Improved-type single-girder crane

An improved technology for cranes, which is applied in the direction of cranes, trolley cranes, load hanging components, etc., can solve the problems of heavy main beam structure, unstable operation of electric hoist, high cost, etc., and achieve stable operation, good ventilation and heat dissipation, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

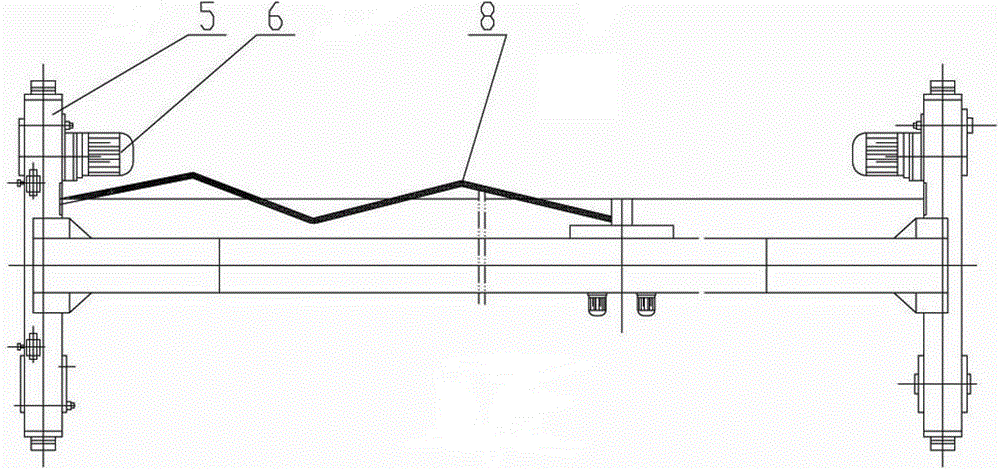

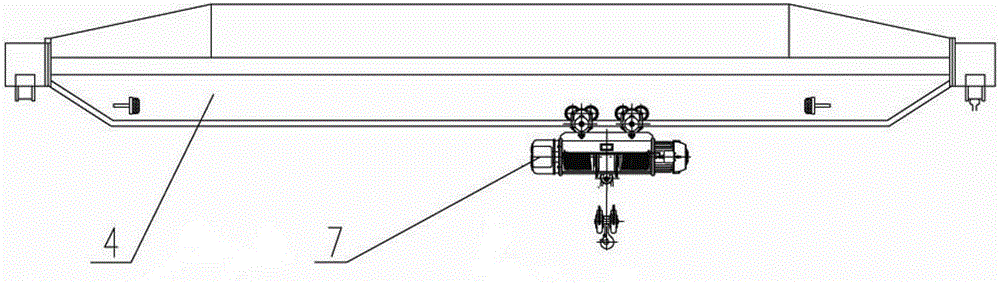

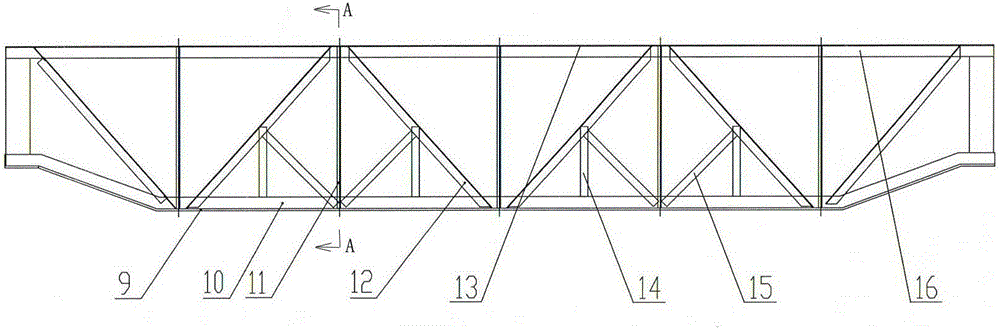

[0020] Embodiment 1: a kind of improved single girder crane, see Figure 4 , Figure 5 , Figure 6 and Figure 7 , including a main beam 17 and beams 5 at both ends, the main beam 17 includes a bottom steel plate 9 and a top cover plate 13, the flange of the steel plate 9 is used as the walking track of the electric hoist, and the inside of the flange is welded with slats 10. The thickness and width of the steel plate 9 are designed according to the requirements of different lifting weights, and the width of the slats meets the design requirements. There are several vertical plates 11 vertically connected between the bottom steel plate 9 and the upper cover plate 13, and the two sides of each vertical plate 11 are respectively The oblique vertical plate 12 is welded obliquely, and the two sides of the vertical vertical plate 11, the oblique vertical plate 12 and the upper cover plate 13 are respectively provided with flanging (bending). The upper ends of the upright boards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com