Matte varnish convenient for UV electrostatic spraying and preparation method of matte varnish

A technology of electrostatic spraying and topcoat, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve problems such as poor after-sales service, unsuitable topcoat, lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a kind of matte clear topcoat that is convenient to UV electrostatic spraying, and this matte clear topcoat is suitable for electrostatic spraying process, utilizes electrostatic spraying process to be able to spray this matte clear topcoat on the six sides of the product at one time. On the processing surface, the construction difficulty of the matte clear topcoat is greatly simplified, which facilitates the improvement of construction efficiency. The entire construction process is less dependent on labor, which reduces the introduction of human errors. The obtained paint film has high flatness, low odor and environmental protection. .

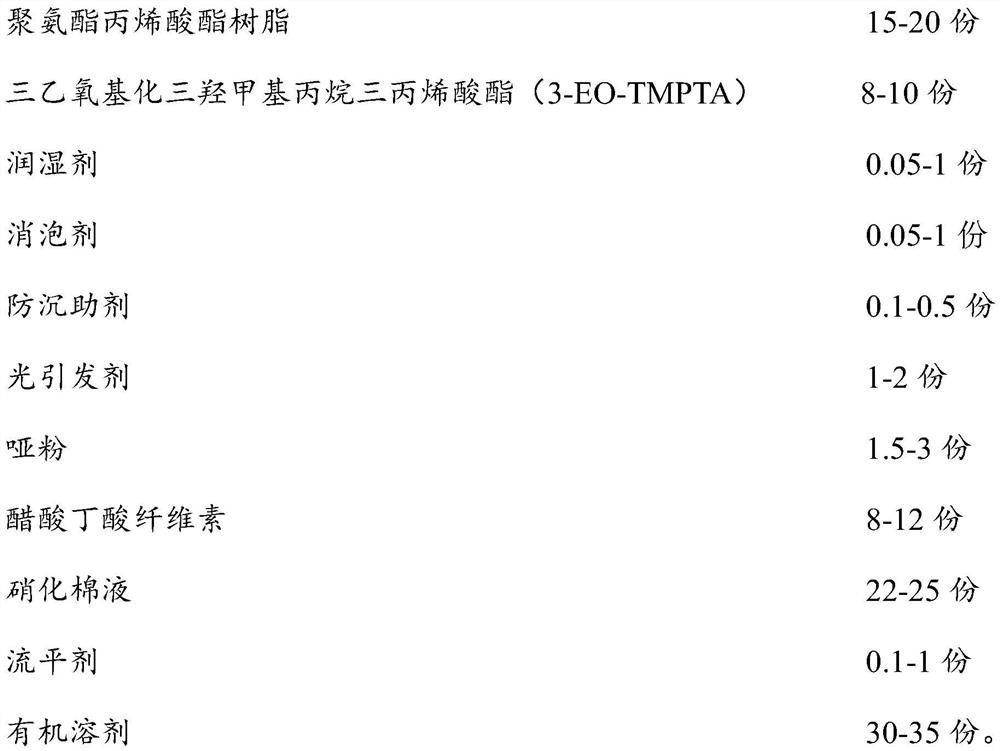

[0026] This embodiment provides a kind of matte clear finish paint that is convenient to UV electrostatic spraying, and this matte clear finish paint is calculated in parts by weight, and its component comprises:

[0027]

[0028]

[0029] In this embodiment, the matte clear finish that is convenient for ...

Embodiment 2

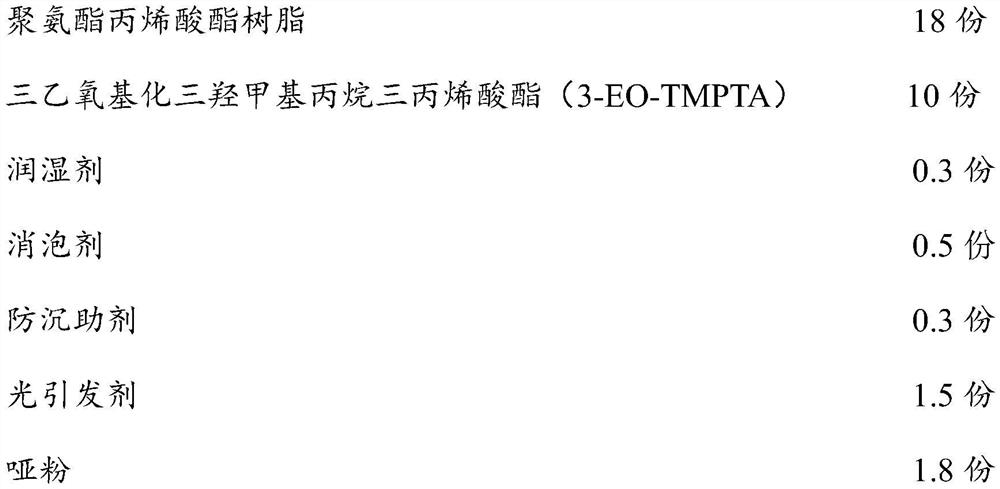

[0036] This embodiment provides a kind of matte clear finish paint that is convenient to UV electrostatic spraying, and this matte clear finish paint is calculated in parts by weight, and its component comprises:

[0037]

[0038]

[0039] In this embodiment, the matte clear finish that is convenient for electrostatic spraying is specifically prepared by the following method:

[0040] a. First weigh 20 parts of urethane acrylate resin and put it into the reaction kettle, then weigh 1 part of wetting agent, 1 part of defoamer, and 0.5 parts of anti-settling Auxiliary agent, 12 parts of cellulose acetate butyrate, 25 parts of nitrocellulose solution, 1 part of leveling agent, 2 parts of photoinitiator and 10 parts of triethoxylated trimethylolpropane triacrylate ( 3-EO-TMPTA) was added to the reactor and dispersed for 10 minutes;

[0041] b. Then increase the stirring speed of the reactor to 1200rpm, and weigh 3 parts of the dummy powder and continue to put it into the re...

Embodiment 3

[0045] This embodiment provides a kind of matte clear finish paint that is convenient to UV electrostatic spraying, and this matte clear finish paint is calculated in parts by weight, and its component comprises:

[0046]

[0047] In this embodiment, the matte clear finish that is convenient for electrostatic spraying is specifically prepared by the following method:

[0048] a. First weigh 17 parts of polyurethane acrylate resin and put it into the reaction kettle, then weigh 0.6 parts of wetting agent, 0.55 parts of defoamer, and 0.3 parts of anti-settling Auxiliary agent, 10 parts of cellulose acetate butyrate, 23.5 parts of nitrocellulose liquid, 0.6 part of leveling agent, 1.5 parts of photoinitiator and 9 parts of triethoxylated trimethylolpropane triacrylate ( 3-EO-TMPTA) was added to the reactor and dispersed for 9 minutes;

[0049] b. Then increase the stirring speed of the reactor to 1100rpm, and weigh 2.3 parts of the dummy powder and continue to put it into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com