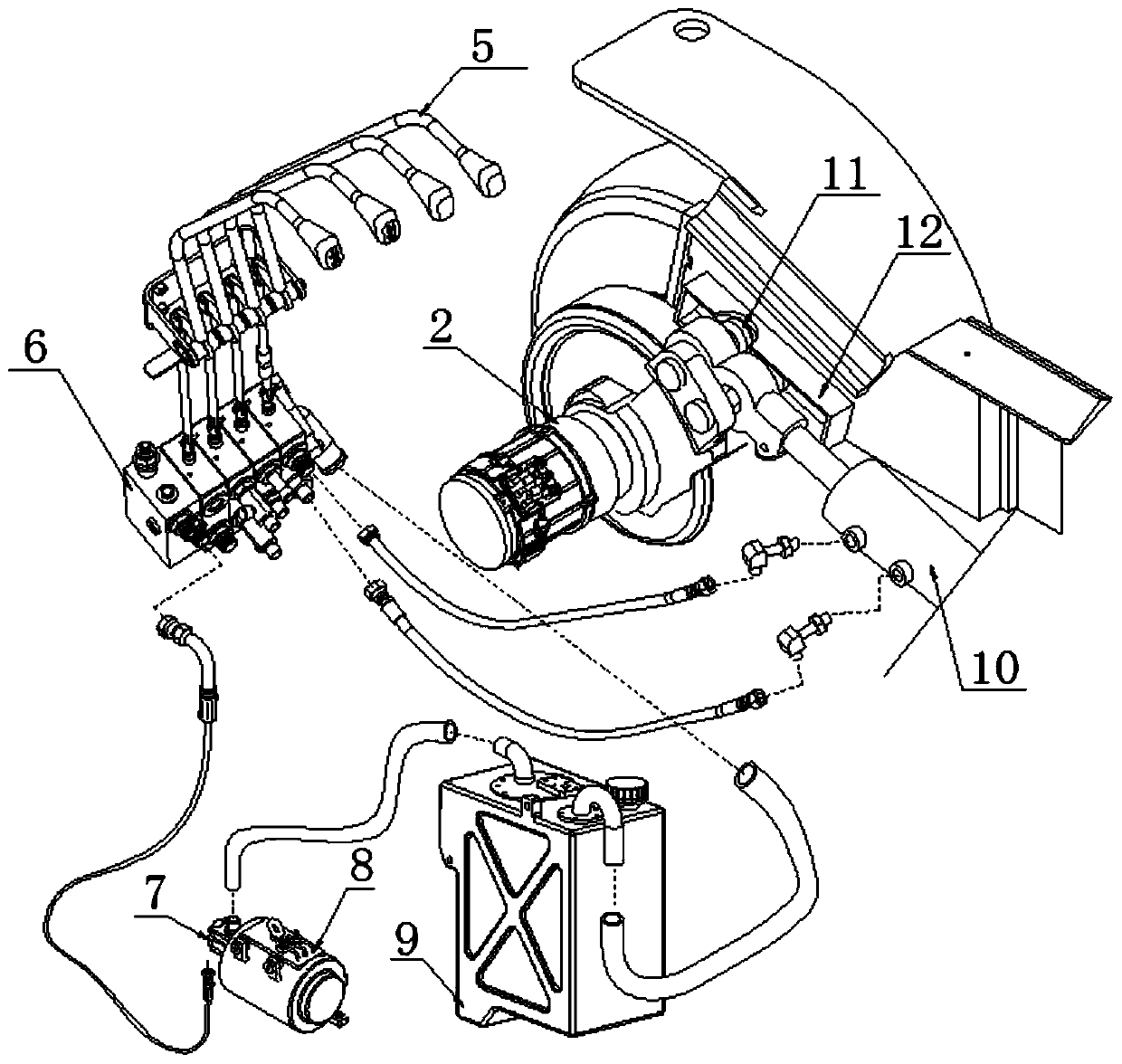

Forklift with adjustable wheelbase

The invention discloses a forklift with adjustable wheelbase. The forklift comprises a forklift body, driving wheel assemblies arranged at the front part of the forklift body and steering wheel assemblies arranged at the rear part of the forklift body, wherein counterweights are arranged on the parts, of the forklift body, above the steering wheel assemblies; an adjusting device for adjusting the distance between the driving wheel assemblies and the steering wheel assemblies is arranged on the forklift body and used to adjust the positions, of the driving wheel assemblies, relative to the forklift body. The distance between the driving wheel assemblies and the steering wheel assemblies can be adjusted; when the distance between the driving wheel assemblies and the steering wheel assemblies decreases, the turning radius of the forklift decreases and thus the flexibility of the forklift is improved; and when the distance between the driving wheel assemblies and the steering wheel assemblies increases, the distance between the counterweights and fulcrums can be increased to increase the force moment of the counterweights, so as to increase the lifting weight of a fork to increase the rated lifting weight of the forklift. Moreover, the positions, of the driving wheel assemblies, relative to the forklift body can usually be adjusted at no load, so that the driving force of a driving device can be reduced to be much smaller than the driving force required for adjusting steering wheels.

