Mounting equipment car

A technology for installing equipment and power equipment, applied in hoisting devices, hoisting devices, transportation and packaging, etc., can solve problems affecting construction efficiency, consumption, and increasing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

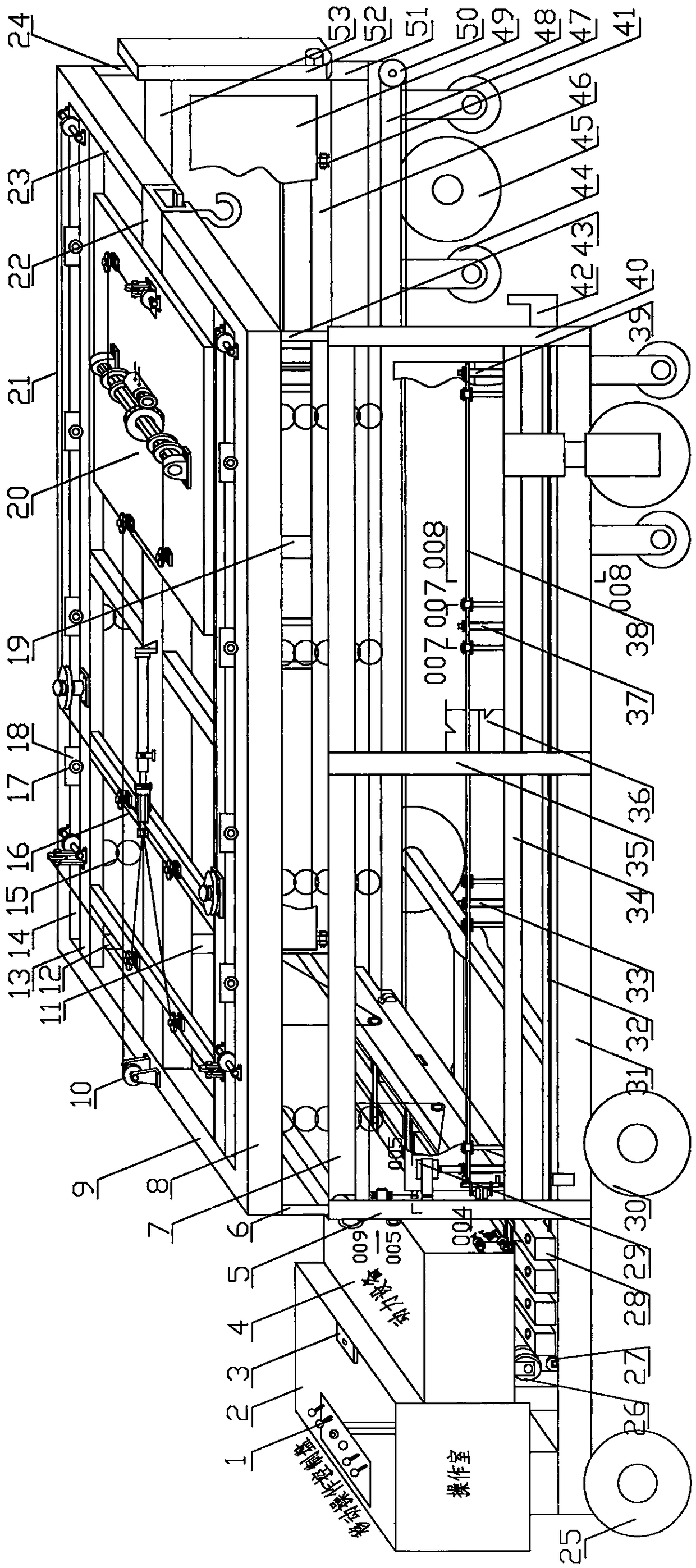

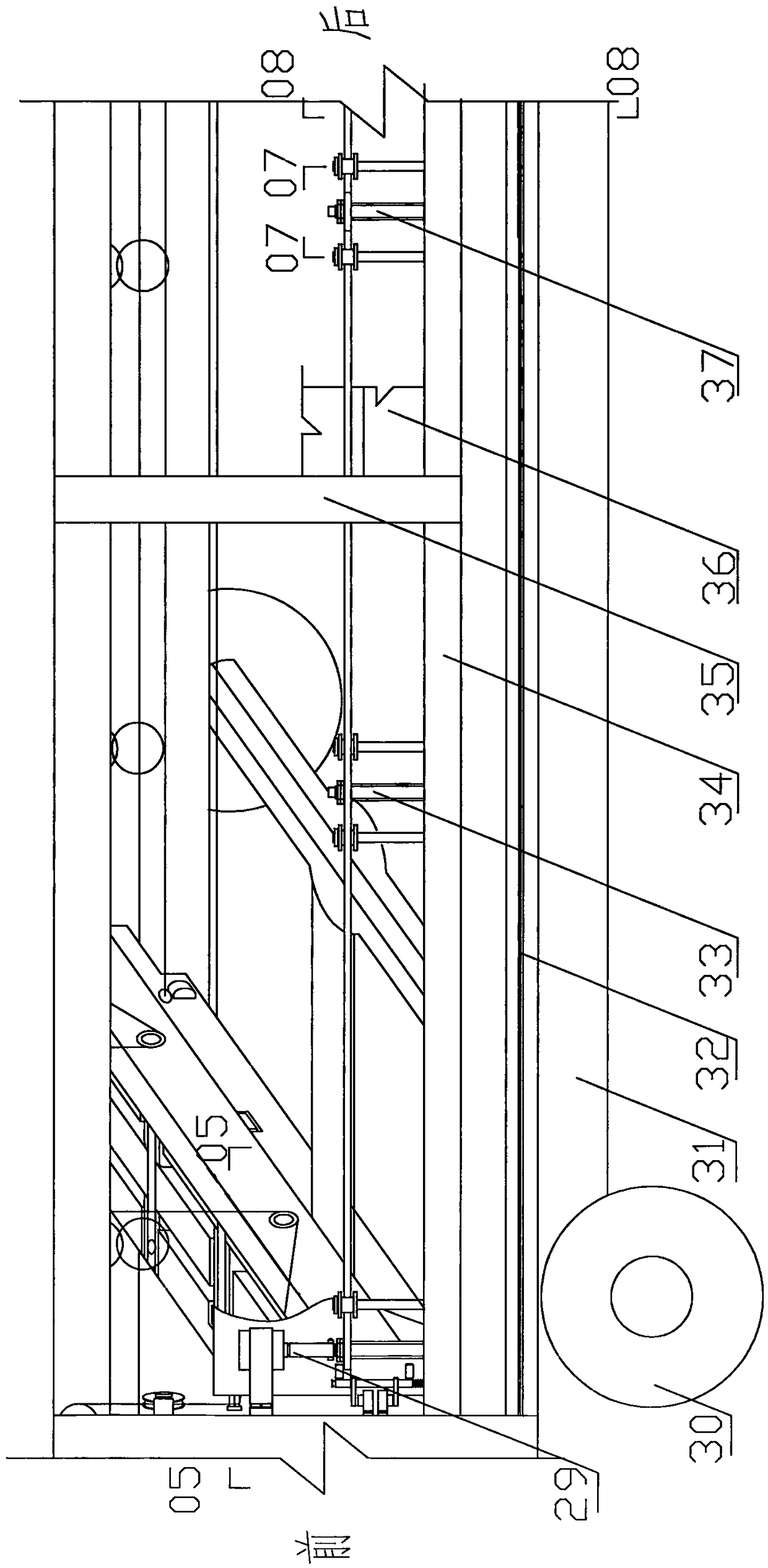

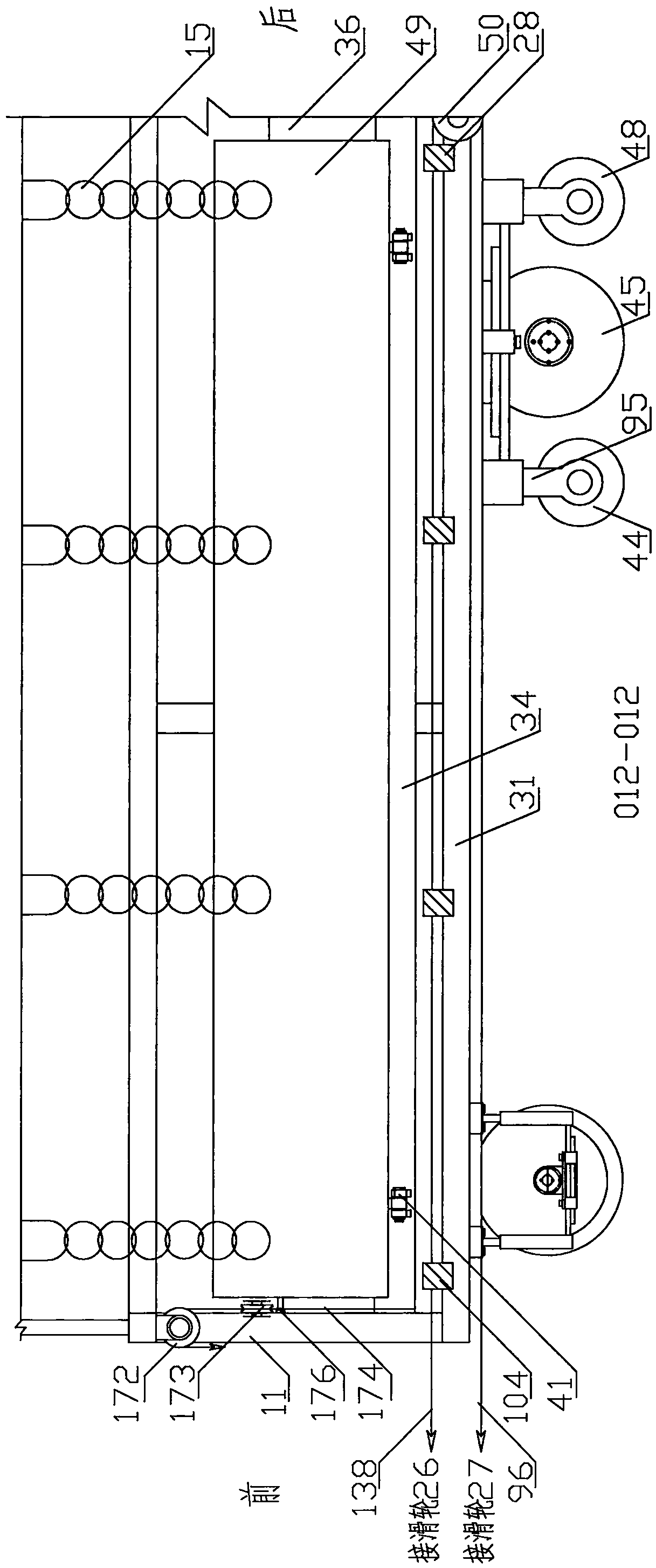

[0281] The present invention will be further described with reference to accompanying drawing, figure 1 It is a schematic diagram of the overall structure of the present invention, and its bottom beam is retracted at the bottom of the power equipment position, figure 2 for figure 1 Several bottom beams are connected to the two bottom longitudinal beams on both sides of the box by the driving mechanism. An installation equipment vehicle of the present invention is composed of power equipment, chassis, body and electrical equipment, etc., and has the basic functions of a car. Be that: box body is made of its two sides, top and bottom, and the composition of two sides structure, is connected with the left bottom longitudinal beam 31 and the lower end of right rear column 51 by left front column 5, left rear column 40, right front column 11, right rear column 51 respectively. The outer side of the right bottom longitudinal beam 47, the upper ends of the columns are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com