High-rise building fabricated interlayer hoisting machine and construction method

A high-rise building and prefabricated technology, applied to cranes, etc., can solve problems such as the inability to meet the requirements of the car crane hoisting site, affect the application of tower crane hoisting procedures, and the inability to complete high-rise operations, etc., to achieve simple structure, light overall weight, and easy disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

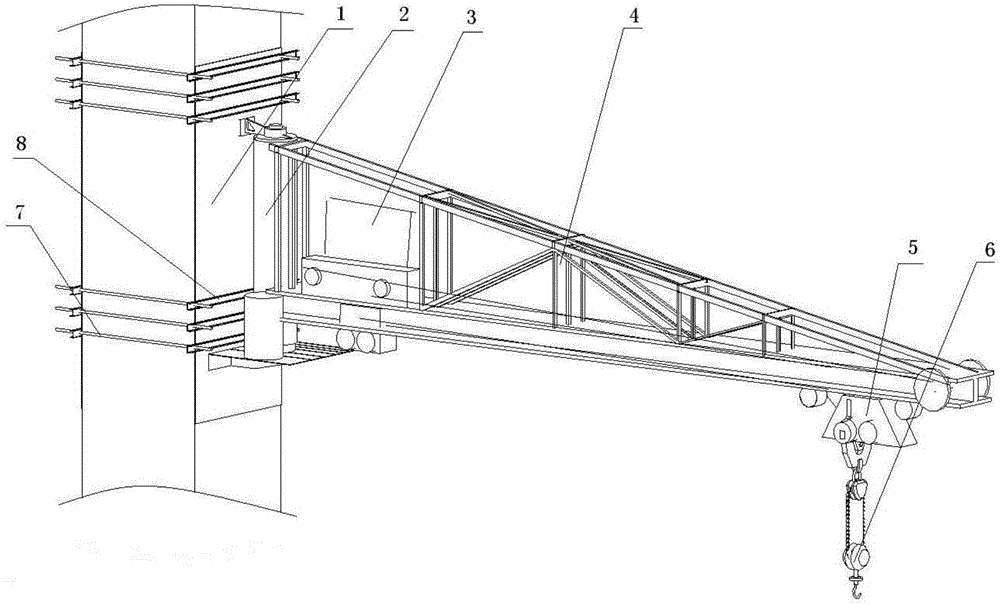

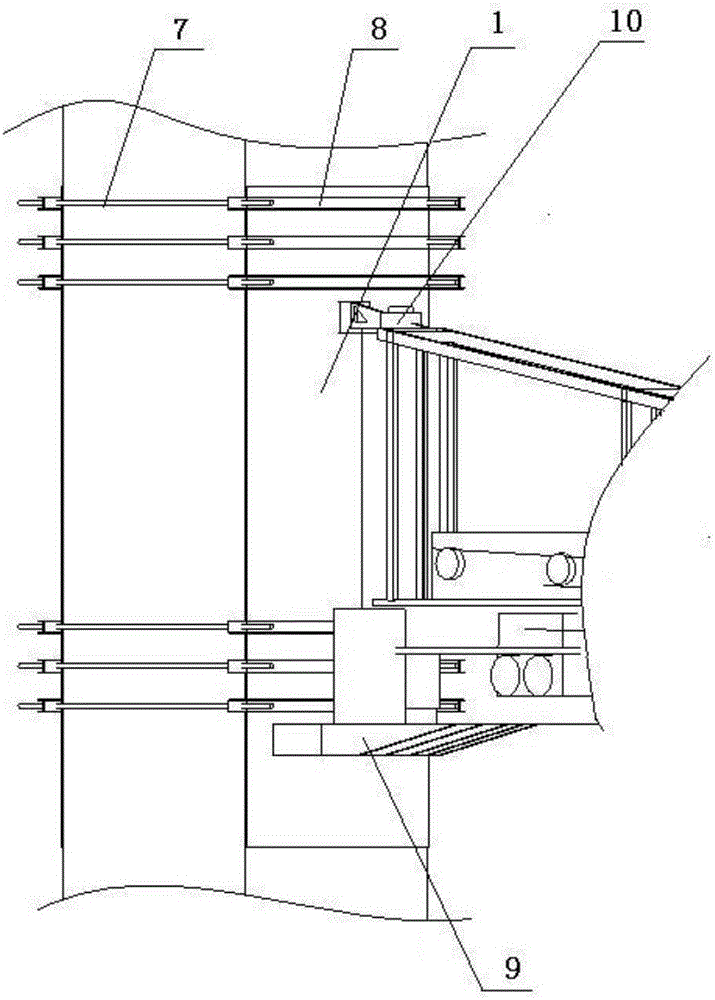

[0029] A high-rise building prefabricated inter-story hoisting machine, such as figure 1 As shown, it includes a cantilever beam 4, a rotating mechanism 2, a hoisting hoist 3 and a running trolley 5. The cantilever beam is a right-angled triangle structure, and its vertical right-angled side is equipped with a rotating mechanism. The rotating mechanism is installed on the concrete column through a bracket assembly. 1, the rotating mechanism drives the cantilever beam to achieve horizontal rotation; a hoisting winch is installed on the cantilever beam close to the concrete column, and a sliding running trolley is installed at the bottom of the cantilever end of the cantilever beam, and the running trolley is driven by the hoisting hoist. Lifting hook 6 is installed at the bottom.

[0030] In this embodiment, the structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com