Owner:HANGCHA GRP

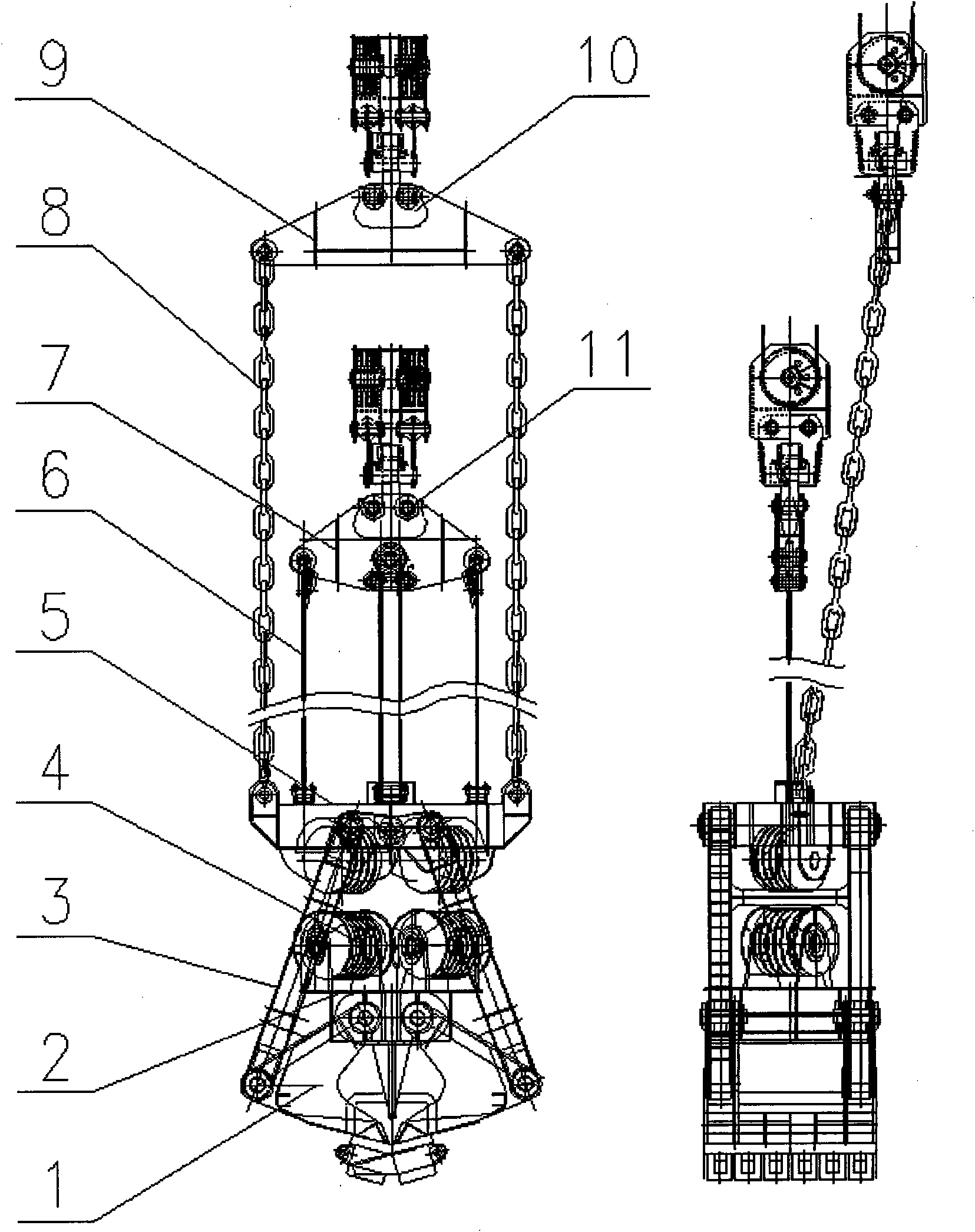

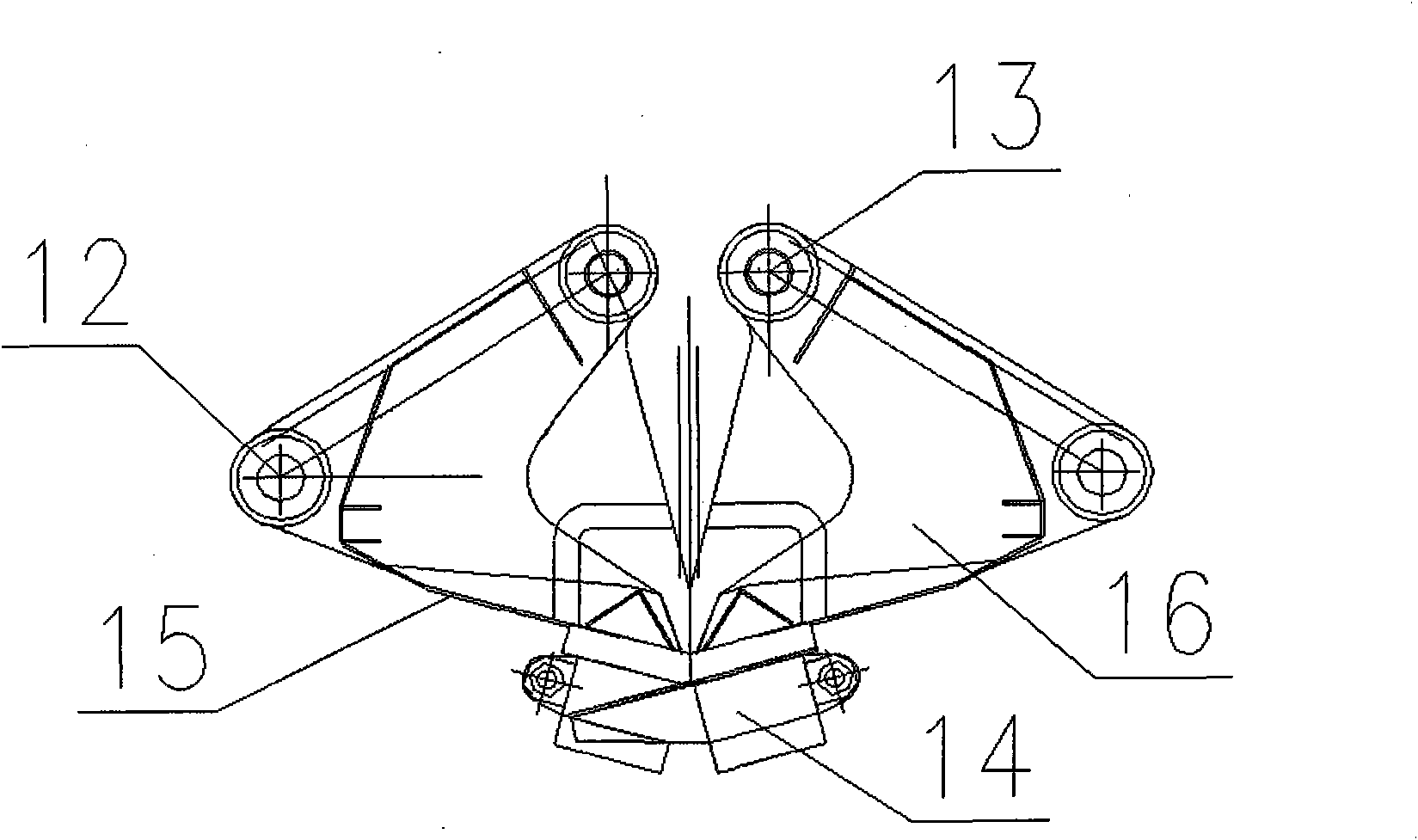

Giant undersea salvage grab bucket

InactiveCN101913417ALarge lifting capacityImprove digging abilityVessel salvagingOcean bottomMarine engineering

