Foundation pit support and water stop integrated structure and construction method thereof

A foundation pit support and construction method technology, which is applied in the direction of foundation structure engineering, excavation, protection devices, etc., can solve the problems of large amount of steel bars, large lifting weight, uneven force, etc., and achieve low concrete performance requirements and avoid Easy to collapse holes and avoid leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Such as Figure 9-10 As shown, an integrated foundation pit support and waterproof structure includes a concrete wall 1 arranged below the ground around the foundation pit. The concrete wall 1 is provided with a plurality of vertically placed cylindrical reinforcement cages 2 .

[0033] Such as Figure 1-10 As shown, a construction method of foundation pit support and water-stop integrated structure, comprising the following steps:

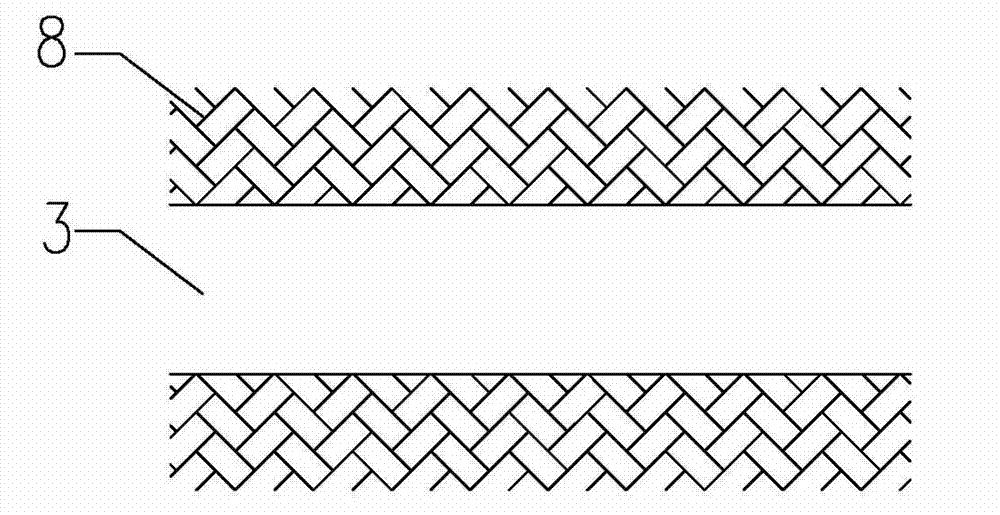

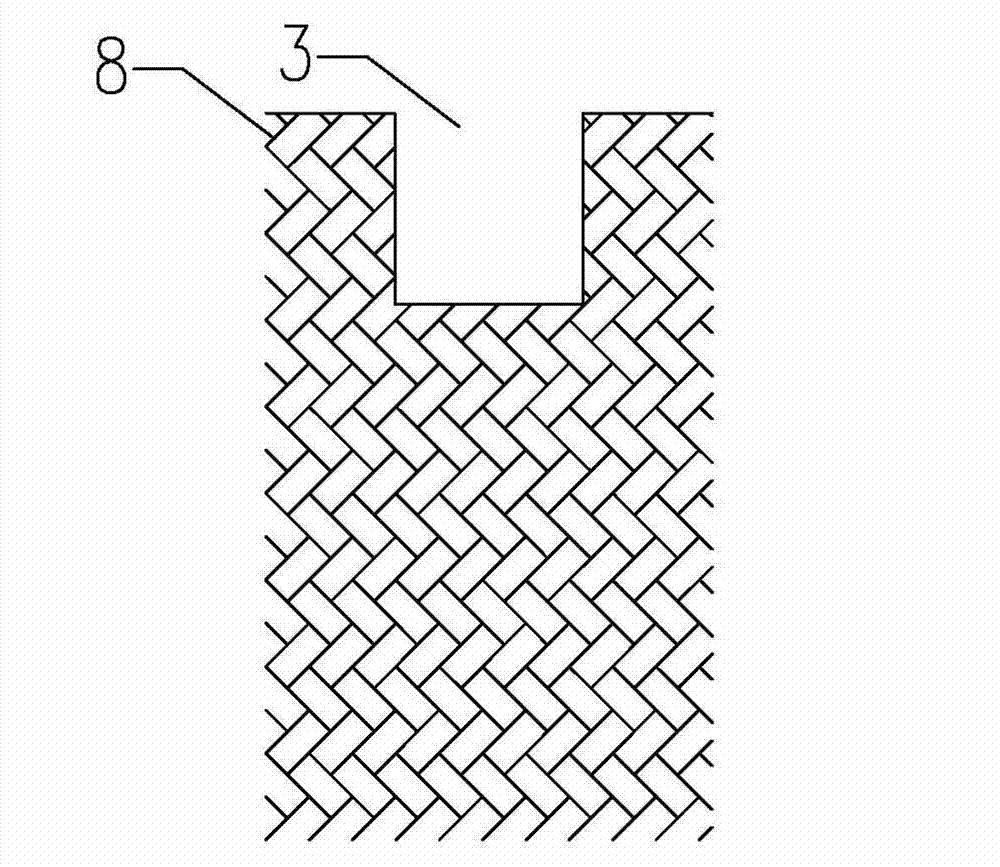

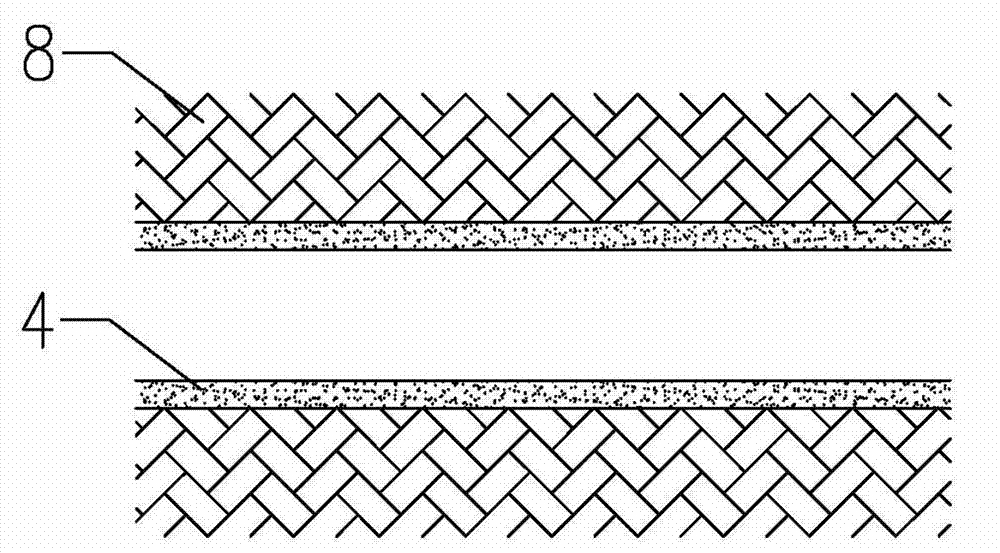

[0034] 1) excavate the guide groove 3 on the surface;

[0035] 2) Concrete guide wall 4 is poured on the side wall of the guide groove;

[0036] 3) Grab the earth-square cuboid groove section 5 in the guide groove with a groove forming machine, and use mud 6 to protect the wall in the cuboid groove section 5;

[0037] 4) After cleaning the slag at the bottom of the cuboid trough section 5, vertically place a cylindrical reinforcement cage 6 in the cuboid trough section 5 and fix it;

[0038] 5) Lower the pouring conduit in the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com