Gunwale hoisting device for pipe-laying ship

A technology for lifting devices and pipe-laying ships, which is applied to ship accessories, transportation and packaging, cargo handling equipment, etc., and can solve problems that affect the construction progress of the project, expensive prices, and high maintenance costs for failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

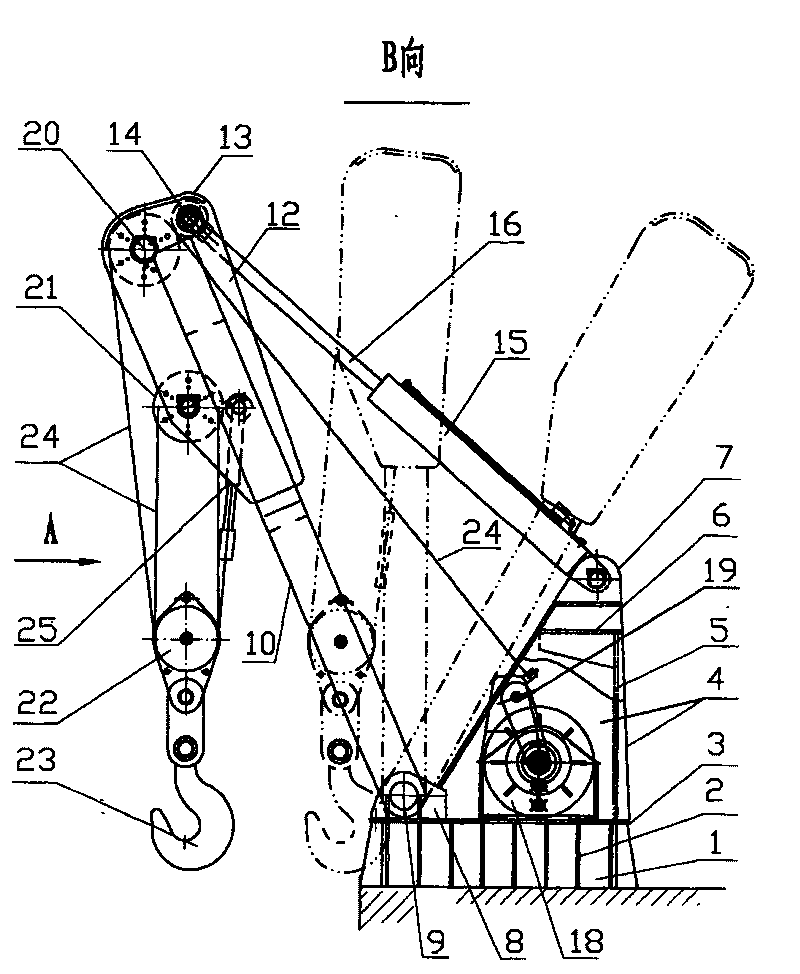

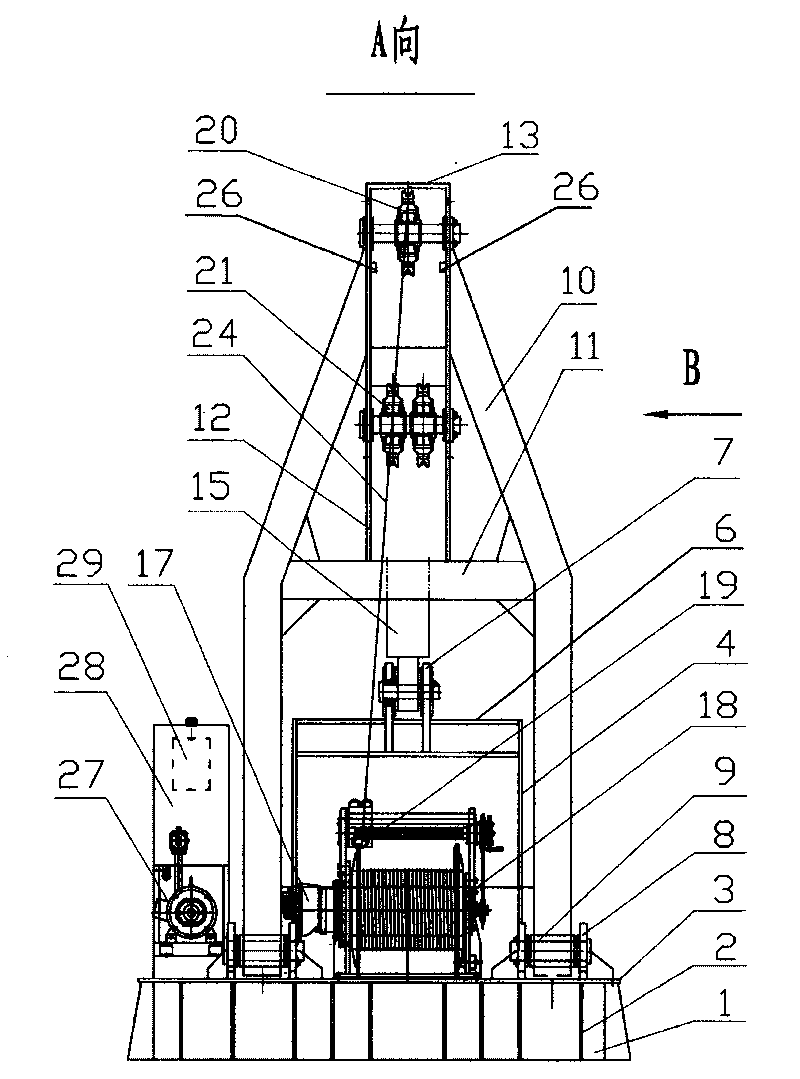

[0020] An embodiment is illustrated in conjunction with the accompanying drawings:

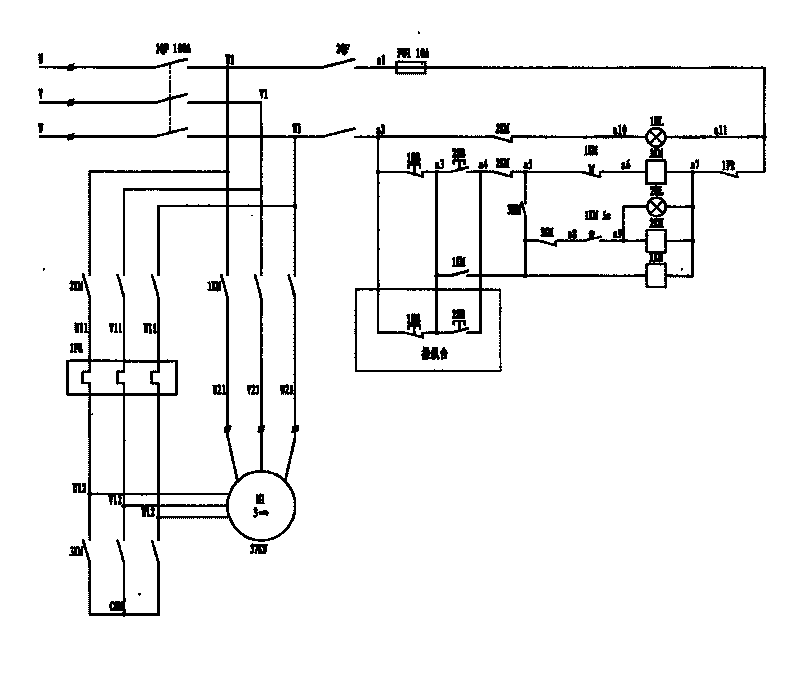

[0021] figure 1 , 2 Among them, 1 is the vertical plate around the base, 2 is the reinforcing plate of the base, 3 is the flat top plate of the base, 4 is the left and right side plates of the winch seat, 5 is the rear side plate of the winch seat, 6 is the top plate of the winch seat, and 7 is the lower hinge of the hydraulic cylinder Seat 8 is the large hinge seat of the boom, 9 is the large hinge shaft, 10 is the main stand of the boom, 11 is the main beam, 12 is the double ear plate of the boom, 13 is the top cover, and 14 is the upper hinge shaft of the hydraulic cylinder. 15 is a hydraulic cylinder liner, 16 is a hydraulic cylinder piston, 17 is a winch hydraulic motor, 18 is a hydraulic winch, 19 is a rope puller, 20 is a rope pulley, 21 is a double fixed pulley, 22 is a three-moving pulley, and 23 is a hook , 24 is a steel wire rope, 25 is a weight sensor, 26 is a length sensor, 27 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com