The invention discloses a giant undersea salvage grab bucket. The grab bucket comprises a grab bucket body, a grab bucket central beam, a grab bucket head part, grab bucket balance beams, a pulley block system, steel wire ropes and bearer cables, wherein the pulley block system improves the excavating force of the grab bucket by providing a magnifying power through wound steel wire ropes; and besides, high-intensity bucket teeth are arranged on the grab bucket body, so when the grab bucket is used for salvaging a sunken ship, the grab bucket body can dive to a sea floor in hundred meters, tear steel plates of the sunken ship by using a giant excavating force and then grab the sunken ship and salvage the sunken ship up. The giant undersea salvage grab bucket not only has basic functions of the conventional grab bucket, comprising a basic function of grabbing wares, but also has super high hoisting capacity and 500-ton grabbing capacity, and is particularly suitable for undersea sunken ship salvage. As the grab bucket has great excavating capacity and can tear steel plates of sunken ships, the efficiency of marine sunken ship salvage is greatly improved and the economic benefit of grab buckets is improved.

Owner:SHANGHAI MARITIME UNIVERSITY

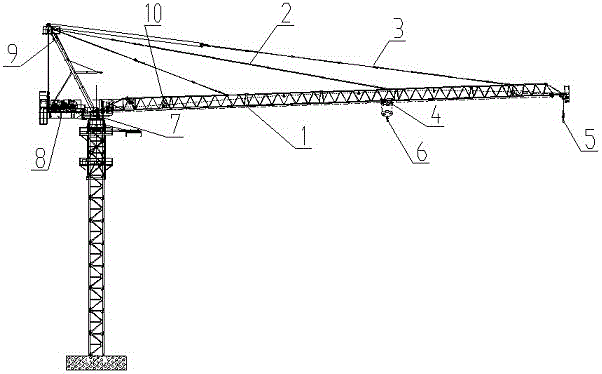

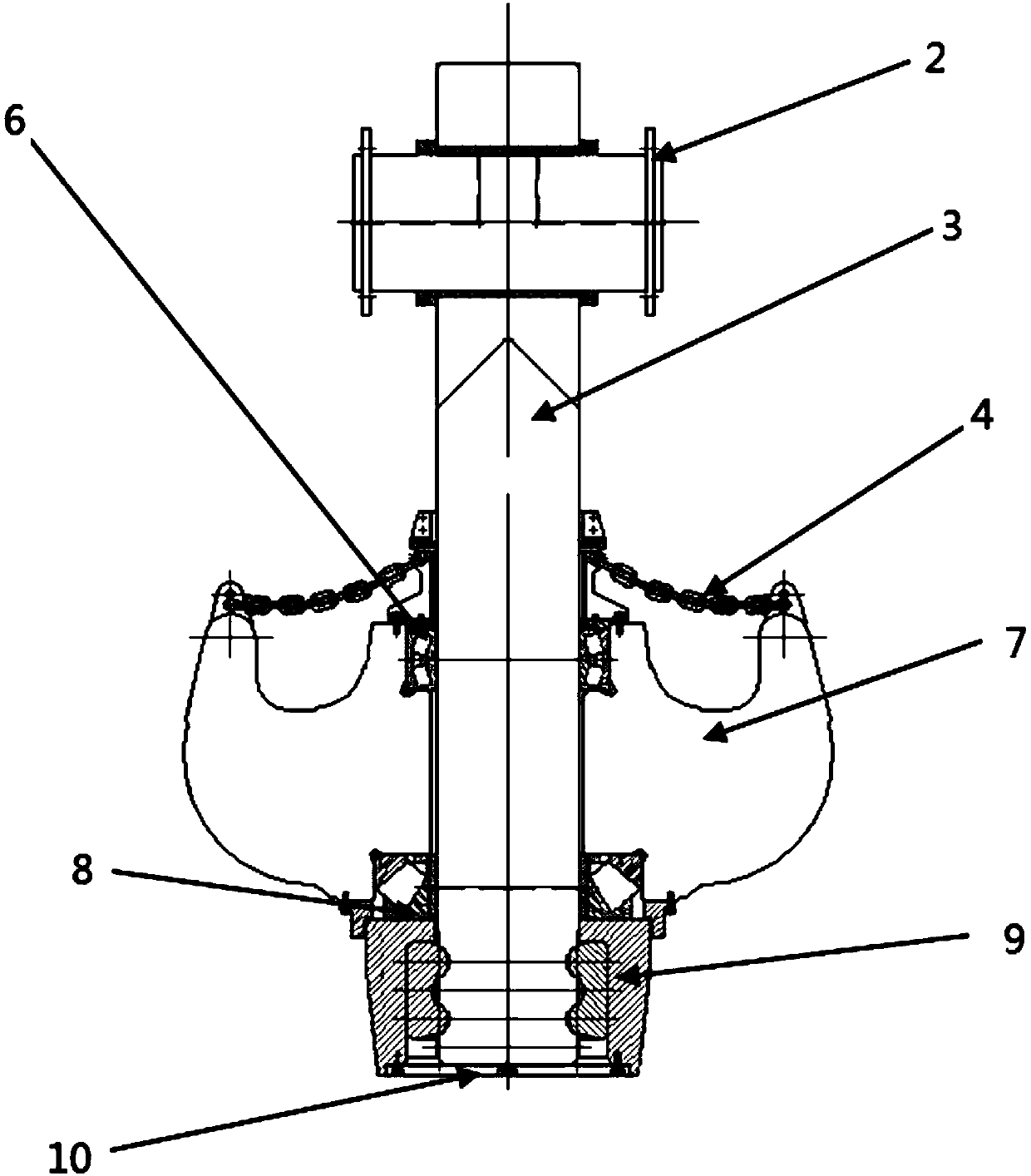

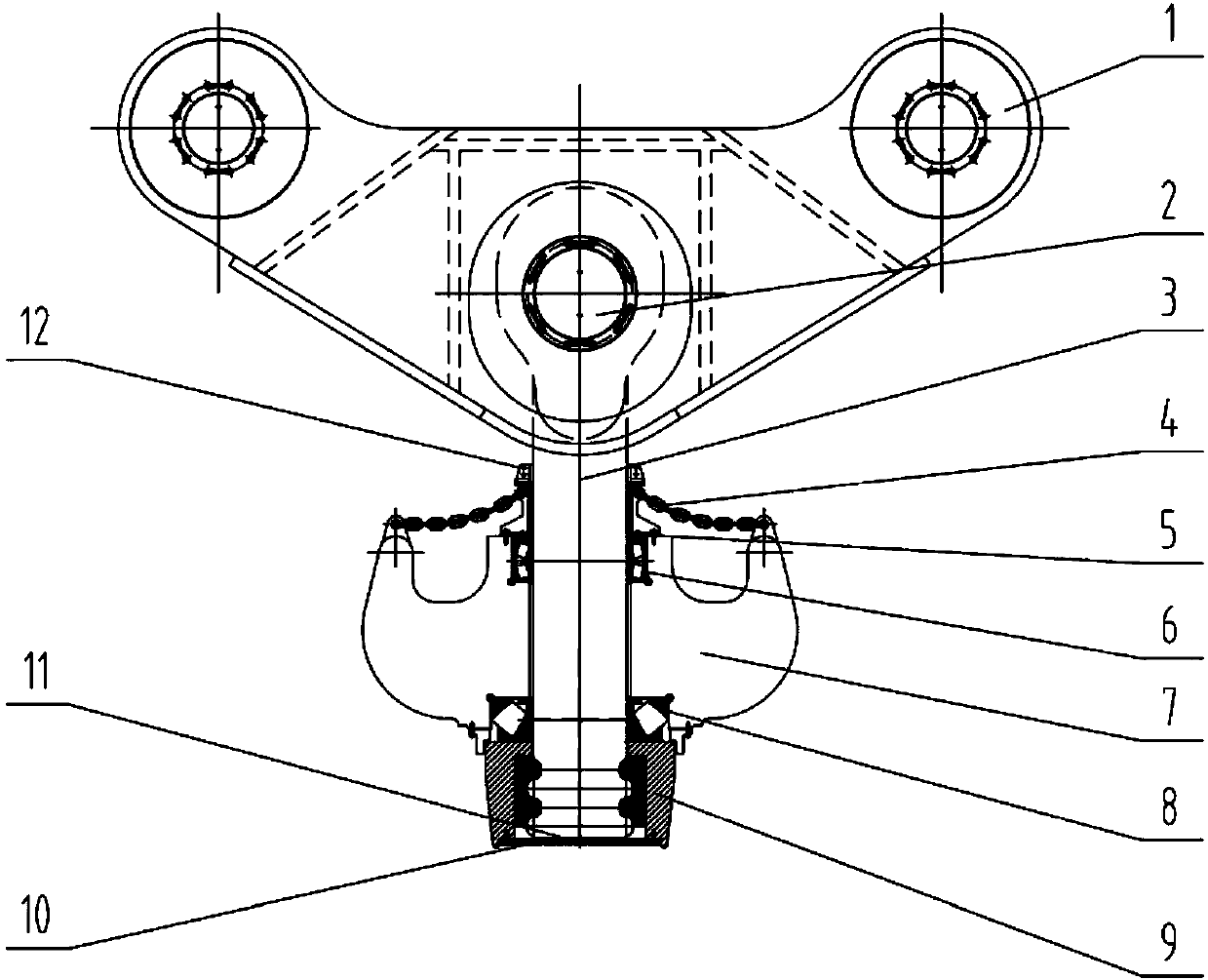

Movable arm and flat arm dual-purpose tower crane

