Rapid hoisting construction method for low-clearance diaphragm wall reinforcement cage

A construction method and reinforcement cage technology, applied in sheet pile walls, auxiliary devices, manufacturing tools, etc., can solve problems such as turning over and straightening, and lifting reinforcement cages of underground diaphragm walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

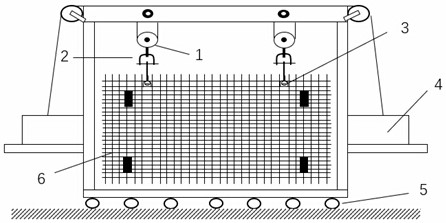

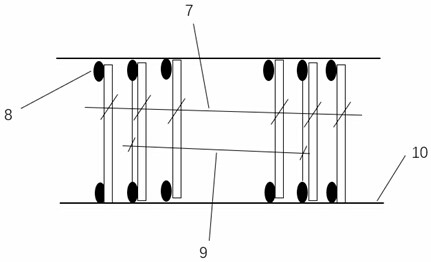

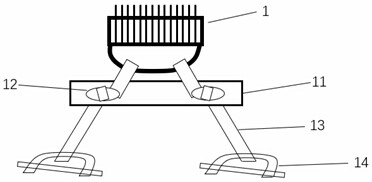

[0020] Such as Figure 1~3 As shown, a construction method for fast hoisting of steel cages connected to walls with low headroom, the steel cages 6 are hoisted by crawler cranes and hoisted in sections. After the steel cage 6 is manufactured, the reserved sections on the steel cage 6 are divided into sections, and hoisted in sections according to the sequence of "bottom to top". The sectioning method is as follows: turn the sleeve wire opening connecting the entire reinforcement cage 6 with the main reinforcement 8 and reinforcement of the lower section to the upper reinforcement cage 6 wire opening, and after each interface is turned up, check whether the main reinforcement 8 and reinforcement are all separated , After the inspection and acceptance is completed, the reinforcement cage 6 can be lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com