The invention discloses a movable arm and flat arm dual-purpose tower crane. The tower crane comprises a tower top, a cargo boom and a balance arm used for connecting the tower top and the cargo boom. The cargo boom is provided with a flat arm amplitude-change mechanism and a movable arm amplitude-change mechanism, and a pivoting support is hinged to the root of the cargo boom. The end of the cargo boom is connected with a movable arm lifting hook, and the movable arm lifting hook controls the elevation angle change of the cargo boom through the movable arm amplitude-change mechanism to make amplitude-change movement. The first chord is connected with one end of a flat arm pull rod and one end of a movable arm pull rod, and the other end of the flat arm pull rod and the other end of the movable arm pull rod are connected with the tower top. The lower chord is connected with a flat arm trolley. The lower side of the flat arm trolley hangs a flat arm lifting hook through a lifting steel wire rope, and the flat arm lifting hook controls horizontal displacement of the flat arm trolley through the flat arm amplitude-change mechanism to make amplitude-change movement. The movable arm and flat arm dual-purpose tower crane has a flat arm operating mode and a movable arm operating mode, the functions of a movable arm tower crane and a flat arm tower crane can be fused, the operating functions can be switched at will, and the advantages of the two tower cranes can be achieved at the same time.

Owner:XUZHOU CONSTR MACHINERY

Super tonnage split lifting hook

InactiveCN107555309AImprove performanceImprove the form of forcePortable liftingLoad-engaging elementsUltimate tensile strengthSpherical roller bearing

The invention discloses a super tonnage split lifting hook. The lifting hook comprises a movable pulley set, a lifting hook rod, a lifting hook shaft, a lifting hook body, a self-aligning roller bearing and a thrust self-aligning roller bearing. The lifting hook further comprises a connecting assembly connecting the lifting hook rod with the lifting hook body. The connecting assembly comprises anembracing type wedging sleeve and a lifting hook hoop arranged below the thrust self-aligning roller bearing. The lifting hook hoop is fixedly connected with the lifting hook rod through the embracingtype wedging sleeve. According to the provided lifting hook, the single-hook lifting weight is super large, and the single hook hoisting weight is 5,000 tons or above. Due to the fact that the lifting hook is split, the embracing type wedging sleeve and the hoop are connected to install the lifting hook body and the lifting hook rod together, and the novel split lifting hook is initiated in the world; the stress of the split lifting hook is reasonable, the dead load is small, the structural strength is high, the dead load of lifting hook sets is greatly reduced, and accordingly the operationcapability and operation efficiency of a floating crane are improved.

Owner:SHANGHAI MARITIME UNIVERSITY

Variable-stroke high-and-low-beam travelling crane for crane machine room

The invention discloses a variable-stroke high-and-low-beam travelling crane for a crane machine room. The variable-stroke high-and-low-beam travelling crane comprises an upper track beam, a lower track beam, an electric hoist and a plurality of running blocks, wherein the plurality of running blocks include first running blocks and second running blocks; the upper track beam and the lower track beam are in sliding fit through the first running blocks; the lower track beam and the electric hoist are in sliding fit through the second running blocks; the upper track beam comprises a movable beam and a fixed beam; the fixed beam is located in the machine room; the machine room is located on a turntable of a gate seat crane; the right end of the fixed beam is fixed on an upright post; the upright post is arranged on the turntable of the gate seat crane; the left end of the fixed beam is supported by a support beam located on the turntable and connected with the right end of the movable beam through a hinge; and the left end of the movable beam extends out of the machine room and is detachably connected with the upright post of the gate seat crane through a digging line. The travelling crane is convenient to operate and high in loading capacity, has a large outreach and can be completely fixed in the machine room when not used.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

Intelligent monitoring high-precision positioning drum hoisting device and hoisting method applied by same

PendingCN112499482ALarge lifting capacityEasy to operateLoad-engaging girdersBase supporting structuresControl engineeringProcess engineering

The invention discloses an intelligent monitoring high-precision positioning steam pocket hoisting device and a hoisting method applied to the same. The intelligent monitoring high-precision positioning steam drum hoisting device comprises a supporting beam assembly, a hydraulic lifting assembly fixedly arranged on the supporting beam assembly, a steel strand anchored to the hydraulic lifting assembly, and a monitoring alarm assembly used for monitoring the boiler steam drum hoisting process in real time. The invention further discloses a boiler drum double-lifting-point inclined hoisting method, two sets of positioning drum hoisting devices are used for conducting double-lifting-point inclined hoisting on the boiler drum, trial hoisting is conducted before formal hoisting, and whether thedevices and related control loops work normally or not is checked; and during formal hoisting, the position of the boiler drum is monitored in real time through the monitoring and alarming assembly,and obstacle avoidance is conducted till the boiler drum is in place safely. In the hoisting process, digital intelligent monitoring can be conducted on the boiler drum, stress balance of related components is guaranteed, and the boiler drum can be safely and stably placed in place.

Owner:中国电建集团河北工程有限公司

Counterweight synchronous moving mechanism of movable arm type crane

InactiveCN107827000AEnhanced lifting characteristicsIncrease productivityCranesEngineeringMechanical engineering

The invention discloses a counterweight synchronous moving mechanism of a movable arm type crane and relates to the field of cranes. The counterweight synchronous moving mechanism is small in structure, good in stability and high in safety. The mechanism comprises a cargo boom, a balance arm, a counterweight and a counterweight moving mechanism, wherein the counterweight moving mechanism can drivethe counterweight to move in the length direction of the balance arm. The counterweight moving mechanism comprises a first driving rod, a second driving rod, a third driving rod, a fourth driving rodand a support, wherein the support is connected with the balance arm. The support, the third driving rod, the fourth driving rod and the counterweight are connected to form a crank sliding block mechanism. The first driving rod is hinged to the fixed hinge point, the first driving rod is connected with the cargo boom and can rotate together with the cargo boom, the second driving rod is hinged tothe first driving rod and the third driving rod, and the second driving rod can transmit the rotation of the first driving rod to the third driving rod. According to the counterweight synchronous moving mechanism, all the driving rods are used for converting the rotating motion of the cargo boom into the movement of the counterweight.

Owner:SICHUAN CONSTR MACHINERY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com